Multi-disciplinary Optimization with Standard Co-simulation

Interfaces

Marco Inzillo

1

and Carlos Kavka

2

1

DIMES, Università della Callabria, via Pietro Bucci, Arcavacata di Rende, 87030, Cosenza, Italy

2

Department of Research and Development, ESTECO SpA, Area Science Park, Padriciano 99, 34149, Trieste, Italy

Keywords: Functional Mock-up Interface, Numerical Simulations, Multi-objective Optimization, Multi-disciplinary

Optimization, Co-simulation.

Abstract: Numerical simulations and optimization are at the base of the design process of modern complex engineering

systems. Typically, individual components are simulated by using highly specialized software tools applicable

to single or narrow domains (mechanical stress, fluid dynamics, thermodynamics, acoustic, etc.) and then

combined together in order to build complex systems to be co-simulated and optimized. This distributed

engineering development process requires that model components must be developed in such a way, that they

could be easily interchanged between different departments of the same company, may be geographically

distributed or even between independent companies. This position paper provides a short discussion about the

currently available standards and presents work in progress concerning the definition of new standards for the

interconnection of complex engineering systems and its optimization as required in modern engineering

design. The paper is complemented with a few examples which provides a base for further discussion.

1 INTRODUCTION

Modern engineering extensively relies on numerical

simulations, which can be used in the design phase of

almost any product. This process is typically handled

by highly specialized software applications, each of

which focuses in a single or a narrow set of

disciplines. With so large number of tools, a support

for the exchange of simulation models between

suppliers is required. The best possible answer to

integration and interoperability problems is the

adoption of a common standard. In particular, the

Functional Mock-up Interface (FMI) is emerging as

the leading industry standard to support model

exchange and co-simulation (Blochwitz, 2011). Its

main feature is the encapsulation of the different

model executors in predefined shells (Functional

Mock-up Units or FMUs) which provide all required

operations and data structures supporting interaction

and orchestration services. The standard is well

defined, widely used, and many support software

tools are provided in order to create FMUs or to link

them into other applications, facilitating the design of

FMI compliant software applications (Modelica,

2010). The co-simulation aspects of the FMI standard

focus on the interaction among models by following

a master-slave architecture, where the FMUs are the

slaves and an ad-hoc algorithm implements the

master logic. The standard does not impose a specific

master algorithm, but a significant number of

algorithms and techniques which cover many

industrial scenarios are provided in the literature

(Bastian, 2011) (Van Acker, 2015). The lack of a

defined master algorithm in the FMI standard is an

advantage in one sense, since a specific algorithm

with the required trade-off between complexity and

accuracy can be used for a specific industrial design

process. However, carefully design is essential to

avoid non-deterministic or unexpected behaviours as

noted for example in (Schierz, 2015).

Nowadays, globalized market requires industrial

engineering design strategies to be extremely

competitive, with the consequence that numerical

simulation by itself is not enough to successfully

accomplish industrial requirements. It necessarily has

to be combined with optimization techniques, which

are used to guide the simulation process in order to

obtain the best possible designs. Current engineering

design problems require to handle simultaneously

multiple objectives at the same time and consider also

multiple disciplines. Since the design objectives can

in many cases be contradictory between themselves

Inzillo, M. and Kavka, C.

Multi-disciplinary Optimization with Standard Co-simulation Interfaces.

DOI: 10.5220/0006472704530458

In Proceedings of the 12th International Conference on Software Technologies (ICSOFT 2017), pages 453-458

ISBN: 978-989-758-262-2

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

453

(think on power and fuel consumption in engine

design for example), the optimization strategies are

required to be multi-objective in order to consider all

objectives at the same time. Instead of producing a

single design as the result of the optimization process,

the multi-objective optimization (MOO) methods

produce the so-called Pareto front, which corresponds

to the set of solutions which represents the best trade-

off between the different objectives (Deb, 2014). A

multi-disciplinary engineering design process

requires also the use of Multi-Disciplinary

Optimization (MDO) methods to exploit the

interactions between the disciplines during

optimization, instead of considering each discipline

independently of the others.

The paper is organized as follows. Next section

presents related work on the use of the FMI standard

in the context of co-simulation and optimization.

Section 3 discusses research issues complemented

with current efforts to standardize the model structure

and interconnection patterns for the definition of

multi-component systems, while section 4 presents

two optimization examples in a multiple FMI and co-

simulation system. The paper completes with

conclusions and discussions about future research

directions.

2 RELATED WORK

Recently, the Modelica Association project “System

Structure and Parameterization” (SSP) has started

efforts to define a standardized format for the

connection of a set of FMU models (Köhler, 2016).

This standard is expected to define not only the

structure of the system, but also the parameter

definition of the system as a whole and its associated

experimental setup. Interestingly, a few open and

commercial tools are presenting in their web pages an

indication of preliminary support for the SSP standard

even if its development is yet ongoing.

Many algorithms and techniques have been

proposed in literature to implement the co-simulation

master algorithms, considering many different

scenarios and other aspects, like for example the co-

simulation of FMUs with different time rates (Van

Acker, 2015) and systems that include feedback loops

(Broman, 2013). Typically, the algorithms are

presented in the literature in terms of pseudocode

listings or non-executable diagrams, which can

eventually be used to generate code (Aslan, 2015)

(Galtier, 2015) (Cremona 2016). An exception is

(Campagna, 2016), where the algorithms are

represented with BPMN 2.0, a standard business

process formalism (OMG, 2017) which includes both

a graphical diagram and an executable representation.

The use of FMI as an automatic deployment

model and its integration in the modeFRONTIER

multi-objective and multi-disciplinary optimization

environment was presented in (Batteh, 2015). In this

work, the authors demonstrate the advantages of

using the FMI standard for model exchange in the

robust design of a heat exchanger, in the optimization

of an electric vehicle range and a hydraulic crane.

3 RESEARCH ISSUES

There are many ongoing research activities which

address open issues like multi-model exchange

standards, master co-simulation algorithms definition

and their role when combined with multi-objective

and multi-disciplinary optimization.

Concerning model exchange, a large number of

software tools support import and export operations

in FMU format, making FMI the de-facto exchange

standard in industrial engineering design today. One

important limitation of the FMI standard is that it can

be used to incorporate only a single model into an

FMU file. The work of the SSP Modelica project (as

presented in the previous section) is definitely one of

the best news for the engineering design community,

since a new official standard defined on top of FMI

will certainly provide an adequate framework for

formally specifying multiple FMI collaboration.

However, there is yet no clear indication if the

standard will cover also the co-simulation master

definition or it will just stop at the parameter

exchange and model structure. An adequate co-

simulation master algorithm is essential to guarantee

stability and accuracy in the co-simulation process

(Schierz, 2015). This aspect is particularly important,

since FMI for co-simulation does not define a

standard graphical or textual representation of a co-

simulation scenario. In particular, it does not specify

a way to describe how the involved FMUs are

coupled. The specification only states that subsystem

composition may be performed in different ways and

typically results in some form of a component-

connection graph structure (Modelica, 2011).

However, the way in which the different sub-systems

are orchestrated by the master algorithm, combining

discrete and continuous-time dynamics is left to the

algorithm definition provided by the co-simulation

tool. As mentioned in previous section, the BPMN 2.0

standard, which includes a graphical representation

and a directly executable representation, provides an

interesting approach for master algorithms definition.

ICSOFT 2017 - 12th International Conference on Software Technologies

454

The main advantage of this approach is that it makes

easy to understand, maintain and enhance the master

algorithms, which are not just simply hardcoded but

are made available in a standard format (Campagna,

2016).

Other important research issue concerns

optimization, which plays a major role in current

engineering design where systems are simulated by

using numerical models. The FMI standard provides

a well-defined interface, which can be used by

optimization tools to interact with the numerical

models. However, if the system under design is

composed of a number of sub-components, a kind of

global instance of the whole system is required in

order to handle all co-simulation and orchestration

aspects. The optimization system can then interact

just with this global instance, setting not only

individual FMU parameters, but also system-wide

parameters covering global settings. By including

information from all subsystems into a single

configuration file, the complete system becomes a

kind of black-box accessible from the outside world

by just specifying the values of the parameters and the

operations requested, getting back the values of

metrics when simulation is completed. The

discussions currently going on in the Modelica SSP

project are a good step in this direction.

4 EXAMPLES

This section introduces two simple examples, a work

in progress expecting to contribute to discussions on

the use of FMI, co-simulation and optimization in

engineering design, supporting a required discussion

on procedures, the use of standards and industrial

requirements.

All examples have been prepared with

OpenModelica for model definitions (OpenModelica,

2017), FMI SDK and Modelon FMI library for FMI

interaction (Modelica 2017), and modeFRONTIER

as the optimization tool (Esteco, 2017).

Since the SSP standard is not yet defined, a

custom XML file definition has been used in these

preliminary examples to specify the interaction

between the optimizer and the simulated system. Of

course, when a standard defined by the SSP project

will be approved, the format defined by the standard

will be used in the forthcoming research activities.

The currently proposed XML file contains 5 sections.

The first indicates the individual models that define

the complete system with one entry for each FMU.

The second section defines the connection patterns

between the different FMUs. The third section

contains the global parameters of the whole system,

the fourth section the individual parameters for each

FMU and the last section the list of outputs (or

metrics) to be extracted at the end of the co-

simulation process. This file can be complemented

with a section on configuration parameters for the co-

simulation algorithm, indicating also the required co-

simulation approach (different time steps, feedback

support, etc.).

4.1 Single Discipline Multi-objective

Optimization

The first example consists in the multi-objective

optimization of a single system with no co-simulation

requirements. The system is a well-known electrical

full-wave rectifier, which generates a DC voltage

starting from standard AC voltage (see Figure 1). The

system contains four diodes to perform the wave

rectification process (identified with the label D), and

a capacitor (labelled as C) across the load resistance

in order to reduce the ripple of voltage variations.

Figure 1: The full wave rectifier. Note the four diodes

bridge (D), a capacitor (C), the AC generator on the left and

the DC voltage sensor on the right.

While this example is very modest in electronic

terms, it has been selected since it simple enough to

illustrate the concepts involved in this research. As

mentioned before, starting from an alternate voltage,

the objective is to produce a rectified continuous

voltage.

Figure 2: Voltage produced as result of the rectification

process.

Figure 2 shows the positive voltage cycles and on

top of them, the output produced by the system as the

result of the rectification process. Different values of

the saturation current of the diodes and the

capacitance of the capacitor generate different shapes

Multi-disciplinary Optimization with Standard Co-simulation Interfaces

455

of the curve. A good rectifier should provide a value

of the output voltage which is as steady and smooth

as possible, or in other words, the line on top of the

diagram should be as straight as possible.

In order to enhance the characteristics of the

rectifier, a multi-objective optimization is performed.

The optimization problem consists in finding the best

designs, by varying the values of the diodes saturation

current and capacitor capacitance, which generate a

voltage that is as near as the target voltage as possible,

with a minimum peak voltage. The XML file defining

the system contains one single line to identify the

FMU model, the definition of the two parameters of

the system (diodes saturation current and capacitor

capacitance) and two output metrics (DC voltage and

peak voltages). By using an optimization algorithm,

in our experiment a genetic algorithm, the

optimization process generates and evaluates a

number of designs, producing as result a Pareto front

(see Figure 3), where the designs that corresponds to

the best compromise between the required DC

voltage and the peak voltages are shown and can be

selected.

Figure 3: The Pareto front as a result of the optimization

process. The points in red (or double circled) corresponds

to the best solutions, which maximize the voltage and

minimize the peak current.

4.2 Multi-disciplinary Multi-objective

Optimization with Co-simulation

The second example consists in the multi-objective

optimization of a system composed of four sub-

systems with co-simulation requirements. Three

systems belong to the electronic domain while one

belongs to the mechanical domain. In this example,

each one of these four subsystems, is defined in terms

of a single FMU. The objective is to get an electric

motor running at a certain target speed, which is

reached in the minimum possible time, by selecting

adequate parameter for the controller and the full-

wave rectifier. The model is shown in Figure 4 as a

box diagram. The first subsystem (labelled as

fullWaveRectifier1) is the rectifier presented in

section 4.1, which generates DC from standard AC

for power requirements, the second subsystem

(regulator1) is a voltage regulator which generates the

voltage required in order to control the speed of a

motor (see Figure 5), the third subsystem (motor1)

simulates the DC motor (see Figure

6

), and the fourth

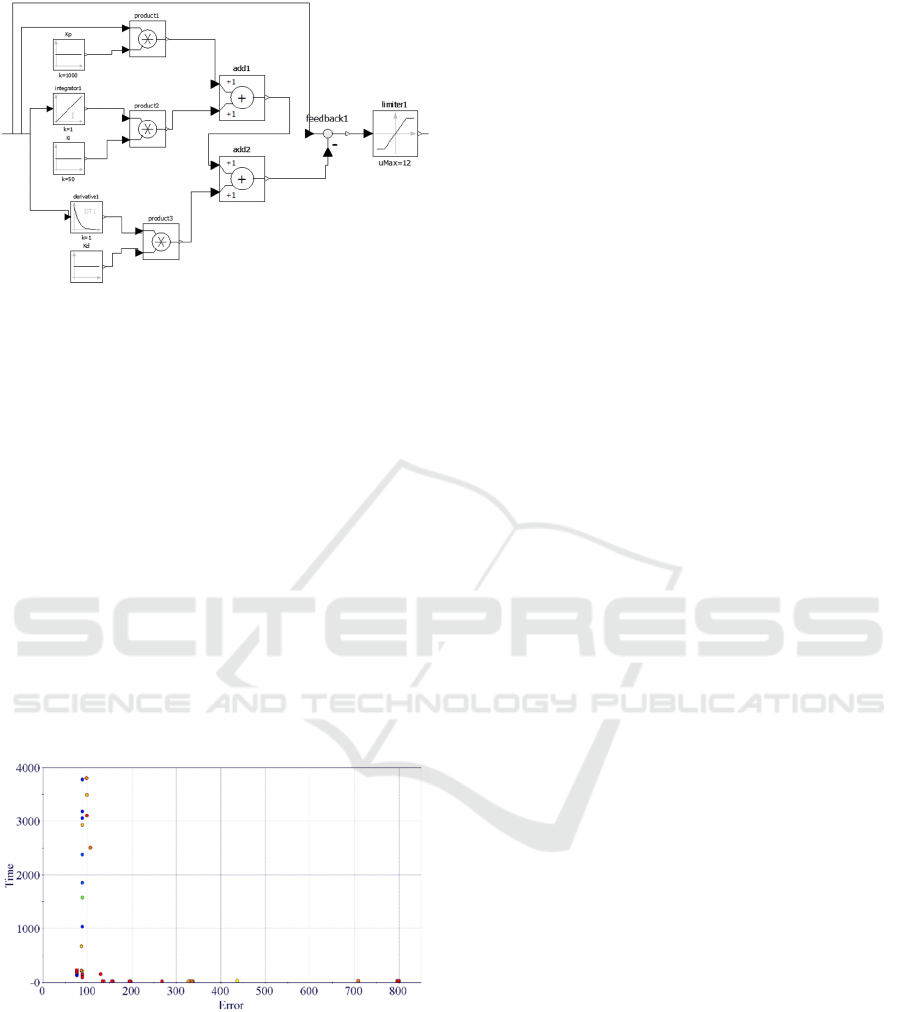

subsystem (newController1) is a typical PID

controller (see Figure 7 ), which controls the regulator

in order to keep the motor at the required speed.

Figure 4: The box diagram of the DC motor controller,

which consists of four subsystems, a full-wave rectifier, a

voltage regulator, a mechanical DC motor and a PID

controller.

Figure 5: The regulator, which produces the voltage

required to drive the DC motor based on the reference

voltage provided by the rectifier and the control signal sent

by the controller.

Figure 6: The DC motor, a mechanical system which rotates

at a speed defined by its input voltage and measured by a

speed sensor.

ICSOFT 2017 - 12th International Conference on Software Technologies

456

Figure 7: The PID controller, which has three coefficients

which are to be optimized in order to provide the right

control signals to the regulator.

Besides the two parameters for the DC rectifier

(described before), the controller introduces three

new parameters: the coefficients of the value of the

error (P), past values of the error (I) and the future

trends of the error (D), as usual in typical PID

controllers. Two objectives are considered for the

optimization: the error in the final velocity of the

motor, which has to be minimized, and the time

required for the motor to reach the required regime,

which also needs to be minimized.

The first section of the XML configuration file

used in this research experiments contains one line for

each FMU model. The connection section specifies

the connection pattern between the four models.

Beside rectifier parameters, the three PID coefficients

are specified in the parameters section.

Figure 8: The Pareto front as a result of the optimization

process. The points on the lower left corner corresponds to

the best solutions, which minimize the time required to

reach the expected regime while minimizing the error on

the speed.

Figure 8 shows the Pareto front obtained as results

of the multi-objective optimization process, with the

optimum designs which minimize both objectives

indicated in the lower left corner.

5 CONCLUSIONS

The FMI Functional Mock-Up Interface is a leading

technology which strongly encourages cooperation in

industrial engineering design. It provides a standard

interface for coupling physical models which can

eventually belong to different domains and may have

been developed with different simulation software

tools. FMI is particularly effective in addressing

problems like the export and the import of model

components in simulation tools for model exchange,

providing also a base for the standardization of co-

simulation interfaces in nonlinear dynamic systems.

However, even if some guidelines are presented in the

standard, no specifications for the co-simulation

master algorithm are formally defined.

The currently ongoing SSP project from Modelica

is definitely an effective attempt to defined a standard

approach to deal with multiple FMUs and their

parameters when complex systems with several

components have to be simulated and interchanged.

However, aspects like the master co-simulation

details are not yet fully considered.

This paper, as a position paper, raises some points

which are important to be considered in co-simulation

of complex systems, particularly in the context of

multi-objective and multi-disciplinary optimization.

REFERENCES

Aslan M., Oguztuzun H., Durak U., and Taylan K., 2015,

MOKA: An Object-Oriented Framework for FMI Co-

simulation, in Proceedings of the Conference on

Summer Computer Simulation, San Diego, CA, USA:

Society for Computer Simulation International, pp. 1–8

Bastian J., Clauß C., Wolf S., and Schneider P., 2011,

Master for co-simulation using FMI, in 8th

International Modelica Conference, Dresden.

Batteh J., Gohl J., Pitchaikani A., Duggan A., and Fateh N.,

2015, Automated Deployment of Modelica Models in

Excel via Functional Mockup Interface and Integration

with modeFRONTIER, in Proceedings of the 11th

International Modelica Conference, Versailles, France.

Blochwitz T., Otter M., Arnold M., Bausch C., Clau C.,

Elmqvist H., Junghanns A., Mauss J., Monteiro M.,

Neidhold T., Neumerkel D., Olsson H., Peetz J.-V., and

Wolf S., 2011, The Functional Mockup Interface for

Tool independent Exchange of Simulation Models, in

Proceedings of the 8th International Modelica

Conference.

Broman D., Brooks C., Greenberg L., Lee E. A., Masin M.,

Tripakis S. and Wetter M., 2013, Determinate Composi-

tion of FMUs for Co-simulation, in Proceedings of the

Eleventh ACM International Conference on Embedded

Multi-disciplinary Optimization with Standard Co-simulation Interfaces

457

Software, ser. EMSOFT ’13. Piscataway, NJ, USA:

IEEE Press, pp. 2:1–2:12.

Campagna D., Kavka, C., Turco A., Pogace B., Poloni C.,

2016, Solving time-dependent coupled systems through

FMI co-simulation and BPMN process orchestration,

Proceedings of the 2016 IEEE International

Symposium on Systems Engineering (ISSE),

Edinburgh, UK.

Cremona F., Lohstroh M., Tripakis S., Brooks C., and A.

Lee E., 2016, FIDE: An FMI integrated development

environment, in Proceedings of the 31 Annual ACM

Symposium on Applied Computing, SAC ’16. ACM,

pp. 1759–1766.

Deb, Kalyanmoy, 2014, Multi-objective optimization, in

Search methodologies: introductory tutorials in

optimization and decision support techniques, Editors:

Burke E, Kendall G, Springer, pp. 403-449

Esteco 2017, modeFRONTIER: the multi objective and

multi-disciplinary optimization environment,

http://www.esteco.com/modefrontier.

Galtier V., Vialle S., Dad C., Tavella J.-P., Lam-Yee-Mui,

and Plessis G, 2015, FMI-based distributed multi-

simulation with DACCOSIM, in Proceedings of the

Symposium on Theory of Modelling & Simulation:

DEVS Integrative M&S Symposium, Society for

Computer Simulation International, pp. 39–46.

Köhler J., Heinkel H.M., Mai P., Krasser J., Deppe M. and

Nagasawa M., 2016, Modelica-Association-Project

System Structure and Parameterization – Early Insights,

Proceedings of the 1st Japanese Modelica Conference,

May 23-24, 2016, Tokyo, Japan, pp. 35-42

Modelica Association Project, 2017, Functional Mock-up

Interface for Co-Simulation, https://www.fmi-standard.

org.

OMG, 2017, The Business Process Model and Notation

BPMN 2.0 standard, http://www.bpmn.org.

OpenModelica, 2017, OpenModelica: the open source

Modelica based modelling and simulation environment.

https://www.openmodelica.org.

Schierz T., Arnold M., and Claus C., 2015, Co-Simulation

with communication step size control in an FMI

compatible master algorithm, in Proceedings of the

11th International Modelica Conference, Versailles,

France.

Van Acker B., Denil J., Vangheluwe H., and De

Meulenaere P., 2015, Generation of an Optimised

Master Algorithm for FMI Co-simulation, in

Proceedings of the Symposium on Theory of Modelling

& Simulation: DEVS Integrative M&S Symposium,

ser. DEVS ’15. San Diego, CA, USA, pp. 205–212.

ICSOFT 2017 - 12th International Conference on Software Technologies

458