Optimizing PTP Motions of Industrial Robots through Addition of

Via-points

Zygimantas Ziaukas, Kai Eggers, Jens Kotlarski and Tobias Ortmaier

Institute of Mechatronic Systems, Gottfried Wilhelm Leibniz Universit

¨

at Hannover, Appelstr. 11a, Hanover, Germany

Keywords:

Energy Savings, Energy Efficiency, Time Savings, Efficient Trajectory, Reduced Moment of Inertia, Industrial

Robotics.

Abstract:

This paper presents how the addition of via-points can improve the state-of-the-art trajectory planning towards

lower energy consumption and/or lower travel time. In contrast to existing approaches using trajectory in-

terpolation methods like B-splines, exclusively standard commands of commonly available robotic systems

are used in order to get practicable results. The system’s energy demand for a given trajectory is determined

based on a model of system energy characterized by low complexity. Trajectory profiles are obtained from

original robot trajectory planning by using hardware in the loop. Therefore, results can directly be formulated

in machine code. Experimental results demonstrate the effectiveness of the proposed approach. Depending

on the given task, energy savings up to 17.3 % at equal travel time and time savings up to 13.3 % compared

to initial PTP motion are possible. The approaches presented are applicable to any robotic application that

utilizes PTP motions, e. g. pick-and-place or spot welding tasks.

1 INTRODUCTION

Sales of industrial robots reached an all time high

of 248,000 units sold in 2015 worldwide, increasing

by about 12 % compared to the previous year (IFR,

2016). For the future, ongoing significant growth is

expected. A rising degree of automation leads to an

increase of overall energy consumption. On the one

hand, manufacturers aim to reduce production costs

to stay competitive in the dynamic global market. On

the other hand, sustainability becomes more and more

a matter of interest regarding the companies’ image

and the requirement to meet legal regulations.

Earlier works mainly focus on optimizing cycle times,

as manufacturers seek to maximize their production

output and, therefore, their sales volume (Vergnano

et al., 2012),(Riazi et al., 2015),(Wigstrom et al.,

2013). Nowadays, due to the aforementioned reasons,

the reduction of energy consumption, becomes more

relevant (Brossog et al., 2015).

In this paper, we present methods to reduce en-

ergy consumption as well as travel time for robotic

PTP motions. Both criteria are the main target of most

optimization approaches. Thanks to the generic opti-

mization method, travel time as well as energy con-

sumption can be considered independently or at the

same time.

Several methods for the reduction of either en-

ergy consumption or travel time have been presented.

In (Vergnano et al., 2012), the view is expanded on

multi-robot systems. Scheduling is optimized using

idle times to slow down operations with the highest

energy consumption. Furthermore, it was recognized

that different operations have different optimization

possibilities. Our research confirms these findings.

Similar methods can be found in e.g. (Riazi et al.,

2015) and in (Wigstrom et al., 2013) where addition-

ally the movements of the individual robots are opti-

mized.

Towards reducing energy consumption of indi-

vidual robots’ PTP motions, an approach with asyn-

chronous fly-by in joint space is presented in (Meike

and Ribickis, 2011). Unnecessary acceleration and

deceleration phases, identified by an algorithm, are

diminished and motion profiles are smoothened by

using cubic B-splines for trajectory interpolation. In

(You et al., 2011), cubic spline interpolation is modi-

fied, resulting in energy and travel time reduction.

The opportunity of using recuperated energy

from deceleration phases via DC-Bus is presented in

(Hansen et al., 2013). Either direct usage in times

of simultaneous acceleration and deceleration of dif-

ferent axes or energy storage, e.g. in capacitors, is

conceivable. This approach is continued in (Hansen

Ziaukas, Z., Eggers, K., Kotlarski, J. and Ortmaier, T.

Optimizing PTP Motions of Industrial Robots through Addition of Via-points.

DOI: 10.5220/0006396005270538

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 527-538

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

527

et al., 2015). Further approaches to reduce energy

consumption for PTP motions are presented in (Paes

et al., 2014),(Mohammed et al., 2014).

Some of the previously mentioned works also in-

clude a possible reduction of travel time by replacing

the objective function. An early approach towards

time optimization is presented in (Bobrow, 1988).

Cartesian trajectories are represented by B-Splines

and adjusted in a time-optimal way.

Moreover, in (Gleeson et al., 2015), continued in

(Gleeson et al., 2016), trajectories are optimized and

code for robot control is generated automatically. By

setting via-points and corresponding zone radii which

specify the maximum approximation of the via-point

and assure a collision free trajectory, the time optimal

trajectory is defined. In (Gattringer et al., 2013), an

approach of directly manipulating a PTP trajectory’s

joint angle functions over time is introduced.

The methods we propose are based on a model of

system energy which, in contrast to the present trend

of research (Meike and Ribickis, 2011),(Hansen et al.,

2012), is more simple. The survey in (Brossog et al.,

2015) shows that current research in this field devel-

ops towards more detailed energy models, including

power losses such as core losses, windage and fric-

tion losses, stator and rotor losses, stray load losses,

inverter, and rectifier losses. For optimization meth-

ods like ours, this level of detail is inefficient. We

intend to present a sufficient energy model for serial

kinematic industrial robots, based on which a practi-

cable optimization approach for the reduction of en-

ergy consumption can be applied and customized to

commercial robot control systems. Supplementally,

we show that our approach can be modified easily to

meet different criteria. Exemplary, travel time is con-

sidered.

Our model is described and validated in section

2. Standard PTP trajectory planning approaches, im-

plemented in modern robot controls, and our meth-

ods of modifying them in order to reduce energy con-

sumption and/or travel time are presented in section

3. Finally, results and conclusions are presented in

sections 4 and 5.

Additionally, in section 5.2 we introduce an future

works approach of optimizing trajectories by adding

via-points to initial PTP motions with minimized mo-

ment of inertia. Already in (Geering et al., 1985) it

is mentioned that minimization of moment of inertia

with respect to revolute joints leads to time-optimal

trajectories. This method has significant advantages

regarding computation time needed, as the complex-

ity of the cost function is further reduced and even

less knowledge of the system is required.

Figure 1: Typical power consumption measurement for an

industrial robot in different operating phases.

2 MODEL OF SYSTEM ENERGY

Comprehensive energy demand modelling ap-

proaches for mechatronic systems have been

presented in earlier publications (Hansen et al., 2013;

Pellicciari et al., 2013). However, the proposed

model is specifically designed for industrial robots,

which enables significant model complexity reduc-

tions without perceptible changes in accuracy. This

leads to advantages in feasibility, computation time,

and system identification effort. Assuming that the

parameters of the inverse dynamics model are known,

the presented power model uses only three additional

parameters that can be identified in a single mea-

surement. The correct simulation and comparison

of the energy consumption for different travel times

requires a model representing the consumption while

in motion as well as in standstill. In order to clarify

the different power consumption phases, a typical

power measurement for a PTP motion is shown in

Figure 1. The operational state can be divided into

three different phases:

• MOTION means that the robot is currently moving,

• HOLD describes a robot in active control with

lifted holding brakes, while

• IDLE signifies that the holding brakes have been

applied.

The causes for the power consumption in the dif-

ferent phases are explained in section 2.1, along with

the identification of the required parameters. The

modelling of the motion-dependent power consump-

tion is formulated in section 2.2. Validation measure-

ments are presented in section 2.3.

2.1 Operating Phases

The power consumption during the different operat-

ing phases can be explained by consideration of a

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

528

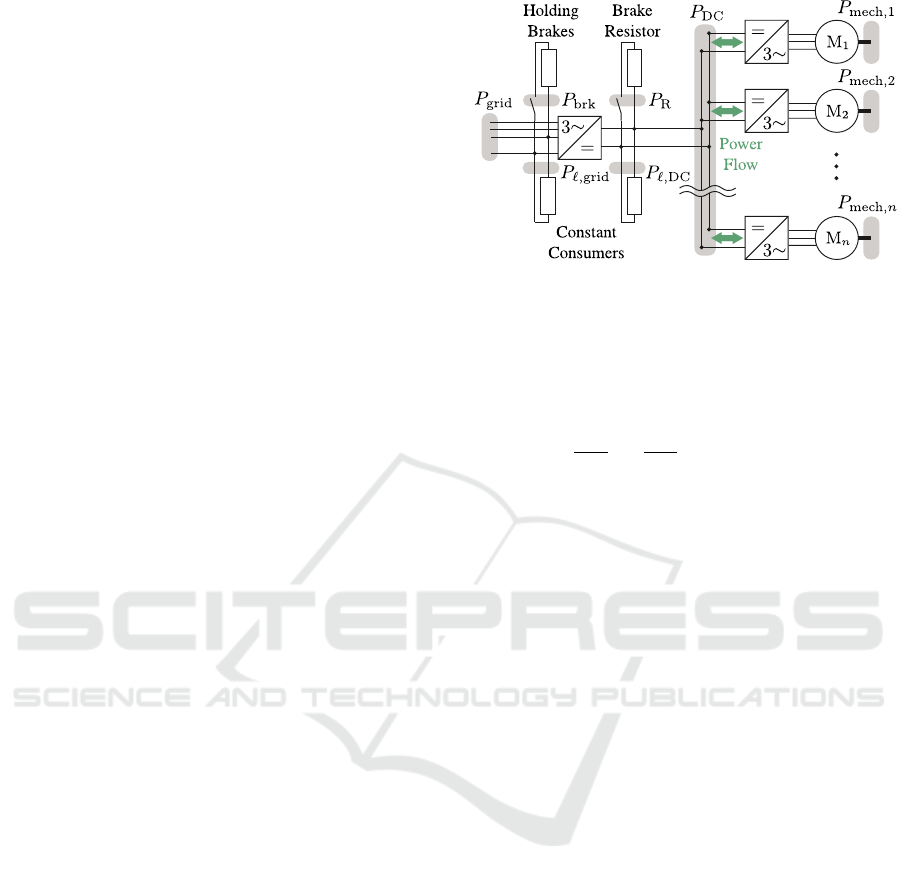

simplified electrical substitute circuit diagram (Fig-

ure 2). During the MOTION phase, the power con-

sumption depends on the robot’s mechanical power

demand P

mech,i

that is induced by the given motion.

A detailed description of the modelling approach for

this particular term can be found in section 2.2. The

sum of mechanical powers is represented by an aux-

iliary variable P

DC

that characterizes the power flow

within the DC bus. Since most state-of-the-art robot

controls are not able to recuperate, excess power P

R

is

dissipated through a brake resistor. All further DC bus

losses are summarized as a constant loss power P

`,DC

.

Constant losses on the grid side are split into two

groups: the power P

brk

is required to keep the brakes

lifted while P

`,grid

summarizes the constant losses of

all peripheral components (e. g. controller, cooling

fans, IO modules, sensors, etc.).

During the IDLE phase, all the components on a

600 V level are inactive and the holding brakes are

applied. Hence, the measurable power P

idle

equals

P

`,grid

. In the HOLD phase, the power demand is in-

duced by the constant losses on the grid side, on the

DC side, and by the brake lifting power:

P

hold

= P

`,grid

+ P

`,DC

+ P

brk

. (1)

The power consumption for the static holding is

not considered separately. It is instead included in

the constant DC losses P

`,DC

. The dependency on

the robot configuration is neglected: measurements

have shown a maximum deviation of P

hold

of ap-

prox. 10 % for the KUKA KR 16 and 5 % for the

KUKA KR 210 for the most extreme poses (see sec-

tion 2.3 for the test bed description). The influence for

the KR 210 is lower due to its counterbalancing sys-

tem. However, with regard to the robots’ peak powers

of approx. 8 kW (KR 16, see Figure 4) and 20 kW

(KR 210, see Figure 5), the deviation comes down to

less than 0.01 % in each case.

The utilization of substitute powers for various

losses is a major change in comparison to existing

approaches (Hansen et al., 2013; Pellicciari et al.,

2013). Industrial robots usually feature backlash free

gears with high friction. Hence, the mechanical losses

clearly exceed the electrical ones. Therefore, the pro-

posed simplifications only have a minor impact on

the grid power consumption (see also section 2.3).

The main advantage of this approach is the signifi-

cant reduction of required parameters which enables

the model for application on an industrial level.

2.2 Motion-dependent Power

Consumption

This section focuses on the calculation of the motion-

dependent power consumption. Assuming that a tra-

Figure 2: Electrical substitute circuit diagram for an indus-

trial robot.

jectory of an industrial robot is predefined, the calcu-

lation of the system power demand starts with deter-

mining the motor torques τ (t). In general, the model

for inverse dynamics is given by

τ (t) =diag(

1

u

G,1

,...,

1

u

G,n

)(M (q)¨q + c(q, ˙q) + g(q))

+ h(q, ˙q), (2)

where q, ˙q, ¨q are time-dependent joint angles, veloc-

ities, and accelerations given by the trajectory plan-

ning algorithm. The term u

G,i

represents the gear fac-

tor for joint i while the vector τ contains the respec-

tive motor torques τ

i

. M contains moments of inertia,

c Coriolis effects, and g gravitational effects. h sum-

marizes non-linear effects which in our regarded case

is merely friction. In (Hamon et al., 2010), a com-

monly used friction model including Coulomb fric-

tion and viscous damping (coefficients f

c,i

and f

v,i

,

respectively) is presented. It is applied for this model,

expressing friction torque τ

f,i

for joint i as

τ

f,i

(t) = h

i

(t) = f

c,i

sign(

˙

ω

i

(t)) + f

v,i

˙

ω

i

(t), (3)

where ω

i

is the angular motor velocity of motor i

which can be determined as

ω

i

(t) = u

G,i

˙q

i

(t). (4)

Most robotic manufacturers utilize a model of the

inverse dynamics within the robot control system for

implementation of feed forward control. Thus, it can

be assumed that the system friction parameters are

known. If not, they can be obtained using established

identification methods (Johnson and Lorenz, 1992).

Equations 2 and 4 are used to obtain the mechanical

power P

mech,i

(t) for each motor i:

P

mech,i

(t) = τ

i

(t) ω

i

(t). (5)

The The total DC bus power P

DC

is obtained by

summing up the mechanical power of the n individual

motors:

P

DC

(t) =

n

∑

i=1

P

mech,i

(t). (6)

Optimizing PTP Motions of Industrial Robots through Addition of Via-points

529

For state-of-the-art industrial robots, the DC bus

features a capacitor that is usually dimensioned to

smoothen the rectified voltage, not to buffer excess

energy in generator operation phases. Therefore, the

capacity is neglected. However, it can be imple-

mented according to (Hansen et al., 2012) if desired.

Further, the rectifiers in industrial robot cabinets are

usually not able to recuperate. Hence, negative values

for P

DC

need to be partly corrected. The excess power

in generator operating phases can cover the constant

losses within the DC bus, but the grid side losses will

remain. The remaining power consumption is marked

as P

gen

in Figure 1. This behaviour is considered as

follows:

P

DC

(t) + P

`,DC

≥ 0 :

P

grid

(t) = P

DC

(t) + P

`,DC

+ P

`,grid

+ P

brk

,

P

R

(t) = 0,

P

DC

(t) + P

`,DC

< 0 :

P

grid

(t) = P

gen

= P

`,grid

+ P

brk

,

P

R

(t) = −(P

DC

(t) + P

`,DC

),

where P

R

(t) is the power dissipated via the brake

resistor. The time integral of the grid power demand

over trajectory time (from t

start

to t

end

)

E

grid

=

Z

t

end

t

start

P

grid

(t) dt (7)

equals the grid energy demand of the system for a

given trajectory.

2.3 Validation

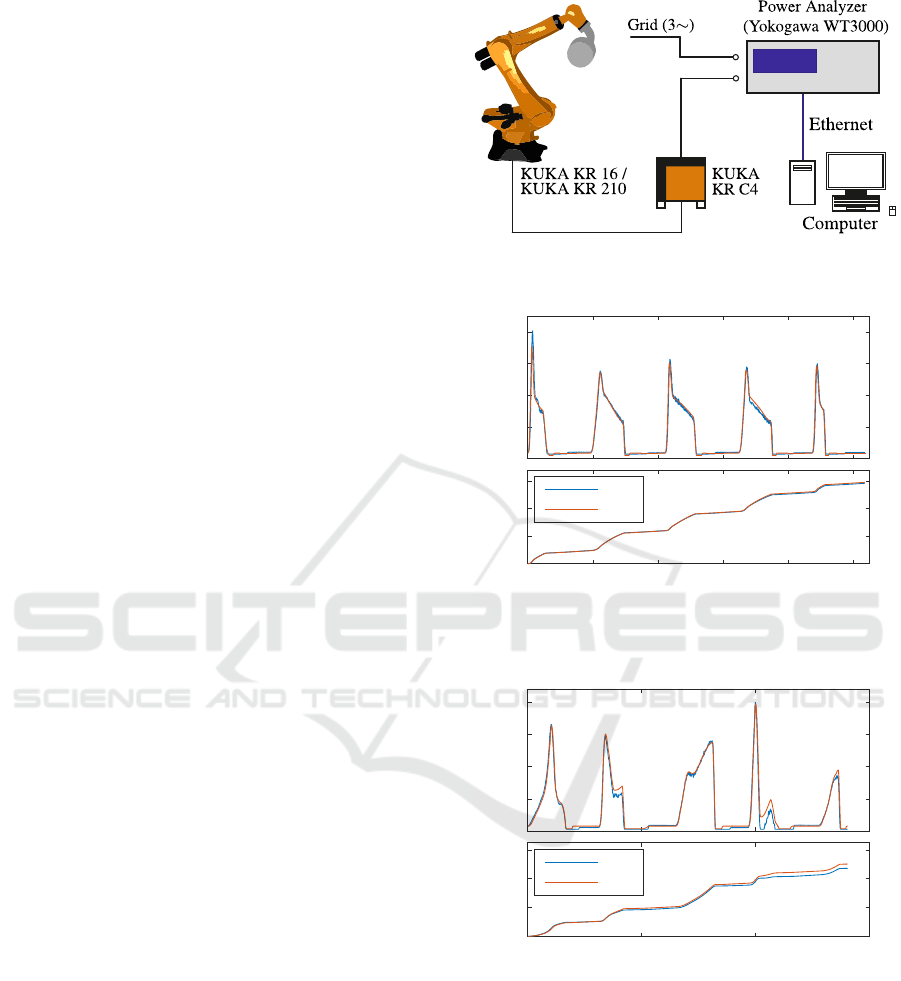

In order to demonstrate its portability, the model is ap-

plied to and parameterized for two robots of different

sizes, namely a KUKA KR 16 and a KUKA KR 210

with respective payloads of 16 kg and 210 kg. The test

setup for the validation is shown in Figure 3. The grid

power is measured using a Yokogawa WT 3000 pre-

cision power analyzer. The robots are equipped with

a test weight of 15 kg and 200 kg.

The Figures 4 and 5 show the measured as well as

the simulated power demand and the grid energy de-

mand for both robots. The validation trajectory con-

sists of five PTP motions, separated by one-second

pauses. The resulting grid energy demand for the

KR 210 is slightly overestimated by the simulation by

+5.3 %. At about 10 s, the power demand differs a lit-

tle bit more extreme than for the other motions. This

might occur due to inaccuracies in the robot control’s

inverse dynamic model for this exact movement.

For the KR 16, the simulation provided an even lower

deviation of 1.2 % for the given trajectory. Fur-

ther measurements with varying trajectories delivered

Figure 3: Test setting for validation trajectory measurement;

figures are properties of the respective manufacturers.

0

2

4

6

8

P

grid

[kW]

KUKA KR 16

0 2 4 6 8 10

t [s]

0

5

10

15

E

grid

[kJ]

meas.

sim.

Figure 4: Measured and simulated power demand for the

KUKA KR 16.

0

5

10

15

20

P

grid

[kW]

KUKA KR 210

0 5 10 15

t [s]

0

20

40

60

E

grid

[kJ]

meas.

sim.

Figure 5: Measured and simulated power demand for the

KUKA KR 210.

comparable results with an error within approx. ±

5 %. The validation results show that the model with

the proposed complexity reductions, in contrast to in-

creasingly complex models in the current develop-

ment of research, adequately depicts the real system’s

grid power and energy demand.

While different simplifications have been intro-

duced for the modelling of the electrical part of the

drive system, it is important to reach a high accuracy

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

530

0 1 2 3 4 5

t [s]

-2

0

2

4

6

P

mech;1

[kW]

#

1

= 20

/

C

#

1

= 70

/

C

Figure 6: Mechanical power comparison for axis i = 1 at

different motor temperatures based on measured (traced)

values for τ

1

and ω

1

.

for the calucation of the mechanical power. Although

there is a strong dependency between robot tempera-

ture and its power demand, previous works often ne-

glect this. While (Brossog et al., 2015),(Meike et al.,

2014) consider the robot temperature, only the tem-

perature dependencies of motor resistors are taken

into account.

Figure 6 demonstrates the impact of the robot (i. e.

motor) temperature on the mechanical power. The

values are based on the traced values at a KR 210 us-

ing its internal sensors. While the motor temperature

ϑ

i

does not equal the gear temperature, it sufficiently

displays the robot’s thermal state. The measured grid

energy consumption for the same motion at different

temperatures is shown in Figure 7. It becomes ob-

vious that a consideration of the temperature within

the model is inevitable. Therefore, the model should

either utilize temperature-dependent friction parame-

ters or they need to be identified for a task-specific

thermal state. For this paper, the friction parameters

were identified for motor temperatures of 60

◦

C. Un-

less stated otherwise, all presented measurements and

results refer to this operating point.

3 OPTIMIZATION APPROACH

The following section describes state-of-the-art tra-

jectory planning implemented in several standard in-

dustrial robot control systems. Following, the pro-

posed approach to modify trajectories towards less

energy consumption is introduced. Additionally, op-

timization of travel time is considered. Furthermore,

the optimization method including its cost functions

and boundaries are presented.

3.1 Standard Trajectory Planning

A common solution for PTP trajectory planning is

based on trapezoidal acceleration profiles with syn-

20 30 40 50 60 70 80

#

1

[

/

C]

1

1.2

1.4

E

grid

=E

grid;60

Figure 7: Dependency of grid energy demand E

grid

on tem-

perature normalized to the grid energy demand E

grid,60

at

60

◦

C motor temperature.

chronously moving axes (Biagiotti and Melchiorri,

2008). This results in continuous joint angle, velocity,

and acceleration functions, but in a non-continuous

jerk function. However, the actual acceleration func-

tions of modern robot controls differ from strict trape-

zoidal profiles to further improve travel time. Accel-

eration is constrained by the maximum torque lim-

its of the axes (Costantinescu and Croft, 2000). This

leads to at least one axis reaching its torque limit,

as shown in the results section. All axes move syn-

chronously.

3.2 Trajectory Modification by adding

Via-Points

By adding via-points we are able to modify a given

trajectory towards optimized energy consumption

and/or travel time. The advantage of this method,

in contrast to previous works using spline interpola-

tion such as (Meike and Ribickis, 2011),(You et al.,

2011),(Hansen et al., 2012), is the simple implemen-

tation to commercial robot controls. The method ex-

clusively utilizes standard control commands. Ini-

tially, this seems paradoxical since adding via-points

seem like a detour on the way from starting to final

configuration. However, if the via-points are placed

in an certain position, a configuration with reduced

moments of inertia M(q) can result. According to

(2), a reduction of M (q) can be exploited to

• increase joint acceleration at equal joint torque or

• decrease joint torque at equal joint acceleration.

Possible benefits are pointed out in the following

two scenarios: Assuming the user wants to lower en-

ergy consumption for a given PTP motion without

changing the travel time, lower joint torques can de-

crease the total energy demand, whereas maintaining

equal acceleration keeps the travel time constant.

Alternatively, the user wants to lower travel time

for a given PTP motion. This could be accomplished

Optimizing PTP Motions of Industrial Robots through Addition of Via-points

531

by increasing joint acceleration, which is limited by

maximum joint torque, as described in section 3.1.

Thanks to the reduced moment of inertia in via-point

configuration compared to the initial trajectory, accel-

eration can be increased without exceeding the torque

limits.

The addition of via-points can also desynchro-

nize the axes’ movement. Non-synchronously mov-

ing axes allow the usage of recuperated energy from

deceleration phases through DC-bus linkage, which

leads to a reduction of dissipated energy and, there-

fore, to a higher overall energy efficiency. Figure 2

shows the corresponding energy flows.

Any number of via-points can be added to the ini-

tial trajectory. However, in order to assure a sim-

ple understanding we present our methods and results

based on the addition of one via point. Note that more

via-points increase the computational expense due to

the increased dimension of the optimization parame-

ter vector.

Furthermore, apart from the optimization of en-

ergy consumption, other targets can be considered by

replacing the cost function. As the optimization of

travel time is often addressed in previous works, it is

additionally considered in this paper.

3.3 Optimization Method

The initial trajectory with synchronously moving axes

as described in section 3.1 is programmed in robot

control as shown in Figure 8. It represents a PTP

motion from starting joint angle configuration q

s

to

end configuration q

e

. Velocity and acceleration are

set to maximum (100 %) which are the default values

in most common robot control systems.

The optimization target is set by defining the cost

function. Basically, any type of cost function can be

formulated. Following, we focus on reduction of en-

ergy consumption and additionally travel time.

3.3.1 Optimization of Energy Consumption

The optimization parameter vector

p

e

= (p

1

, p

2

,..., p

n

|

{z }

p

e,joint config.

,v,a)

T

(8)

contains all n joint angles of the via-point added to the

initial trajectory between start and end configuration,

velocity v, and acceleration a. Velocity and accelera-

tion are expressed in percentage of the respective set

maximums.

The initial as well as the temporary trajectories of

iteration steps, are generated using original trajectory

planning of the robot control system. This is realized

1 for i=1 to 6

2 $acc axis[i]=100 initial accel. and velocity

3 $vel axis[i]=100 settings in %

4 endfor

5

6

7

8 Points for PTP motion in joint space

9 PTP {A1 q

s,1

, A2 q

s,2

, A3 q

s,3

, A4 q

s,4

, A5 q

s,5

,

A6 q

s,6

}

10

11 PTP {A1 q

e,1

, A2 q

e,2

, A3 q

e,3

, A4 q

e,4

, A5 q

e,5

,

A6 q

e,6

}

Figure 8: Trajectory Source Code in Kuka Robot Language.

by including hardware in the loop of optimization.

This method of trajectory generation automatically

satisfies all constraints like maximum motor torques,

maximum gear torques, maximum joint velocities set

by the robot manufacturer. It also allows to simply

implement the optimized trajectory in the robot con-

trol by using standard commands. In contrast, if the

trajectory is interpolated e.g. using B-splines, this

becomes more problematic. The resulting joint an-

gles q(t), velocities ˙q(t), and accelerations ¨q(t) are

then used to calculate the energy consumption of the

motion as described in section 2.2. The optimization

problem is formulated as a minimization of total en-

ergy demand

p

∗

e

= argmin

p

e

E

grid

(q

s

,p

e

,q

e

)

, (9)

where p

∗

e

is the optimal parameter vector. All param-

eters’ upper and lower bounds are

q

i,min

≤ p

i

≤ q

i,max

∀ i = 1... n, (10)

0% ≤ v ≤ 100 %, (11)

0% ≤ a ≤ 100 %, (12)

where limits to p

i

originate from kinematic con-

straints, preventing the robot from colliding with ob-

stacles or itself. Additionally, a non-linear constraint

t

temp

≤ t

thr

(13)

is implemented to ensure that the travel time of the

temporary optimized trajectory t

temp

in each iteration

does not impair the threshold travel time t

thr

. Thresh-

old travel time commonly is the travel time of the ini-

tial trajectory t

init

.

3.3.2 Optimization of Travel Time

In contrast, if the target is to optimize the travel time,

the optimization parameter vector slightly changes to

p

t

=

p

1

, p

2

,..., p

n

T

. (14)

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

532

1 for i=1 to 6

2 $acc axis[i]=a

∗

opt. acceleration and velocity

3 $vel

axis[i]=v

∗

settings in %

4 endfor

5

6 $apo.

cptp

=100 via-point approx. set to max.

only affects points between

start and end configuration

7

8 Points for PTP motion in joint space

9 PTP {A1 q

s,1

, A2 q

s,2

, A3 q

s,3

, A4 q

s,4

, A5 q

s,5

,

A6 q

s,6

}

10 PTP {A1 p

∗

1

, A2 p

∗

2

, A3 p

∗

3

, A4 p

∗

4

, A5 p

∗

5

,

A6 p

∗

6

}

c ptp

11 PTP {A1 q

e,1

, A2 q

e,2

, A3 q

e,3

, A4 q

e,4

, A5 q

e,5

,

A6 q

e,6

}

Figure 9: Optimized Trajectory Source Code.

In this case, the optimization process has no influ-

ence on velocity and acceleration settings, as minimal

travel time arises from both variables set to their max-

imum of

v = v

max

= 100%, (15)

a = a

max

= 100%. (16)

Again, trajectories are generated utilizing the orig-

inal trajectory planning from the robot control. This

includes calculation of travel time t

trav

. The resulting

cost function is

p

∗

t

= argmin

p

t

(t

trav

(q

s

,p

t

,q

e

)) (17)

and does not include the model of system energy in

section 2. Parameter bounds are the same as defined

in (10), respectively.

Additional non-linear constraints can be consid-

ered to further tune the trajectory according to re-

quired characteristics. For instance, in order to re-

strict the deviation of the optimized trajectory from

the initial, a constraint to ensure the optimized tra-

jectory stays in bounds of a tube with a defined radius

around the initial trajectory can be used (Hussong and

Heimann, 2007).

Analogically, any kind of restriction can be con-

sidered, however, additional non-linear constraints

can lead to less flexibility for the optimization which

leads to less advance in performance. Improvement

possibilities depend on the initial trajectory and the

workspace circumstances.

3.3.3 Optimization Procedure

The non-linear optimization problem is solved using

an active-set algorithm. The starting point for opti-

mization is set in the middle (in joint space) between

start and end configuration

p

start

e,joint config.

= p

start

t

=

q

s

+ q

e

2

. (18)

The resulting optimal parameter vector is then used

to optimize the robot control program. In case of

the addition of multiple via-points, starting points are

equidistantly distributed.

The whole optimization process runs automati-

cally. A robot control program on a KUKA KR C4

is read and relevant information is extracted. Then,

the actual optimization process is performed. After-

wards, a robot control program, including the added

resulting via-points, is generated. Exemplary, a re-

sulting optimized code for a single added via-point is

shown in Figure 9.

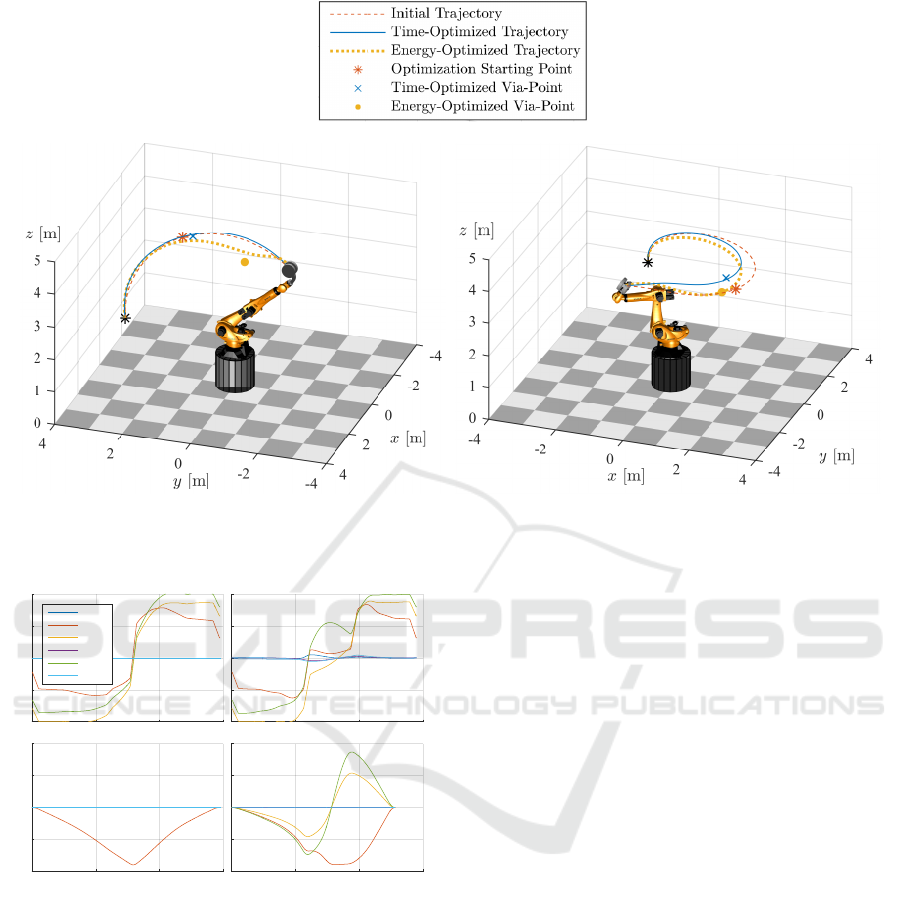

4 RESULTS

This section presents optimization results for differ-

ent PTP trajectories on the KUKA KR 210 industrial

robot, shown in Figure 10. The model of system en-

ergy in section 2 and the optimization method in sec-

tion 3 are applied. All trajectories analyzed include an

additional test load of 200 kg mounted at the robot’s

end-effector flange.

Furthermore, initial trajectories move with max-

imum velocity and acceleration, as it is a standard

in industrial application to achieve minimum travel

times.

Like many other high-payload robots, the KR 210

has a counterbalancing system between axis 1 and

2. This lowers high torque demands for axis 2 in

Table 1: Start and End Configurations (in Degrees) of the

PTP Trajectories with Energy and Time Optimized Via-

Points.

T1

q

T

s

= [ 0.0 -5.0 0.0 0.0 0.0 0.0 ]

q

T

via,e

= [ -2.2 -69.8 6.9 4.0 -67.9 1.4 ]

q

T

via,t

= [ -0.3 -69.9 -42.7 0.4 -105.8 0.0 ]

q

T

e

= [ 0.0 -140.0 0.0 0.0 0.0 0.0 ]

T2

q

T

s

= [-150.0 -5.0 -90.0 -45.0 -50.0 -45.0 ]

q

T

via,e

= [ -18.6 -51.4 -15.2 74.1 65.8 25.6 ]

q

T

via,t

= [ -9.3 -39.9 -38.7 61.1 96.0 22.1 ]

q

T

e

= [-150.0 -90.0 90.0 180.0 125.0 120.0 ]

T3

q

T

s

= [ -55.0 -5.0 10.0 100.0 10.0 -40.0 ]

q

T

via,e

= [ -28.0 -39.0 -23.6 -21.1 125.0 54.2 ]

q

T

via,t

= [ -22.3 -53.1 -26.9 -40.1 55.0 5.3 ]

q

T

e

= [ 15.0 -105.0 -60.0 -180.0 100.0 50.0 ]

T4

q

T

s

= [-165.0 -115.0 -110.0 -316.0 -114.0 -316.0 ]

q

T

via,e

= [ 16.5 -55.1 27.2 -4.7 47.1 -10.6 ]

q

T

via,t

= [ 17.2 -51.2 26.6 -13.5 6.4 -14.3 ]

q

T

e

= [ 166.0 -9.0 111.0 319.0 115.0 319.0 ]

Optimizing PTP Motions of Industrial Robots through Addition of Via-points

533

stretched configurations. The influence of the coun-

terbalancing system on the robot is included in the

dynamic model (Hansen et al., 2012).

Table 1 shows exemplary chosen PTP trajecto-

ries including their starting and ending configurations.

The trajectories cover different motion characteris-

tics, such as horizontal and vertical motion, a combi-

nation of both and an all axis motion from minimum

to maximum joint angle limit.

Additionally, the axis configurations of optimized

via-points q

∗

e,via

and q

∗

t,via

for energy-optimized PTP

motions are presented. Associated velocity and ac-

celeration values are v

T1

= 74.7 %, v

T2

= 80 %, v

T3

=

72%, and v

T4

= 80 %, whereas acceleration stays at

almost 100 % for all four trajectories.

Table 2: Results for Energy and Time Optimized Trajec-

tories. The Colors, Associated to Figure 10, Highlight the

Results.

Travel

Time [s]

Energy

Cons. [J]

Time-Opt.

Slowed [J]

T1

init

2.96 9733

T1

opti,e

2.96 8060 (-17.2 %)

T1

opti,t

2.57 (-13.3 %) 9476 (- 2.6 %) 8195 (-15.8 %)

T2

init

3.50 15005

T2

opti,e

3.50 12992 (-13.4 %)

T2

opti,t

3.09 (-11.7 %) 15751 (+ 5.0 %) 13535 (- 9.8 %)

T3

init

3.01 11769

T3

opti,e

3.01 9678 (-17.3 %)

T3

opti,t

2.85 (- 5.33 %) 13841 (+ 17.7 %)11345 (- 3.6 %)

T4

init

4.84 30268

T4

opti,e

4.84 26692 (-11.8 %)

T4

opti,t

4.44 (- 8.3 %) 30251 (- 0.1 %) 27422 (- 9.4 %)

The resulting energy savings are summarized in

Table 2. For the exemplary chosen trajectories, we

achieve energy savings up to 17.3 %.

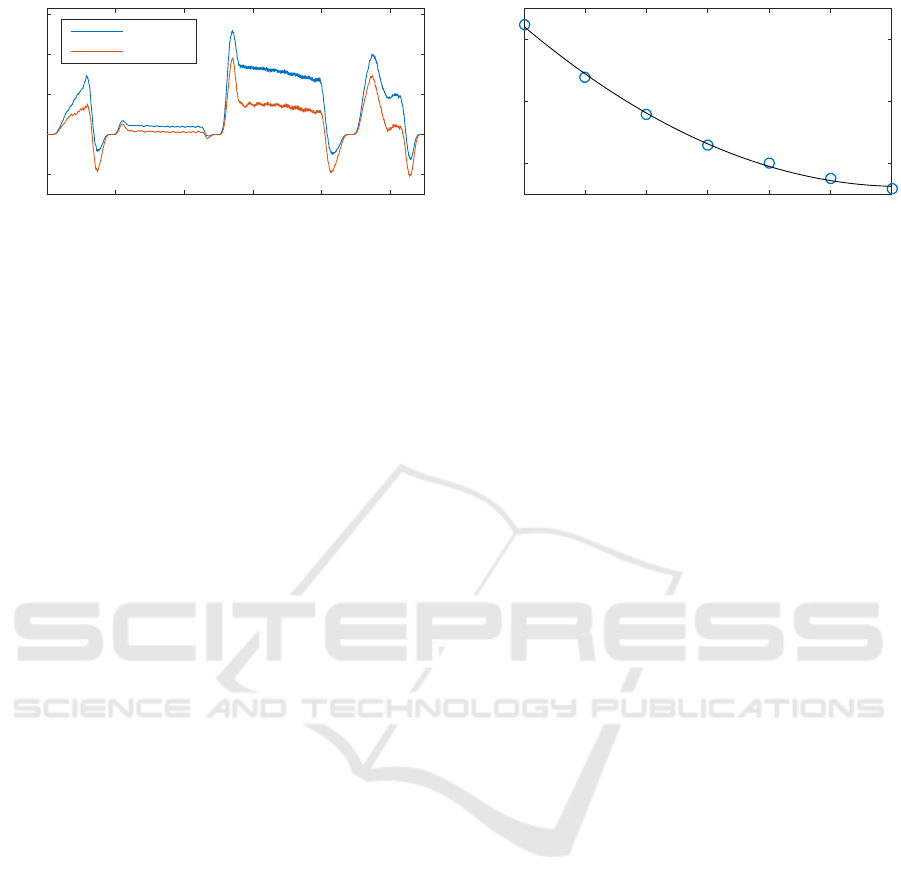

In order to clarify the effects leading to the im-

provement, T1 is analyzed in detail. Figure 11 shows

initial and energy-optimized joint motor torques of

T1. As mentioned in 3.1, torque limited trajectory

generation leads to at least one axis reaching its max-

imum torque limit. Even though only axis 2 is sup-

posed to move, the other horizontal axes have to com-

pensate torques due to moments of inertia, Coriolis

and gravitational effects. For T1, axes 3 and 5 even

reach their torque limits. The added via-point of the

energy-optimized trajectory allows the axes torques to

be lowered more quickly. Axes 2 and 5 cross the zero

torque level approximately 0.4 s earlier than the ini-

tial trajectory. Overall reduced torques lead to energy

savings of 17.2 %. Retardations are prevented due to

the applied boundaries.

Alternatively, the cost function can be exchanged

to minimize the travel time. Optimization of travel

time is performed as an example for other optimiza-

tion targets. Time savings up to approximately 13 %

are accomplished.

Initial and time-optimized joint velocities of T1 in

Figure 11 allow for a closer look at the time optimiza-

tion. Standard trajectory planning for a difference be-

tween start and end configuration in only one axis, in

this case axis 2, results in a single movement of that

axis. In contrast, the optimized trajectory shows an

additional movement of the previously passive axes,

especially the parallel ones. The additional motions

lead to an optimized configuration regarding moments

of inertia, Coriolis and gravitational effects. Regard-

ing axis 2, this allows for a motion with increased ve-

locity after reaching its peak at about 1.6 s, leading to

time savings of 13.3 % and simultaneous energy sav-

ings of 2.6 % as a side effect.

The time savings can then be used to reduce ac-

celeration and/or velocity settings, leading to reduced

energy consumption. Hence, resulting energy savings

are included in Table 2. The energy savings of the

time-optimal slowed down trajectory come close to

the energy-optimized results, but do not reach those.

However, for optimization of travel time no model of

system energy is required.

5 CONCLUSION AND FUTURE

WORKS

5.1 Conclusion

A new approach to automatically improve PTP mo-

tions of robotic systems using standard robot control

has been presented. The proposed methods were suc-

cessfully implemented on the KUKA KR 210. The re-

sulting optimized source code differs from the initial

one only by the added via-points which can be added

using standard commands of common robot control

systems.

Exemplary, in this paper the addition of one via-

point is considered. In case of multiple via-points, the

procedure is same. The initial multiple via-points are

distributed equidistantly between start and end con-

figuration, as described in section 3.3.3, and then all

of them are optimized at the same time towards min-

imizing the respective cost function. Note that ad-

dition of multiple via-points increases the dimension

of the parameter vector by six per additional via-point

for a robot with n = 6 degrees of freedom which raises

computational expenses. However, the optimized tra-

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

534

(a) Trajectory T1 (b) Trajectory T2

Figure 10: Exemplary Considered Trajectories T1 and T2.

-1

-0.5

0

0.5

1

= ==

max

T1

init

Joint Torques

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

T1

opti;e

Joint Torques

0 1 2 3

t [s]

-1

-0.5

0

0.5

1

v=v

max

T1

init

Joint Velocities

0 1 2 3

t [s]

T1

opti;t

Joint Velocities

Figure 11: Comparison of Initial to Energy-Optimized Joint

Motor Torques and Initial to Time-Optimized Joint Veloci-

ties of T1.

jectory could be specified more exactly which may

lead to further optimization potential.

The via-point’s configuration in joint space is cal-

culated by formulating an optimization problem. Sev-

eral optimization targets can be implemented by ex-

changing the cost function. In this paper we focus on

reducing energy consumption and additionally con-

sider optimization of travel time. Collision avoidance

can be implemented by setting non-linear constraints.

In comparison to existing approaches, our model

of system energy is more simple and requires less in-

formation of the system. However, it is suitable to

depict the energy demand of serial cinematic indus-

trial robots and to be implemented for optimization

procedure.

Based on the introduced model of system energy,

the optimization problem to reduce energy consump-

tion has been formulated. The experimental results

have shown energy savings up to 17.3 %.

In contrast, targeting to the optimization of travel

time, a different cost function has been formulated.

The implementation of this target has resulted in

time savings up to 13.3 %. These savings can also be

used, to reduce energy consumption by decreasing

acceleration and velocity settings on robot control.

Hence, energy savings up to 15.8 % are achieved.

Future works may focus on the addition of multi-

ple via-points to the initial trajectory and on the eval-

uation of the results for a high number of different ini-

tial trajectories. Furthermore, the methods presented

in this paper could be tested for different types of in-

dustrial robots.

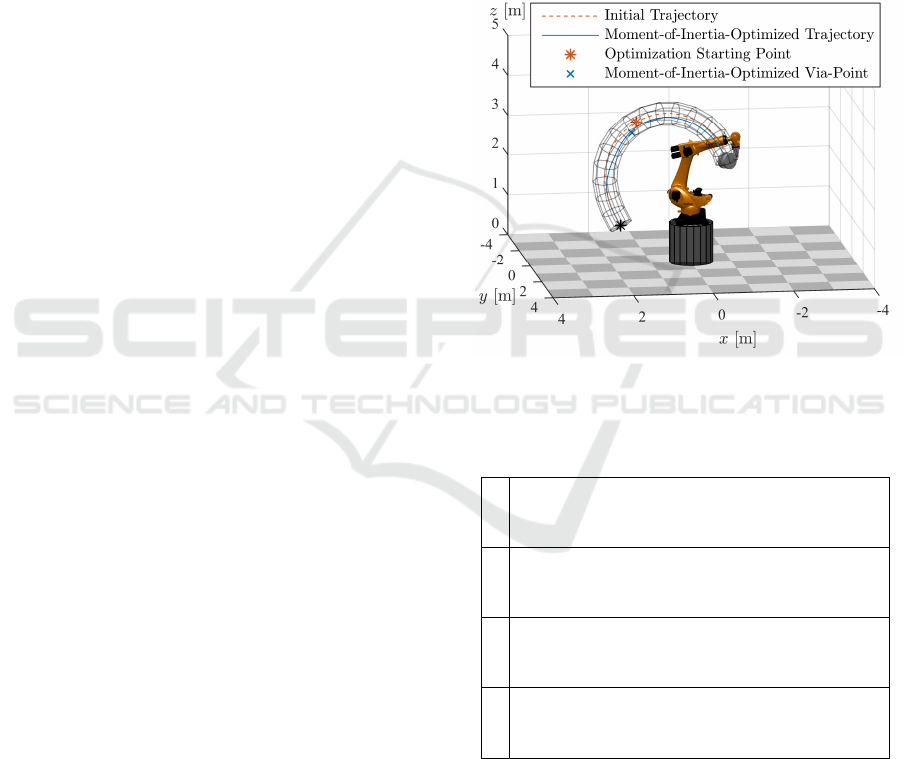

5.2 Reduced Complexity Optimization

Method

Reviewing the resulting trajectories of the presented

approach lead to another method. Future works may

focus on the direct minimization of moment of iner-

tia. The complete model of system energy as well

Optimizing PTP Motions of Industrial Robots through Addition of Via-points

535

as the inverse dynamics are highly complex and re-

quire a lot of system information. The advantages of

reduced moments of inertia are explained in section

3.2. Following, an approach to optimize robot trajec-

tories focusing on direct minimization of moment of

inertia is proposed. In this case, the Cartesian inertia

matrix M needs to be calculated.

The cost function for this approach is

p

∗

in

= argmin

p

in

M

(ax ax)

(p

in

)

, (19)

where ax is the axis for which the moment of

inertia is to be minimized, and parameter vector p

in

equals p

t

. The chosen axis depends on the initial

trajectory. Initial and optimized robot control codes

are programmed in the same manner as shown in

section 3.3.

This approach comes along with some challenges.

The cost function does not include any information

about the resulting travel time or energy consump-

tion. Therefore, an explicit target for the optimization

can not be set.

Furthermore, reducing the moment of inertia is

not suitable for all kinds of trajectories. Those with a

significant downwards movement of the end-effector

profit from gravitational effects. This profit increases

with greater moment of inertia, as the mass of

robot links induce a joint torque in the direction of

movement and, therefore, lower the share of overall

joint torques provided by the motors.

Finally, the minimum could be a long distance away

from initial trajectory, resulting in a great detour and

no improvement in performance. However, non-

linear constraints can prevent this problem. In this

paper, the exemplary single via-point is kept inside a

tube around the initial trajectory, as shown in Figure

12. This constraint is implemented by calculating the

via-point’s distances in workspace to all points of the

initial trajectory. The minimum of these distances is

the via-point’s distance to the trajectory and it must

not exceed the tube radius. Besides, it allows not

only a radial shift of the via-point, but in any three

dimensional direction.

Experimental Results

The aforementioned approach is applied to the

trajectories previously considered in this paper. To

avoid the problem of excessive detours, an additional

non-linear constraint is implemented. This constraint

keeps the optimized via-point inside a tube with

a radius of r = 0.3 m around the initial trajectory.

However, this only represents a possible first solution

for the problems pointed out before and the settings

of that constraint also depend robot and trajectory

characteristics. The optimized via-points for each

trajectory are presented in Table 3, associated energy

and time savings are listed in Table 4. Minimizing

the moment of inertia in via-point configuration has

shown time savings up to 9.6 % and energy savings

up to 6.3 %. Initial and optimized trajectory T3 in

workspace are shown in Figure 12. Although this

approach cannot set a specific target, it requires less

information of the system and significantly lowers

computational time of the optimization.

Figure 12: Initial and Moment of Inertia Optimized Trajec-

tory T3.

Table 3: Start and End Configurations of the PTP Trajecto-

ries with their Moment of Inertia Optimized Via-Points.

T1

q

T

s

= [ 0.0 -5.0 0.0 0.0 0.0 0.0 ]

q

T

via,in

= [ -0.0 -63.1 -50.0 28.6 -50.0 -6.8 ]

q

T

s

= [ 0.0 -140.0 0.0 0.0 0.0 0.0 ]

T2

q

T

s

= [-150.0 -5.0 -90.0 -45.0 -50.0 -45.0 ]

q

T

via,in

= [ 0.1 -49.1 -0.90 1.8 151.7 170.0 ]

q

T

e

= [-150.0 -90.0 90.0 180.0 125.0 120.0 ]

T3

q

T

s

= [-55.0 -5.0 10.0 100.0 10.0 -40.0 ]

q

T

via,in

= [-20.0 -55.0 -25.0 -6.6 150.0 100.0 ]

q

T

e

= [ 15.0 -105.0 -60.0 -180.0 100.0 50.0 ]

T4

q

T

s

= [-165.0 -115.0 -110.0 -316.0 -114.0 -316.0]

q

T

via,in

= [ 0.5 -62.0 0.5 2.0 -147.4 -0.1 ]

q

T

e

= [166.0 -9.0 111.0 319.0 115.0 319.0 ]

The results show that the approach of reducing

moment of inertia is more suitable to optimize tra-

jectories’ travel time at this stage. To obtain optimal

configuration concerning moment of inertia, given the

previously mentioned constraints, major additional

axes motion is necessary. This may lead to higher

energy demand, e. g. for trajectories T1 and T2.

However, T3 and T4 show that further development

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

536

may enable to optimize energy consumption and

travel time simultaneously. Furthermore, the reduced

complexity cost function favors the possibility of

online application. Suitable constraints to develop

this approach need to be addressed in future works.

Table 4: Results for Moment of Inertia Optimized Exem-

plary Trajectories.

Travel

Time [s]

Energy

Consumption [J]

T1

init

2.96 9733

T1

opti,in

2.78 (- 6.1 %) 10394 (+ 6.8 %)

T2

init

3.50 15005

T2

opti,in

3.20 (- 8.6 %) 16193 (+ 7.9 %)

T3

init

3.01 11769

T3

opti,in

2.72 (- 9.6 %) 11021 (- 6.4 %)

T4

init

4.84 30268

T4

opti,in

4.57 (- 5.6 %) 28492 (- 5.9 %)

ACKNOWLEDGEMENTS

The authors would like to thank the KUKA Roboter

GmbH for granting us access to their laboratories to

perform power measurements on a KUKA KR 210.

REFERENCES

(2016). World record: 248.000 industrial robots revolution-

ising the global economy. IFR press release.

Biagiotti, L. and Melchiorri, C. (2008). Trajectory Planning

for Automatic Machines and Robots. Springer Science

& Business Media.

Bobrow, J. E. (1988). Optimal Robot Plant Planning Us-

ing the Minimum-Time Criterion. IEEE Journal on

Robotics and Automation, 4(4):443–450.

Brossog, M., Bornschlegl, M., Franke, J., et al. (2015). Re-

ducing the Energy Consumption of Industrial Robots

in Manufacturing Systems. The International Jour-

nal of Advanced Manufacturing Technology, 78(5-

8):1315–1328.

Costantinescu, D. and Croft, E. (2000). Smooth and time-

optimal trajectory planning for industrial manipula-

tors along specified paths. Journal of Robotic Systems,

17(5):233–249.

Gattringer, H., Riepl, R., and Neubauer, M. (2013). Op-

timizing Industrial Robots for Accurate High-Speed

Applications. Journal of Industrial Engineering,

2013.

Geering, H. P., Guzzella, L., Hepner, S. A., and Onder, C. H.

(1985). Time-Optimal Motions of Robots in Assem-

bly Tasks. In Proc. of the IEEE Conf. on Decision and

Control, pages 982–989.

Gleeson, D., Bj

¨

orkenstam, S., Bohlin, R., Carlson, J. S., and

Lennartson, B. (2015). Optimizing Robot Trajectories

for Automatic Robot Code Generation. In Proc. of the

IEEE Int. Conf. on Automation Science and Engineer-

ing, pages 495–500. IEEE.

Gleeson, D., Bj

¨

orkenstam, S., Bohlin, R., Carlson, J. S., and

Lennartson, B. (2016). Towards Energy Optimiza-

tion Using Trajectory Smoothing and Automatic Code

Generation for Robotic Assembly. Procedia CIRP,

44:341–346.

Hamon, P., Gautier, M., and Garrec, P. (2010). Dy-

namic Identification of Robots With a Dry Friction

Model Depending on Load and Velocity. In Proc. of

the IEEE/RSJ International Conference on Intelligent

Robots and Systems, pages 6187–6193.

Hansen, C., Eggers, K., Kotlarski, J., and Ortmaier, T.

(2015). Concurrent Energy Efficiency Optimization

of Multi-Axis Positioning Tasks. In Proc. of the IEEE

Int. Conf. on Industrial Electronics and Applications,

pages 518–525.

Hansen, C., Kotlarski, J., and Ortmaier, T. (2013). Path

Planning Approach for the Amplification of Electri-

cal Energy Exchange in Multi Axis Robotic Systems.

In Proc. of the IEEE Int. Conf. on Mechatronics and

Automation, pages 44–50.

Hansen, C.,

¨

Oltjen, J., Meike, D., and Ortmaier, T. (2012).

Enhanced Approach for Energy-Efficient Trajectory

Generation of Industrial Robots. In Proc. of the IEEE

Int. Conf. on Automation Science and Engineering,

pages 1–7.

Hussong, A. and Heimann, B. (2007). Restricted Minimum-

Effort Motion Planning for serial Manipulators. In

Proceedings of the 12th IFToMM World Congress.

Johnson, C. T. and Lorenz, R. D. (1992). Experimental

identification of friction and its compensation in pre-

cise, position controlled mechanisms. IEEE Transac-

tions on Industry Applications, 28(6):1392–1398.

Meike, D., Pellicciari, M., and Berselli, G. (2014). Energy

Efficient Use of Multirobot Production Lines in the

Automotive Industry: Detailed System Modeling and

Optimization. IEEE Transactions on Automation Sci-

ence and Engineering, 11(3):798–809.

Meike, D. and Ribickis, L. (2011). Industrial Robot Path

Optimization Approach with Asynchronous Fly-By in

Joint Space. In Proc. of the IEEE International Sym-

posium on Industrial Electronics, pages 911–915.

Mohammed, A., Schmidt, B., Wang, L., and Gao, L.

(2014). Minimizing Energy Consumption for Robot

Arm Movement. Procedia CIRP, 25:400–405.

Paes, K., Dewulf, W., Vander Elst, K., Kellens, K., and

Slaets, P. (2014). Energy Efficient Trajectories for an

Industrial ABB Robot. Procedia CIRP, 15:105–110.

Pellicciari, M., Berselli, G., Leali, F., and Vergnano, A.

(2013). A method for reducing the energy consump-

tion of pick-and-place industrial robots. Mechatron-

ics, 23(3):326–334.

Riazi, S., Bengtsson, K., Wigstr

¨

om, O., Vidarsson, E., and

Lennartson, B. (2015). Energy Optimization of Multi-

Robot Systems. In Proc. of the IEEE Int. Conf. on Au-

tomation Science and Engineering, pages 1345–1350.

Optimizing PTP Motions of Industrial Robots through Addition of Via-points

537

Vergnano, A., Thorstensson, C., Lennartson, B., Falk-

man, P., Pellicciari, M., Leali, F., and Biller, S.

(2012). Modeling and Optimization of Energy Con-

sumption in Cooperative Multi-Robot Systems. IEEE

Transactions on Automation Science and Engineer-

ing, 9(2):423–428.

Wigstrom, O., Lennartson, B., Vergnano, A., and Brei-

tholtz, C. (2013). High-Level Scheduling of Energy

Optimal Trajectories. IEEE Transactions on Automa-

tion Science and Engineering, 10(1):57–64.

You, W., Kong, M., and Sun, L. (2011). Optimal Motion

Generation for Heavy Duty Industrial RobotsControl

Scheme and Algorithm. In Proc. of the IEEE Int. Conf.

on Mechatronics, pages 528–533.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

538