Dynamic Modelling of Commercial Aircraft Secondary Flight

Control Systems

Graham Hardwick and Isabella Panella

Systems Engineering, UTC Aerospace Systems, Stafford Road, Wolverhampton, U.K.

Keywords: Commercial, Aircraft, High-lift, Secondary, Flight, Controls, Systems, Mathematical Modelling, Design.

Abstract: This paper describes the use of mathematical modelling within secondary flight control systems for

commercial aircraft. The modelling process is described from generation of model requirements, model

management through to model validation. The paper describes an example of a parametrised high-lift

system model developed in Simulink. Analyses of the model outputs are provided and a sensitivity analysis

is performed on a selected design parameter. This work highlights the advantages of integrated modelling to

support the conceptual design phase within the lifecycle system design process.

1 INTRODUCTION

Commercial aircraft utilise secondary flight control

surfaces, such as flaps and slats to modify the wing

profile in order to increase aerodynamic lift for a

given air speed. This allows aircraft landing

speeds/distances to be reduced. The “high-lift”

system is often an alternative definition used in the

aerospace industry to refer to secondary flight

control system actuation.

UTC Aerospace Systems design, manufacture,

and integrate secondary flight control systems for a

variety of commercial aircraft, from wide body to

single aisle configuration, from business jets to the

A380.

This paper describes the use of mathematical

modelling of the secondary flight control system at

UTC Aerospace. System modelling tools are utilised

from the proposal/concept stage all the way through

system design, development, manufacturing, system

integration, and in service-conditions.

Due to the long timescales of commercial aircraft

project lifecycles the models need to be:

• Appropriate to application. For example

pseudo dynamic modelling is used for static

size case development or fully dynamic so that

transient dynamics can be interrogated.

• Modular and documented. Due to programs

spanning over decades, technologies and

modelling capability will evolve and the model

will need to be modular and well documented

in order to support future updates.

• Refer to requirements. Model requires

appropriate referencing to requirements where

appropriate.

• Version controlled so that configuration of the

model can be accessed and co-ordinated with

the correct design build standard of the

hardware.

• Verified using unit, subsystem and system

physical tests.

The validation and verification system design

process is a legacy approach in system design and

within the aerospace industry has been endorsed

within the standards defined in ARP4754A, 2010,

SAE International. Systems engineering utilises

Model Based Design within the systems Validation

and Verification cycle as a core instrument to

guarantee robustness and integrity within the

systems, as reported in INCOSE.

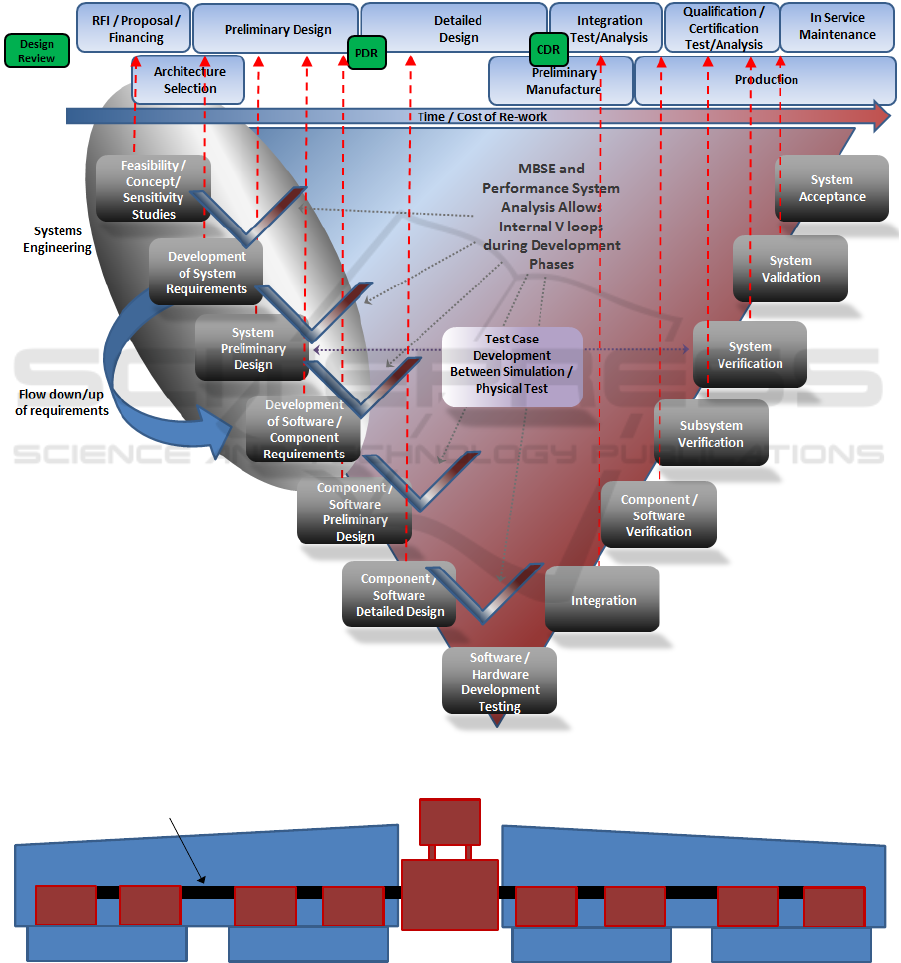

The validation and verification processes based

on modelling and simulation have been further

detailed in Figure 1, whereby iterative cycles of

validation and verification for each stage are

highighted. This process is followed for the

implementation of the functional high lift system.

The work herein presented details the iterative

nature of the preliminary design stage of a product

life cycle. Referring to figure 1, this paper explores

the first level of iteration which enables to derive a

functional framework from customers’ requirements

Hardwick, G. and Panella, I.

Dynamic Modelling of Commercial Aircraft Secondary Flight Control Systems.

DOI: 10.5220/0006418800930101

In Proceedings of the 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 93-101

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

93

through a process of requirements allocation and

elicitation implemented through modelling and

simulation, specifically through:

• Sensitivity studies

• Trade off analysis

• Test case development

• Decomposition of requirements

The engineering product development schedule

is superimposed with the validation and verification

process to highlight the stages where MBSE can add

value.

In general, model based design emphasises the

use of models through the entire life cycle such as

developing test cases and aiding verification

activities, generating prototype control code,

supporting solving problems, as well as for hardware

in the loop activities and also supporting

certification activities.

Figure 1: Validation and Verification System Design Process.

Figure 2: High Lift architecture.

PDU &

Position

Sensing

Actuator 1 Actuator 1Actuator 2 Actuator 2

Actuator 3

Actuator 3

Actuator 4

Actuator 4

Flap Inboard Surface Flap Inboard Surface Flap Outboard SurfaceFlap Outboard Surface

Controller

Transmission

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

94

2 HIGH LIFT FUNCTIONAL

ARCHITECTURE

The following describes the High Lift Functional

architecture. The architecture shown in Figure 2 is

the result of a previous study presented in Hardwick,

Hanna, and Panella, 2017. It describes a generic

medium sized commercial aircraft flap system,

characterised by a single transmission line and

distributed actuators spaced symmetrically with

respect to the aircraft centreline. This architecture

presents only a flap system and does not include the

slat actuators.

The physical layout includes elements of the

functionalities that a high lift system needs to

present which are:

• Central source Power Drive Unit (PDU) which

provides the power drive actuation to the

system and has position sensing capability;

This interfaces with the secondary flight

controller for control and monitoring functions.

The PDU is dual channel for redundancy.

Hydraulic valves are controlled by the flight

controller and regulate the flow to the

hydraulic motors. The motors drive a

mechanical gearbox that drives the

transmission.

• Transmission shafts connect the PDU to the

actuators on the wing and hence enabling

synchronous movement of both wings.

• Mechanical wing actuation with four rotary

geared actuators (RGA) per wing; These

contain gearboxes which provide mechanical

advantage to the transmission drive torques.

This enables the transmission to drive

aerodynamic loads with large torques.

• The secondary flight control system interfaces

with the PDU, sensors and safety devices

which arrest the system during failure case

scenarios. It also interfaces with the main

aircraft flight controller.

3 MATHEMATICAL MODEL

Herein, the mathematical model of a High Lift

System is described and mapped into a Simulink

model, which is then described.

The model is used to perform a sensitivity study

to support optimal design point for the selection of

the PDU, considering as the key parameter its gear

ratio. A discussion of the model verification is also

presented.

The first step is to define the model

requirements. Requirements enable the definition of

the overall performance requirement for the system,

operational and environmental conditions, as well as

regulatory considerations are needed to ensure

safety. They set the “boundary conditions” for the

systems, which will need to be validated and

verified.

It is important to consider another constraint

when implementing a simulation model. The model

complexity is proportional to run time. Therefore,

the model fidelity needs to be traded with the speed

of simulation that we want to achieve.

Once the requirements are defined, specific

performance descriptions need to be allocated to the

functional blocks, and model outputs are linked to

the systems requirements, such as:

• Flap system deployment times;

• Flap system hydraulic flow rate;

• Dynamic and steady state transmission

loads;

• PDU normal operating velocity.

Dynamic modelling has been achieved through

the application of first order differential equations.

These equations are represented in the form of a

state-space model within the Simulink modelling

environment, which utilises a non-stiff variable step

ordinary differential solver (ODE). The model

contains continuous states but the governing

equations are non-linear and hence the system is a

non-linear time invariant system. State space

modelling is a control systems technique to represent

the dynamic behaviour of a system as reported in

ZadehandDesoer, 1963.

3.1 Model Architecture

The functional architecture is now mapped into the

simulation environment through the application of

mathematical equations capturing the individual

functions’ behaviour, according to mechanical,

hydraulic and electrical physics laws.

Examples of the equations used to create the

blocks are provided in the following sections.

The principle of operation is the following.

Mechanical transmission blocks connect the PDU to

the actuators. The drive to the PDU is generated by

transferring hydraulic power into mechanical using

hydraulic motors.

Figure 3 highlights the system architecture

mapped into a Simulink model. This contains the

following subsystems:

Dynamic Modelling of Commercial Aircraft Secondary Flight Control Systems

95

Figure 3: Model architecture of a generic secondary flight control system in Simulink.

• “Controller” is the Secondary flight

controller (which contains I/O to the

aircraft controller);

• “Power Drive Unit” is the Dual channel

power drive unit;

• “LH and RH Wing” are the two mechanical

wings containing the high lift system;

• “Aero Loads and Hydraulics” are the

interface definition of the aerodynamic

loads and hydraulic system.

The PDU and the controller (figure 2) are

translated into the Simulink diagram (figure 3) and

are connected using “GoTo” blocks for example:

• Ch1(2)_Enable – controller to PDU enable

electrical signal.

• PDU_Position – PDU to controller

position

• Aero1(n) – Aerodynamic loads between

the interface and wings

• Psupply – Hydraulic supply pressure

between interface and PDU

3.2 High Lift Transmission

The high lift transmission wing subsystems are

modelled as mechanical blocks that include

component stiffness, inertia, damping, transmission

efficiency and drag. These blocks are defined as

“LH Wing” and RH Wing” in figure 3. A portion of

these blocks have been expanded in figure 4.

Each inertia element contains one dimensional

rotational states (accelerations / velocities). For

example the equation to convert relative

transmission shaft deflection (dx) and velocity (dv)

into a transmission torques is modelled as follows

(where k

trans

and c

trans

are the respective torsional

stiffness and damping of the transmission):

Shaft Torque = k

trans

*dx + c

trans

*dv (1)

Figure 4 provides the Simulink model of the

transmission system including shafts and flap panels

showing the connections between the Simulink

blocks. The shaft torque is multiplied by a

transmission efficiency η

trans

that calculates the

downstream torque for example:

Output Torque = Input Torque*η

trans

(2)

All shaft torques attached to the panel are

summated and then integrated with the aerodynamic

loads into the flap panel dynamic model. This

process is repeated down the transmission line. The

transmission torque and aerodynamic loads are

inputs to the flap panel block.

The net torque acting on the flap panel (T

flap

) is

calculated as follows. The aerodynamic loads (T

aero

)

are converted into the transmission torque reference

frame using the actuator gear ratio (G

act

) and

mechanical efficiency (η

act

). This is summed with

the torque from the transmission shafts (T

trans

) and

drag (T

drag

) is deducted which is described in

equation 3:

T

flap

= (η

act

* T

aero

/ G

act

) + T

trans

-T

drag

(3)

The model contains additional complexities for

example determining the direction of the drag torque

dependant on the direction of rotation.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

96

Figure 4: Model of High Lift system in the wing.

Figure 5: Power Drive Unit Model.

Dynamic Modelling of Commercial Aircraft Secondary Flight Control Systems

97

The net torque on the flap panel (T

flap

) is

converted into panel acceleration (A

flap

) by dividing

by the inertia of the panel and transmission

components (I

act

).

A

flap

= (η

act

* T

flap

/ I) (4)

The velocities and displacements are then

determined by integrator blocks.

3.3 Power Drive Unit

The power drive unit model incorporates two

hydraulic channels that contain a constant

displacement motor and control valve to activate the

motor. More complex hydraulic control arrangements

can be used to control the power drive unit more

precisely such as electro hydraulic servo valves.

This block is defined as “Power Drive Unit” in

figure 3 and has been expanded in figure 5.

The PDU enable signal controls both the brake in

the PDU and the control valve. The control valve

dynamics are represented by a first order transfer

function using the time constant T

c

:

Valve Transfer Function = 1/(1 + T

c

.(s)) (5)

Movement of the control valve determines the

pressure drop across (ΔP) the motor. The pressure

drop is converted to a motor torque (T

m

) by

multiplying by the motor displacement (K

mot

) and

incorporating drag (T

drag_m

) and motor efficiency

(η

mot)

as shown by equation 6:

T

m

= ΔP*K

mot

*η

mot

- T

drag_m

(6)

Hydraulic motor acceleration is calculated by

dividing the motor torque by the motor inertia.

Integrating the acceleration provides the angular

velocity of the motor. Both motor speeds are

transferred through a gearbox where the PDU output

shaft position and velocity states are passed to the

wing.

3.4 Secondary Flight System

Controller

The secondary flight control opens the control valve

and releases the system brakes when the position

demand is not equal to the present PDU position.

When the system reaches target position the control

valve is closed and all brakes are engaged.

Multiple brakes are often used in high-lift

systems due to the transmission disconnect failure

scenarios. When activated the brakes prevent

excessive asymmetry between the left and right hand

wing. An actual high-lift controller will typically

have a number of sensors to monitor certain failure

conditions and arrest the system before they become

catastrophic. However, for the purposes of this paper

these are omitted.

3.5 Model Parameters

A list of the model parameters is provided in the

appendix and these are set via the use of Matlab

functions. This allows multiple model parameters to

be run through batches. All parameters used in the

model are arbitrary and do not relate to a particular

aircraft. The model outputs are used to assess the

operating speed of the system and resulting

deployment times. The transmission loads generated

is also analysed.

4 RESULTS

4.1 Time Histories

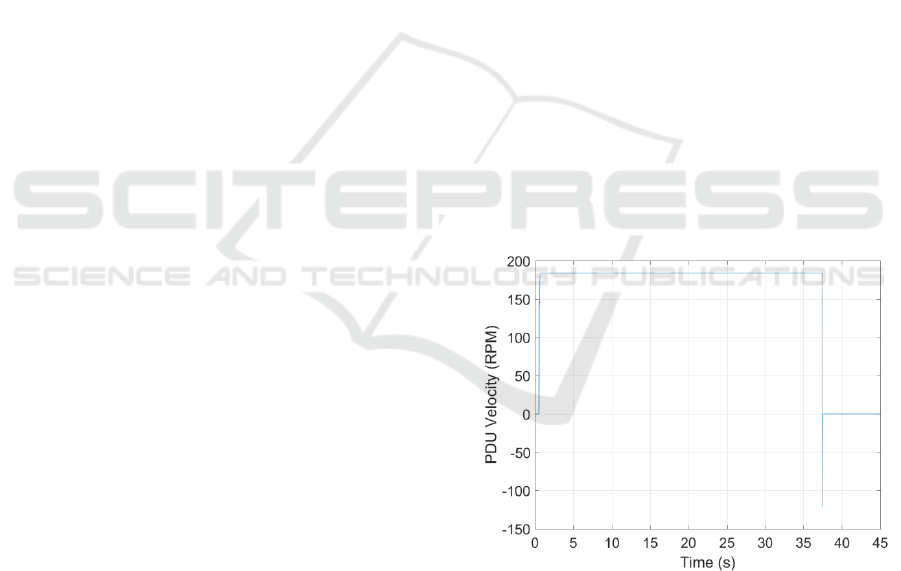

The basic output from the model is logged in time

histories. Figure 6 highlights the PDU output shaft

velocity during deployment.

Figure 6: Time history of PDU output shaft velocity.

This shows that when the system proceeds at a

normal operating speed of 184 rpm. It takes

approximately 36.9s to fully deploy the system from

the stowed condition.

Both hydraulic motors consume approximately

12.6 l/min flow rate during operation as provided by

figure 7:

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

98

Figure 7: Hydraulic motor flow rate consumption.

The following time history shows the system

position at both the PDU and the wing tips. It can be

seen that the wing tips marginally lag the PDU. The

lag is due to stiffness of the transmission system and

it is the expected systems behaviour.

Figure 8: System Position at the PDU and wing tip

sensors.

Finally the transmission torque from each wing

can be plotted. This shows an initial transient peak

torque at 97Nm reducing to a steady state torque of

93Nm per wing.

Figure 9: Wing torques during deployment.

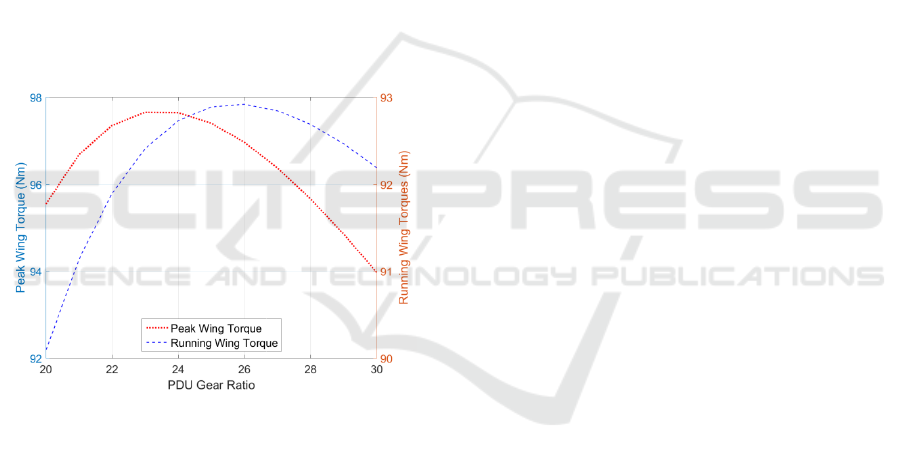

4.2 Sensitivity Study

The model parameters have been fed into the model

as ranges in order to assess the systems sensitivity.

The example provided shows how the gear ratios of

the PDU gearbox can be modified to achieve various

system requirements such as:

• Minimise running and peak transmission

torques;

• Minimising the hydraulic flow rate

consumption;

• Reducing deployment time.

Figure 10 provides the results from a batch of

simulations where the PDU gear ratio was varied

between 20:1 to 30:1.

The results from the simulations indicate the

optimal gear ratio to be 26:1 which maximises

operating speeds and hence reducing deployment

times. An optimum occurs because of the trade-off

between the mechanical advantage of the PDU and

the drag which increases as function of speed.

Figure 10: Operating velocity and flow rate vs gear ratio.

Figure 11: Normal operating velocity and deployment

time vs gear ratio.

Optimum

Delay in

rotation

between

PDU and

wingtip

Dynamic Modelling of Commercial Aircraft Secondary Flight Control Systems

99

At low gear ratios the PDU has a lower

mechanical advantage and hence the PDU’s torque

capability is lower, which implies lower operating

speeds. At high gear ratios the motor speed is higher

for a given PDU output speed and the speed induced

drag in the motor increases and limits the PDU

speed.

Figure 11 presents the sensitivity analysis of the

variation of the PDU ratio vs. the normal operating

velocity (blue line) and the PDU gear ratio vs. the

deployment time. The optimal gear ratio is the one

defined by the value for which we have operating

velocity and minimum deployment time. In this

example, the optimum PDU gear ratio for this

system is 26:1. The transmission torques generated

by the model can be used to as an input into stress

sizing simulations. Figure 12 shows that the running

torques in the transmission are highest at 26:1 due to

the highest operating speeds. The peak transmission

torque has a marginally different trend due to the

dynamic transmission characteristics.

Figure 12: Peak and running torque in the wing

transmission vs gear ratio.

A hydraulic high lift system is typically sized

based upon cold temperature operating and breakout

performance. The reason behind it is that the drag in

the transmission is at the highest while the PDU

capability is the lowest.

5 MODEL VERIFICATION

The mathematical models provided herein have been

verified against physical test data. This has provided

the confidence to use the model outputs to support

the design and development of numerous high lift

aircraft systems.

Model verification has been performed at

numerous stages of the system engineering process

for example at component level (actuator, PDU etc.)

and against full system rig and simulated results.

Excellent model correlation has been achieved at

both individual component and full system level

over a range of environmental temperatures,

aerodynamic loads across multiple programs.

Models have been further utilised in software

and hardware in the loop environments with

suppliers and customers.

Models of secondary flight control systems

developed in the Simulink environment have been

rapid prototyped to support hardware in the loop

simulation.

This has provided the following benefits:

• Development time of software algorithms

significantly improved;

• Control models tested in simulation prior to

integration on the test rigs improve systems’

robustness and easiness of integration.

• Use of the mathematical model as a precise

implementation of the controller and thereby

reducing misinterpretation of formal

requirements.

In recent years there has been a significant shift

in the aerospace industry to move from rig tests to

modelling and simulation environments. Simulations

allow testing of the system in extreme cases that test

rigs may not be able to perform due to:

• Too dangerous/expensive to perform;

• Not possible to perform such as all system

tolerances being maximised/minimised;

• Limitations of the test rigs.

6 CONCLUSIONS

This work has described the modelling process of a

commercial aircraft high-lift transmission and power

drive system. An example model was provided that

was developed in the Simulink modelling

environment and results of a sensitivity analysis

have been provided. Model validation has been

discussed together with the integration of models

into other engineering environments.

This paper provides a generic functional model

and demonstrates the analysis techniques used

within the design and development of high lift

systems that are in-service.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

100

REFERENCES

Hardwick, G., Hanna, S., Panella, I. 2017. Functional

Modelling of High Lift Systems. NAFEMS World

Congress 2017. NAFEMS, awaiting publication.

Walden, D. 2015. INCOSE Systems Engineering

Handbook 4

th

Ed. INCOSE . WILEY.

SEBoK. 2017. Guide to the Systems Engineering Body of

Knowledge – Validation and verification diagram,

sebokwiki.org.

ARP4754A, 2010, Guidelines for Development of Civil

Aircraft and Systems, SAE International

Zadeh, Desoer, 1963. “Linear System Theory – The State

Space Approach” McGraw Hill, New York

APPENDIX

Table 1: Table of model parameters.

K

hyd

Hydraulic fluid bulk modulus

ρ

hyd

Hydraulic fluid density

I

mot

Hydraulic motor inertia

K

mot

Hydraulic motor displacement

T

s

Control valve time constant

A

valve

Control valve area

C

valve

Coefficient of discharge for control valve

P

PDU

PDU brake disengagement pressure

G

PDU

PDU gearbox ratio

η

mot

Motor efficiency

T

drag_m

Motor drag

k

trans

Transmission torsional stiffness

c

trans

Transmission torsional damping

η

trans

Transmission dynamic efficiency

T

drag

Transmission system drag

I

act

Actuator inertia

T

OBB

Outboard brake response time

P

OBB

Outboard brake disengagement pressure

G

sensor

Gear ratio position sensor

T

aero

Aerodynamic loads at all actuators

G

act

Gear ratios of rotary geared actuators

η

act

Actuator efficiency

Dynamic Modelling of Commercial Aircraft Secondary Flight Control Systems

101