Formal Verification for Validation of PSEEL’s PLC Program

Mohamed Niang

1,2

, Alexandre Philippot

1

, François Gellot

1

, Raphaël Coupat

2

, Bernard Riera

1

and Sébastien Lefebvre

2

1

CReSTIC (EA3804), University of Reims Champagne Ardenne Moulin de la Housse,

BP 1039, 51687 Reims CEDEX 2, France

2

IP.TE (CES), Direction de l’ingénierie, Société Nationale des Chemins de fer Français,

6 avenue François Mitterrand – 93574 La plaine Saint Denis CEDEX, France

Keywords: Model-checking, Recipe Book, Factory Tests, Systems Engineers, Railways, Safety.

Abstract: In order to keep its leadership in French rail market and to improve work conditions of its systems engineers

during automation projects, the SNCF (French acronym for National Society of French Railways) wants to

develop solutions increasing the productivity. One of these improvements focuses on the current

methodology used by systems engineers to verify and validate PLC programs of electrical installations. This

task remains one of the most important during an automation project because it is supposed to ensure

installations safety, but it must be optimized. Through an industrial thesis financed by SNCF, the aim of this

research project is to improve this method and reduce time validation of programs by providing a tool which

will help systems engineers to verify and validate quickly and automatically PLC programs during any

automation project, not necessarily during factory tests but directly from their office.

1 INTRODUCTION

In automated systems, most of accidents that occur

in industry have been discovered to be the result of

Programming errors (Mokadem et al., 2010).

Therefore, verification of PLC program before its

implementation remains a very important task

during an automation project. This verification must

concern both functional and safety parts. The first

one ensures that the PLC programs meet the

functional specifications, and the second one

consists in verifying if the controlled system can be

or not exposed to dangerous states leading to human

and equipment damage. Nowadays, some

verification and validation techniques like tests and

simulation are available.

At SNCF, the system engineers apply currently

these methods to validate the control command

(programs and electrical cabinets’ wiring) of PSEEL

(Power Supply Equipment of the Electric Lines) by

using a recipe book which contains a set of scenarios

or sequential instructions. According to their know-

how and experience during these last decades about

their systems, they consider that a PSEEL’s control

command is valid once it satisfies the whole test.

The verification consists in executing manually each

instruction contained in the recipe book during

factory tests, and then comparing the obtained

results with the expected ones. This verification is

therefore not automatic, and requires too much time

because of the length of tests (almost 100 pages of

instructions). Moreover, although it was used to

validate PLC programs for several decades, this

method is not efficient to check formally safety part

of PLC programs insofar as it verifies only if PLC

programs meet the requirements specifications.

Our first task in this work is to optimize this

current methodology of verification by making it

faster and automatic with the use of a model-

checker. Then we propose an exhaustive method

which will be used to verify the safety part of PLC

programs.

After a presentation of general context in section

2, we detail the principle of our methodology and

illustrate it through an application in section 3.

Exhaustiveness of recipe book is studied in section

4, and section 5 introduces a solution for automatic

generation of models used for programs verification.

We conclude finally this paper and propose some

work prospects in section 6.

Niang, M., Philippot, A., Gellot, F., Coupat, R., Riera, B. and Lefebvre, S.

Formal Verification for Validation of PSEEL’s PLC Program.

DOI: 10.5220/0006418705670574

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 567-574

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

567

2 GENERAL CONTEXT

The PSEEL are the electrical supply points of the

electrified lines, called catenaries. Their role is to

transform, to supply, and to rectifier in the case of

DC supply, the tension of the High-Voltage (HV)

network into compatible tension with traction units

(1500 V DC or 25kV AC). They are composed of

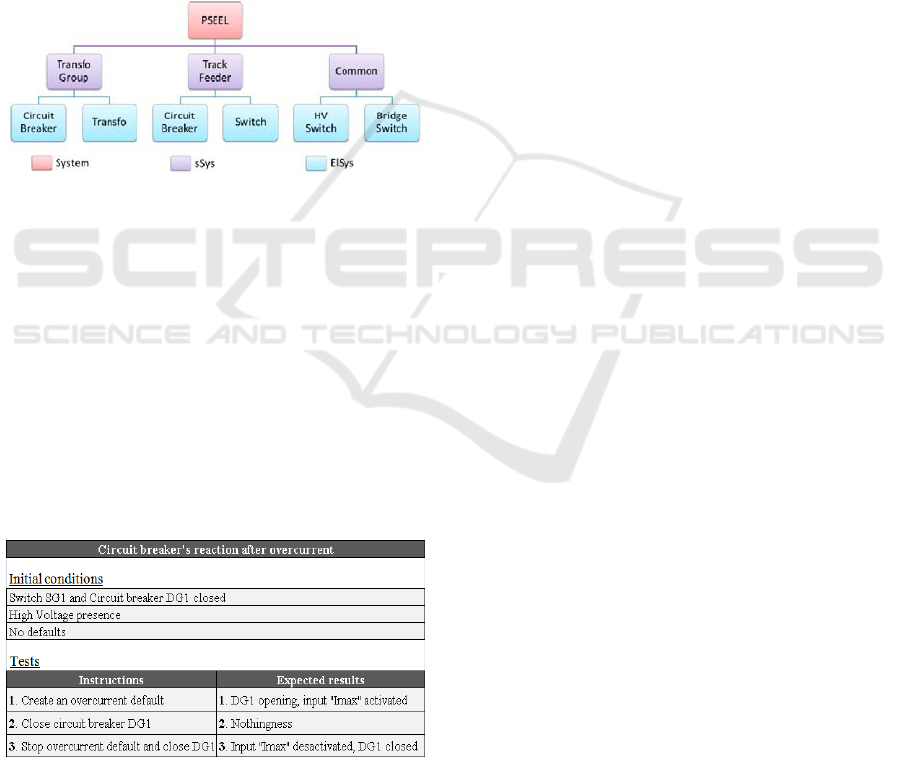

sub-systems (sSys) like Transformer Group, Track

feeder, and common, and each of these sub-systems

is composed of elements of sub-Systems (ElSys) like

switch, circuit breaker, and so on (Figure 1). These

electrical systems are subject to strict standards of

railway safety (EN 50126, 2012) (IEC 60870-4,

2013).

Figure 1: Decomposition of PSEEL.

The PSEEL are distributed automated systems

whose control command can be done either locally

or remotely in a centralized control station named

Central Sub-Stations (CSS).

The recipe book represents for SNCF the main

reference for validation of PSEEL’s control

command systems since many years. It contains

several scenarios that systems engineers execute on

PSEEL and analyze its behavior in order to validate

or not its control command. An example of a test

scenario is presented in Table 1.

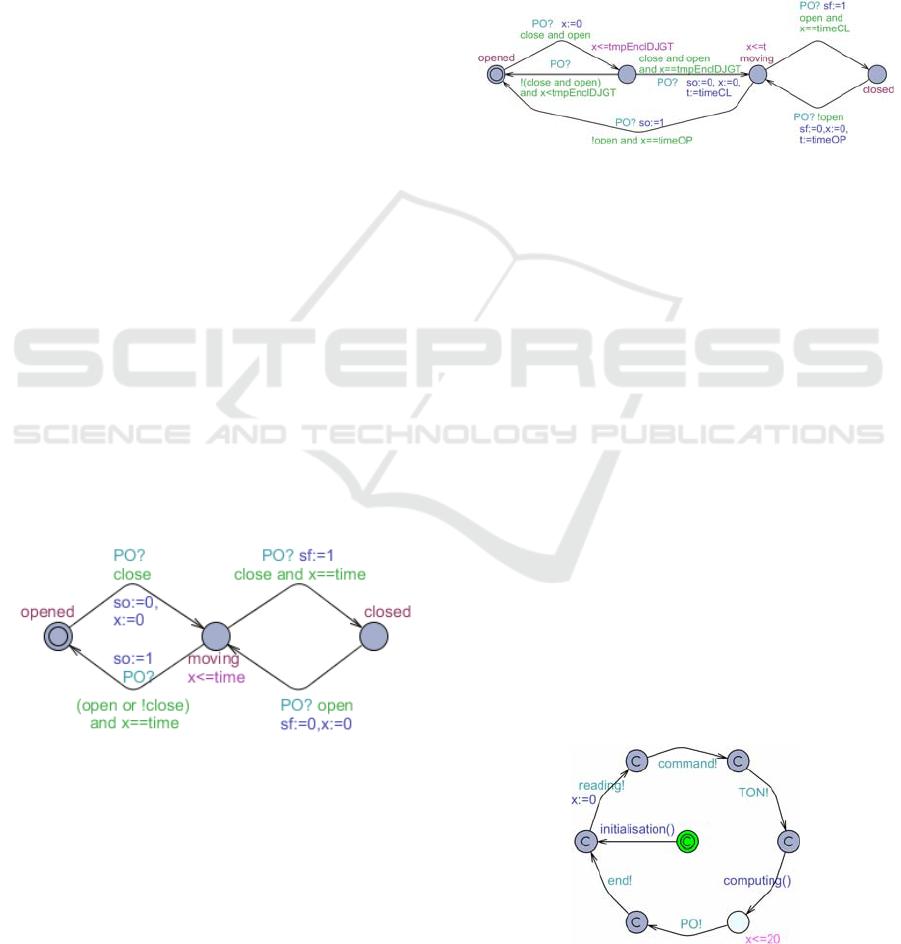

Table 1: Example of one test scenario in recipe book.

During an automation project, the recipe book

and the PLC programs are automatically generated

with software named Odil (Coupat, 2014). For this,

the systems engineers enter all inputs data of the

system (like single line diagram of PSEEL,

equipment configuration, inputs/outputs ...) and

then, Odil generates automatically programs and

recipe book. After a proofreading of these latter,

they verify online the correctness of whole control

command (PLC program and electrical cabinets)

during factory tests, by executing all the scenarios of

the recipe book on system. Moreover during factory

tests, they need to connect devices simulators to

cabinets (like switches and circuit breakers) in order

to make tests possible. One major difficulty they can

encounter during tests is that in case of an

unsatisfied instruction in factory, they must analyze

the problem and determine its cause (programming

error or wiring error of electrical cabinets). For

example in the test scenario described in Table 1,

when the circuit breaker does not open after

overcurrent (instruction N°1), there are two possible

explanations:

o The information “Imax” is not received by the

PLC (because the input is not wired for

example);

o The information is received but the SFC program

of the circuit breaker does not evolve (bad

program).

Despite their experience, this diagnosis may remain

long and complex in some cases. The main approach

of our methodology consists in dividing the

validation

step into two parts: offline validation of

PLC programs with model-checker Uppaal

(Behrmann et al., 2002), and then online validation

of electrical cabinets during factory tests with virtual

commissioning. Thus, PLC programs can be

validated earlier with Uppaal and before factory

tests. Moreover, this validation step does not require

physical devices simulators because they are now

included in Uppaal models. From a model of

PSEEL, PLC programs, and recipe book, Uppaal is

able to check automatically during the simulation if

the PLC programs satisfy the recipe book. For this,

the model-checker executes all scenarios of recipe

book on the system, and verifies if there exists at

least one instruction in the recipe book whose effect

on the PSEEL does not correspond to the expected

one. Then, simulation results will help to diagnose

easily the problem if it exists, or otherwise to

validate the PLC programs. The validation of

electrical cabinets will be done online and also

automatically, with the use of virtual commissioning

connected to electrical cabinets (not presented in this

paper). The advantage of this methodology is as

follows: not only the validation of programs will be

faster and automatic, but it will also facilitate the

validation of electrical cabinets. In fact, once we

implement valid PLC programs in the system, any

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

568

encountered problem during factory tests would

necessarily result from wiring errors of electrical

cabinets. Another objective in this work is to

propose with model-checking an exhaustive method

which verifies the safety part of PLC programs.

System modeling is the first step of our approach.

3 SYSTEM MODELING

In this section, we present and illustrate our

methodology through its application on a

transformer group (PSEEL’s sub-system). System

modeling requires careful structural analysis of

PSEEL and PLC programs because the models must

have the same behavior as real system. The

transformer group is controlled by one PLC, and is

basically composed of circuit breakers, switches,

and transformer. Its program’s outputs correspond to

the orders sent to devices, and inputs are the

observed faults on operative part and the devices’

states (opened or closed). The programs are

designed in STRATON (www.copalp.com) using

some of the standardized languages (IEC 61131-3,

2003) such as Ladder Diagram (LD), Sequential

Function Chart (SFC) and Structured Text (ST). But

in our Uppaal models, the whole program needs to

be translated into ST because the model-checker

cannot interpret the other languages. Whatever the

programming language would be, each scan cycle

includes three main phases: input reading, program

execution and output updating.

3.1 Transformer Group Modeling

Figure 2: UPPAAL model of switch.

The variables “so” and “sf” (Figure 2) represent

respectively the information “switch opened” and

“switch closed”, and “close” (respectively “open”)

represents closing order (respectively opening order)

sent by the programs. The switch can reach three

possible states: opened (so=true and sf=false),

moving (so=false and sf=false), and closed

(so=false and sf=true). Initially opened, it starts

moving once it receives closing order from the

program. Then, after a certain duration (x==time) it

becomes fully closed if the order was still

maintained, or otherwise returns to the initial state if

closing order was released or if opening order was

activated. The switch’s behaviour is practically the

same when it receives opening order from closed

state. We recall here that the order sent by operator

is not directly received by the device, but rather by

its SFC program which will apply it or not, if the

program allows this action.

Figure 3: UPPAAL model of circuit breaker.

The model of a circuit breaker presented in

Figure 3 has some particularities compared to switch

model:

o To close the circuit breaker, the two orders (open

and close) must be maintained simultaneously

for a certain duration (x==tmpEnclDJGT);

o To open it, just release the opening order;

o Contrary to the switch, opening time (timeOP) is

different from closing time (timeCL).

Note that although the transformer has continuous

behaviour (magnetic, thermal…), we do not take it

into account in its model. So we represent it as a

structure of variables (observers, parameters, and

observed faults) because these are the only

information we need for this model:

struct {bool defBLQ, blocDef, defTemp, defBLQR,

blocDefRed, defTempRed, wdMicom, TcMC,

temp2TR, AMR, fuFuRC, AvDiode, imaxGT,

OoAbsUHT, OoDjAbsUHT, deblocGT, absUBarre,

presenceSGT, pres_Hexa; int tmpReencGT;} GT1;

3.2 Control Program Modeling

Figure 4: UPPAAL model of PLC cycle.

Formal Verification for Validation of PSEEL’s PLC Program

569

The model in Figure 4 synchronizes all the other

models of the system thanks to broadcast channels.

PLC cycle structured as a loop includes a clock x

which measures the cycle time (equal to 20 time

units here). Initialisation of SFC programs and

parameters is required during the first PLC cycle.

Then, the cycle is composed of 6 steps:

o Input reading (faults and devices’ states)

o Command reading (sent by operators)

o Timers evolution (synchronised with TON!

channel)

o Execution of main program (SFC programs

update) followed by output writing;

o Evolution of operative part (channel PO!)

o End of cycle (channel end!)

To reduce states space, most of states are declared as

committed so that time can elapse only during

program execution. Therefore the duration of input

acquisition and output emission is negligible.

Figure 5: UPPAAL model of a TON block.

The control program contains timing operations,

described by functional blocks called TON (Timer

On-delay). Its behaviour is explained in IEC 61131-

3 standard. This TON block has two input variables

(boolean variable in to start or stop counting time,

and time parameter PT which indicates the timing

delay) and two output variables (boolean variable Q

which equals 1 if the delay has expired, and time

variable x which gives the time elapsed from the last

rising edge of in). Initially idle, its location becomes

running when the timer has been switched on, and

timeout when the fixed delay (PT) has been

reached. The model in Figure 5 has been inspired in

(Mokadem et al., 2010).

Any SFC program can use more than two TON

block in its different steps. So instead of using a

TON block for any step, we declare only one TON

block per SFC program. In fact, after a structural

analysis of these SFC programs, we noticed that we

can never have more than one step simultaneously

activated. Thus, a single TON block can be used by

all steps of one SFC program without any conflict.

However, for two successive steps using the same

TON, we must make sure that between the two

steps’ activation, the TON’s output changes from 1

to 0. For this, we must define correctly the inputs in

and PT of the TON block used by the SFC program.

In the example described in Figure 6, both steps x1

and x2 use the same TON. When x1 is activated,

time starts elapsing until it reaches 500ms. Then,

output Q and transition ft1 change from 0 to 1,

leading to x2’s activation and x1’s deactivation.

Therefore, the input in (whose expression is shown

in Figure 6) moves from 1 to 0 and resets the timer

(thus output Q changes from 1 to 0 and input PT

changes from 500ms to 1000ms). During the next

PLC cycle, the value of ft1 will be updated because

the step x1 is no more activated, so the input in will

move again from 0 to 1 and time will start again

elapsing for x2. But with these operations, we

noticed a delay of one PLC scan time from x2’s

activation to timer’s restart. To compensate this

delay, we subtract it to the pre-set time of x2. This

optimization will reduce the number of TON used,

and consequently the space of reachable states.

The whole program is not represented in our

model because some lines of code are only dedicated

to send information to other PLC through network

(Factory Instrumentation Protocol).

Figure 6: Example of TON’s use in a SFC program.

So the control program is basically composed of:

o SFC block programs: which command the

equipment like switches and circuits breakers.

The structure of the SFC program depends on the

kind of equipment.

o LD programs: where devices’ states are read and

all observed faults are collected and used to

compute observers.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

570

The SFC programs will be translated into Structured

Text language (ST), using the classical algebraic

representation of SFC (Machado et al., 2006). The

LD programs will also be translated into ST

language (Figure 7).

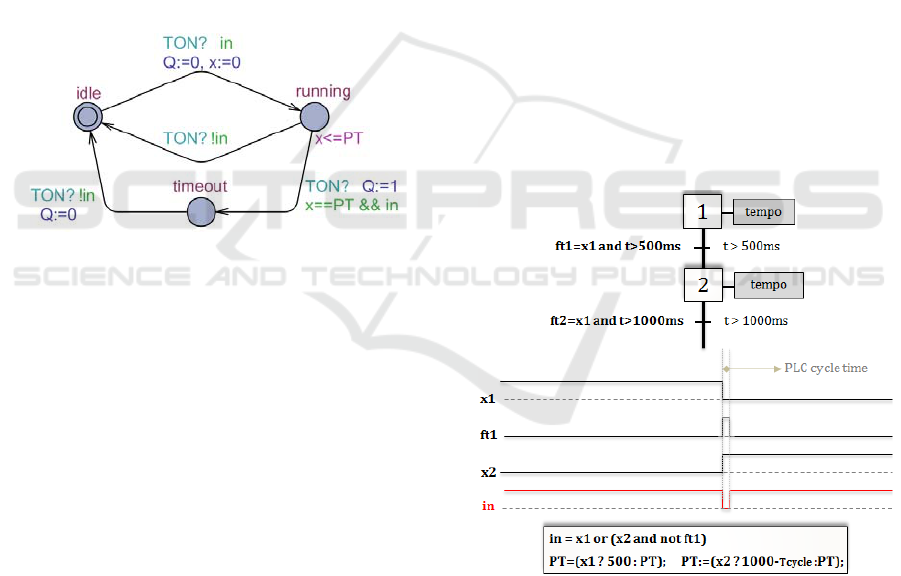

Figure 7: Example of LD programs translation into ST.

3.3 Recipe Book Modeling

After a structural analysis of recipe book, we

realized that it could be translated into SFC

programs (one per scenario) because it is composed

of actions and transitions. In Figure 8 we present the

translation of scenario described in Table 1. The

variable “start elapsing” is dedicated to trigger a

timer which counts the elapsed time in one step of

the scenario (x1, x2, or x3 in this example). So if

there is a step on which the elapsed time exceeds a

certain value (which is not supposed to be reached if

the program is valid), it will mean that program

presents errors because the transition associated to

that step cannot be satisfied.

This translation will be applied for all scenarios

of transformer group’s recipe book.

Then, the model described in Figure 9 will call

and execute sequentially all scenarios. The recipe

book’s evolution state will be updated during any

PLC scan time. Each state automaton of this model

(except the initial and last ones) corresponds to one

scenario. During simulation, one scenario can be

executed only if the previous one (if it exists) was

satisfied. Therefore the program is valid only if the

final state automaton (named valides in Figure 9) is

reachable, or if it does not exist a blocking

instruction in recipe book.

Figure 8: Translation of scenario into SFC program.

Figure 9: Uppal model of recipe book.

Figure 10: Simulation view.

Formal Verification for Validation of PSEEL’s PLC Program

571

3.4 Simulation Results

To validate the PLC program, all scenarios must be

executed and satisfied during simulation. For this,

we can verify if the final state automaton is

reachable by using the query:

E <> recipe_book.valides (1)

However the model checker does not return any

trace if (1) is not satisfied. Thus (1) is only useful to

determine if programs are valid or not, but not

sufficient for diagnosis. So instead of this property,

we verify if there exists a blocking step of a scenario

where the corresponding condition is not satisfied by

using the query:

E<>time_step.timeout (2)

Time step is a timer which counts the elapsed time

for any step of the recipe book. If (2) is satisfied, the

model checker will return directly the scenario and

blocking step on which simulation stopped.

Moreover, by analysing the current state of

programs, it will help for diagnosis. After a first

simulation (see results in Table 2), we realized that

(1) is satisfied and (2) is not: this is far from being a

surprise because the program we used here has

already been validated during factory tests.

In the following example, we used a modified

program to verify if problems can be diagnosed

during simulation. Table 2 presents simulation

results, and gives the time and memory used for

verification (on a windows machine with 4Gb RAM,

Core i5).

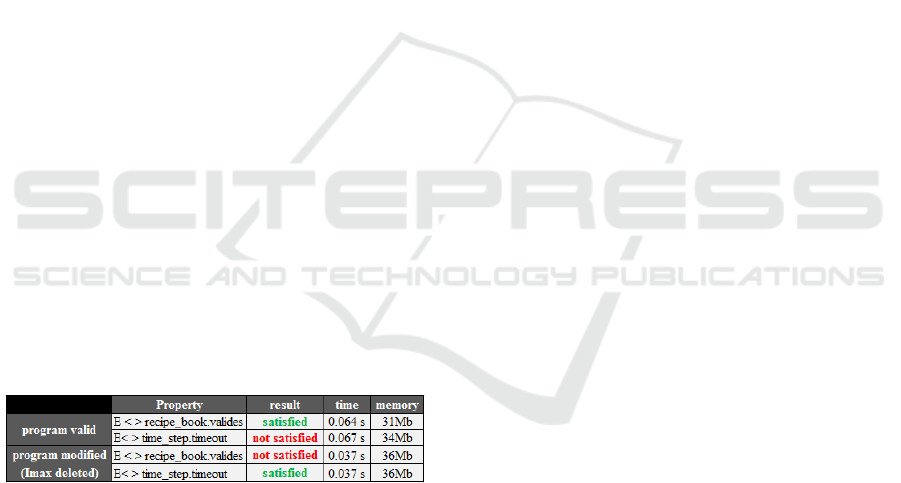

Table 2: Simulation results.

As expected, (1) is not satisfied for the modified

program, but to diagnose the problem, it is not

sufficient. So when we verify by using (2), the

model-checker has shown that the instruction N°1 of

overcurrent test is blocking (step x1 of Figure 8)

because the circuit breaker did not open after

overcurrent. Moreover, when we analyse the current

state of circuit breaker SFC program in simulation

results (see in Figure 10), we notice that its

evolution stopped in that moment on a step where it

was waiting for opening order (step x5 of SFC

program grafCtrCmdeDJGT1 in variables column

of Figure 10). Thus, we conclude that the transition

following that step is not correct because it did not

take into account the overcurrent information. This

result was expected because the expression “or

Imax” was initially deleted from that transition.

After correction and second simulation, the

instruction N°2 of overcurrent test (transition ft2 of

Figure 8) is not satisfied because the circuit breaker

started closing when it received that order whereas it

should not. In fact, the circuit breaker must stay

opened while overcurrent does not disappear. This

result was also expected because the expression

“and not Imax” was also deleted from SFC

program’s transition. In that way, we can diagnose

quickly and correct the whole program by referring

to the expected results of recipe book, and

simulation does not require too much memory. Its

efficiency has already been validated with some

examples of wrong programs.

4 SAFETY PART VERIFICATION

Although recipe book has served to validate

PSEEL’s programs for many decades, it is not

sufficient to verify formally installations safety. In

fact, the previous method does not study all the

reachable states of system (meaning all the 2

Ne

possible states, with Ne = number PSEEL’s sensors

+ number of received orders). Moreover, it has also

been proved in (Coupat, 2014) with a specific

PSEEL, that there exists one scenario (with low

occurrence) not included in recipe book, but which

can expose that PSEEL in dangerous state, meaning

that the method is not exhaustive. So supposing that

events like sending orders by operator or faults

apparition can occur whenever on system, the

principle is to check with Uppaal if each of these

states is not dangerous (meaning does not violate a

set of safety properties). Therefore recipe book will

no more represent a reference of verification. We

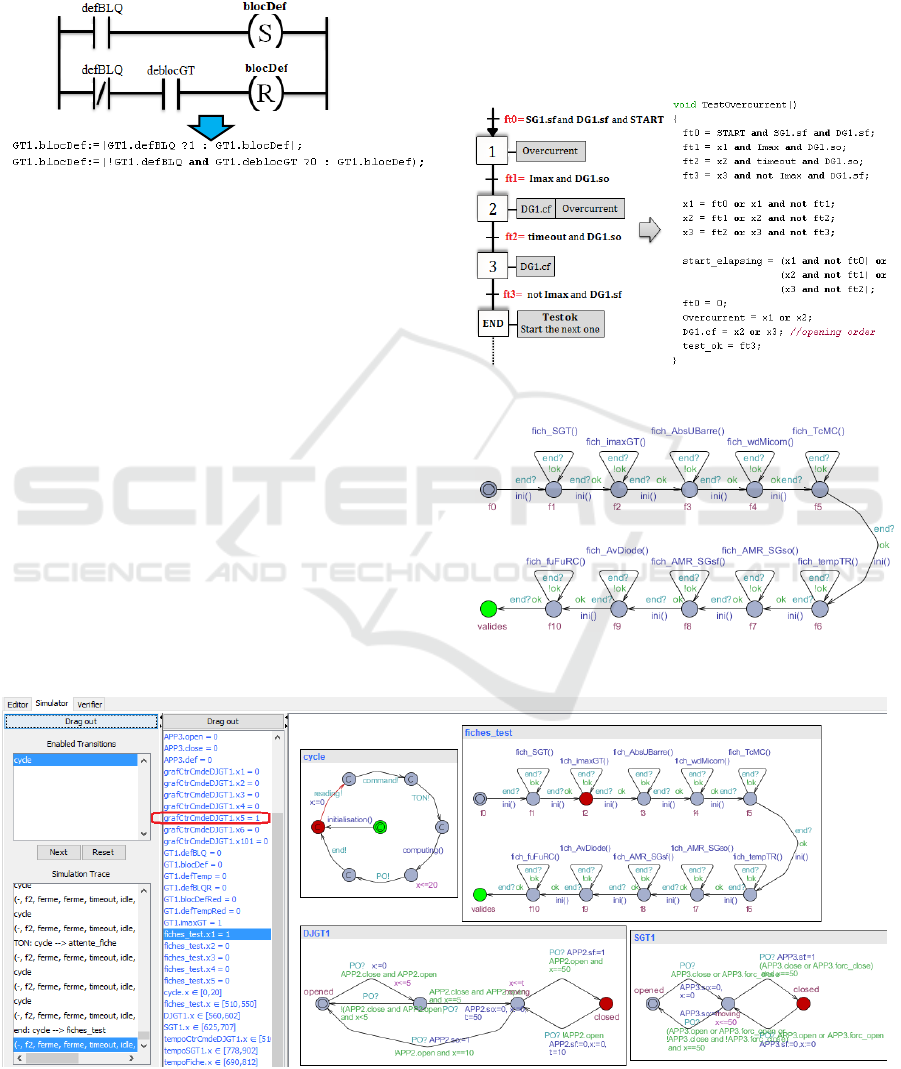

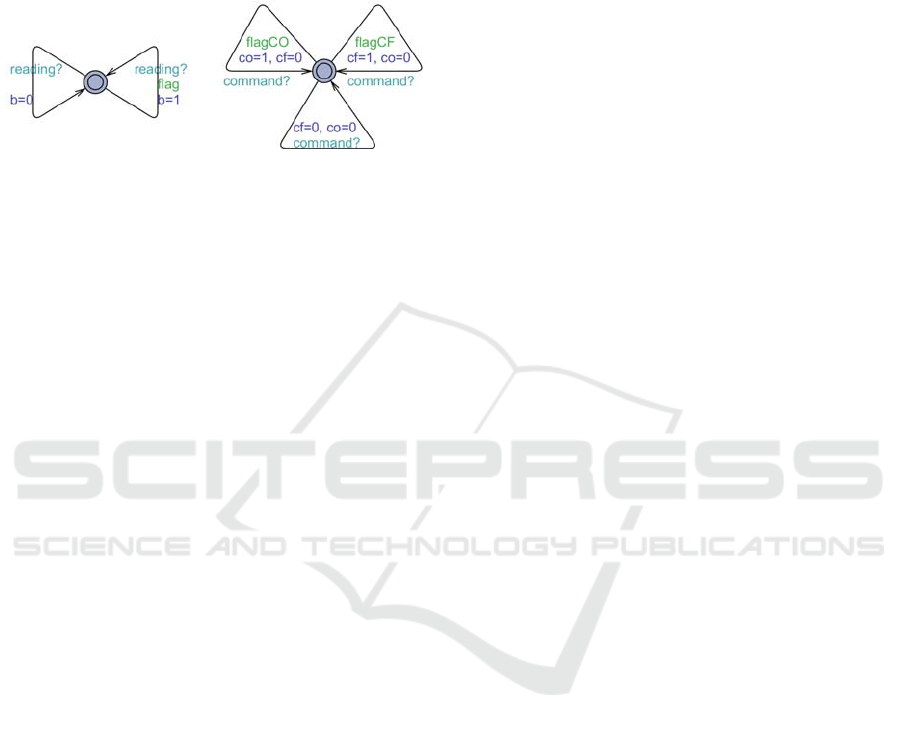

delete its model and we add two others ones that

generate randomly faults (left side on Figure 11) and

sending order (right side of Figure 11). With the first

model, fault can take two possible boolean values

(true or false), and with the second one a device’s

SFC program can receive opening order from

operator (co=true and cf=false), closing order

(co=false and cf= true), or no order (co=false and

cf=false). During a PLC cycle, an order sent by an

operator would not have any effect on system if the

SFC program of the targeted device was not in a step

waiting for that order. Thus, to avoid ineffective

orders and reduce states space, we added some

guards in these models.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

572

This method is more efficient than the first one

because all the reachable states of system are

browsed and studied, unlike the first method. And it

can verify not only the safety part but also the

functional correctness of PLC programs, according

to the set of properties we verify.

Figure 11: Uppaal models of fault and sending order.

With a program already validated by recipe

book, we have to verify with this second method if

there exists at least a path which leads system to a

dangerous state. In that case, it would mean that the

recipe book does not contain all required tests, and is

therefore insufficient to guarantee safety. Currently,

the SNCF experts help us to determine all the

dangerous states of PSEEL in order to define all

safety properties and complete the verification. We

can already verify its efficiency by applying it to the

previous modified program. An example of

dangerous state is that a blocking fault appears

during 300ms without the circuit breaker opens:

E<>cycle.fin and TON_fault.timeout

and DG1.sf

(3)

TON_fault is a timer which counts the elapsed time

since fault’s apparition while circuit breaker stays

closed. After simulation, we noticed that this state is

reachable only if overcurrent fault appears for

300ms: that is obvious because the variable “Imax”

was deleted from that SFC program.

This simulation requires more memory time

(20.56s and 140Mb with (3)) because of states space

increase, but this method is more efficient than the

first one. All the errors detectable by recipe book are

also detectable by this second method, meaning that

the latter is also more exhaustive.

5 AUTOMATIC GENERATION

OF UPPAAL MODELS

The methodology of formal verification must be

applied for any new automation project. Because of

heterogeneity of PSEEL and programs, systems

engineers would be obliged to adapt Uppaal models

according to installation’s structure, recipe book and

program’s content. This additional task goes against

our principle in this work because it increases time

project. As for programs and recipe book, we

propose to generate automatically with Odil the

Uppaal file (*.xml) which contains all required

inputs data (PSEEL models, programs, and recipe

book). The methodology used to generate this xml

file is not detailed in this paper, but presented in

(Coupat, 2014). The xml file contains exactly the

same information as for program and recipe book,

but in a different language. After automatic

generation, the systems engineers have just to import

from Uppaal the generated xml file (for any sub-

system of PSEEL), and execute it in order to analyse

results and validate automatically programs, directly

from their office and not necessarily in factory.

Some examples of xml files has been generated and

used for simulation.

6 CONCLUSION

The main objective of this research work was to

optimize validation step of PSEEL’s PLC programs.

The current method used by SNCF’s systems

engineers consists in testing online some scenarios

in the program by using a recipe book, and validate

programs if all tests are satisfied. The simulation is

necessarily done after electrical cabinets’ design and

program’s implementation in PLC, and requires too

much times (one week at least) because tests are

manual. Moreover, manual tests can imply human

errors due to mental workload (Coupat et al., 2014).

The proposed solution in this work aims to solve

these problems insofar as programs validation is

faster and automatic (recipe book of transformer

group is browsed in a few tens of milliseconds, see

in Table 2), and can be done earlier without any use

of physical device simulator compared to the

previous method. Another objective in this work was

to develop a method which verifies the safety of

PLC programs. With model-checker Uppaal, we

verify formally for each reachable state of system, if

the set of dangerous states (representing the property

to verify) is not violated. We proposed also in this

work to generate automatically the Uppaal models of

verification for any new project, so that systems

engineers will not lose time in designing it

themselves.

The method of automatic verification has been

presented to SNCF’s systems engineers, and was

judged interesting insofar as it allows to verify

quickly and automatically the correctness of any

PLC programs. Moreover, it has been used to verify

Formal Verification for Validation of PSEEL’s PLC Program

573

a program newly developed by systems engineers

and not tested yet during factory tests. For this we

implemented the program in our tool, and we

corrected all the problems detected in the new

program. The obtained results was presented to

systems engineers, then they were approved.

In addition to reduce time project and human

error during verification, these results will facilitate

validation step of electrical cabinets’ wiring. In fact,

systems engineers use recipe book to validate both

programs and cabinets. When they encounter an

instruction not satisfied in recipe book, they must

analyze it and determine if it is due to programming

error, or wiring error. With our method, they can

now exclude the first hypothesis during factory tests

because programs are validated earlier.

Our future work will focus on the improvement

of validation step of electrical cabinets’ wiring. As

for program validation, we will try to make it faster

and automatic in order to reduce at most time

validation during any automation project.

REFERENCES

Behrmann, G., Bengtsson, J., David, A., Larsen, K.-G.,

Pettersson, P., Yi, W., 2002. Uppaal implementation

secrets. 7th International Symposium on Formal

Techniques in Real-Time and Fault Tolerant Systems.

In Springer, Verlag London, UK 2002: 3-22.

Coupat, R., 2014. Automatic generation of safe PLC

program for PSEEL, Phd, Reims, University of Reims

Champagne-Ardenne, december 2014.

Coupat, R., Meslay, M., Burette, M.-A., Philippot, A.,

Annebicque, D., Riera, B., 2014. Standardization and

Safety Control Generation for SNCF Systems

Engineer. 19

th

IFAC World Congress 2014 (IFAC WC

2014), Cape Town, South Africa, 2014.

EN 50126, 2012. Applications ferroviaires - Spécification

et démonstration de la fiabilité, de la disponibilité, de

la maintenabilité et de la sécurité (FDMS).

Mokadem, H.-B., Bérard, B., Gourcuff, V., De Smet, O.,

Roussel, J.-M., 2010, Verification of a timed multitask

system with UPPAAL. IEEE Transactions on

Automation Science and Engineering, Institute of

Electrical and Electronics Engineers, 7 (4), pp.921 -

932.<10.1109/TASE.2010.2050199>.<hal- 0527736>.

IEC 60870-4, 2013. Telecontrol equipment and systems.

Part 4: Performance requirements Ed. 1.

IEC (International Electrotechnical Commission). IEC

Standard 61131: Programmable controllers - Part 3,

1993.

Machado, J., Denis, B., Lesage, J.-J., Faure, J.-M., Ferreira

Da Silva, J., 2006. Logic controllers dependability

verification using a plant model In Proc. 3rd IFAC

Workshop on Discrete-Event System Design,

(DESDes’06), Rydzyna (Poland), Sept. 2006, pages

37-42.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

574