Simulation of an Urban Bus Fuelled with Several Biodiesel Blends

Advantages and Disadvantages on the Efficiency and Emissions

João P. Ribau

1

and Carla M. Silva

2

1

IDMEC, LAETA, Instituto Superior Técnico, Universidade de Lisboa, 1049-001 Lisboa, Portugal

2

Instituto Dom Luiz, Faculdade de Ciências, Universidade de Lisboa, 1749-016 Lisboa, Portugal

Keywords: Biodiesel, Fuel Blends, Bus, Engine, Efficiency, Emissions.

Abstract: Nowadays, most anthropogenic emissions occur in urban regions, with significant local impacts on air quality

and public health. Decision makers and governments have been introducing policies in the energy and

transport sectors aiming to improve the efficiency of energy use, meeting climate change commitments,

fostering fossil energy independency and promoting the use of biofuels in the transport sector.

This study aims to investigate the main advantages and disadvantages of introducing biodiesel into the

Portuguese passenger road transport system. Biodiesel-diesel blends with a minimum of 7.5% and a maximum

of 100% of biodiesel content (B7.5-B100) will be studied. An urban passenger bus is modelled in the vehicle

simulation software AVL CRUISE in different driving conditions. The use of biodiesel blends are compared

with the use of pure diesel concerning the engine efficiency and emissions. The trend is that the use of

biodiesel has some advantages, from which the most agreed are the reduction of the pollutant emissions of

HC, CO, and PM; however, with the main disadvantage of increasing the fuel consumption and NOx

emissions.

1 INTRODUCTION

Worldwide governments have been introducing a

large number of policies aiming to improve efficiency

of energy use, foster fossil energy independency, and

promote alternative fuels especially in the road

transport sector. Some examples of a global trend to

diminish emissions from the transportation sector are

the Kyoto protocol, the 2003/30/EC European

directive on biofuels for the transport sector, and the

European 20-20-20 targets (EUR-Lex 2014).

The transport sector has an increasing and

significant impact on energy use and on the

greenhouse gas and pollutant emissions. Most

anthropogenic emissions occur in urban regions, with

significant local impacts on air quality and public

health.

One of the approaches taken by the transport

sector was the implementation of biofuels as a

replacement or an additive to the fossil fuels used in

road vehicles. The replacement of fossil fuels with

renewable biofuels has been set as a target worldwide

to reduce greenhouse effect and energy dependence

as well as to improve agricultural economy. One of

the goals stated by the European Parliament s that the

transport fuels should contain 10% of renewable

products (calculated on an energy basis) by 2020.

In particular, biodiesel blends have emerged in the

last years as an alternative fuel for transportation.

Nevertheless the use of biodiesel is not a

contemporary idea. Several vegetable and animal oils

were used in the first diesel engines by Rudolph

Diesel himself, who envisioned that these oils could

power diesel engines for agriculture in remote areas

of the world, where petroleum was not available.

Pioneering work on biodiesels was performed in

South Africa between the great world wars, since this

country has not oil reserves. (Martins 2013)

Nevertheless, only in the past 20-30 years biofuels

have gain attention due to the world increasing

concern about the energy security of supply, and

climate change.

Biodiesel has been produced on an industrial scale

in the European Union since 1992, largely in response

to positive signals from the EU institutions.

Today, there are approximately 120 plants in the

EU producing up to 6,100,000 tons of biodiesel

annually. These plants are mainly located in

Germany, Netherlands, France, Italy, Austria, and

Sweden. (EBB 2017) Today in Europe, rapeseed is

still the main feedstock for biodiesel production. Up-

392

Ribau, J. and Silva, C.

Simulation of an Urban Bus Fuelled with Several Biodiesel Blends - Advantages and Disadvantages on the Efficiency and Emissions.

DOI: 10.5220/0006386103920399

In Proceedings of the 3rd International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2017), pages 392-399

ISBN: 978-989-758-242-4

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

to-date information and statistics on biodiesel

production in Europe is available from the European

Biodiesel Board (EBB 2017)

Biodiesel is most commonly obtained from a

chemical reaction between an acid and an alcohol –

esterification. Maybe the most well-known method is

the transesterification, from which triglycerides react

with an alcohol with the presence of a catalyst,

producing ester and glycerol. These esters can be

obtained from different vegetable oils and animal

oils, and are known as FAME – fatty acid methyl

ester. Other processes are available to produce

biodiesel, e.g. using biotechnology, hydrotreatment

of vegetable oils. (Edwards et al. 2011)

Although biodiesel is a promising solution there

are some market penetration issues which delays its

further use in the transport sector, mainly concerning

the fuel quality standards (which are crucial for the

aimed engine operation, fuel storage and handling),

air quality impact, and engine components durability.

This study aims to investigate the main direct

advantages and disadvantages of introducing

biodiesel into the Portuguese passenger road transport

system, namely the impact in the developed power,

pollutant emissions, and energy efficiency. Biodiesel-

diesel blends with a minimum of 7.5% and a

maximum of 100% of biodiesel content (B7.5-B100)

will be studied. An urban passenger bus is modelled

in the vehicle simulation software AVL CRUISE in

different driving conditions.

In section 2 some of the main properties of the

biodiesel as an automotive fuel are highlighted. In

section 3 the vehicle simulation procedure and data

are presented. In section 4 the results are discussed

followed by the conclusions in section 5.

2 BIODIESEL AS AUTOMOTIVE

FUEL

As referred in the previous section, the biodiesel use

in the transport sector has been widely investigated

due to its renewability, comparable properties to

fossil diesel, and the reduction in main emission

products.

Biodiesel can be used in internal combustion

engines (compression ignited, which are known as

diesel engines) in pure form, or blended with fossil

diesel. It can be used in engines with little or no

modifications, depending on the biodiesel blend.

Biodiesel blends are referred to as Bxx. The ‘xx’

indicates the amount of biodiesel by volume in the

blend of biodiesel and fossil-diesel. For example, B80

refers to a blend of 80% biodiesel and 20% fossil-

diesel by volume.

Automotive engine manufacturers in the

European Union have been performing tests on

biodiesel blends with fossil diesel from 5-10 % to 100

% pure. These have resulted in guarantees for each

type of use and blend. Modifications (seals, piping,

and injection) are required for use at 100 % pure

biodiesel. The use of biodiesel as a low-blend

component in transport fuel (up to 7 percent in Europe

for the time being according to EN 590) does not

require any changes in the distribution system,

therefore avoiding expensive infrastructure changes.

(EBB 2017)

The blended fuel becomes interesting since the

use of biodiesel has its pros and cons, and a blend may

balance the fuel properties towards the most

beneficial use possible. Several studies have been

analyzing the potential of biodiesel as an automotive

fuel. In (Datta & Mandal 2016; Xue et al. 2011)

detailed reviews of different biodiesels are presented,

concerning their properties, feedstock, and

experimental results on engines; and the overall

outcome is that the higher is the content of biodiesel

in the fuel most likely is the engine to emit less

pollutants (with exception of nitrogen oxides - NOx),

although the fuel economy and power decreases.

Nevertheless there are exceptions, which depend

mostly on the fuel properties, engine control systems,

pollutant treatment systems, and operation of the

engine.

Most studies indicate that using biodiesel there is

a decrease on CO (carbon monoxide), HC

(hydrocarbons), and PM (particulate matter)

emissions. On the other hand, there is an increase on

NOx emissions, and increase of the fuel consumption.

In (Wu et al. 2009) pure biodiesel fuels were tested in

heavy-duty engines relating these previous

conclusions with the different fuel properties. With

the same purpose and conclusions (Karavalakis et al.

2016; Rakopoulos et al. 2011; Buyukkaya 2010)

analyzed and compared several blends of biodiesel

with fossil diesel as fuel.

The creation of combustion models and emissions

prediction is extremely difficult since these events

depend on many variables and may change for

different engine operation points as demonstrated in

(Lešnik et al. 2014)

2.1 Properties and Outcomes of

Biodiesel as Fuel

The combustion, energy efficiency, and resultant

emissions of any biodiesel fueled engine depend on

Simulation of an Urban Bus Fuelled with Several Biodiesel Blends - Advantages and Disadvantages on the Efficiency and Emissions

393

the composition and thermophysical properties of the

biodiesel used.

Since biodiesels can have several different

feedstocks (e.g. corn, colza, sunflower seeds, cotton,

waste oils, animal oils, vegetable oils,… the final fuel

can also have different characteristics. Some of those

characteristics are advantageous and other

disadvantageous comparatively to diesel.

(Sadeghinezhad et al. 2013; Alleman et al. 2016)

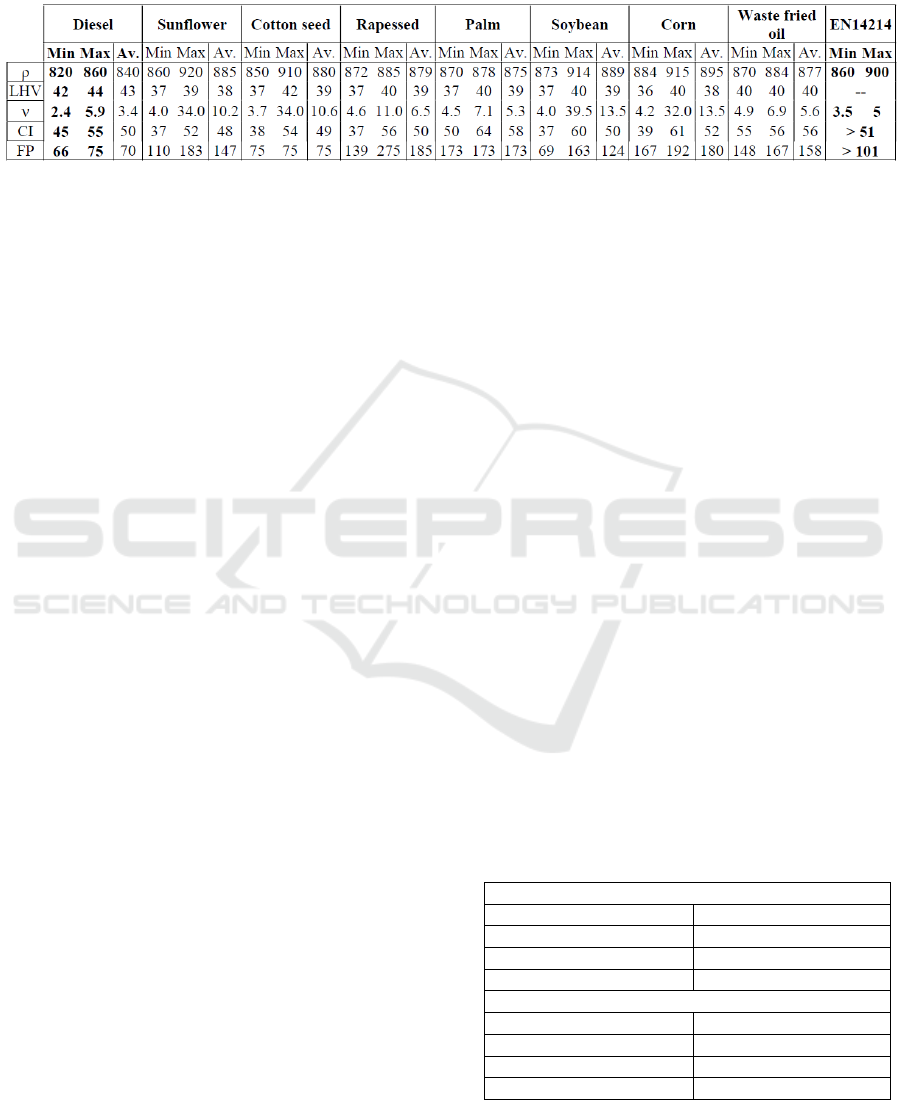

Table 1 is a compilation of different biodiesel

properties from different feedstocks, and compares

them with diesel.

In order for biodiesel to be legally used in internal

combustion engines and road vehicles in Europe, two

sets of standards establish the specifications for

biodiesel fuels in the European Union:

• EN 14214 includes specifications for fatty acid

methyl ester (FAME) fuel for diesel engines. B100

that meets this standard could be used unblended in a

diesel engine (if the engine has been adapted to

operate on B100) or blended with petroleum diesel

fuel.

• EN 590, the European diesel fuel specification,

is also applicable to biodiesel blends up to 7% of

FAME.

2.1.1 Viscosity and Compressibility

Although some studies claim that higher viscosity of

biodiesel may enhance fuel spray penetration,

improving air–fuel mixing, it also may lead to

inefficient fuel injection atomization decreasing

combustion efficiency.

Concerning the fuel compressibility, it is lower in

biodiesel than in fossil, meaning that injection may be

performed faster (i.e. the ignition may also occur

faster supported by the increased cetane index). In

this case the pressure and temperatures become

higher enhancing the combustion.

2.1.2 Cetane Number

The number of cetane represents how easy a fuel can

auto-ignite. Higher cetane numbers help ensure good

cold start properties and minimize the formation of

white smoke.

The higher cetane number in biodiesel compared

with fossil diesel, enhances the ignition of the fuel

and promotes the temperature and pressure increase

during combustion, i.e. the developed power. This

may lead to the improvement of the combustion itself

(higher combustion efficiency), lowering the CO and

HC emissions, but increasing NO

x

.

2.1.3 Heating Value and Oxygen Content

The heating value of any fuel is an important measure

of its energy content that potentially could be released

to produce work. The lower heating value (LHV) is

the energy content accounting with the latent heat of

the water content vaporization.

The LHV together with the volumetric density of

a fuel are very important since they determine the fuel

consumption required to deliver a specific amount of

energy into a specific volume (for storage or inside an

engine cylinder). It should be noted that the fuel-air

stoichiometric mixture LHV is the most important,

since that it is the fuel-air mixture that promotes the

engine combustion.

Since biodiesel is composed with more oxygen

atoms, its energy content (LHV) is lower than fossil

diesel, leading to a reduction on the developed power

and torque. For the same reason its stoichiometric

relation is also lower meaning that less air is needed.

The higher oxygen content is also responsible for the

increase of NO

x

emissions.

2.1.4 Cloud and Flash Point

The flash point is the lowest temperature at a given

ambient pressure for which the fuel vapor and air

mixture are stoichiometric and is easily ignited. It

aims to show the fuel flammability (Martins 2013). A

very low flash point suggests a less secure fuel (to

store and handle), i.e. minimum flash point for diesel

fuel is required for fire safety. The cloud point is the

temperature at which wax crystals begin to form, and

usually defines the minimum working temperature of

the fuel. In very cold climates, this cloud point may

be problematic.

2.1.5 Hygroscopy and Impurities

The water content in biodiesel can come from poor

drying techniques during manufacturing, or from its

hygroscopic properties, absorbing water from

atmospheric moisture and when in contact with

excessive water during transport or storage. Excess

water can lead to corrosion and provides an

environment for microorganisms growth. Moreover it

may decrease the net released heat of combustion.

2.1.6 Sulphur Content

Sulphur is released to the atmosphere as sulphur

dioxide during the combustion of biodiesel,

degrading the exhaust catalyst systems, causing acid

pollutant emissions which have significant

environmental and health issues. Generally, biodiesel

SMS 2017 - Special Session on Sustainable mobility solutions: vehicle and traffic simulation, on-road trials and EV charging

394

Table 1: A compilation of several biodiesels properties (ρ - density @ 15ºC (kg/m

3

), LHV (MJ/kg), ν- kinematic viscosity @

40ºC (mm

2

/s ), CI - cetane index, FP - flash point (ºC)) (Sadeghinezhad et al. 2013; Wu et al. 2009; Rakopoulos et al. 2011;

Lešnik et al. 2014; Merkisz et al. 2016; Rakopoulos et al. 2008; Ozcanli et al. 2013).

contains lower sulphur than fossil diesel. The

diversity of biodiesel feedstocks also makes the final

fuel sulphur content diverse and sometimes above the

one in the fossil diesel. (He et al. 2009)

2.2 General Known Advantages and

Disadvantages

Using a certain biodiesel in a compression ignition

engine (diesel engine), may result in some advantages

comparatively to diesel, but it may also brig some

disadvantages. From several studies it was clear that

some benefits promoted by specific properties were

not found in other studies performing the same

experiments. This is often due to different injection

control, engine operation, ambient conditions, and

even fuel physicochemical properties. However,

some of the following major advantages and

disadvantages of biodiesel comparatively to fossil

diesel should be expected:

Advantages

High cetane number, which increase the

possibility of achieving high engine speeds and

injection delays. Better ignition, and higher pressure

and temperature during combustion;

And then, reduction of some pollutant emissions

(CO, HC, PM, as well as the smoke level) due to

more efficient combustion;

Low sulfur content, i.e. less sulfur related

emissions;

Good lubrication properties;

Little toxicity and irritation to human body;

Reduced engine noise;

Relatively high ignition temperature (flash point),

i.e. safety in operation and storage;

It is an alternative (and renewable, from certain

perspectives) fuel to fossil energy.

Disadvantages

Lower energy content, then higher fuel

consumption and possibly lower power and torque;

Possible increased emission of NO

x

, due to more

oxygen content in the fuel and more complete

combustion;

Increased emission of aldehydes;

Higher viscosity, which may have negative impact

on the fuel atomization;

Lower cloud point, i.e. worse low-temperature

properties (difficult engine start and fuel pump

issues);

Shorter oil change interval due to deposit

precipitation;

Increased corrosion, which reduces durability of

components made from elastomers, rubbers, and

certain alloys made from copper, steel, aluminum,

zinc and lead;

Intense hygroscopy, since the fuel is able of

bonding 40 times more water than diesel fuel, which

may lead to greater susceptibility to microbiological

contamination;

3 VEHICLE MODELLING

A passenger bus was modelled using the vehicle

simulation software AVL CRUISE, developed by

AVL (AVL 2017). The simulated vehicle has the

characteristics as presented in Table 2 and Figure 1:

Table 2: Vehicle specifications.

Vehicle body

Curb weight (kg) 12080

Gross weight (kg) 14300

Width / Length 2.55 / 12

Wheel base (m) 6120

Engine

Number of cylinders 6

Displacement (cm

3

) 7800

Max. power (kW) @ rpm 210 @ 2000 rpm

Max. torque (N.m) @ rpm 1080 @ 1200-1800 rpm

Simulation of an Urban Bus Fuelled with Several Biodiesel Blends - Advantages and Disadvantages on the Efficiency and Emissions

395

Figure 1: AVL CRUISE model.

Four driving cycles were considered for the bus

simulation (Figure 1): ETC, UDDS, Lisbon_cyc, and

Porto_cyc. The EPA (United States Environmental

Protection Agency) Urban Dynamometer Driving

Schedule (UDDS) has been developed for chassis

dynamometer testing of heavy-duty vehicles; and the

ETC cycle was developed by the former FIGE

Institute, Aachen, Germany, based on real road cycle

measurements of heavy duty vehicles (DieselNet

2017). The Lisbon_cyc and Porto_cyc are real

measured bus routes performed in Lisbon and Oporto

cities, Portugal.

Table 3: Driving cycles specifications.

Driving cycles ETC UDDS Lisbon_cyc Porto_cyc

Time (s) 1799 1060 5240 2138

Distance (km) 29.48 8.90 23.04 7.67

Av. speed (km/h) 58.97 30.4 15.82 12.91

Max. Speed (km/h) 91.1 93.3 65.5 54

Av. grade (%) -- -- -2.1/2.3 -3.8/3.2

The first approach taken was to simulate the bus using

pure diesel as fuel performing the four driving cycles

with the full passenger capacity, i.e. using the gross

weight. Then, the objective is to shown the engine

emissions, and efficiency, for different biodiesel

blends with fossil diesel (5%, 10%, 20% 40%, 60%

80%, 100%). Since the variation of the results is very

sensitive to fuel properties (and biodiesel properties

may vary depending on the fuel feedstock, and

production processes), engine operation and ambient

conditions, data from several studies were analyzed

Figure 2: Driving cycles profile.

and implemented in the results as a simple sensitive

analysis. Moreover, in order to avoid pollutant

treatment system influence, the emissions results are

from the engine exhaust.

Therefore, the results presented in section 4, contain

the simulation results and present also some data

based on this studies concerning the biodiesel blend

influence in this kind of heavy-duty engines (Table

4), including data from different biodiesel sources.

Table 4: Studies used in sensitivity data.

blends efficiency Emissions feedstock Reference

B0-100 yes

NOx, CO,

HC, PM

animal

vegetal

(EPA 2017)

B5, 20,

70, 100

yes

NOx, CO,

HC

rapeseed

(Buyukkaya

2010)

B10, 20 yes

NOx, CO,

HC, PM

sunflower,

cottonseed

(Rakopoulos et

al. 2008)

B100 --

NOx, CO,

HC, PM

cottonseed

soybean

rapeseed palm

oil cooking oil

(Wu et al. 2009)

B100 --

NOx, CO,

HC, PM

rapeseed

(Merkisz et al.

2016)

B100 --

NOx, CO,

HC, PM

rapeseed

(Zhang et al.

2009)

0

20

40

60

80

100

0 500 1000 1500 2000

speed(km/h)

Time(s)

ETC

0

50

100

150

200

250

0

20

40

60

80

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500

elevation(m)

speed(km/h)

Time(s)

Lisbon_cyc

elevation

0

20

40

60

80

100

0 150 300 450 600 750 900 1050

speed(km/h)

Time(s)

UDDS

‐10

0

10

20

30

40

0

10

20

30

40

50

60

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200

elevation(m)

speed(km/h)

Time(s)

Porto_cyc

elevation

SMS 2017 - Special Session on Sustainable mobility solutions: vehicle and traffic simulation, on-road trials and EV charging

396

4 SIMULATION OF ENGINE

PERFORMANCE USING

BIODIESEL

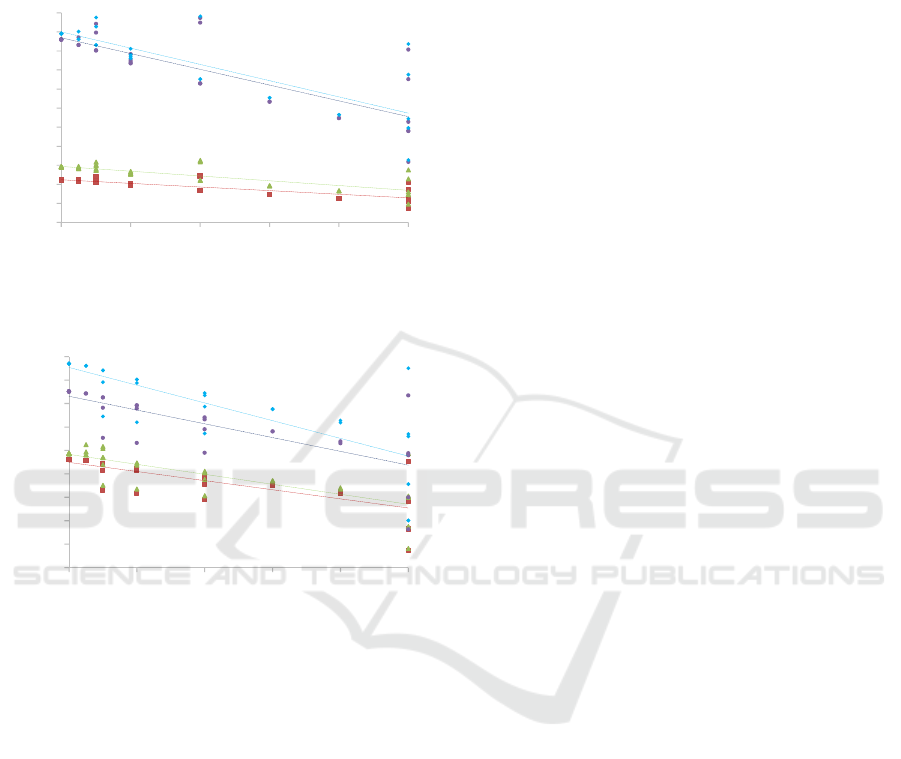

In this section we present the main results obtained

from the vehicle simulation (Figure 3 to Figure 7).

As expected the real driving cycles, Porto_cyc and

Lisbon_cyc, are the most demanding, i.e. the fuel

consumption is higher. Following the same trend the

PM and HC emissions are also higher in real cycles.

Figure 3: Engine fuel consumption function of the biodiesel

blend for the four simulated driving cycles.

The increase of biodiesel in the fuel mixture

causes a reduction of fuel calorific value, increases

fuel density and kinematic viscosity. This leads to the

increase of the fuel mass in the engine. Although

higher combustion efficiency is expected, the fact is

that the lower caloric value of biodiesel leads to

higher specific consumption rates, and usually to a

reduction of the maximum torque and power.

Many studies have been studying the effect of the

biodiesel engine performance and emissions (e.g. the

studies cited in this paper). The dissimilarities of the

results may rely on several variables as highlighted in

section 2, like fuel properties and feedstock, engine,

etc. Differences in chemical composition properties

of diesel and biodiesel fuel influence on different

mass fraction of the elements C, H, S and O in the

biodiesel fuel mixtures. Nevertheless, most of the

authors generally agree that biodiesel increases the

combustion efficiency, and temperature.

Figure 4: Engine NOx emissions function of the biodiesel

blend for the four simulated driving cycles.

Figure 5: Engine CO emissions function of the biodiesel

blend for the four simulated driving cycles.

The oxygen weight content of biodiesel is higher

than that of diesel.

The oxygenated compounds of the biodiesel

together with the combustion mixture in-cylinder

remaining time due to the higher cetane number

improve the fuel oxidation i.e. the combustion

process is more complete. For this reason there will

be less unburned fuel and HC emissions.

The oxygen contained in fuel contributes to an

increase of the local oxygen–fuel ratio during

combustion enabling a more complete combustion

even in fuel-rich regions of the combustion chamber,

contradicting the mechanism of PM and soot

formation. The particulate emission reduction and

specifically the reduction in soot emissions become

one of the most important advantages of biodiesel.

As the oxygen content increases with the biofuel

blend, larger fractions of the fuel carbon are

converted to CO in the rich premixed region, rather

than soot formation. Nevertheless CO emissions are

also reduced. However the improved combustion

efficiency is able to enable a more complete

combustion.

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

0 20406080100

fuelcons.(g/km)

biodieselblend(%)

ETC

UDDS

Porto_cyc

Lisbon_cyc

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

0 20406080100

NOx(g/km)

biodieselblend(%)

ETC

UDDS

Porto_cyc

Lisbon_cyc

1

2

3

4

5

6

7

0 20406080100

CO(g/km)

biodieselblend(%)

ETC

UDDS

Porto_cyc

Lisbon_cyc

Simulation of an Urban Bus Fuelled with Several Biodiesel Blends - Advantages and Disadvantages on the Efficiency and Emissions

397

Nevertheless, the higher temperature of

combustion and higher oxygen content in the mixture,

and also the increased stoichiometric burning (less

rich) for biodiesel blends have disadvantages, for

instance the increased formation of NOx emissions.

Figure 6: Engine HC emissions function of the biodiesel

blend for the four simulated driving cycles.

Figure 7: Engine PM emissions function of the biodiesel

blend for the four simulated driving cycles.

5 CONCLUSIONS

An urban bus was simulated performing four different

driving cycles, from which two were real measured

driving cycles. Using biodiesel instead of the

conventional fossil diesel in road vehicles has some

advantages, from which the most agreed are the

reduction of the pollutant emissions of HC, CO, and

PM. Nevertheless, the use of such “renewable” fuel,

in pure form or blended, has some disadvantages – the

higher fuel consumption and higher NOx emissions.

Although this seems to be the trend, it is also true that

the fuel feedstock, fuel properties, and engine

operation, may produce varied results. Therefore it is

important to specify the fuel provenience, and from a

global perspective, its advantages should be

accounted at a life cycle level analyzing the impact at

the engine and from its production.

The impact of using biodiesel in the engine is also be

supported by exhaust treatment systems, like EGR

(Exhaust gas recirculation for NOx reduction), DFP

(diesel particulate filters), which may increase the

potential local advantages of using biodiesel.

Finally, the costs of using biodiesel should also be

addressed in future work. The increased consumption

should be balanced by a competitive price

comparatively to diesel. And, the vehicle investment

costs should also be considered. The inherent

properties of biodiesel may lead to the increase of

maintenance or some modifications to the fuel system

(engine included), especially for biodiesel blends

above 10%.

ACKNOWLEDGEMENTS

This work was supported by the FCT (Fundação para

a Ciência e a Tecnologia, Ministério da Educação e

Ciência, Portugal) the Post-Doctoral grant

SFRH/BPD/101090/2014, and the Program

Investigator FCT IF/00181/2012. The authors would

like to ackouwledge AVL troughout the AVL AST

University Partnership Program (UPP). This work

was supported by FCT, through IDMEC, under

LAETA-UID/EMS/50022/2013; and by IDL under

UID/GEO/50019/2013.

REFERENCES

Alleman, T.L. et al., 2016. Biodiesel Handling and Use

Guide (Fifth Edition), Available at:

http://www.afdc.energy.gov/uploads/publication/biodi

esel_handling_use_guide.pdf.

AVL, 2017. AVL CRUISE

TM

.

Buyukkaya, E., 2010. Effects of biodiesel on a di diesel

engine performance, emission and combustion

characteristics. Fuel, 89(10), pp.3099–3105. Available

at: http://dx.doi.org/10.1016/j.fuel.2010.05.034.

Datta, A. & Mandal, B.K., 2016. A comprehensive review

of biodiesel as an alternative fuel for compression

ignition engine. Renewable and Sustainable Energy

Reviews, 57, pp.799–821. Available at:

http://dx.doi.org/10.1016/j.rser.2015.12.170.

DieselNet, 2017. DieselNet.

EBB, 2017. European Biodiesel Board. Available at:

http://www.ebb-eu.org/ [Accessed February 8, 2017].

Edwards, R. (JRC/IES), Larive, J.-F. (CONCAWE) &

Beziat, J.-C. (Renault/EUCAR), 2011. Well-to-wheels

Analysis of Future Automotive Fuels and Powertrains

in the European Context. JRC Scientific and Technical

Reports, European Union,

0

1

2

3

4

5

6

7

8

9

10

11

0 20406080100

HC(g/km)

biodieselblend(%)

ETC

UDDS

Porto_cyc

Lisbon_cyc

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

0 20406080100

PM(g/km)

biodieselblend(%)

ETC

UDDS

Porto_cyc

Lisbon_cyc

SMS 2017 - Special Session on Sustainable mobility solutions: vehicle and traffic simulation, on-road trials and EV charging

398

EPA, 2017. United States Environmental Protection

Agency. Available at: https://www.epa.gov/.

EUR-Lex, 2014. EUR-Lex, Directive 2009/33/EC of the

European Parliament and of the Council of 23 April

2009 on the promotion of clean and energy-efficient

road transport vehicles.

He, B.B., Van Gerpen, J.H. & Thompson, J.C., 2009. Sulfur

content in selected oils and fats and their corresponding

methyl esters. Applied Engineering in Agriculture,

25(2), pp.223–226. Available at:

https://www.scopus.com/inward/record.uri?eid=2-

s2.0-

65549164736&partnerID=40&md5=c72aaebabec6059

840b252d54136b5a6.

Lešnik, L. et al., 2014. Numerical and experimental study

of combustion, performance and emission

characteristics of a heavy-duty di diesel engine running

on diesel, biodiesel and their blends. Energy

Conversion and Management, 81, pp.534–546.

Martins, J., 2013. Motores de combustão interna,

Merkisz, J. et al., 2016. Rapeseed Oil Methyl Esters (RME)

as Fuel for Urban Transport. In Alternative Fuels,

Technical and Environmental Conditions. Rijeka:

InTech. Available at: http://dx.doi.org/10.5772/62218.

Ozcanli, M., Gungor, C. & Aydin, K., 2013. Biodiesel Fuel

Specifications : A Review. Energy Sources,

7036(March), pp.37–41.

Rakopoulos, C.D. et al., 2008. Performance and emissions

of bus engine using blends of diesel fuel with bio-diesel

of sunflower or cottonseed oils derived from Greek

feedstock. Fuel, 87(2), pp.147–157.

Rakopoulos, D.C. et al., 2011. Comparative environmental

behavior of bus engine operating on blends of diesel

fuel with four straight vegetable oils of Greek origin:

Sunflower, cottonseed, corn and olive. Fuel, 90(11),

pp.3439–3446. Available at: http://dx.doi.org/

10.1016/j.fuel.2011.06.009.

Sadeghinezhad, E. et al., 2013. A comprehensive review of

bio-diesel as alternative fuel for compression ignition

engines. Renewable and Sustainable Energy Reviews,

28, pp.410–424. Available at:

http://www.sciencedirect.com/science/article/pii/S136

4032113005431.

Wu, F. et al., 2009. A study on emission performance of a

diesel engine fueled with five typical methyl ester

biodiesels. Atmospheric Environment, 43(7), pp.1481–

1485. Available at:

http://dx.doi.org/10.1016/j.atmosenv.2008.12.007.

Xue, J., Grift, T.E. & Hansen, A.C., 2011. Effect of

biodiesel on engine performances and emissions.

Renewable and Sustainable Energy Reviews, 15(2),

pp.1098–1116. Available at:

http://dx.doi.org/10.1016/j.rser.2010.11.016.

Zhang, J. et al., 2009. Effect of SME biodiesel blends on

PM2.5 emission from a heavy-duty engine.

Atmospheric Environment, 43(15), pp.2442–2448.

Available at: http://dx.doi.org/10.1016/

j.atmosenv.2009.01.052.

Simulation of an Urban Bus Fuelled with Several Biodiesel Blends - Advantages and Disadvantages on the Efficiency and Emissions

399