Re-optimisation Control of a Fed-batch Fermentation Process using

Bootstrap Aggregated Extreme Learning Machine

Carolina Maria Cardona Baron and Jie Zhang

School of Chemical Engineering and Advanced Materials, Newcastle University, Newcastle upon Tyne NE1 7RU, U.K.

Keywords: Fed-Batch Processes, Fermentation, Neural Networks, Extreme Learning Machine, Re-optimisation.

Abstract: This paper presents using bootstrap aggregated extreme learning machine for the on-line re-optimisation

control of a fed-batch fermentation process. In order to overcome the difficulty in developing mechanistic

model, data driven models are developed using extreme learning machine (ELM). ELM has the advantage

of fast training in that the hidden layer weights are randomly assigned. A single ELM model can lack of

robustness due the randomly assigned hidden layer weights. To overcome this problem, multiple ELM

models are developed from bootstrap re-sampling replications of the original training data and are then

combined. In addition to enhanced model accuracy, bootstrap aggregated ELM can also give model

prediction confidence bounds. A reliable optimal control policy is achieved by means of the inclusion of

model prediction confidence bounds within the optimisation objective function to penalise wide model

prediction confidence bounds which are associated with uncertain predictions as a consequence of plant

model-mismatch. Finally, in order to deal with process disturbances, an on-line re-optimisation strategy is

developed and successfully implemented.

1 INTRODUCTION

The production of Saccharamyces cervisia

commonly called baker’s yeast follows a

fed-batch fermentation process. The massive

consumption of this product results in a competitive

market, making the maximization of biomass

production a key target to be achieved. The

complexity of the fermentation processes dynamics

makes this a non-trivial and challenging but also

very interesting optimisation problem.

The challenges that are faced in the optimal

control of biochemical processes comprise the

modelling of highly non-linear systems,

characterisation of those kinds of processes, and the

development of a reliable control policy capable of

providing good performance under plant model

mismatch. On one side, mechanistic models are

usually very difficult to be developed, due to the

complex dynamics of the growing microorganisms.

Therefore, data-driven modelling techniques based

on process operation data have been recently

developed to provide accurate solutions for process

modelling (Chen et al., 1995; Tian et al., 2002).

Nevertheless, typically the collection of process

operational data is limited, in part because of the

highly costs involved in the experiments for data

acquirement, coupled with the physical limitation to

measure certain key process variables.

Therefore, in the last decades, data-driven

modelling techniques based on neuronal networks

have been widely accepted as they can provide an

effective way to build accurate models based on

process operation data (Tian et al., 2001; Zhang et

al., 1997; Zhang and Morris, 1999; Zhang, 2005).

Certainly, the leading advantage of neural networks

is their ability to model complex non-linear

processes, which is perhaps achieved through their

parallel structure, which provides them with

excellent capabilities to store knowledge. It is not a

coincidence that neural networks resembles the

human brain in the sense that knowledge is learnt

from observations and stored in the form of inter-

neural connection strengths Noor et al. (2010).

Typically, neural network performance can be

affected by over fitting of the training data and their

generalization capabilities can be seriously

compromised, resulting in considerable prediction

errors when unseen data is presented to the network.

Furthermore, the speed of learning process is also

concerned, since typically the training process with

traditional feedforward training algorithms is very

Baron, C. and Zhang, J.

Re-optimisation Control of a Fed-batch Fermentation Process using Bootstrap Aggregated Extreme Learning Machine.

DOI: 10.5220/0006477601650176

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 165-176

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

165

slow, because all the parameters of the network need

to be tuned. Therefore, to address those common

drawbacks, a novel algorithm developed by Huang

et al. (2006), called Extreme Learning Machine

(ELM), provides an extremely fast learning speed,

coupled with better generalization capabilities in

comparison to traditional learning algorithms. In

ELM some of the network parameters are randomly

chosen, reducing the computational efforts in

network training. However, single ELM models may

lack robustness and give varying performance due to

the hidden layer weights are randomly assigned. To

address this issue, the idea of bootstrap aggregated

neural networks (Zhang, 1999) can be used in

developing bootstrap aggregated ELM. The use of

bootstrap aggregated neural networks is widely

recognized as an effective method to reduce the lack

of robustness in the models that is caused principally

due to over-fitting, enhancing the model

generalization capabilities (Ahmad and Zhang,

2006; Xiong and Zhang, 2005; Zhang et al., 2006;

Osuolale

and Zhang, 2017).

In the last decade, a reliable optimisation strategy

based on bootstrap aggregated neural network

models has been proposed by Zhang (2004), in

which a reliable optimal control policy is obtained

by means of the inclusion of model prediction

confidence bounds within the objective function of

the optimisation problem. The modified optimisation

objective function penalises wide model prediction

confidence bounds. In this way, an optimal control

can be successfully implemented in the actual

process without suffering from performance

degradation, which is commonly caused by plant-

model mismatch.

The rest of the paper is organised as follows.

Section 2 presents a feed-batch fermentation

process. Section 3 presents bootstrap aggregated

ELM. Modelling of the feed-batch fermentation

process using bootstrap aggregated ELM is

presented in Section 4. Section 5 presents reliable

optimisation control of the feed-batch fermentation

process. Both off-line optimisation and on-line re-

optimisation control are presented. Finally, Section 6

draws some concluding remarks.

2 A FED-BATCH

FERMENTATION PROCESS

The fed-batch fermentation process uses Baker’s

yeast as the basis reactant and the kinetic and

dynamic model is taken from (Yuzgec et al., 2009),

which gives a dynamic model based on mass

balance equations described by glucose, ethanol,

oxygen and biomass concentrations. The kinetic

model is represented by the following 12 equations

(Yuzgec et al., 2009):

Glucose uptake rate:

=

,

+

1−

(1)

Oxidation capacity:

,

=

,

+

+

(2)

Specific growth rate limit:

,

=

/

(3)

Oxidative glucose metabolism:

,

=

,

,

/

⁄

(4)

Reductive glucose metabolism:

,

=

−

,

(5)

Ethanol uptake rate:

,

=

,

+

+

(6)

Oxidative ethanol metabolism:

,

=

,

,

−

,

/

/

(7)

Ethanol production rate:

,

=

,

/

(8)

Total specific growth rate:

=

,

/

+

,

/

+

,

/

(9)

Carbon dioxide production rate:

=

,

/

+

,

/

+

,

/

(10)

Oxygen consumption rate:

=

,

/

+

,

/

(11)

Respiratory Quotient:

=

⁄

(12)

The mass balance equations describe the

dynamic of glucose, ethanol, oxygen and biomass

concentrations as follows (Yuzgec et al., 2009):

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

166

=

−

−

/

+

,

/

+

(13)

=−

+

∗

−

−

(14)

=

,

−

,

−

(15)

=

−

(16)

= (17)

=113

.

(18)

where C

s

, C

o

, C

e

, and C

x

represent, respectively, the

concentrations of glucose, oxygen, ethanol and

biomass, F and F

a

stand for feed rate and air feed

rate respectively, and A

R

denotes the cross-sectional

area of the reactor. The other symbols and values of

model parameters are given in Tables 1 and 2.

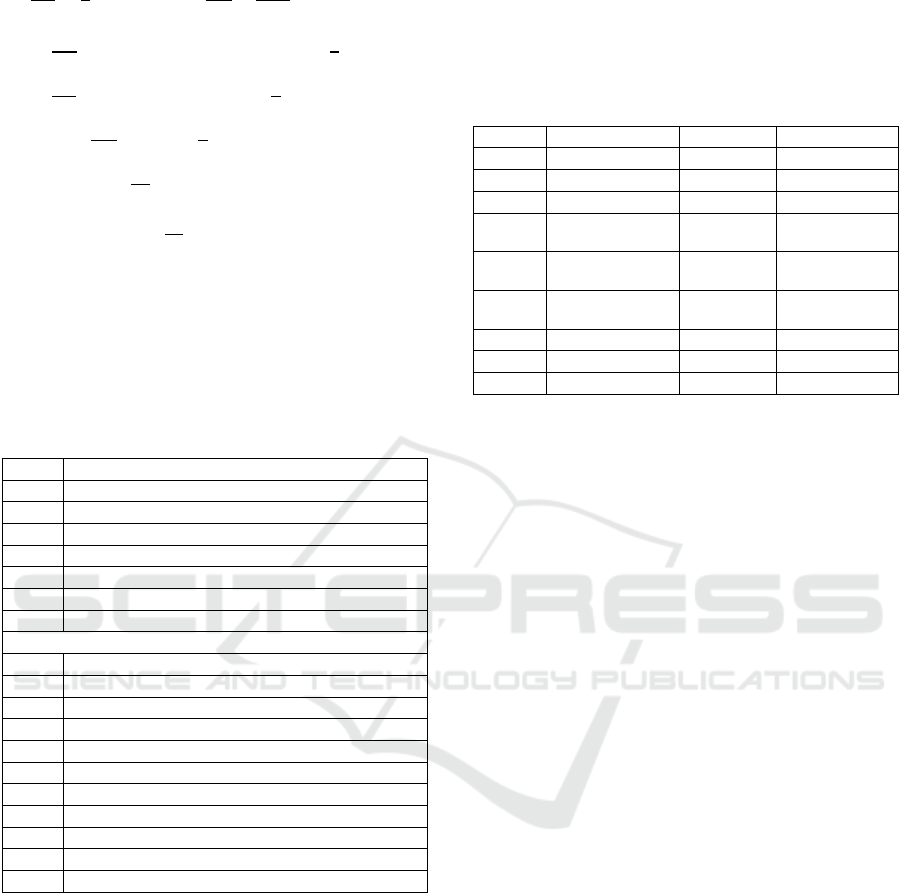

Table 1: Definition of process variables and parameters.

k

L

ao total volumetric mass transfer coefficient (h

-1

)

K

e

saturation constant for ethanol (gL

-1

)

K

i

inhibition constant (gL

-1

)

K

o

saturation constant for oxygen (gL

-1

)

K

s

saturation constant for substrate (gL

-1

)

Y

i/j

yield of component i on j (gg

-1

)

V volume (L)

μ specific growth rate (h

-1

)

Superscripts and subscripts:

* interface

cr critic

e ethanol

lim limitation

o oxygen

ox oxidative

pr production

red reductive

s substrate (glucose)

up uptake

x biomass

Based on the mechanistic model, a simulation

programme is developed in MATLAB. The

simulation programme is used to generate process

operational data and to test the developed models

and optimisation control policies. The batch initial

conditions considered for the simulation are taken

from (Yuzgec et al., 2009) and are summarized as

follows:

Initial conditions:

0

=

7gL

;

0

=7.8

gL

;

0

=

0gL

;

0

=15gL

;

0

=50000

Volume of the fermentor V

=100

Concentration of feed S

=

325

Final time: t

=16.5ℎ

Table 2: Numeric values of the parameters in the fed-batch

model.

K

e

0.1 gL

-1

Yx/e 0.7187 gg

-1

K

i

3.5 gL

-1

Qe,max 0.238 gg

-1

h

-1

K

o

9.6×10

-5

gL

-1

Qo,max 0.255 gg

-1

h

-1

K

s

0.612 gL

-1

Qs,max 2.943 gg

-1

h

-1

OX

SX

Y

/

0.585 gg

-1

Q

m

0.03 gg

-1

h

-1

red

SX

Y

/

0.05 gg

-1

S

o

325 gh

-1

Y

o/s

0.3857 gg

-1

*

o

C

0.006 gh

-1

Y

o/e

0.8904 gg

-1

A

R

12.56 m

2

Y

e/s

0.4859 gg

-1

μ

cr

0.21 h

-1

Y

e/o

1.1236 gg

-1

3 BOOTSTRAP AGGREGATED

EXTREME LEARNING

MACHINES

3.1 Extreme Learning Machine

Feedforward neural networks are very useful to

model complex non-linear systems and are capable

to estimate the relationships between process

variables just by learning from the training data

presented to the network through the execution of a

learning algorithm. Although the development of

neural network models is significantly more

practical and easier to implement than the classical

mathematical modelling approaches, the time

required to train neural networks using traditional

learning algorithms is considerably high, making the

learning a slow process (Huang et al., 2006).

Huang et al. (2006) mention that the attention of

researchers has been dedicated to the generalization

capabilities of neural networks using finite training

data sets. However, the training process typically

involves the tuning of all network parameters, i.e.

weights and biases, and in many cases requires

iterative computations until acceptable performance

has been achieved. To reduce the computational

burden in neural network training, Huang et al.

(2006) propose the ELM, a novel learning algorithm

for single hidden layer feedforward networks

(SLFN) in which some of the network parameters

are chosen randomly, reducing significantly the

learning speed while achieving good generalization

capabilities.

Re-optimisation Control of a Fed-batch Fermentation Process using Bootstrap Aggregated Extreme Learning Machine

167

Figure 1: A single hidden layer feedforward network.

The algorithm proposed by Huang et al. (2006) is

described as follows: a SLFN is built from distinct

pair of samples

,

with

=

,

,…,

∈

and

=

,

,…,

∈

. The SLFN has Ñ hidden neurons. The th

neuron in the hidden layer is connected with the

input layer through a weighting vector,

=

,

,…,

, and has activation function

and bias

. At the output layer, nodes are connected

through the weighting vector

=

,

,…,

that links the th hidden neuron with the output

nodes, which have a linear activation function.

=

∙

+

=

Ñ

Ñ

=1,2,…,

(19)

As long as the SLFN with

infinitely

differentiable can learn distinct observations,

which can be written as

∑

−

=0

Ñ

, then it

should exist a finite value for

,

,

that meet the

following:

∙

+

=

Ñ

=1,2,…,

(20)

The relationship given in Eq(20) can be written

in matrix notation as Eq(21), where is called the

hidden layer output matrix:

=

(21)

,…,

Ñ

,

,…,

Ñ

,

,…,

=

∙

+

⋯

Ñ

∙

+

Ñ

⋮⋱⋮

∙

+

⋯

Ñ

∙

+

Ñ

Ñ

(22)

=

⋮

Ñ

Ñ

and =

⋮

(23)

Then, the proposed algorithm (Huang et al.,

2006) suggests setting the parameters

,

randomly and compute the matrix H. Following that,

the remaining unknown variable in Eq(21) is only

the vector , which can be found as:

=

(24)

In the above equation,

corresponds to the

Moore-Penrose generalized inverse of the matrix ,

which can be found through several methods; for

instance, the orthogonal projection, singular value

decomposition (SVD), orthogonalization method

and iterative method. The last two methods are

avoided since iterations are undesired because can

increase the computation times of the ELM

algorithm. Instead, if

is non-singular, the

orthogonal projection method can be used, so

=

. Whereas, in many cases the matrix

tends to be singular, the SVD method performs

well under those circumstances.

3.2 Bootstrap Aggregated ELM

In the light of the techniques to develop the multiple

neural networks, Noor et al. (2010) identifies three

basic kinds of stacked neural networks, in which the

individual networks are combined using a particular

method. The first type is the multiple model neural

networks, characterized for using different training

data to build the individual networks; hence, training

data can relate to different inputs and include

information about a wider operation region. This

approach also allows different training algorithms

for each network. Conversely, the second category

employs the same data to train the individual

networks, but re-sampled or divided according to

one of the following algorithms: bootstrap re-

sampling (Efron, 1982), adaboost or ‘adaptive

boosting’ or randomisation. Finally, the third

category involves a selective combination of neural

networks, in order to reduce the error induced by

networks with poorest generalization capabilities.

With this in mind, the scope of this work is centred

in bootstrap aggregated ELM, known as BA-ELM.

As is mentioned by Zhang (1999), the principle

of stacked neural networks, shown in Figure 2, is to

develop several neural networks to model the same

relationship. Hence, model generalization capability

and accuracy can be improved as a result of a proper

combination of all networks, instead of just selecting

the “best” single neural network. The overall output

of a BA-ELM, expressed in Eq(1), is a weighted

combination of the individual networks outputs.

O

1

x

n

x

2

x

1

1

2

Ñ

...

β

11

Inpu

t

L

ayer Ou

t

pu

t

layer

...

1

m

...

β

1m

β

Ñ1

β

Ñm

O

m

Hidden layer

β

21

β

2m

activation function: g(x) activation function: linear

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

168

=

(25)

where,

is the BA-ELM predictor,

is the

th ELM,

is the aggregating weight for the th

ELM, is the vector of inputs and is the number

of ELM models. The selection of weighting

parameters is fundamental to achieve good

performance. In general, the simple approach taking

equal weights is enough to attain enhanced results.

However, aggregating weights can also be computed

using principal component regression (PCR), since it

is less sensitive to highly correlated data, which is

the case for the individual networks.

Figure 2: Bootstrap aggregated ELM.

Finally, an advantage in using BA-ELM is that

confidence bounds for model predictions can be

calculated from the individual network estimations

as follows (Zhang, 1999):

=

1

−1

;

−

;∙

⁄

(26)

where

corresponds to the standard error of the th

predicted value,

;∙

=

∑

;

⁄

and

is the number of ELM models. Under the

assumption that prediction errors are normally

distributed, the 95% prediction confidence bound

can be found as

;∙

±1.96

. Thus, more

reliable predictions are associated with small values

of

.

4 PROCESS MODELLING USING

BOOTSTRAP AGGREGATED

ELM

4.1 Data Generation and

Pre-Processing

Simulated process operational data were generated

from simulation. In total, 75 batches were simulated.

The feed profiles of these batches were obtained by

adding random variations to a base feed profile. The

batch time in divided into 17 equal intervals and the

substrate feed rate is kept constant in each interval.

Thus the feed profile can be represented by a vector

of 17 elements. The ELM model is of the following

form:

y=f(x

1

, x

2

, …, x

17

) (27)

where y is the biomass concentration at the end of a

batch, x

1

to x

17

are the substrate feed rates over a

batch.

Data pre-processing is carried out to remove

undesired information such as noise, outliers, non-

representative samples, etc. Data pre-processing

tools include for example normalization to scale the

data, filtering to cope with measurement noise,

removing trends and outliers to eliminate

inconsistent data that potentially will lead to wrong

results, etc.

4.2 BA-ELM Modelling

Once the data have been scaled to unity variance and

zero mean in the previous step, 80% (60 batches) of

data are selected for model building and the

remaining 20% (15 batches) are left as the unseen

validation data. Then, the original training set is here

re-sampled using bootstrap re-sampling with replace-

ment (Efron, 1982) to produce =50 different

bootstrap replication sets, which are going to be used

to train each one of the individual neural networks.

Specifically, the bootstrap re-sampling is a simple

technique in which, random samples (batches) from

the original data are picked. As a consequence, some

samples can be picked more than once and some may

not be picked at all. In this way, the learning informa-

tion presented to each network is slightly different,

which is the powerful concept of BAGNET (Zhang,

1999), since the networks do not learn exactly the

same information, they can complement to each other.

Figure 3 shows model predictions on the 15

unseen batches (validation data) and their respective

confidence bounds. It can be seen that the model

predictions are reasonably accurate. The SSE of the

individual networks on training and validation data

are shown in Figure 4. In general, from the graph it

can be seen that network performance on training data

is not always consistent with the performance on the

unseen validation data, since a network with a small

SSE value on the training data can have a large SSE

value on the validation data or vice versa, thus it is

evident that a single neural network is not robust

enough to produce accurate predictions.

x

ŷ

Σ

Re-optimisation Control of a Fed-batch Fermentation Process using Bootstrap Aggregated Extreme Learning Machine

169

Figure 3: Model predictions on validation data.

Figure 4: Model errors of individual networks.

Furthermore, the networks highlighted in colour

red in Figure 4 were removed from the stacked

network, under the criterion of being the worst

performing on training data. However, only 6 were

chosen because bad performing on training data does

not necessarily imply also poor performance on

unseen data; for instance, networks #12 and #21

were in the worst group, but those networks actually

have good performance on validation data. For this

reason, it is not advisable to remove a lot of those

bad performing networks, because some of those can

produce quite accurate results on validation data.

Conversely, the networks #13, #32 and #38

performed bad in both cases, thus it is appropriate to

remove the influence of those networks. Highlighted

in colour green, the minimum SSEs on training data

was 0.0767 due to the network #45, and 0.1501 for

validation data due to the network #50.

On the other hand, Figure 5 clearly shows the

advantage of stacking multiple neural networks.

Figure 5 shows the model performance of

aggregating different numbers of ELM, from 1 (the

first single ELM) to 50 (aggregating all 50 ELM

models). It shows the SSE values of BA-ELM with

different numbers of ELM models on the training

Figure 5: Model error of stacked networks.

and validation data. Thus, the highest error in both

cases occurs, as is expected, when just one network

produces the predicted value. Then, the error is

significantly reduced while more networks are being

combined. It is important to notice the consistent

pattern of SSE reduction on the training data and the

validation data. Additionally, the influence of the

removed networks can be seen in colour red, which

corresponds to the SSEs before those networks were

eliminated. Before removing the worst networks, the

minimum SSEs on training data was 0.0530 with the

contribution of 47 networks, and 0.2207 for

validation data with 28 networks added. After

removing the bad performing networks, the values

decrease to 0.0492 with the contribution of 37

networks on training data, and 0.2191 for validation

data with 37 networks added. On balance, the SSEs

were reduced in both training and validation data

just by means of an arrangement of multiple non-

robust models.

5 PROCESS OPTIMISATION

USING BOOTSTRAP

AGGREGATED ELM

5.1 Off-line Optimisation

The operation objective of the fed-batch

fermentation process is to produce as much product

as possible. Here the objective function J is defined

in terms of the neural network model, and

particularly in this study, the width of the model

prediction confidence bounds is included to improve

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

170

the reliability of the optimal control policy. The

optimisation problem can be written as follows:

min

=−

+

:

0≤≤3000

ℎ

⁄

≤

=100000

(28)

where

is the BAGNET output, which

specifically corresponds to the predicted biomass

concentration at the end of the batch

, =

,

,…,

is the vector of substrate feed rates

divided in hourly intervals;

is the standard error

of model prediction, and is a penalty factor for

.

Operational constraints are imposed, for instance,

the feed flow rate is bounded to maximum 3000

[L/h] and the volume of the total biomass is

restricted by the fermenter volume

. This objective

function is aimed to maximise the amount of product

while minimise the width of the model prediction

confidence bounds to achieve a reliable optimal

control policy.

The optimisation problem given in Eq(28) was

solved using the Interior-Point algorithm, available

in Matlab

®

Optimisation Toolbox, which is an

effective non-linear programming method, specially

for constrained problems.

Different values of were considered, in order to

analyse the influence of penalising wide model

prediction confidence bounds. Then, the optimal

control policy obtained for all the cases was applied

to the mechanistic model based simulation to

evaluate the performance. The results are presented

in Table 3, which contains the value of biomass

given by the mechanistic model, the neural network

prediction and the confidence bound

, for each

value of .

Specifically, the first entry in Table 3

corresponds to =0, which is equivalent to the

optimisation problem without considering the

confidence bounds in the objective function, in other

words, the unreliable control policy. In that case, the

neural network prediction for the final biomass was

75.788 [g/L] while the actual value (from

mechanistic model) was significantly lower 51.583

[g/L], and

=0.182. The notable difference

between the model prediction and the actual value is

in fact what motivated the researchers to include the

confidence bounds into the objective function, since

as has been evidenced, an optimal control policy on

the model can lead to poor performance when

applied to the actual process due to plant model

mismatches.

Thus, the value of was increased gradually in

order to analyse the effect of the penalisation term in

the objective function. Consequently, as is shown in

Table 3 with =1 a considerable improvement of

the actual value of biomass was achieved (59.544

[g/L]), which of course also results in the reduction

of the

to 0.167. After trying with further values of

, the actual final biomass concentration reached

71.236 [g/L] when =12, and the confidence

bounds were reduced to half its initial value; at the

same time, the neural network prediction decrease to

75.409 [g/L]. Therefore, from Table 3 it is possible

to appreciate that by means of increasing the

penalisation of wide model prediction confidence

bounds, the optimal substrate feeding profile

becomes more reliable, since the performance on the

actual process is not degraded.

Nevertheless, as the value of increases, the

meaning on the objective function in Eq(4) is to give

more importance to the reduction of the

, which as

a consequence, will sacrifice the maximisation of the

final product concentration. Therefore, there is an

inherently conflict between the two terms in the

objective function. Thus, while the error becomes

smaller, the maximisation term is reduced, as well as

the actual biomass. To make clear that point, further

values of were tried, corresponding to the last two

columns of Table 3; for =120, the value of

was notably reduced as well as the relative error

between the model prediction and the actual value.

However, this was achieved with a reduction in the

final biomass production. For this reason, the value

of =12 is selected as the optimal weighting

factor, since it offers a balance between both

objectives.

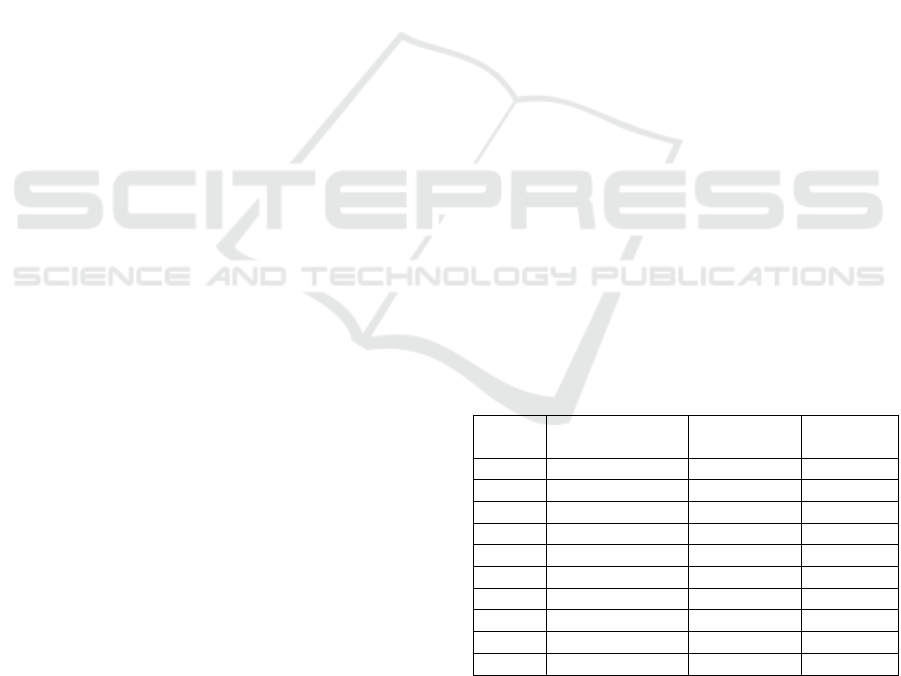

Table 3: Final biomass concentrations and

with respect

to λ.

λ

Mechanistic

model

BA-ELM

σ

e

0 51.583 75.788 0.182

1 59.544 75.781 0.167

2 65.733 75.763 0.155

3 68.959 75.739 0.145

5 70.203 75.682 0.130

6 70.521 75.650 0.125

9 71.163 75.520 0.107

12 71.236 75.409 0.096

45 71.163 74.549 0.059

120 70.943 72.702 0.036

Figure 6 shows the optimal feeding profiles

which correspond to the ‘unreliable’ optimal control

policy when =0 (continuous blue line) and the

improved profile when =12 (red dashed line).

Figures 7 and 8 present the profiles of biomass,

glucose, oxygen, ethanol and volume when the

Re-optimisation Control of a Fed-batch Fermentation Process using Bootstrap Aggregated Extreme Learning Machine

171

optimal substrate feeding profile is applied to the

process, which is in fact the simulation of the

mechanistic model.

Figure 6: Optimisation results: Control Policy.

Figure 7 shows the actual biomass profile and the

prediction value of the neural network. From this

figure, it is absolutely evident the poor performance

obtained with the unreliable control policy

(continuous blue line), since the final biomass

concentration value of 51.583 [g/L], is quite far from

the target prediction by the neural network ( ) of

75.788 [g/L]. Conversely, with the feeding profile

when=12 (red dashed line), although the final

value 71.236 [g/L], was not exactly the same as that

predicted by the neural network 75.409[g/L], the

control policy is more reliable since it is shown to

have good performance on the actual process. The

small box at the top left of the graph is a zooming

Figure 7: Optimisation results: Biomass.

window that shows closely the final value of

biomass with the enhanced profile, and shows that

the target without considering the confidence bounds

( ) was slightly higher than the target given by the

reliable profile ( ).

Moreover, Figure 8 shows the concentrations of

glucose, oxygen, ethanol and the reaction volume.

Particularly, it is interesting to analyse the ethanol

formation, since is considerably high when =0,

with a final concentration around 30 [g/L], which is

perhaps what is causing the drop of the final biomass

concentration. It must be remembered that, Ethanol

formation is undesirable, since is a by-product that

can deteriorate the amount and quality of the

product. Thus, the reliable control profile obtained

when =12, gives better performance because the

ethanol formation is successfully reduced to

concentrations around 10 [g/L]. Although this is not

directly included in the objective function, it is

implicitly related with the confidence bounds. In

other words, increasing the penalization of wide

Figure 8: Optimisation results: Glucose, Oxygen, Ethanol,

and Volume.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

172

other words, increasing the penalization of wide

confidence bounds, the optimisation algorithm tries

to find an optimal profile closer to the knowledge of

the network, which was trained with data with

reduced ethanol concentration. Therefore, the

optimal control policy is more reliable also in the

sense that it tries to generate a control policy that is

well known by all the individual networks.

5.2 On-line Re-optimisation

In a realistic scenario, besides plant model

mismatch, disturbances can also lead to poor

performance of the process when the optimal profile

is applied. To cope with this situation, the on-line re-

optimisation strategy (Xiong and Zhang, 2005) is

implemented by means of taking on-line

measurements of the process every 4 hours and re-

estimating the optimal control profile for the

remaining batch period.

Initially, the optimal profile is calculated off-line

for the complete batch time

=

,

,…,

,

which corresponds to the optimal profile found

earlier with =12. The process is operated with the

first two values f

1

and f

2

of

applied to the process

(mechanistic model based simulation). Then, when

two hours have elapsed, a measurement of the

process is taken and, a new optimal profile ids re-

calculate for the remaining stages in the batch,

which now starts from the third interval, and the

result is given as

=

,

,…,

. Then, the

process is fed with the new

,

,

,

, and 4

hours later the process is measured again. Similarly,

a new optimal profile is estimated but now starting

from the seventh interval

=

,

,…,

; just

,

,

,

are actually used because at the

end of tenth interval the process is measured once

again, and another re-optimised profile is found

=

,

,…,

; 4 hour later the last re-

optimisation is executed and the batch is finished

with this profile

=

,

,

.

In order to perform the re-optimisations, it is

necessary to develop four neural network models

that include as inputs the process measurements and

the feeding profile considering just the appropriate

feeding intervals. Of course, all the networks are

aimed to predict the biomass concentration at the

end of the batch. Therefore, the new BA-ELM

models can be written as follows:

=

2

,

, where

2

is the

biomass concentration measurement at =

2ℎ and

=

,

,…,

are the feed

flow rate intervals in

/ℎ

.

=

6

,

, where

6

is the

biomass concentration measurement at =

6ℎ and

=

,

,…,

are the feed

flow rate intervals in

/ℎ

.

=

10

,

, where

10

is the

biomass concentration measurement at =

10ℎ and

=

,

,…,

are the feed

flow rate intervals in

/ℎ

.

=

14

,

, where

14

is the

biomass concentration measurement at =

14ℎ and

=

,

,

are the feed

flow rate intervals in

/ℎ

.

Once the four neural networks were developed, the

process was simulated but a disturbance was

introduced by modifying one of the mechanistic

model parameters. The initial substrate

concentration

was change from its nominal value

of 325 gL

to 305 gL

, to pretend an unknown

behaviour of the process and validate the on-line

optimisation strategy.

From Table 4 it can be observed that, by means

of updating the control policy, taking measurements

of the process, was possible to modify the initial

deviation of the process due to the disturbance, to

achieve the same final biomass concentration as was

obtained with the reliable off-line profile. The neural

network prediction for the on-line case in Table 4 is

given by the fourth neural network. Moreover, it is

natural that, although the fourth neural network is

the most accurate of all, an error between the actual

process and the network prediction occurs, since the

process is under the effect of disturbance and the

neural network was not trained to learn any

observation with that kind of mismatch. However,

what is important rather than the error in the

prediction is that the target final biomass was

modified and reached a closer value to the desired

target.

Table 4: Final biomass concentration.

Off-line On-line

Mechanistic model 71.236 –

Model+disturbance 67.4971 71.1244

Neural Network 75.409 73.7741

Re-optimisation Control of a Fed-batch Fermentation Process using Bootstrap Aggregated Extreme Learning Machine

173

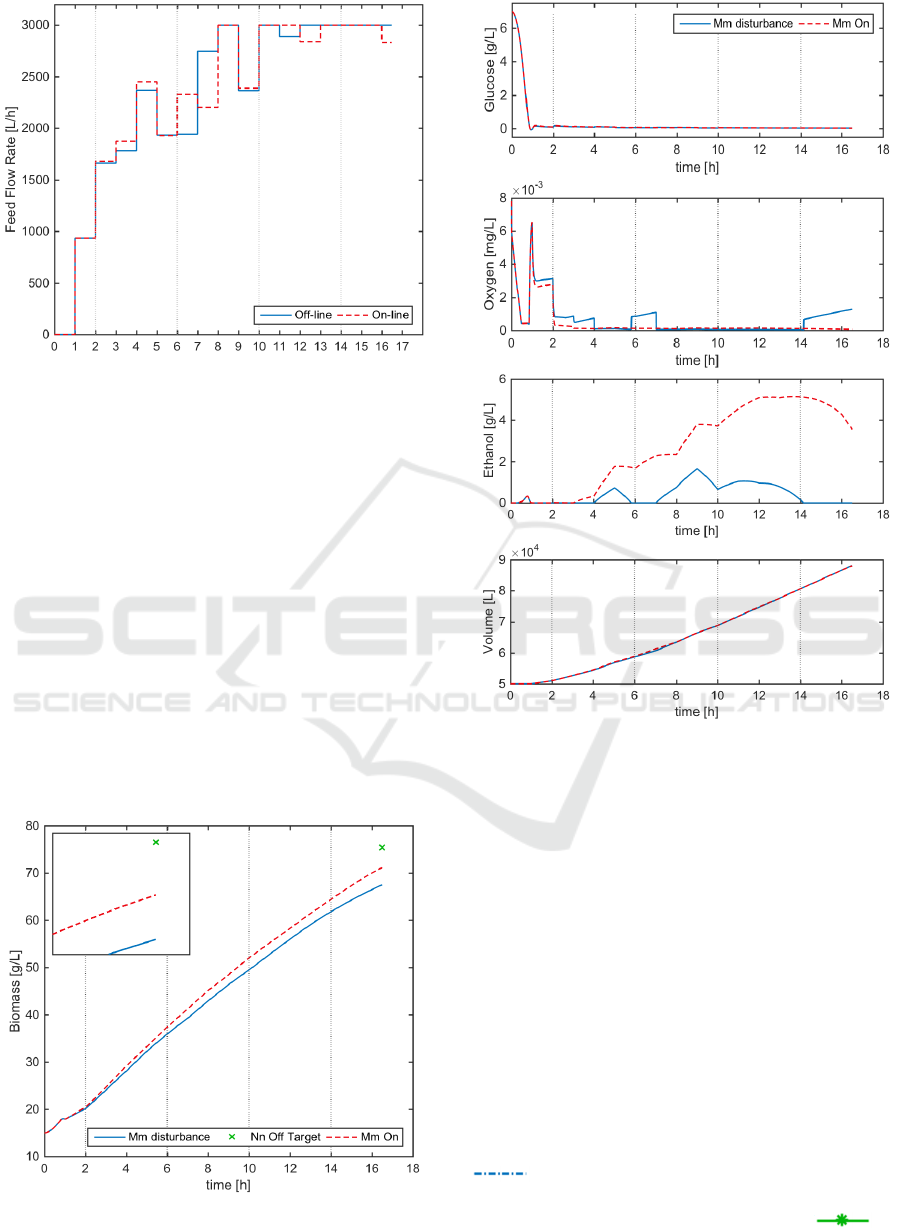

Figure 9: On-line Optimisation results: Control Policy.

To illustrate the results obtained, Figure 9 shows

the initial control policy calculated off-line

(continuous blue line) and the re-optimised profile

(dashed red line), which was updated every four

hours starting in the second hour, according to the

division lines in the graph. Figure 10 shows the

biomass concentration profile, where it can be seen

that the first two hours both profiles are equal, since

no re-calculation has been performed. After the

second hour, the feed flow rate is successfully

modified to drive the biomass concentration towards

the desired optimal value. The small box at the top

left corner is a zooming window that illustrates

closely the difference of the off-line control policy

applied on the process under disturbance

(continuous blue line) and the successful modified

profile (dashed red line).

Figure 10: On-line Optimisation results: Biomass.

Figure 11: On-line Optimisation results: Glucose, Oxygen,

Ethanol, Volume.

Figure 11 shows the overall process

performance, represented by the concentrations of

glucose, oxygen, ethanol and volume profiles. With

respect to ethanol concentration, there is an extra

amount of ethanol production, when the on-line re-

optimisation is performed, which perhaps is due to

the efforts to achieve the biomass production target,

since the substrate feed rate remains in the upper

bound most of the time after the 10

th

interval.

Finally, as an illustration of the control policy re-

calculations during the batch that lead to the optimal

feeding profile previously shown in Figure 8 (dashed

red line), Figure 12 contains all the re-optimised

profiles and highlights the time interval that is

actually applied to the process with a thick line. For

example, the off-line control policy denoted as

(

) is just applied for the first two hours, which

are represented with a thick line. Then, after the

second hour, the new optimal profile

() is

applied for the next four hours. Then, again a new

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

174

re-calculation is made, and the profile

() is

applied for four hours, when is replaced by

(

). The last re-optimisation corresponds to

(

), which is entirely applied, since it is the

ending period of the batch. Consequently, although

all the feeding profiles are calculated for the entire

batch time, the resulting optimal profile, which is

denoted as

( ) is built just with the first

four intervals of each is profile.

Figure 12: On-line Optimisation results: Detailed Control

Policy.

6 CONCLUSIONS

Modelling and reliable optimisation control of a fed-

batch fermentation process using bootstrap

aggregated extreme learning machine (BA-ELM) is

studied in this paper. It is shown that aggregating

multiple ELM models can enhance model prediction

performance. As the training of each ELM is very

quick, building BA-ELM models does not have

computation issues. The model prediction

confidence bound of BA-ELM model is

incorporated in the optimisation objective so that the

reliability of the calculated optimal control policy

can be enhanced. In order to overcome the

detrimental effect of unknown disturbances, on-line

re-optimisation is carried out to update the off-line

calculated optimal control policy. Applications to a

simulated fed-batch fermentation process

demonstrate the effectiveness of the proposed

modelling and reliable optimisation control

technique.

ACKNOWLEDGEMENTS

The work was supported by the EU (Project No.

PIRSES-GA-2013-612230) and National Natural

Science Foundation of China (61673236).

REFERENCES

Ahmad, Z., Zhang, J. 2006. Combination of multiple

neural networks using data fusion techniques for

enhanced nonlinear process modelling. Computers &

Chemical Engineering, 30(2), 295-308.

Chen, L., Zhang, J., Morris, A. J., Montague, G. A., Kent,

C. A., Norton, J. P. 1995. Combining neural networks

with physical knowledge in modelling and state

estimation of bioprocesses. Proceedings of the 3rd

European Control Conference, Rome, Italy, 5-8

September, 1995, 2426-2431.

Efron, B. 1982. The Jacknife, the Bootstrap and Other

Resampling Plans. Philadelphia: Society for Industrial

and Applied Mathematics.

Huang, G.-B., Zhu, Q.-Y., Siew, C.-K. 2006. Extreme

learning machine: Theory and applications.

Neurocomputing, 70, 489-501.

Noor, R. A. M., Ahmad, Z., Don, M. M., Uzir, M. H.

2010. Modelling and control of different types of

polymerization processes using neural networks

technique: A review. The Canadian Journal of

Chemical Engineering, 88, 1065-1084.

Osuolale, F., Zhang, J. 2017. Thermodynamic

optimization of atmospheric distillation unit.

Computers & Chemical Engineering, 103, 201-209.

Tian, Y., Zhang, J., Morris, A. J. 2001. Modelling and

optimal control of a batch polymerisation reactor using

a hybrid stacked recurrent neural network model. Ind.

Eng. Chem. Res. 40(21), 4525-4535.

Tian, Y., Zhang, J., Morris J. 2002. Optimal control of a

fed-batch bioreactor based upon an augmented

recurrent neural network model. Neurocomputing,

48(1-4), 919-936.

Xiong, Z., Zhang, J. 2005. Neural network model-based

on-line re-optimisation control of fed-batch processes

using a modified iterative dynamic programming

algorithm. Chemical Engineering and Processing:

Process Intensification, 44, 477-484.

Xiong, Z., Zhang, J. 2005. Optimal control of fed-batch

processes based on multiple neural networks. Applied

Intelligence, 22(2), 149-161.

Yuzgec, U., Turker, M., Hocalar, A. 2009. On-line

evolutionary optimization of an industrial fed-batch

yeast fermentation process. ISA Trans, 48, 79-92.

Zhang, J., Morris, A. J., Martin, E. B., Kiparissides, C.

1997. Inferential estimation of polymer quality using

stacked neural networks. Computers & Chemical

Engineering, 21, s1025-s1030.

Zhang, J. 1999. Developing robust non-linear models

through bootstrap aggregated neural networks.

Neurocomputing, 25, 93-113.

Zhang, J., Morris, A. J. 1999. Recurrent neuro-fuzzy

networks for nonlinear process modelling. IEEE

Transactions on Neural Networks, 10(2), 313-326.

Zhang, J. 2004. A reliable neural network model based

optimal control strategy for a batch polymerization

reactor. Industrial and Engineering Chemistry

Research, 43, 1030-038.

Re-optimisation Control of a Fed-batch Fermentation Process using Bootstrap Aggregated Extreme Learning Machine

175

Zhang, J. 2005. Modelling and optimal control of batch

processes using recurrent neuro-fuzzy networks. IEEE

Transactions on Fuzzy Systems, 13(4), 417-427.

Zhang, J., Jin, Q., Xu, Y. M. 2006. Inferential estimation

of polymer melt index using sequentially trained

bootstrap aggregated neural networks. Chemical

Engineering and Technology, 29(4), 442-448.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

176