An Automated Quadcopter CAD based Design and Modeling Platform

using Solidworks API and Smart Dynamic Assembly

Mohammad Shaqura

1

and Jeff S. Shamma

2

1

Mechanical Engineering, Physical Science and Engineering, King Abdullah University of Science and Technology,

Thuwal, Saudi Arabia

2

Electrical Engineering, Computer, Electrical and Mathematical Sciences and Engineering,

King Abdullah University of Science and Technology, Thuwal, Saudi Arabia

Keywords:

Multirotor Robots, UAV, CAD Modeling, API, Dynamic Assembly, Flight Simulation.

Abstract:

Multirotors micro aerial vehicles (UAV) have become a standard platform in robotics and control research

related to algorithmic development as well as design innovation. Custom-built designs based on open-source

architecture and off-the-shelf components are attractive for researchers due to low cost and easy rapid pro-

totyping. Hardware selection and integration is usually based on heuristics. Building a realistic quadcopter

simulator requires accurate modeling and knowledge of its dynamics and the effect of each component on

that. Often, moving from simulation to actual experiment is a challenging task due to the huge dynamical

differences when working with the real system. The presented work aims to strengthen the bridge between

simulations and actual system through an automated CAD based modeling software system that generates re-

alistic models mathematically and visually for Matlab Simscape physics simulation and visualization utilizing

Solidworks API, smart mating techniques and dynamical analysis. A proof of concept application with user

friendly interface is built for Windows OS and the system components are further illustrated.

1 INTRODUCTION

Quadcopters have become popular testbeds in control

research due to their high maneuverability and ability

to execute complex motion patterns. This agility is re-

sulted from the large torques about the center of mass

caused by the propulsion forces away from the center.

Although several robust quadcopter systems are avail-

able in the market, most do not meet the autonomous

research needs, flexibility and modularity required for

development. Researchers often choose to build their

own quadcopter systems using off-the-shelf compo-

nents and open-source flight controllers. This allows

full access to hardware/software interfaces and con-

trol/estimation functions.

Testing high-level control algorithms such as au-

tonomous navigation, optimal coverage, multi-agent

control and mapping requires low level control sta-

bility meaning that the vehicle should achieve good

performance in hover and attitude control which re-

sults in better velocity and position control. If one

choose custom hardware building, the selection op-

tions of components is limitless and usually this is

done based on heuristics, suggestions and best guess.

Several generic quadcoptors simulation toolboxes

are available across multiple platforms. (Corke, 1996)

Usually, a simplified quadcopter model is utilized

with minimum geometrical and dynamical details. A

good knowledge of the model is assumed to be known

by the user and it is added as an input in the form

of a configuration or model structure file. The simu-

lation results is as good as the model describing the

actual system. Physical simulators, such as Matlab

Simscape, V-Rep and Gazebo, provide powerful real-

istic results through simulating the modeled individ-

ual components of the system. (Rohmer, 2013), (The

MathWorks Inc., 2016), (Koenig, 2004), (Meyer,

2012). The physics engine solver simulates the be-

havior of the system under components uncertainty

(sensors/actuators noise) and external forces. Users

of these simulators face two challenges, the high com-

putational and graphical requirements needed and the

hectic modeling, design and redesign task which usu-

ally require good expertise in Computer Aided Design

software tools. The first challenge is being attenuated

with the accelerated advancement in computer hard-

ware that made running some physical simulation en-

gine possible on a personal computer.

Prior to creating a realistic quadcopter simulation,

one need to acquire enough knowledge about the ge-

122

Shaqura, M. and Shamma, J.

An Automated Quadcopter CAD based Design and Modeling Platform using Solidworks API and Smart Dynamic Assembly.

DOI: 10.5220/0006438601220131

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 122-131

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

ometrical and aerodynamical effects. This includes

mass and inertial properties, thrust and power systems

modeling. These are classically determined through

mechanical assessment to measure thrust created by

each rotor, center of gravity (COG) with respect to

the vehicle center, total mass and individual compo-

nent mass and the inertia tensor(Domingues, 2009).

Different approaches have been applied to simplify

the modeling task and determine an easily controlled

model representation of the quadcopter system. This

can be in the form of linear approximation, experi-

mental data driven models or online model parameter

identification using deterministic and stochastic esti-

mation techniques (Sa, 2012).

Modern Computer Aided Design (CAD) tools are

packed with tremendous engineering capabilities be-

yond the 3D design default functionality. Solidworks

for instance offer powerful engineering tools for de-

sign, modeling and analysis such as flow simulation

with embedded CFD solvers and motion assessment

(Zhang, 2014), (Kuantama, 2017).

In this work, a system to automate the quad-

copter design, modeling and simulation is developed

in the form of user friendly interface. The tool is

developed based on the Solidworks Application Pro-

gram Interface (API) and Matlab Simscape toolbox

for model validation, simulation and control devel-

opment. Solidworks API allow developers to cre-

ate a standalone applications that utilized its engi-

neering capabilities. Using this interface, the user

specifies the quadcopter frame and components specs

including material, weight, dimensions and location

or choose from the library of commercially available

products. The software uses the provided specifica-

tions to generate the 3D model, identify its parameters

and the Matlab simulation environment files. In the

next section, the quadcopter equation of motions and

model parameters are presented. Then, the compact

component representation is discussed and how smart

mating works in an automated environment. In sec-

tion 4, general overview of the software tool use and

functionality is presented. Then, the article is con-

cluded with opportunities and future directions of this

project.

2 QUADCOPTER DYNAMICAL

MODEL

The quadrotor model is a 12 states nonlinear model,

x,y, z denotes position, v

x

,v

y

,v

z

denote the velocities,

φ,θ,ψ denote the roll, pitch and yaw attitude angles

respectively, ω

x

,ω

y

,ω

z

denote the rotational veloci-

ties. When presenting the quadrotors dynamics, one

should define a reference frame or known as inertial

frame where the states of the system are evolving with

respect to that reference. The actuation mechanism

(propulsion) in quadrotors acts directly on the body

frame, to illustrate this, the z-axis coincides with the

line pointing outward from the center of the quadro-

tors regardless of the orientation. In the inertial refer-

ence frame, the z-axis is fixed and present the altitude

of the quadrotors from a reference plane, e.g. ground.

Entities in the body frame should be transformed to

the inertial frame through a rotational matrix that is a

nonlinear function of the attitude angles. Let A and

B denote the inertial and body frames respectively, to

transform a vector from B to A, it is multiplied by the

rotational matrix:

R

A

B

=

cψcθ − sφsψsθ −cφsψ cψsθ+ cθsψsφ

cθsψ + cψsθsφ cφcψ sψsθ− cψcθsφ

−cφsθ sφ cφcθ

(1)

where c denotes the cosine function and s the sine

function. The dynamical model of forces and mo-

ments can be written as:

m

¨r

x

¨r

y

¨r

z

−

0

0

mg

= R

A

B

F

x

F

y

F

z

(2)

J

˙

ω

x

˙

ω

y

˙

ω

z

+

ω

x

ω

y

ω

z

× J

ω

x

ω

y

ω

z

=

τ

x

τ

y

τ

z

(3)

where ¨r

x

, ¨r

y

, ¨r

z

are the accelerations in the inertial

frame, m is the mass of the quadrotor, g is the gravita-

tional acceleration 9.81m/s

2

, F is the total thrust force

generated by all engines and F

x

,F

y

,F

z

and τ

x

,τ

y

,τ

z

are

the forces and torques in body frame. J is the iner-

tia matrix. The thrust and torque acting on the air-

frame that is generated by each rotating engine are

denoted by T

i

and Q

i

respectively for i ∈ {1, ..., 4}.

These forces and torques are directly proportional to

the square of the rotor speed.

T

i

= p

T

s

2

i

Q

i

= p

Q

s

2

i

(4)

p

T

and p

Q

are the thrust and torque coefficients.

These are functions of motor specs, rotor radius and

area and density of air. s

1

..s

4

denote the rotor speeds.

The forces and torques in body frame can be ex-

pressed as:

F

x

F

y

F

z

= (

4

∑

i=1

|T

i

|)

0

0

1

+

P

x

P

y

P

z

(5)

τ

x

τ

y

τ

z

=

L p

T

(s

2

2

− s

2

4

)

L p

T

(s

2

3

− s

2

1

)

p

Q

(−s

2

1

+ s

2

2

− s

2

3

+ s

2

4

)

(6)

An Automated Quadcopter CAD based Design and Modeling Platform using Solidworks API and Smart Dynamic Assembly

123

Where P

x

,P

y

,P

z

are the induced aerodynamical forces

acting on the vehicle when it is away from hover state.

L is the length of vehicle’s arm (distance between cen-

ter of the quadcopter and the effective thrust point).

The better the knowledge of thrust model, aerody-

namical effect and mass and inertial properties, the

more accurate the model is represented.

Figure 1: RISC Frame With Actual Hardware Mass, Mate-

rial and Representation Properties.

2.1 CAD based Model Identification

Quadrotors mainly consist of several parts beside the

main frame, more discussion of the main hardware

subsystems are presented in the next section. Each

part is made of certain material and we assume ho-

mogeneity in densities except for parts that are made

of multiple components and each has a considerable

mass relative to the part and the full assembly.

2.1.1 Mass and Inertia Matrix

Mass is calculated for each part in Kilograms and the

full weight of the assembly is computed using the vol-

ume and density of every part utilizing Solidworks

mass calculation and library of materials. The mass

of any part can be overridden if custom designed or

non-standard material is used to build the part. Cen-

ter of Gravity can be estimated numerically which

can be a challenging task. Some experimental ap-

proximation techniques are available. CAD engineer-

ing tools offers accurate calculation of the center of

gravity (COG). Good approximation of COG is in-

deed important as the equation of motions forces and

torques caused by the off center actuators acts on that

point. The non homogeneity of quadcopter different

parts and the way they are assembled affects the loca-

tion of the COG and therefore affect the dynamics of

the vehicle Some heuristics are also employed here by

considering centering the parts with the considerable

relative mass, e.g. batteries. The inertia matrix of a

3D object in free motion is given by:

J =

J

xx

J

xy

J

xz

J

yx

J

yy

J

yz

J

zx

J

zy

J

zz

(7)

Under the assumption of rigid body fixed mass vehi-

cle and alignment of quadcopter axis with the princi-

ple axis of inertia. One can neglect the off-diagonal

inertial components and consider only the principle

moments of inertia J

xx

, J

yy

& J

zz

. Here we take the

vehicle as is and we do not assume symmetrical mass

distribution. The full inertia matrix is computed using

Solidworks Mass Properties utility.

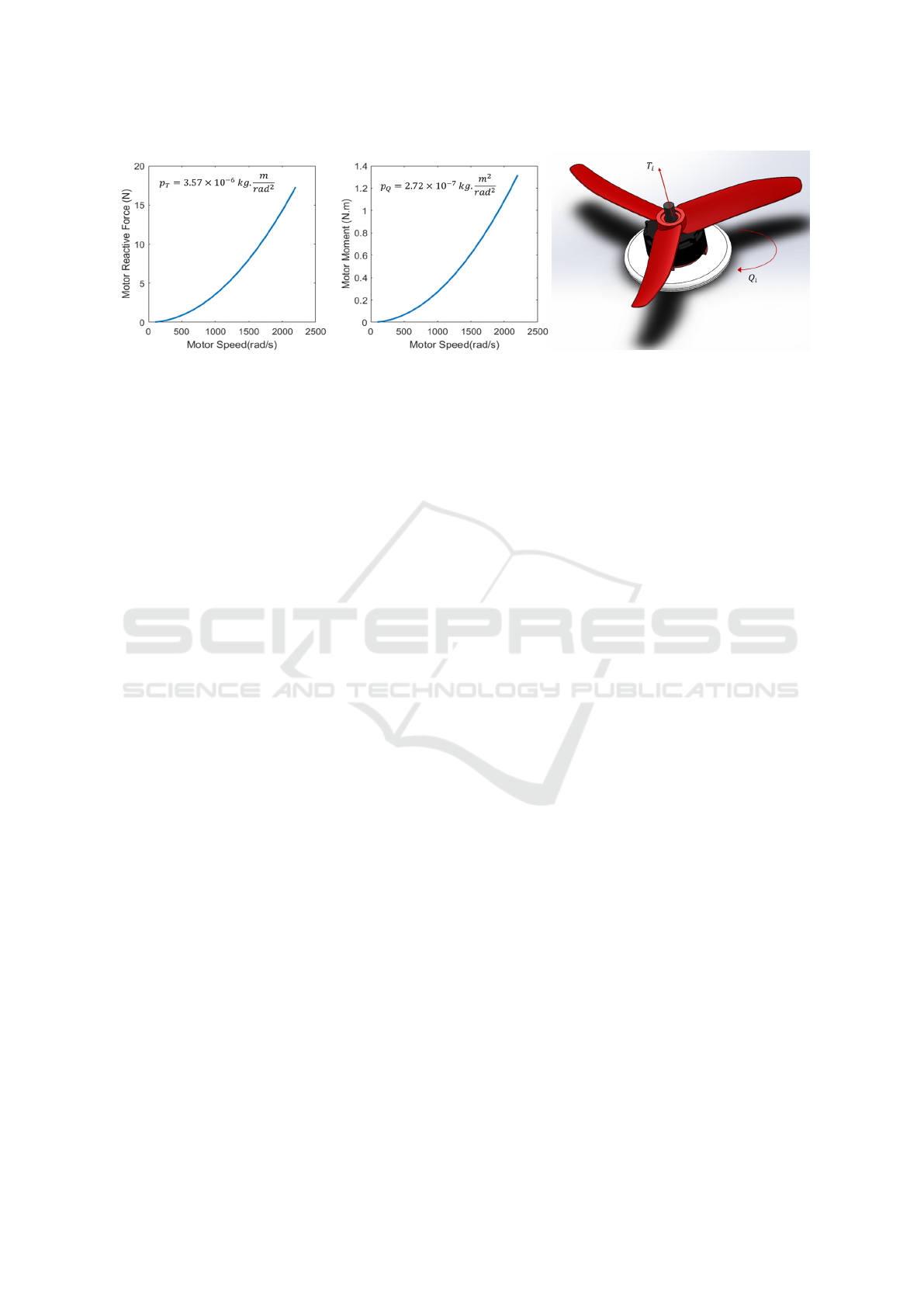

2.1.2 Thrust and Torque Model

The aim of this analysis is to illustrate the use of

CAD simulation to generate the model of the force

and torque effect on the frame exerted by each rotor.

The model of this effect can be complicated which is

in general a nonlinear function of the rotational speed

of the rotor, further detailed discussion are present in

(Mahony, 2012). A quadratic model similar to equa-

tion (4) or a higher polynomial model can be consid-

ered. The goal is to find the rotor parameters p

T

& p

Q

using physics engine of the CAD software. A sub-

assembly that consists of the engine, the propeller and

their mount on the frame is considered for the rota-

tional speed effect of the rotor on the frame as shown

in figure (2). Motion Analysis and Simualtion toolbox

is used to solve for the forces and torques acting the

motor frame interface for a series of rotational speed

s

0

i

, s

1

i

, s

2

i

, ..., s

n

i

where s

0

i

> 0 , s

n

i

< s

max

. s

max

is

the maximum motor rpm which can be found as part

of the engine specifications. One can easily change

the motor/propeller configuration and recompute the

force and torque. An example of force and moment

quadratic fit is shown in figure (2).

Further analysis is carried out to understand the

force and torque models affecting the full frame. Flow

Simulation Toolbox in Solidworks with its embed-

ded computational fluid dynamics (CFD) solver is

used to compute the overall thrust and torque effect

by the four rotors on the frame with all components

mounted. In addition to modeling purpose, this anal-

ysis is useful for design and performance optimiza-

tion. It allows the user to examine different hardware

selections and configurations for better stability and

controllability. Examples of these analyses are:

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

124

Figure 2: Left: Force and Moment of Brushless Motor and Propeller. Right: Motor/Propeller Model ID Setup In SolidWorks

Motion Analysis Toolbox. Material and Physical Specs Match The Actual Hardware.

• Lift Force Analysis: by rotating the four engines at

variable speeds and recording the generated force

in the body frame z direction. It is important to

make sure the actuators are capable of generating

thrust force that is sufficient to lift the weight of

full frame. Higher maximum thrust is preferable

but it is limited by the motor/propeller selection

which is restricted by the size of the frame and

other power components. See figure (3).

• Vorticity and Turbulence: this analysis can help in

frame sizing. In general, the larger the distance

from center of the quad to center of the rotor (L),

the lower the vorticity and the overall thrust gen-

erated. High value of vorticity affects stability of

the vehicle and make the control more challenging

and less robust(4).

• Frame Optimization: in case of customized de-

sign frame. Vibration analysis of the frame due to

material selection or design geometry to minimize

vibration is desired. High values affects stability

and create large amount of noise in the inertial and

visual sensing components.

• Power Requirements: after the selection of desired

performance and operating time, one need to ex-

amine the system with the extra load of electrical

speed controllers (ESC) and batteries. This pro-

cess can be iterative until a trade-off of total mass,

generated thrust and operating time is found.

• Motor/Propeller Sizing: different combinations of

motor/propellers can be examined to maximize

thrust output and avoid incompatibilities

• Components Reconfiguration: optimizing parts

attachment to the main frame by examining dif-

ferent configurations that led to different mass dis-

tribution and determining maximum and optimal

loading.

• Heat and Structural Stress: this is an advanced

analysis that requires through understanding of

hardware specifications to simulate heat generated

from each component and stress on the frame and

attachment interfaces. This analysis requires ad-

vance simulation tools and considerable computa-

tional resources.

2.1.3 Aerodynamical Effect

The aerodynamical drag can be neglected when op-

erating in near-hover state where φ, θ, ω

x

, ω

y

& ω

z

are zero or close to zero. This effects increases during

rotational and translational motion resulting in deflec-

tion from its desired state or trajectory tracking errors.

Often, this effect is neglected when modeling multi-

rotors unlike the case of fixed wing UAVs and con-

sidered as noise in the model that is compensated for

in the estimation and control level. As the vehicles

becomes larger and more agile, the higher the impor-

tance of modeling or estimating these forces.

A common aerodynamical effect is Blade Flap-

ping that occur mostly when the quadcopter flies in

horizontal translational motion. The advancing blade

of the rotor generates more lift compared to the re-

treating blade which causes inconsistency in the gen-

erated lift and therefore creating oscillation in the ro-

tor blade. This results in shift of the effective thrust

vector. Mathematical modeling of blade flapping

and other aerodynamical effects depends on generated

thrust, rotor size and shape and material properties.

Flow Simulation Toolbox in SolidWorks is used to

generated a table of forces and moments with differ-

ent initial conditions of quadcopter attitudes and ro-

tational speed. The solvers computes the forces and

torques in the three direction F

x

, F

y

, F

z

, τ

x

, τ

y

, τ

z

.

The aerodynamical effect is calculated by subtracting

the rotor thrust and toques from the total values.

An Automated Quadcopter CAD based Design and Modeling Platform using Solidworks API and Smart Dynamic Assembly

125

Figure 3: Airspeed Cut Plot Around Propellers (Red: Max-

imum Speed, Blue: Minimum Speed).

Figure 4: Air Profile Around Quadcopter (Red: Maximum

Speed, Blue: Minimum Speed).

3 DYNAMICAL QUADCOPTOR

ASSEMBLY AND SMART

MATING

In this section, the main idea behind automating the

process of CAD design and quadcopter modeling is

presented. The objective is to generate the 3D draw-

ing of each part and this involves geometrical data,

material specifications and visual appearance. Once

the model of every part is generated, the parts are au-

tomatically assembled introducing what we call smart

mating where each generated part is coupled with de-

fault or customized geometrical mating file. This al-

lows parts being connected properly to form the as-

sembly. Some less common parts may have multiple

mating configurations or no default configuration.

3.1 Component Representation

A Quadcopter system consists of several components

attached mainly to the frame. In order to make rep-

resentation easier, different classes of components is

introduced where each class has its special descriptive

parameters that are entered by the user or automati-

cally generated if a hardware part is selected from the

available library. We classify the components as fol-

lows:

• Frame: its parameters includes size, hub length,

hub width, arm width, rotor mount diameter, legs

length, thickness, material, color.

• Engine: main parameters are mass, maximum di-

ameter, minimum diameter, hub size, color, wire

length, wire type, hole spacing, shaft, hight, KV,

input voltage.

• Propeller: parameters are material, hub size,

length, width, pitch.

• Power: this class involves power components like

batteries, ESCs and electronic controller power

module.

• Hardware A: this class contains other additional

components that is commonly present in every ve-

hicle such as flight controller, telemetry module

and RC receiver.

• Hardware B: other additional sensors are present

in this class such as GPS, range finders and cam-

eras.

The components in the last three classes share some

similar parameter descriptions with some few differ-

ences. It is important to note that not all parame-

ters need to be entered by the user and those missing

values are determined from some ratios of the other

parameters. Certain design rules are predefined for

each class and every component in the class to closely

match reality in terms of geometry and visual proper-

ties. Parameters related to material specifications or

hardware interface are essential for some classes like

materials of Frame and Propellers that are important

for the mass and inertial properties as well as motion

analysis and flow simulation. Length of the propeller,

diameter of frame, propeller shaft are examples of pa-

rameters that are important for hardware comparabil-

ity to prevent sizing or overloading issues. A template

of the design and the model parameters are the two

main components, the desired part can be generated

using one of the following approaches:

1. Full model drawing: it requires considerable

amount of time and engineering design experi-

ence. The model can be made with realistic ge-

ometrical and appearance details.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

126

2. Template manual modification: as part of this

work, a CAD drawing and properties file is cre-

ated. One can update this template file with di-

mensions, mass and material properties of the de-

sired part design.

3. Macro file modification: if a Macro file exists for

the part template, the user can modify the param-

eters in the Macro code to match desired model.

It requires familiarity with Macro file format and

the 3D design software currently in use.

4. Solidworks API: the application programming in-

terface offers interacting with the engineering de-

sign software through another compatible appli-

cation or standalone applications. API is utilized

in this work to automate the process of generating

the model of each part and many other tasks.

The process of automated part generation start by get-

ting the part specifications/parameters from its techni-

cal description, e.g. webstore, datasheet, ...etc. This

data is entered by the user in an application with

Graphical User Interface (GUI) prompting the user

to enter the proper data. The software uses this en-

tered data and the selected hardware class to gener-

ate the parameter description file. Once generated,

these parameters are used to generate a custom call

to the design software (Solidworks is used in this

work) through its API to generate the model from

scratch to satisfy the entered parameters or modify

one of default templates if they exist within the hard-

ware database. This process is illustrated in the chart

shown in (5).

3.2 Smart Mating

Assemblies and parts are the building blocks for cre-

ating the final model of the vehicle. Assemblies are

created by mating parts; introducing geometrical re-

lations between different entities of the parts such as

surfaces, faces, edges and vertices. This is usually

done using assembly mating utility within the design

software. To automate this mating process, one can

introduce rigid geometrical relations between parts

where a specific face/edge from one part is mated with

another compatible entity in the other part. Although

this approach is doable through the software API au-

tomatically, it poses multiple challenges.

The number of possible sub-assemblies grows

with the number of components option which loads

the database further and slow down the process. Ad-

ditionally, it limits modularity of the design which

would make creating a custom model or a sub-

assembly that does not exist in the library more time

consuming and less immune to mating or rendering

errors due to irregularities in some parts’ geometry.

Smart mating is a virtual massless properties that

can be for instance surfaces and edges introduced for

every part. The purpose of these virtual entities is in-

troducing one of multiple mating configurations. Mo-

tors are mounted to the frame using their own mount-

ing bases while propellers are mounted to propeller

through circular alignment of their hubs and the mo-

tors’ hubs.

This configuration of parts can be seen as a pre-

conditioning step to allow smoother automated gen-

eration of the quadcopter assembly. It allows proper

universal way to integrate parts in different vehicles

and early detect incompatibility of parts and sub-

assemblies and therefore prevent possible rendering

errors in the design or degraded performance. Modu-

larity is another strength of this approach where parts

can be exchanged within the software and multiple

combinations can be tried.

Each part to be generated requires two descriptor

files: the first includes the parameters of the compo-

nent that are related to physical and appearance prop-

erties as illustrated in (3.1). The second descriptor

includes information regarding the virtual mating en-

tities and specifies default and alternative configura-

tions. It is essential for the mate descriptor to include

the class of the component and part type.

The process starts with having at least two compo-

nents with their parameters files created as mentioned

previously. The software will start searching for the

mating data of each component. If these files does not

exist, then it is created with the assumption that part

is in the default orientation. If the files exist, then the

software will examine the type of available mates and

its compatibility with the other mates. This insures

the proper parts are being mated. Figure (6) shows an

example of mating surfaces in an airframe.

Each virtual entity in the smart mate file is as-

signed a class and type of hardware. For instance,

a quadcopter frame mating configuration file would

have several virtual surfaces to mount other different

types of hardware. None of these surfaces correspond

to propellers as they are not in physical contact with

the frame. When mating multiple components to the

frame, the software searches for the mate identity in

the frame and match it with its corresponding peer in

the other parts.

4 AUTOMATED QUADCOPTER

MODEL GENERATION

The developed software tool that automate the full

design and modeling process described in the previ-

ous two sections. The system structure is first dis-

An Automated Quadcopter CAD based Design and Modeling Platform using Solidworks API and Smart Dynamic Assembly

127

Figure 5: Automated Component Generation Process.

Figure 6: RISC Pixhawk Frame (Top View) With High-

lighted Smart Mating Surfaces.

cussed then the friendly user interface application

is illustrated. Some details of how the Solidworks

API works and the analysis toolboxes are deliberately

omitted here for the sake of focusing the discussion

on the proposed system and developed software, more

details on explaining the functionality of these can be

found in (Kurowski, 2013), (Matsso, 2013).

4.1 System Structure

The system aims to simplify the process of acquir-

ing detailed models that improve the mathematical

and visual description of a model under control study.

It relieves the need for design experience and system

identification using the an automated CAD based 3D

design and modeling. The overall system structure

is shown in figure (7). The system consists of three

main components, User interface, Software layer that

is the main novelty of this work and the CAD based

design and modeling which is handled by Solidworks

3D design utility, solvers and simulation tools. The

first component is presented in (4.2). The third com-

ponent is discussed in the first 2 sections. In this sec-

tion, the software layer is discussed. Four main func-

tions are performed within this layer.

• Hardware Configuration Files: these are the de-

scriptive .XML files of every part in the assembly.

The content of each file may differ depend on the

class and type of hardware as described earlier.

The file contains physical and geometrical param-

eters of the hardware it is describing. It worths

noting that this file can be generated by typically

reading input data from the user but it can also

be constructed from the CAD models if they ex-

ist. The smart mating configuration files are also

generated for every components to include the de-

scription of the correct orientation and attachment

interface for each part in the assembly.

• Hardware Database: it includes generic compo-

nents and off-the-shelf components 3D designs,

parameters and mating descriptors. This allows

the user to rapidly prototype or customize par-

tially or fully the desired design. The CAD de-

signs are saved as model files to allow quick re-

trieval for components in a different assembly and

dynamic Macros to allow easy modifications of

the components for utilization in updated models.

This database save tremendous amount of time

and computational cost by avoiding performing

the designs from scratch every time the user run

the application.

• Solidworks API Interface: this is the core bridg-

ing function between QuadCAD application and

Solidworks engineering tools (Shen, 2014). The

first basic functionality is 3D modeling of parts

by reading the hardware parameters files and con-

verting them to geometrical programming com-

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

128

mand. Then the mating data is be integrated

through introducing virtual geometrical features

to the designed parts. After that, the assem-

bly function scans the parts configuration files

and mating properties and try to fix any simple

incompatibility by introducing dynamic adapters

between parts and generate warning or errors if

serious hardware conflicts occur between the se-

lected components. The parts are mated using

the smart mate interface in every part to create

sub-assemblies and the main assembly. The mass

properties are then calculated before starting the

motion analysis and flow simulations. The user

choose to perform the CAD based modeling and

select operating conditions and accuracy of anal-

ysis.

• Simulation File Generation for Matlab Simscape:

the application received the simulation results

for the CAD utility and generate model parame-

ters m-file and nonlinear dynamical model of the

quadcoptor utilizing the vehicle equations of mo-

tion. In addition, the CAD models and Simscape

simulation files are generated using a modified

version of the files produces by the Solidworks-

Matlab add-on.

Additional functions related to operating system and

computation and memory resources handling in ad-

dition to interfacing and file processing functions are

not discussed in this context.

4.2 User Interface

The application is developed using Microsoft Visual

Studio Visual Basic and the graphical user interface is

developed using VS WPF (Schneider, 2013). The cur-

rent version run on Windows 7 OS and later. The inter-

face shown in figure (8) is simple self descriptive that

consists of multiple tabs. The first three tabs where

the user inputs hardware specifications for parts or

choose off-the-shelf or previously saved components

instead. If the user skipped one of parts, then the soft-

ware add this part to the assembly if it essential and

neglect it if it is optional. In either case the user is

given a warning for the missing or mismatched com-

ponents. In the Assembly Setting tab, the options to

select default smart mating or custom mating can be

found with other special options to choose one config-

uration in case the component has multiple mounting

possibilities.

Modeling Setting tab contains the analysis and

CAD simulations parameter. The user can here select

the option to apply all system identification related

simulations or select some of them. This part is the

most consuming for computer resources and gener-

ation time especially if high accuracy high resolution

design simulation is required. The process of generat-

ing the CAD model of a quadcopter with good model

identification last for 13-16 hours on an i7 processor

and 8GB RAM laptop machine. This time exponen-

tially increases with the increase in mesh resolution

or solvers constrains.

The Simulation Setting Tab lists the options that

are related to generating the Matlab/Simulink files

with 3D Simscape model with the available simula-

tion setup and assumption. The quadcopter model

assumptions are chosen in this part. The user can

choose to generate the 3D model with its parameters,

the mathematical model or both.

4.3 Simulation Files Generation for

Matlab Simscape

The generated matlab simulation files are combina-

tion of CAD models converted to a format compatible

with Simscape simulation utility. Simulink models

are generated for the control purpose. These are either

models describing the physical system components

for Simscape simulations or mathematical models of

quadcopters for model validation or model based con-

trol design purposes. Other files involve environmen-

tal and gravitational effects in the simulation environ-

ment, system parameters and plotting functions.

The generated simulation setup allows the user

to focus on the design and assessment of controllers

for multirotors vehicles. The inputs to the simulation

model are the rotational speed of the rotors s

1

, s

2

, s

3

,

and s

4

and the outputs are 12 states, 6 translation mo-

tion positions and velocities and 6 rotational motion

attitude and rotational speeds. In addition to stability

and tracking controllers, one can consider advanced

robustness analysis against external disturbances or

operating under partial or full hardware failure. This

can be done through examining different configura-

tions of the Simscape simulation.

5 CONCLUSION AND FUTURE

WORK

An automated software system for the design and

modeling of quadcopter UAV is presented. The appli-

cation is build with a user friendly interface to atten-

uate the difference between quadcopter simulations

and actual experimentation. The system with its hard-

ware library allows the user to rapidly build custom

models with realistic components specifications and

visual representation. Benefiting from the state of the

An Automated Quadcopter CAD based Design and Modeling Platform using Solidworks API and Smart Dynamic Assembly

129

Figure 7: Automated Quadcopter Design and Modeling System Overview.

Figure 8: QuadCAD Design and Modeling Software Interface.

Figure 9: Simscape/Simulink Quadcopter Simulation.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

130

art CAD based design and analysis tools, we build

and easy to use method to generate high quality mod-

els with that do not require prior expertise with this

class of engineering tools. User can iterate between

control design and hardware system examining.

This software is being developed and maintained

by the Robotics, Intelligent Systems and Control Lab

(RISC) at KAUST. We intend to make this project

available for community through an online database

for designers and researchers collaboration. Although

this system is built based on Solidworks API and the

its tools, the concept can be generalized to other CAD

software or standalone system if the appropriate utili-

ties and solvers are available.

Further improvements can be done on the opti-

mization of the application performance and cross

platform availability. Additional more detailed mod-

eling of quadcopter can be considered or simpler

models can be investigated for control development

purposes. Beside the main objective of the system

which is simplifying design and modeling for control

development, it can be used as a hardware advisory

system where users examine different combination of

components and the effect on performance. Further

functionality can be added to the Matlab simulation

environment and other simulation platforms can be

supported.

REFERENCES

Mahony, R., Kumar, V., & Corke, P. (2012). Multirotor

aerial vehicles. IEEE Robotics and Automation mag-

azine, 20(32).

Domingues, J. M. B. (2009). Quadrotor prototype. Unev-

ersidade Tecnica deLisboa. Dissertacio.

Corke, P. I. (1996). A robotics toolbox for MATLAB. IEEE

Robotics & Automation Magazine, 3(1), 24-32.

Rohmer, E., Singh, S. P., & Freese, M. (2013). V-

REP: A versatile and scalable robot simulation frame-

work. In Intelligent Robots and Systems (IROS), 2013

IEEE/RSJ International Conference on (pp. 1321-

1326).

Simscape, Matlab Toolbox (2016). Natick, Massachusetts:

The MathWorks Inc..

Zhang, X., Li, X., Wang, K., & Lu, Y. (2014). A survey

of modelling and identification of quadrotor robot. In

Abstract and Applied Analysis (Vol. 2014). Hindawi

Publishing Corporation.

Kuantama, E., Craciun, D., Tarca, I., & Tarca, R. (2017).

Quadcopter Propeller Design and Performance Anal-

ysis. In New Advances in Mechanisms, Mechanical

Transmissions and Robotics (pp. 269-277). Springer

International Publishing.

Kurowski, P. (2013). Engineering Analysis with SolidWorks

Simulation 2013. SDC publications.

Matsson, J. E. (2013). An Introduction to SolidWorks Flow

Simulation 2013. SDC publications.

Sa, I., & Corke, P. (2012). System identification, estima-

tion and control for a cost effective open-source quad-

copter. In Robotics and automation (icra), 2012 ieee

international conference on (pp. 2202-2209). IEEE.

Shen, H., Yang, Y., & Zhang, J. (2004). SolidWorks API

methods based on VB technology [J]. Computer

Aided Engineering, 4, 014.

Schneider, D. I. (2013). An Introduction to Programming

Using Visual Basic 2012. Prentice Hall Press.

Koenig, N., & Howard, A. (2004). Design and use

paradigms for gazebo, an open-source multi-robot

simulator. In Intelligent Robots and Systems,

2004.(IROS 2004). Proceedings. 2004 IEEE/RSJ In-

ternational Conference on (Vol. 3, pp. 2149-2154).

IEEE.

Meyer, J., Sendobry, A., Kohlbrecher, S., Klingauf, U., &

Von Stryk, O. (2012) Comprehensive simulation of

quadrotor uavs using ros and gazebo. In International

Conference on Simulation, Modeling, and Program-

ming for Autonomous Robots (pp. 400-411). Springer

Berlin Heidelberg.

An Automated Quadcopter CAD based Design and Modeling Platform using Solidworks API and Smart Dynamic Assembly

131