A Sliding-Mode Controller from a Reduced System Model: Ball and

Plate System Experimental Application

Luis Morales, Oscar Camacho, Paulo Leica and Danilo Chávez

Departamento de Automatización y Control Industrial, Escuela Politécnica Nacional Ladrón de Guevara,

E11-253, Quito, Ecuador

Keywords: Ball-Plate System, Sliding-Mode Control, PID Controller, Stabilization, Reduced System Model.

Abstract: The purpose of this work is to design a Sliding-Mode Control from a reduced system model using a PID as

sliding surface. The controller is applied to a Ball and Plate system which has extremely non-linear

characteristics and therefore does not have a unique solution in terms of ball stabilization control. The results

are obtained by simulations and with real experiments in the implemented system. A comparative performance

analysis is done between the proposed approach and a PID controller to stabilize the ball at fixed points of the

plate.

1 INTRODUCTION

The Ball and Plate system is an extension of the ball-

beam system, which has 2 degrees of freedom and

due to its non-linear characteristics has generated

interest in the study and analysis of classic, modern

and non-linear controllers that respond adequately to

the dynamics of the system, which is extremely

unstable since, in open loop small plate inclinations

cause indefinite displacement of the ball.

The system has two actuators that allow to vary

the inclination of the plate to stabilize the ball or to

track paths. Stabilization means keeping the ball in a

desired position and following path demands making

the ball follow a geometric pattern regardless of time.

The system modeling is obtained easily (Nokhbeh

and Khashabi, 2011), therefore, different works has

focused on analyzing the response of controllers in

order to stabilize the ball on the platform (Bay and

Rasmussen, 2016); the high nonlinearity of the

system implies that there is no a unique satisfactory

solution.

Several experiments have been developed in order

to control the system; The typical experiment is with

the classic PID controller. (Ali and Aphiratsakun,

2016), whose parameters tuning is done through

methods such as Ziegler-Nichols, Tyreus-Luyben and

heuristic (Aphiratsakun and Otaryan, 2015). It is not

necessary to know the mathematical model of the

plant to determine best controller tunings Kp, Ki and

Kd, to stabilize the ball on the plate in the shortest

time as possible, and reducing oscillations. In

(Knuplei et al., 2003), a lead controller is proposed,

however, the controller does not present good results

since there is a considerable error in steady state.

Nonlinear controllers based on Lyapunov´s stability

(Wang et al., 2008) have been tested in the platform

with different frictions and it is evidenced that this

parameter affects the performance of the controller

considerably.

Fuzzy controllers are applied in (Fan et al., 2004),

with the purpose of moving the ball through the track

of a path, taking the ball from point A to point B

without crashing obstacles on the plate.

Sliding-Mode Control (SMC) is also used for

stabilization control, the results of (Debono and

Bugeja, 2015) evidence an improvement in the

system response, however the controller employs

complex trigonometric calculations (Valadez et al.,

2014).

Due to robustness of SMC, it can attenuate the

uncertainty in the measurement of the ball’s position,

and it allows to stabilize the ball in less time and with

fewer oscillations. Previous works have shown an

important amount of results in stabilization tasks for

the ball and plate system using PID and SMC

controllers. Different to those papers, the purpose of

this work is to design a Sliding-Mode Control from a

reduced system model using a PID as sliding surface.

The resulting controller is simple and robust

without complex calculations reducing computational

590

Morales, L., Camacho, O., Leica, P. and Chávez, D.

A Sliding-Mode Controller from a Reduced System Model: Ball and Plate System Experimental Application.

DOI: 10.5220/0006425905900597

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 590-597

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

cost and easy implementation (Camacho and Smith,

2000). The results are obtained by simulations and

with real experiments in the implemented system. A

comparative performance analysis is done between

the proposed approach and a PID controller to

stabilize the ball at some fixed points of the plate.

This paper is organized as follows. Section 2

briefly presents the mathematical model of the plant.

Section 3, presents some basic concepts of the SMC

method and its design. Section 4, the simulation and

experimental tests are presented and a comparison is

made between the performance of the conventional

PID and the SMC with the PID sliding surface.

Section 5, presents the conclusions of the work.

2 MATHEMATICAL MODEL

2.1 Ball and Plate System

The ball and plate system consists of a rigid platform,

in which the ball rolls, two servo motors (actuators)

that allow to vary the inclination angles, a camera that

allows feedback the system with the position of the

ball in the X and Y axes, and the control system as

shown in Figure 1.

Figure 1: Schematic diagram of the ball and plate system.

In Figure 1, α is the angle of the plate in X-axis, β

is the angle of Y-axis, u

x

and u

y

are control actions

applied to actuators for X-axis and Y-axis

respectively.

The plant has been designed, built and

implemented in the Laboratory of Automatic Control

at Escuela Politécnica Nacional. The platform has a

glass surface to minimize friction and to be able to

despise the frictional forces and simplify model

calculation and is controlled by two servo motors to

adjust the inclination of the X-axis and the Y-axis.

The plant has a camera with a resolution of 640x640

pixels that acquires images at a 30 fps to determine

the position of the ball and feedback the control loop

(Figure 2). Image processing has algorithms for ball

detection, and has implemented a Kalman Filter for

noise elimination (Cedeño and Gordón, 2016).

Figure 2: Experimental Ball and Plate System.

2.2 Mathematical Model

The mathematical model of the plant shown in

Figure.2., neglecting the surface friction and applying

the Lagrange method (Fan et al., 2004) is:

0

(1)

0

(2)

Table 1, presents the description of the parameters

of equations (1) and (2).

Table 1: Parameters of the mathematical model.

Parameters of Ball and Plate S

y

stem

Symbol Units Description

kg Mass of the ball

kg cm

2

Moment of inertia of the ball

cm Radius of the ball

cm Position of the ball in the X-axis

cm Position of the ball in the Y-axis

ra

d

Angle of the plate from X-axis

ra

d

Angle of the plate from Y-axis

kg m/s

2

Acceleration due to gravity

A Sliding-Mode Controller from a Reduced System Model: Ball and Plate System Experimental Application

591

2.3 Reduced System Model

Considering small angle of inclination of the plate

(±8° = ±0.139 rad), this movement is slow to stabilize

the ball on the plate, therefore: ≅0,

≅0

(Nokhbeh and Khashabi, 2011), thus is obtained:

(3)

(4)

2.3.1 Linearized Model

Linearizing equations (3) and (4) by Taylor Series at

the operating point 0,

̅

0 when the platform

is in horizontal position and keeps the ball in

equilibrium, the following equations were obtained:

(5)

(6)

Considering the gravity 980

, and

moment of inertia of a solid ball

:

700

(7)

700 (8)

Plate´s angles and actuators’ rotation angles are

related by the following equations:

10

(9)

10

(10)

Where:

,

are the rotation angles of the

servomotors. Substituting (9) and (10) in (7) and (8)

respectively gives:

70

(11)

70

(12)

Laplace transform of the model is calculated:

70

(13)

70

(14)

Where:

, are the positions of the ball in the

X-axis and Y-axis respectively, and

,

are

the rotation angles of servo motors of the plant.

3 CONTROLLER’S DESIGN

This work proposes two methods to stabilize the ball

on a desired position of the plate: the PID controller

and the SMC method with sliding surface PID, to

finally compare its performance.

3.1 PID Controller

To stabilize the ball on a plate position two

independent controllers have been designed, one for

X-axis and another for Y-axis of similar

characteristics due to the symmetry of the system.

Heuristically calibrates the parameters of the

controller in the real plant starting from the values

given by the auto-tuning method of a computational

software until obtaining the lowest ISE, index used to

measure the performance of controllers (Kealy and

O’dwyer, 2003) and defined for a period of time as

shown in (15).

(15)

Where: 20 (time of the experiment),

, is

the error between reference and output in the X-axis,

establishing the constant values for the controllers of

the X-axis and Y-axis 0.035, 0.018,

0.0001,

0.073.

3.2 Sliding-Mode Control

Sliding-Mode Control (SMC) is based off the idea of

variable structure control. One of the main

applications of the SMC method is non-linear systems

since robustness to uncertainty is indispensable in the

field of control systems. This method proposes to

define a surface along which the process can slide

until reaching a final value. Control law of SMC is:

(16)

U

c

is the continuous part of the control that allows to

stay on the sliding surface, and U

d

is the

discontinuous part of the control that allows to reach

the sliding surface. (Slotine and Li, 1991) proposes

the surface shows in (17):

(17)

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

592

Where: is the sliding surface, is the sliding

surface order and is the error.

3.3 SMC Method Design

The following procedure has been presented by

(Camacho and Smith, 2000), in which the

mathematical model of a PID controller is taken as

the sliding surface. The design of the controller for

the X-axis is presented, since the Y-axis has the same

characteristics due to the symmetry of the system.

The PID controller for X-axis is:

(18)

Comparing (17) for 2, with (18):

(19)

2

Then, is considered the PID as a sliding surface since

they have the same mathematical form.

(20)

Controller (16), for X-axis is:

(21)

is computed considering

0,

0:

0

(22)

Deriving error in X-axis the following is obtained:

(23)

Substituting (23) in (22), gives:

0

(24)

Substituting the model of the plant in X-axis (11) in

(24),

is computed:

70

(25)

Substituting (25) in (21), gives:

70

(26)

For the calculation of discontinues part

, is

analyzed Lyapunov´s stability.

Considering a Lyapunov function:

/2

(27)

Stability condition denotes that:

0

(28)

Substituting (24) in (28), gives:

70

0

(29)

Substituting (26) in (29) and simplifying, gives:

70

0

(30)

To perform the condition of (30) is proposed:

(31)

Discontinues part

incorporates a nonlinear

element that includes the switching element of the

control law. This part of the controller is

discontinuous across the sliding surface. (Camacho

and Smith, 2000), propose:

|

|

∴

0

(32)

Substituting (32) in (26), the control law is:

70

|

|

(33)

In (Camacho, 1996), is shown the derivatives of the

reference value can be discarded, without any effect

on the control performance, resulting a simpler

controller for X and Y axis:

70

|

|

(34)

70

(35)

Based on the Lyapunov’s stability analysis, these

controllers guaranteed

→0,

→0 when →∞.

Calibrating values

to obtain the lowest

index, experimentally is determined

0.93,

and 0.75 observing that this value eliminates the

chattering and produces an adequate response of the

system. These values were obtained for a step

A Sliding-Mode Controller from a Reduced System Model: Ball and Plate System Experimental Application

593

reference obtaining

0.065. The designed

controller scheme is shown in Figure. 4.

Figure 4: Proposed control scheme.

This section presents the comparison between

both controllers, first, by simulation, and finally the

experimental results are presented in the laboratory

plant shown in Figure. 2. To analyze the performance

of the controllers, measurement indexes are used.

4 RESULTS

4.1 Simulation Results

First, the ball stabilization test is performed at the

plate’s central point whose coordinate is (23 [cm], 23

[cm]), starting from the initial position (0 [cm], 0

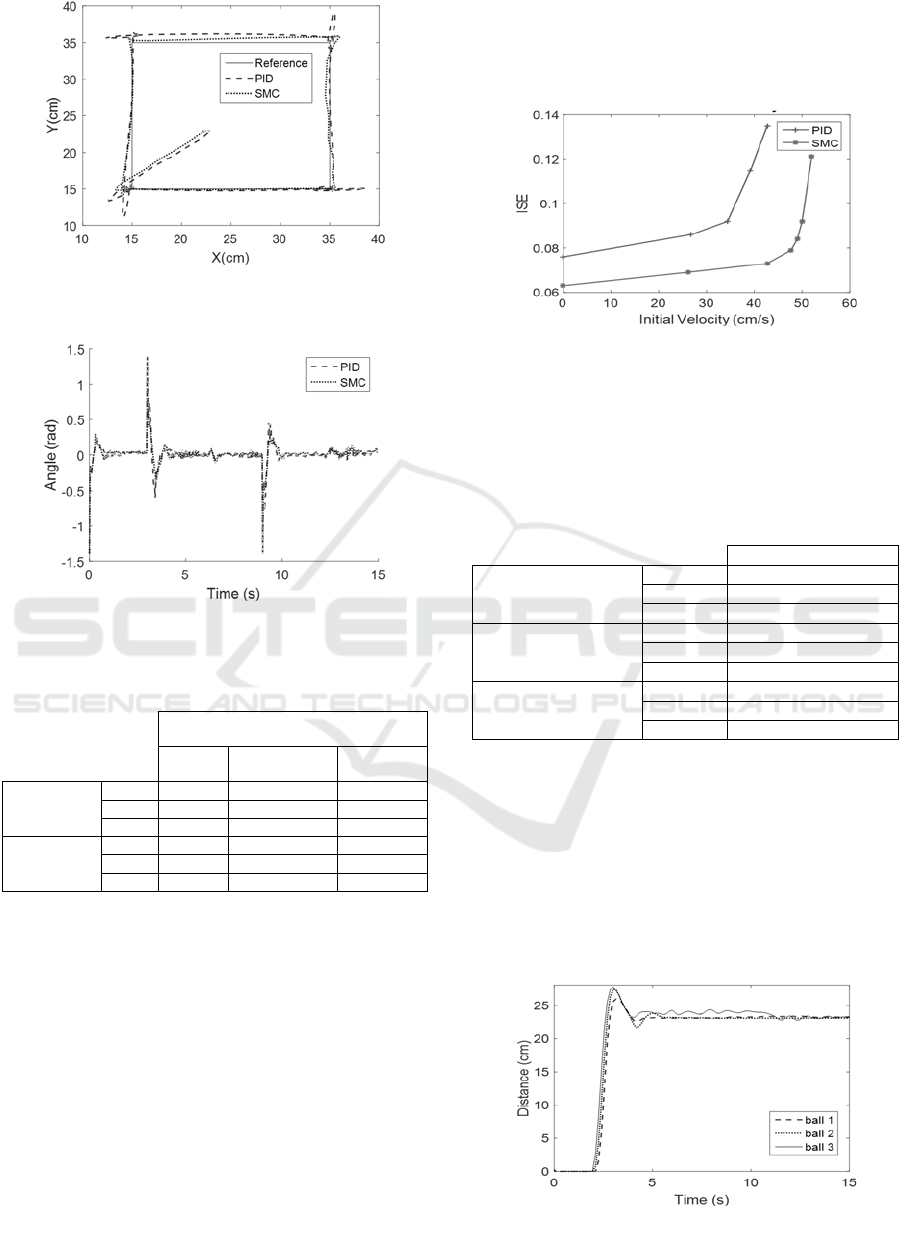

[cm]). Figure 5, illustrates how perform each

controller. It shows the ball position on the X-axis vs.

time, the response on the Y-axis does not presented

since it is similar, in simulation cases.

Figure 5: Simulated ball position on the X-axis.

Results obtained for reaching a sequence of points

corresponding to the vertices of a square 20 [cm] per

side, are presented in Figures 6, 7 and 8, starting from

plate’s central point. Figure 6 and 7, show ball’s

position on X and Y-axis vs. time and Figure 8.,

shows the ball’s movement on the plate.

Figure 6: Simulated ball position on the X-axis.

Figure 7: Simulated ball position on the Y-axis.

Figure 8: Simulated movement of the ball on the plate to

reach the four square vertices.

SMC method allows to reach the desired position

smoother, faster and with lower overshot, since the

control action is not as abrupt as in PID controller.

Performance by index of the two controllers is

shown in Table 2. Settling time has been measured

once the system response is within a band of 5% of

the reference value.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

594

Table 2: Simulation controller’s comparison using

measurement parameters.

PERFORMANCE COMPARISON

INDEXES

ISE

Settling

time (s)

Overshoot

(%)

POINT

PID 0.041 4.0 25.3

SMC 0.036 3.2 18.0

Δ% 12.9% 22.2% 33.7%

SQUARE

VERTICES

PID 0.044 4.7 26.5

SMC 0.041 3.5 19.1

Δ% 7.0% 29.2% 32.4%

There is a considerable difference between the

measured indicators, the most representative is the

settling time and overshot, showing that designed

SMC allows to obtain better results than PID

controller for ball’s stabilizing.

4.2 Experimental Results

Experimental results are obtained using the real plant.

The ball stabilization test is performed at the central

point of the implemented system whose coordinate is

(23 [cm], 23 [cm]), from the position (0 [cm], 0 [cm]),

this is done for the X and Y-axis. Ball’s position is

shown in Figure. 9 and 10. In Figure. 11., ball’s

movement on the plate is shown.

Figure 9: Experimental ball position on the X-axis.

Figure 10: Experimental ball position on the Y-axis.

Figure 11: Experimental movement of the ball on the plate

to stabilize the ball at point (23 [cm], 23 [cm]).

Results obtained for reaching four vertices of a

square 20 [cm] starting from position (23 [cm], 23

[cm]) are presented in Figures. 12, 13 and 14.

SMC method reaches the reference points with a

better performance since its control action is less

abrupt as shown in Figure 15.

Figure 12: Experimental ball position on the X-axis.

Figure 13: Experimental ball position on the Y-axis.

The vibrations in the response of the system are

due to mechanical limitations since the plate is placed

on a central pivot axis.

A Sliding-Mode Controller from a Reduced System Model: Ball and Plate System Experimental Application

595

Figure 14: Experimental movement of the ball on the plate

to reach the four square vertices.

Figure 15: Control Action for X-axis.

Table 3: Experimental controller’s comparison using

measurement parameters.

PERFORMANCE COMPARISON

INDEXES

ISE

Settling time

(s)

Overshoot

(%)

POINT

PID 0.073 2.7 20.8

SMC 0.065 1.2 5.2

Δ% 11.6% 76.9% 120%

SQUARE

VERTICES

PID 0.096 2.3 23.7

SMC 0.082 1.1 9.5

Δ% 15.7% 70.5% 85.5%

The most representative values are the settling

time and the overshot, demonstrating that the SMC

approach allows to obtain better results in this system

in a high variation. It is also observed in the graphs

there is a delay in the action of the actuators of 0.4 [s]

which could be reduced with a dead time scheme

controller that improves the system response.

4.3 Robustness Analysis

The first robustness analysis of both controllers is

shown in Figure. 16., in which the ISE value can be

calculated by testing the ball stabilization at different

initial velocities before a step input. The maximum

initial velocity of the ball in the case of the PID is 42

[cm/s], a greater one becomes the system unstable,

while the SMC allows to reach the maximum velocity

of the ball of 52 [cm/s]. It is evident that the ISE is

lower for all cases with SMC method.

Figure 16: Robustness comparison between both

controllers.

Second robustness analysis was performed with

balls of different mass and radius determining the

of each controller as shown in the Table 4.

Table 4: Experimental controller’s comparison using

measurement parameters for different balls.

ISE

Ball 1

Mass = 129[g]

Radius = 17 [mm]

PID 0.074

SMC 0.064

Δ% 14.1%

BALL 2

Mass = 20 [g]

Radius = 13 [mm]

PID 0.063

SMC 0.052

Δ% 19.1%

BALL 3

Mass = 5 [g]

Radius = 8 [mm]

PID 0.082

SMC 0.070

Δ% 15.7%

Figures 17 and 18, show the behavior of the balls

in the X-axis with the PID controller and the SMC

approach respectively, evidencing that the proposal of

this work improves its stabilization in the best of

cases up to 19%. Balls 1 and 2, are easy to stabilize

due to their weight and size, however ball 3 being

lighter before a small vibration, its position changes

in a more sensitive way, SMC presents a minor error

in steady state.

Figure 17: Experimental ball position on the X-axis for 3

balls stabilizing by PID controller.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

596

Figure 18: Experimental ball position on the X-axis for 3

balls stabilizing by SMC proposed approach.

5 CONCLUSIONS

The results obtained through simulation are similar to

those obtained experimentally, which demonstrate

that the performance of the SMC method is better

than PID, since it allows to stabilize the ball in a

shorter time decreasing the considerably the overshot.

The methodology proposed in this work allows

the design of controllers based on Sliding-Mode

through a PID sliding surface, controllers that in most

applications present excellent results, and whose

performance can be improved by applying this

technique providing robustness to the control system

without complex calculations. To design this

controller, it is indispensable to know the

mathematical model of the plant, and its constants

must be calibrated adequately.

ACKNOWLEDGEMENTS

Oscar Camacho thanks PROMETEO project of

SENESCYT, Republic of Ecuador, for its

sponsorship for the realization of this work. Authors

thank to PIJ-15-17 Project of Escuela Politécnica

Nacional for its sponsorship for the realization of this

work.

REFERENCES

Ali, E., & Aphiratsakun, N. (2016). AU ball on plate

balancing robot. 2015 IEEE International Conference

on Robotics and Biomimetics, IEEE-ROBIO 2015,

2031–2034. https://doi.org/10.1109/ROBIO.2015.7419

072

Aphiratsakun, N., & Otaryan, N. (2015). Ball On The Plate

Model Based on PID Tuning Methods * A. AU Ball On

The Plate Balancing Robot, (1), 3–6.

Bay, C., & Rasmussen, B. (2016). Exploring Controls

Education: A Re-Configurable Ball and Plate Platform

Kit. Retrieved from http://oaktrust.library.tamu.edu/

handle/1969.1/156115

Camacho, O. (1996). A New Approach to Design and Tune

Sliding Mode Controllers for Chemical Processes, PhD

dissertation. University of South Florida, Tampa,

Florida.

Camacho, O., & Smith, C. (2000). Sliding mode control: an

approach to regulate nonlinear chemical processes. ISA

Transactions, 39(2), 205–18. https://doi.org/10.1016/

S0019-0578(99)00043-9

Cedeño, A., & Gordón, M. (2016). Implementación de una

plataforma de estabilización para control de posición y

seguimiento de camino de una esfera. Final Career

Project. Escuela Politécnica Nacional, Quito-Ecuador.

Retrieved from http://bibdigital.epn.edu.ec/handle/

15000/16909

Debono, D., & Bugeja, M. (2015). Application of Sliding

Mode Control to the Ball and Plate Problem. 12th

International Conference on Informatics in Control,

Automation and Robotics (ICINCO), 412–419.

Fan, X., Zhang, N., & Teng, S. (2004). Trajectory planning

and tracking of ball and plate system using hierarchical

fuzzy control scheme. Fuzzy Sets and Systems, 144(2),

297–312. https://doi.org/10.1016/S0165-0114(03)

00135-0

Kealy, T., & O ’dwyer, A. (2003). Analytical ISE

Calculation And Optimum Control System Design.

_Issc. Retrieved from http://arrow.dit.ie/engscheleart

Knuplei, A., Chowdhury, A., & Sveeko, R. (2003).

Modelling and Control design for the ball and plate

system. 2003 IEEE International Conference on

Industrial Technology, 1064–1067. https://doi.org/

10.1109/ICIT.2003.1290810

Nokhbeh, M., & Khashabi, D. (2011). Modelling and

Control of Ball-Plate System Final Project Report.

Slotine, J., & Li, W. (1991). Applied Nonlinear Control.

Prentice Hall, New Jersey.

Valadez, H., Loukianov, A., Castillo, B., & Bayro-

Corrochano, E. (2014). Sliding control variation for

ball-plate system stabilization. 13th International

Workshop on Variable Structure Systems (VSS).

Wang, H., Tian, Y., Fu, S., & Sui, Z. (2008). Nonlinear

control for output regulation of ball and plate system.

Proceedings of the 27th Chinese Control Conference,

CCC, 382–387. https://doi.org/10.1109/CHICC.2008.

4605473

A Sliding-Mode Controller from a Reduced System Model: Ball and Plate System Experimental Application

597