Robust PI

D

, H

and Smith Predictor Controller Design for

Time Delay Systems

Youcef Zennir, Mohand Said Larabi and Hamza Zemaili

Automatic Laboratory of Skikda, Skikda University, 26 route el-hadaiek, Skikda, Algeria

Keywords: Robust Control, Fractional Order Controller, Smith Predictor Controller, H

Controller, Identification,

Industrial System, System with Time Delay.

Abstract: This paper present optimal robust control with different controllers design used in the industrial (didactic or

process) system. We designed a controller base on Smith's predicator controller and Fractional order PID

(PI

D

) controller and H

∞

controller. These control techniques has been used with different controller’s

types to ensure an optimum control in term of dynamic and static performances of a complex didactic

industrial process in accordance with the required specifications. We have described in more details the

process, the mathematical model, the structure of FOPID controller and the approximation method

(singularity function method of Charef) used to approximate fractional order. The principle of control is

decried as well with the different types of controllers used in this study. Finally several simulation and real

results are presented which have proved the efficiency of this new control design in term of: stability,

robustness and precision.

1 INTRODUCTION

To be robust, an industrial process must be well

controlled. Indeed, competitiveness requires keeping

process values as close as possible to its required

optimum performance and process conditions: such

as the products quality, production flexibility,

energy saving and safety of personnel, facilities and

the environment. The main role of industrial

controller is to keep the process under control with

the guarantee of a good dynamic and static

behaviour performance. Which can be achieved by

adjusting and adapting the transfer function

parameters in order to as close as possible to the real

process? In general, an industrial process is

modelled by a non-linear, linear (after linearization)

or linear mathematical model with a time delay

(Boyd, 1991). Regardless if these models are stable

or not are required a controller (control action) to

ensure the desired performance. The objective of

automatic regulation or servo-control of a process is

to keep the process values as close as possible to its

optimum of operating points, predefined by the

process specification (imposed conditions or

performance). Safety aspects of staff and facilities

should be taken into accounts, such as those relating

to energy and respect for the environment. The

specifications define qualitative criteria to be

imposed, which are usually translated by

quantitative criteria, such as stability, precision,

speed or evolution laws. Before going ahead and

develop the controller architecture and structure and

in case of unknown process parameters, an

identification phase is mandatory. Different methods

of identification exist in the literature (Broida,

Strejc, etc.) (Boyd, 1991; Ljung, 1999; Barraud

2006), in our study we have used Ident a Matlab

identifications toolbox function and we did a study

of a flow control system (Figure 4) by computing its

mathematical model (Abraham, 2015) via applying a

different identification methods (Broida, Strejc, etc.)

and synthesis of its control laws using several types:

FOPID, Smith predictor and H

controllers

(Barraud, 2006), and then at the end we checked the

simulation results with the process experiments.

2 CONTROLLERS DESIGN

In the literature, it exist a large number of linear or

discrete linear controllers adequate to control an

industrial process which have a linear system

Zennir, Y., Larabi, M. and Zemaili, H.

Robust PI

λ

D

µ

, H

∞

and Smith Predictor Controller Design for Time Delay Systems.

DOI: 10.5220/0006399805430550

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 543-550

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

543

behavior (Kumar, 2014). Among the most common

and most used controllers are PI, PD and PID

different structures (Shamsuzzoha 2008). Also, there

is another type of controller which is more robust

than the Standart PID such as the Fractional order

PID controller (FOPID) (Bettou, 2008; Bouras,

2013; Djari, 2014). Other types of controllers are

developed specifically to control the systems with

time delay such as Smith's predictor. This controller

was proposed for the first time by OJ Smith in 1957

(Esmaeilzade, 2014).The main idea behind Smith's

predictor is that, since it is well known to correct

systems without time delay with a corrector (PID for

example) (Aidan, 1996; Resceanu, 2009). It does not

correct the system without delay but the output will

then be estimated by delaying it by the value of the

time delay of the system. This very simple approach

leads to the following structure:

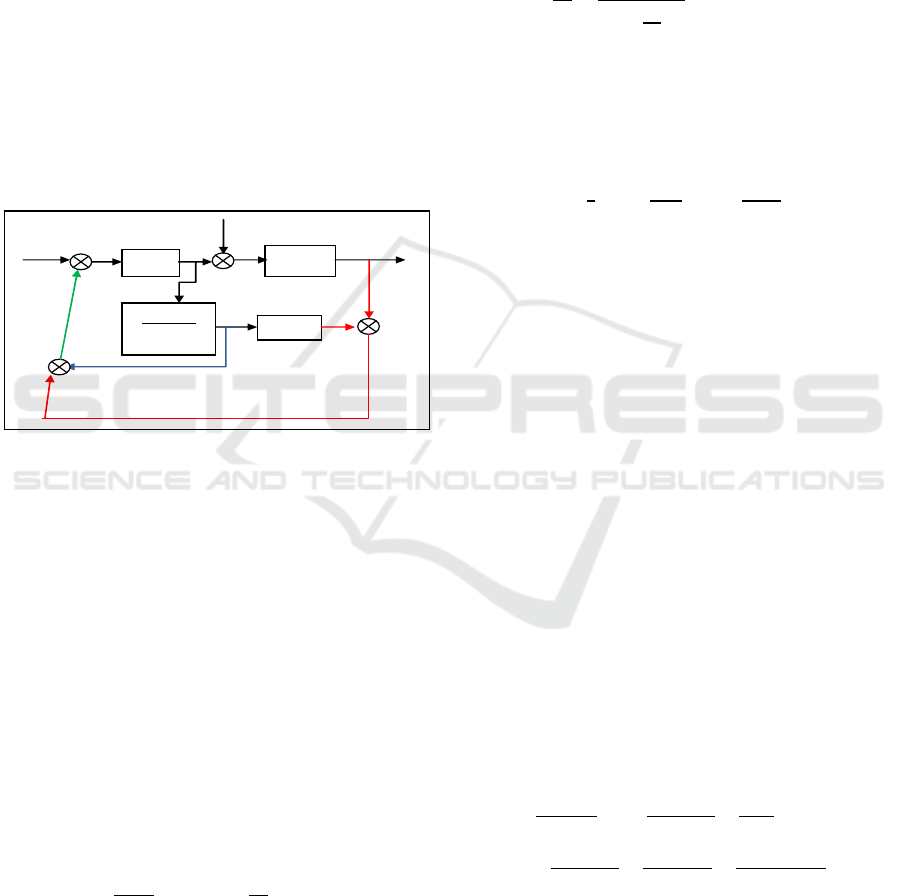

Figure 1: Structure of Smith Predictor ( L=Td; Ks=Kp;

=Td).

Different structures of Smith predictor has been

proposed in literature with different controllers. Note

that, the implementation of a Smith predictor

controller needs a very good model of the process.

In our study we have used only Fractional order PID

(FOPID) controller and with Smith predictor. The

structure type of the FOPID controllers is Fractional

order controller: PI

λ

D

. In control theory, the

conclusion about fractional control system is that it

can increase the stability region and robustness

(Esmaeilzade, 2014) moreover it gives performances

at least as good as its integer counterpart (Grimble,

2006). The transfer function of a FOPID controller,

which was initially proposed by Podlubny in 1999

(Esmaeilzade, 2014), is given by:

1

,

,0

(1)

Where Kp, KI, KD R and , R+: are the

controller tuning parameters and the controller

design problem is to determine the suitable values of

these unknown parameters in such way it responds

to all control objectives (Grimble, 2006). Many

methods in literature have been proposed for FOPID

approximation (Bouras, 2013). In this work we have

used singularity function approximation method of

Charef (Bettou, 2011), applied in FOPID controller.

The fractional-order integrator

,

∈

R+ is

approximated as:

1

≅

1

,

01,

∈

(2)

To have a good tuning parameters of the PI

D (Kc,

Ti, ) we have used the following algorithm

(Bouras, 2013) described in the steps below:

Step1: calculate the parameters

i

for 0≪i≪2

∙

∙

(3)

u

: the unit magnitude frequency of reference

model;

m: the derivation fractional order of the reference

model;

i

: calculated with the reference model parameters.

Step 2: calculate the parameters y

i

for 0≪i≪2

Using the following formulas:

∙

(4)

∙

∙

(5)

∙

∙

(6)

With y

i

: calculated from the transfer function Gp(s)

compared to the variable s at the point ωu; N :

samples number.

Step 3: calculate the parameters X

i

for 0 ≪i≪2

As per the following formulas:

.

(7)

.

.

.

(8)

With X

i

: derived from the controller transfer function

C(s).

Step 4: calculate the parameters K

c

, T

i

, with the

following formulas:

C(s)

tf4(s)

e

-Ls

1

∙

r

u

y

d

Process

e

p

y

a

+

-

+

+

-

+

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

544

.

1

.

(9)

.

(10)

3 OPTIMAL CONTROL WITH H

Several representations are possible to solve the

control problems of the closed loop system, such as

H

∞

and H

2

optimization. Therefore it is practical to

have a general formula, in order to have a "standard

problem" for this type of control. The configuration

of the closed loop system with the various

specifications (weighting functions) is shown in

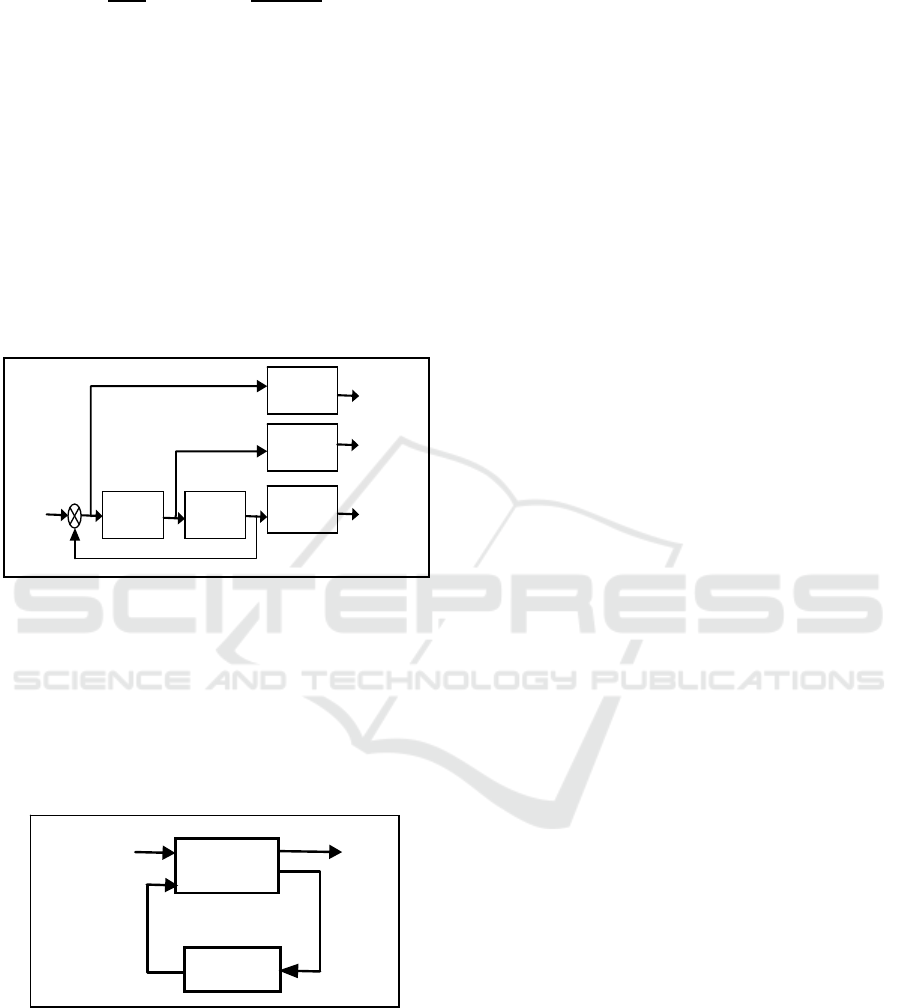

Figure (2).

Figure 2: Problem formulation Standard.

Where: W

t

(s): transfer matrix of the stability

specification; W

a

(s): transfer matrix relating to the

additive error; W

p

(s): matrix for transferring the

performance specification.

The general configuration of the standard

problem (Tsai, 2014) is presented in Fig.7 (LFT,

Linear Fractional Transformations representation).

Figure 3: Standard problem (LFT representation).

Where: u: system commands (dimension "m");

w: disturbance inputs (dimension "l");

y: measurements on the system (outputs)

(dimension "q");

z: controlled outputs (dimension "p"); x: state vector

(dimension "n")

The solution of the standard problem

(generalized mixed sensitivity problem) is found by

computing a control law u - delivered by a controller

K(s) - such that: u = K(s).y minimizing the influence

of the perturbation signal w on the output signal z,

namely:

∞

1

(11)

With:

T(s): Complementary Sensitivity defined by

(12)

L(s): is the Open loop L(s) = G(s) K(s)

R(s): Transfer to Control defined by

(13)

S(s): Sensitivity defined by:

(14)

We have associated with the standard problem the

following cost function T

zw

:

(15)

With:

(16)

(17)

And we have illustrated the steps for obtaining the

K(s) controller parameters by solving the problem

H

∞

. The problem of optimization by H

∞

is to find a

controller K(s) which stabilize the process, so as to

minimize the transfer between the inputs w and the

outputs z.

‖

‖

∞

max

(18)

The structure of the central controller K(s) is given

by the following function:

∞

∞

∞

∞

(19)

The association of the sensitivity function S(s) will

improve our controller performance in term of

closed-loop stability and attenuates the resonance

peaks on the maximum singular value of the

sensitivity S(s) (Tsai, 2014). The solution to the

problem of optimization by H∞ mentioned earlier

will be realized by the iteration on the parameter γ

then the optimal robust controller K(s) will have to

satisfy the condition: ||Tzw(jω)||∞ ≤ γ. The

P(s)

K(s)

w

u y

z

K(s) G(s)

w

p

(s)

W

a

(s)

W

t

(s)

Z

1

(s)

Z

2

(s)

Z

3

(s)

u(s)

e(s)

w

+

-

Robust PI

λ

D

µ

, H

∞

and Smith Predictor Controller Design for Time Delay Systems

545

parameter γ has to satisfy the compromise

"Stability/Performance". The different steps for the

robust controller’s determination are described as

follow. All these calculations steps can be

considered long before obtaining controller

structure, because they must be carried out for each

value of the parameter γ. Therefore it is preferable to

use a calculation algorithm, which computes the

robust controller parameters quicker with very good

accuracy. The robust controller parameters

algorithm is exposed as below:

1. Choice of specifications W

t

, W

p

and W

a

.

2. Realization of the augmented plant P(s).

3. Take γ = 1, synthesize controller H

∞

.

4. Calculation of the cost function Tzw.

5. If ||T

zw

(jω)||

∞

≤ γ go to 7.

6. Otherwise adjust γ and go to 2.

7. Frequency Evaluation’s and temporal results.

8. If the results are satisfactory go to 10.

9. Otherwise adjust γ and go to 1.

10. End.

The implementation of the controller will be

obtained by MATLAB software’s via Robust

Control Toolbox.

4 DIDACTIC INDUSTRIAL

PROCESS

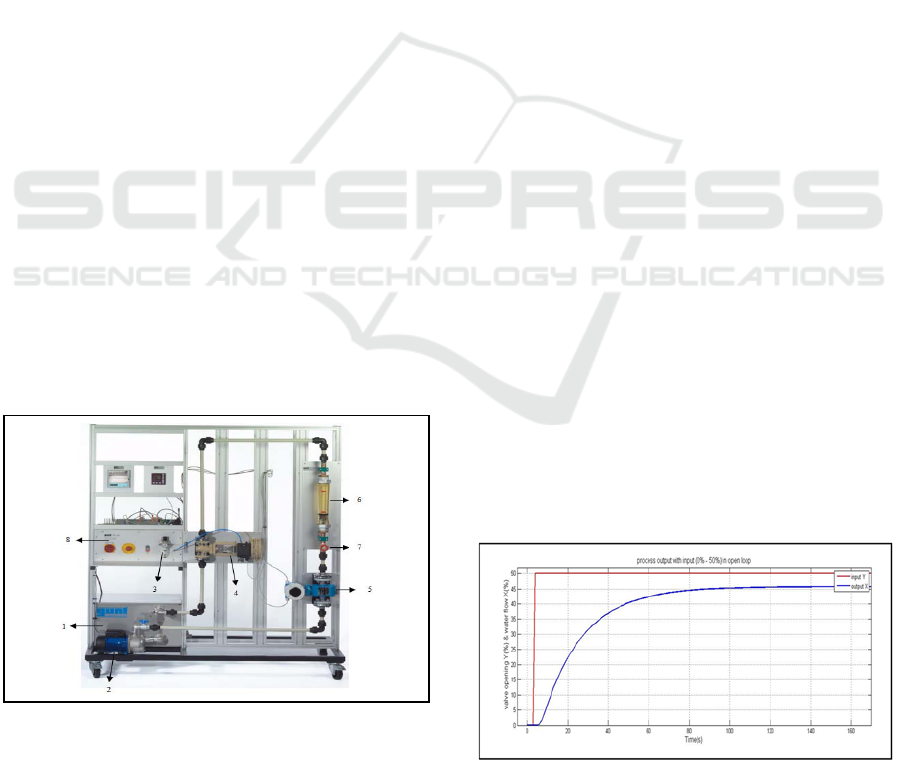

The process illustrated in FIG. 4 consists of

numerous components and accessories (Abraham,

2015). The accessory components are pre-installed

on plates.

Figure 4: Experiment setup of a flow control (Abraham,

2015).

The basic module contains one storage tank: 75L

(1), Centrifugal pump (2), Compressed air controller

with pressure gauge (0-2,5bar) with quick coupling

for supplying experiments (3), orifice with

Differential Pressure Sensor (Electro-pneumatic

control valve) (4), flow Rate Sensor

(Electromagnetic) (5), rotameter (6), valve (7) and

Switch cabinet (8). The Controlled System Flow is

operated with water as the working medium and

consists of a variable area flow meter. The flow

resistance can be configured using a valve (7), which

changes the flow properties in the controlled

systems.

One particular benefit of these controlled

systems is that, thanks to the float, all changes in the

flow rate caused by interference or behaviour of a

controller can be observed directly. The training

system has an electronic sensor with display for

measuring flow rate. It is suitable for measuring

flow rates of liquids in closed tubes. The

measurement variable is the flow rate. The ideal

flow velocity is 1- 3m/s.

The measurement principle is electromagnetic

induction according to Faraday's law.

Electromagnets or coils generate a magnetic field, in

which a conductor moves. This induces a voltage.

Here, the medium flowing in the flow rate sensor

corresponds to the moving conductor. The magnetic

field is generated by pulsed direct current of

alternating polarity. The identification methods used

to identify our process are described in the following

section.

5 PROCESS IDENTIFICATION

The search of an industrial process model is

necessary and must result in a model correctly

representing the behaviour of the process. However,

the model must not be too sophisticated, at the risk

of being incompatible with the available corrector,

or be too simplistic not to mask certain aspects that

are detrimental to proper functioning.

Figure 5: Process step response with input 0 % 50% in

open loop.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

546

The choice of a model, like its determination,

must be judicious (Liung, 1999). The system can

then be excited by a step signal with different

values. In principle, the output and input must be of

the same type with linear system (figure 5). If not,

the system is nonlinear (Barraud, 2006).

We have used Matlab function: ident from the

identification toolbox. The structure of parametric

estimation method is a simple transfer function in

continuous time that describes a linear dynamic

system. This model is characterized by a static gain,

time constants and time delay. If some parameters

are known, we need just enter their values and tick

the box "Known". The estimation algorithm will use

these values for the model. The behaviour of the

system is close to the first-order systems with a

small time delay, so we start from this principle and

we have made the identification with the four

datasets. The general form of the transfer function is

given by the following formula:

tf

s

Xs

Ys

K

T

∙s1

∙e

∙

(20)

The obtained model with this method is illustrated in

the following formula:

tf

s

0.89686

20.539∙s1

∙e

.∙

(21)

The tf4 is the model that represents better the real

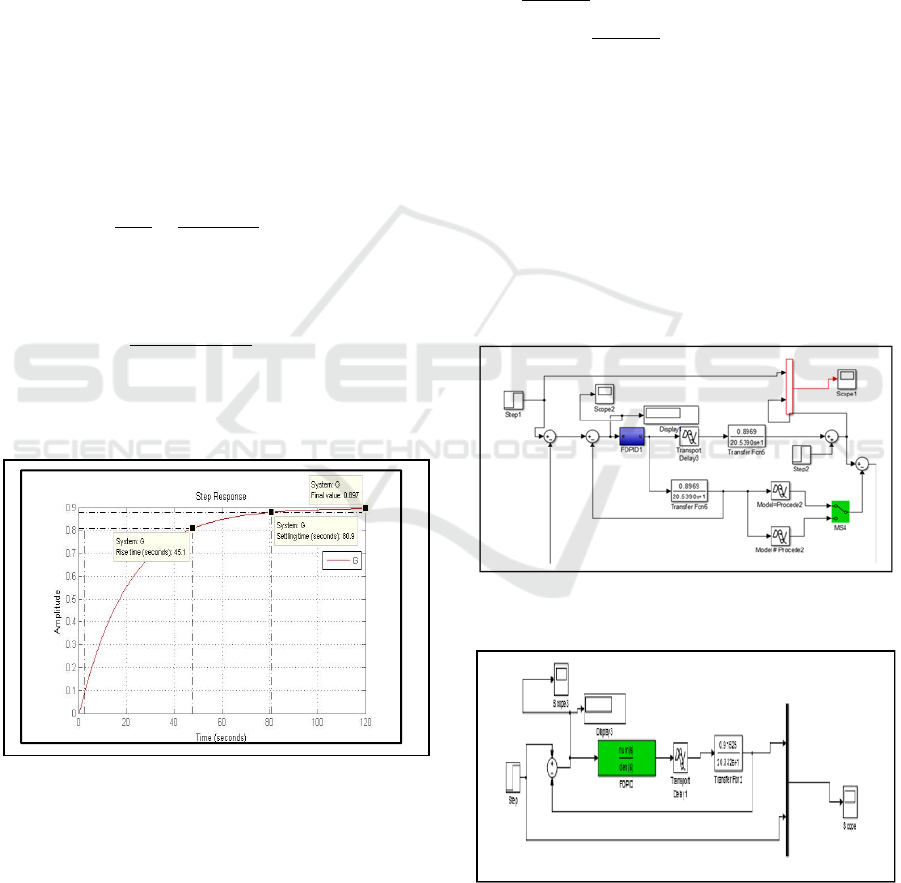

system. The index response of the open-loop model

(tf4) is illustrated in the following figure:

Figure 6: Step response of model tf4 in open loop.

The open loop characteristics are not satisfactory

(the system is very slow, final value different of 1)

(figure 6). Hence the need to used a controller to

ensure the optimal characteristics and improved the

stability of process. In the following section

different controllers used in this study has been

described and on particularly the Smith’s predictor

controller with new structure.

6 SIMULATION

The simulation is done on a closed loop with an step

input. The simulation Parameters are as follows:

FOPID controller: m=0.9; KI =12.3231

H

controller:

= 20.539; System time constant in open loop

a = 10; Acceleration parameter

w

o

= 1/(a*);

∙

: Performances specification

W

2

= [];

.∙

: stability specification

PID controller: kp1=10.5; ki1=0.808; kd1=1.84;

Smith Predictor: Delay1=0.5s and delay2=2.5s;

Disturbance equal 1 at t=40s; Simulation Time

=100s; the simulation is organized as follows:

First study: controlling the system with FOPID

and PID controllers without Smith predictor.

Second study: controlling the system with S

FOPID and PID controllers with Smith predictor.

Finally controlling the system with H robust

controller

The block diagram of the control is as follows:

Figure 7: Block diagram of Smith predictor and FOPID

controller.

Figure 8: Block diagram with FOPID controller.

Robust PI

λ

D

µ

, H

∞

and Smith Predictor Controller Design for Time Delay Systems

547

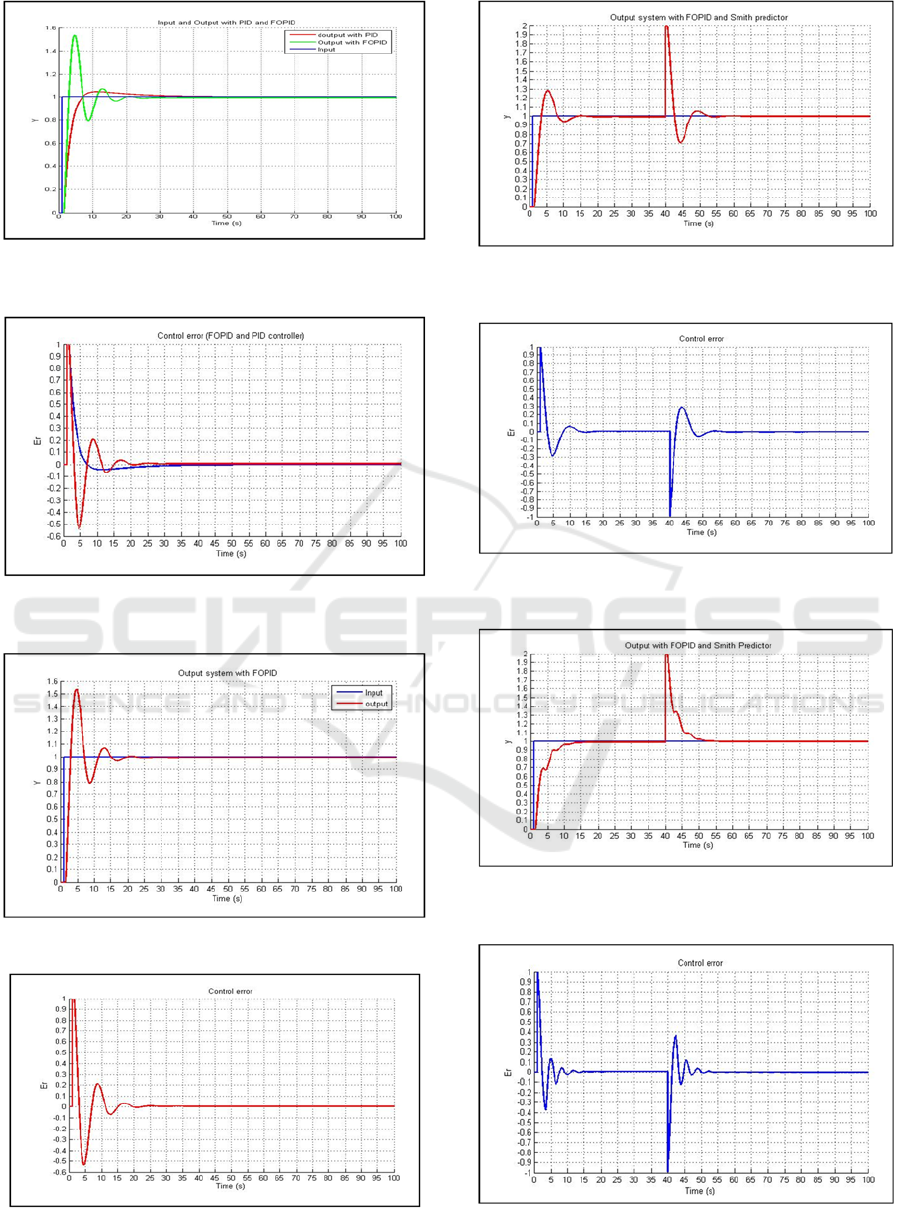

Figure 9: Input and Output curve, with FOPID and PID

controller.

Figure 10: Control error with FOPID (red curve) and PID

controller (bleu curve).

Figure 11: Input and Output curve with FOPID controller.

Figure 12: Control error curve with FOPID controller.

Figure 13: Input and Output curve (Process= model), with

smith Predictor and FOPID controller.

Figure 14: Error control (Process = model), with FOPID

controller.

Figure 15: Input and Output curve (Process model, time

delay=2.5s), with Smith predictor and FOPID controller.

Figure 16: Error control (Process model, time

delay=2.5s), with Smith predictor and FOPID controller.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

548

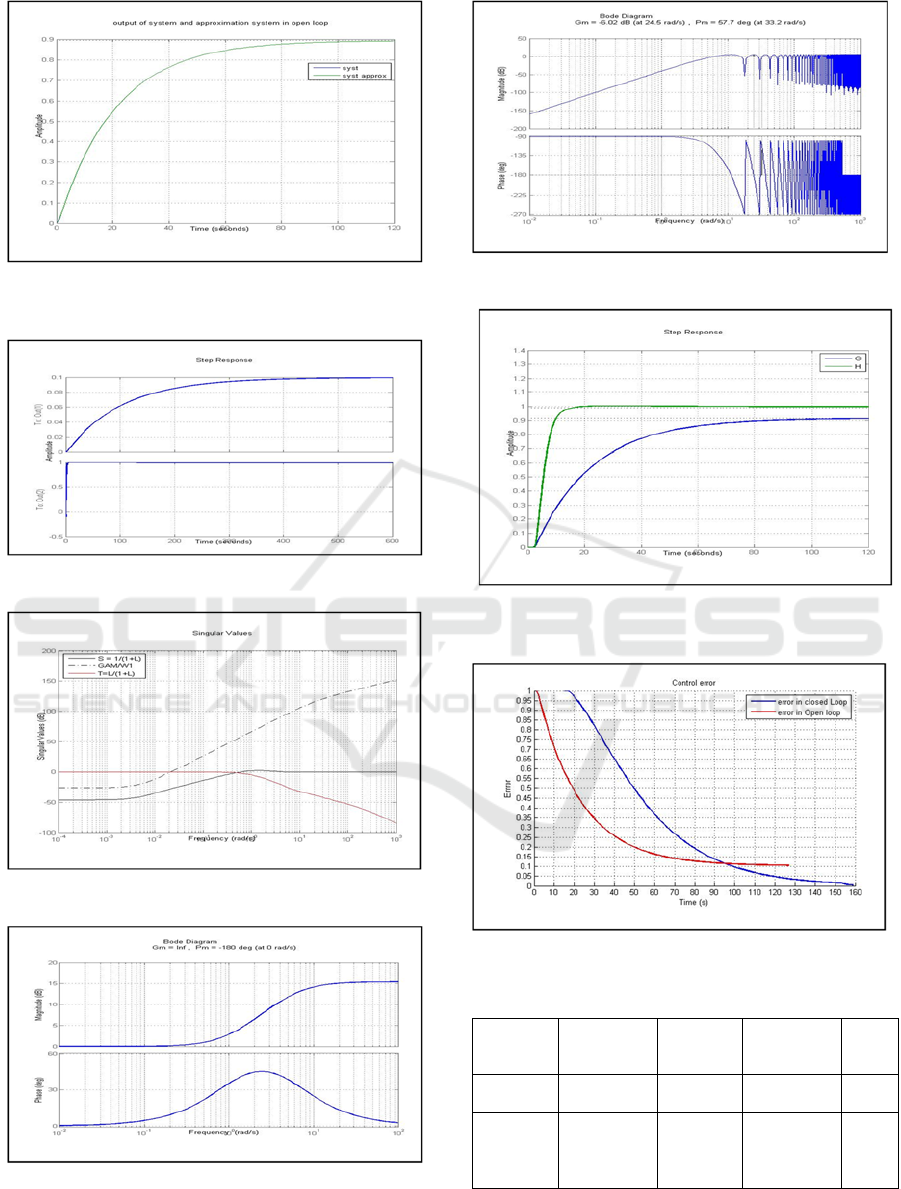

Figure 17: Output of system and approximation system in

open loop.

Figure 18: Output of Z1 and Z3 with (W2=0).

Figure 19: Singular Values.

Figure 20: Frequency response of W3.

Figure 21: Frequency response of disturbances.

Figure 22: Output system curve in open loop (bleu curve)

and in closed loop (green curve).

Figure 23: Control error with H∞ controller.

Table 2: Control error.

Control

error

FOPID

with Smith

Predicto

r

FOPID

PID &

Smith

Predicto

r

H

Process=

model

1.1.10

-6

6.8.

10

-3

6.5.10

-4

3.5.

10

-3

Process

model

(delay

=2.5s)

-9.4.10

-7

8.7.10

-4

The obtained results illustrated in Fig.9 and

Fig.10 show the PID controller is more efficient

Robust PI

λ

D

µ

, H

∞

and Smith Predictor Controller Design for Time Delay Systems

549

(short response time).The Fig.11 until Fig.16

illustrated the efficiency of smith predictor with

FOPID controller with and without disturbance

(very good robustnes, stability and presicion). The

Fig.17 until Fig.23 and Table.III show that the H

∞

controller is more efficient then the FOPID (short

response time and good precision). In the table.III

we can observed that the designed Smith predictor

with FOPID controller gives the best performences

and robustnes.

7 CONCLUSION

In this work we have presented a structure of Smith

Predictor controller based on PID and Fractional

order PID control (FOPID) and robust H

∞

controller

applied to the industrial didactic process, modeled

by a linear model with time delay. A detailed

description of the system was presented with

identification phase. The chosen model has been

validated. the obtained results show the new smith

predictor sutructure with an Fractional order PID

control improves more the performance of the

process compared with PID or H

∞

controller and

keep the study open for further optimization of the

FOPID parameters in case of a big time delay.

Different optimization algorithms can be applied

such as PSO or Genetic algorithms.

REFERENCES

Abraham, D., and Denker, T., 2015. Instruction Manual

RT 450 Modular Process Automation Training

Aidan, O. and John, R., 1996. The control of a process

with time delay by using a modified Smith predictor

compensator. Proceedings of the Irish Conference on

DSP and Control, Trinity College Dublin, pp. 37-44.

Barraud, J., 2006. Control of processes with variable

parameters. Mathematics. E. N.S des Mines de Paris,

p.161.

Bettou, K., 2011. Analyse et réalisation de correcteurs

analogiques d'ordre fractionnaire", Phd-These,

Université de Constantine, p.111.

Bettou, K. Charef, K.A, 2008. A New design method for

fractional PI

λ

D

μ

controller. IJSTA, vol.2(1), pp 414-

429.

Bouras, L. Zennir, Y., and Bourourou, F., 2013. Direct

torque control with SVM based a fractional controller :

Applied to the induction motor. Proceeding of the 3rd

IEEE international conference on system and control,

pp.702-707.

Boyd, S., and Barratt, C., 1991. Linear Controller Design:

Limits of Performance. Originally published by

Prentice-Hall, p.426.

Djari, A., Bouden, T., and Boulkroune, A., 2014. Design

of a fractional order PID controller (FOPID) for a

class of fractional order MIMO systems. J.

Automation & Systems Engineering, vol.8(1), pp. 25-

39.

Esmaeilzade, S.M., Balochian, S., Balochian, H., and

Zhang, Y., 2014. Design of Fractional–order PID

Controllers for Time Delay Systems using Differential

Evolution Algorithm. Indian Journal of Science and

Technology, vol. 7(9), pp.1307–1315.

Grimble, M. J., 2006. Robust Industrial Control Systems:

Optimal approach for polynomial systems. Book,

pp.554.

Kumar, S., and Singh, V.K., 2014. PID controller design

for unstable Processes With time delay. International

journal of innovative research in electrical,

electronics, instrumentation and control engineering,

Vol. 2, Issue 1, pp.837-845.

Kwakernaak, H., 1993. Robust control and H∞

optimization – A tutorial paper. Automatica, Vol. 29

(2), pp. 255-273,

Ljung, L., 1999. System Identification: Theory for the

User. 2

nd

ed. Englewood Cliff, NJ: Prentice Hall.

Reşceanu, F., 2009. New Smith Predictor Structure Used

for the Control of the Quanser SRV-02 Plant. Annals

of the university of Craiova, vol.2.p.7

System. G.U.N.T. Gerätebau, Barsbüttel, Germany,

Version 0.1, p. 215.

Shamsuzzoha, M., and Lee, M., 2008. PID controller

design for integrating processes with time delay.

Korean J. Chem. Eng., vol.25, N° 4, pp.637-645.

Tsai, M., and Gu, D., 2014. Robust and Optimal Control:

A Two-port Framework Approach. Advances in

Industrial Control, Springer, pp.336.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

550