A Multivariable Self-tuning Controller for a D-type Water Tube

Industrial Boiler

Soroush Rastegarpour, Anacleto Petretti, Yasaman Ghanizadeh and Luca Ferrarini

Dipartimento di Elettronica, Informazione e Bioingegneria, Politecnico di Milano,

P.za L. da Vinci 32, 20133 Milano, Italy

Keywords: D-type Drum Boiler, Self-tuning Regulators, Model Identification, Pressure Control, Level Control.

Abstract: The present paper focuses on the development of a control system strategy on medium size industrial boilers

(up to 1 MW) with the aim of having safe and efficient operation for the boiler itself. The class of the

considered boiler is D-type water tube boiler. The basic plant model is based on Åström and Bell nonlinear

dynamic model with simple adaptation due to specific geometries and physical constraints. The control system

is mainly a combination of a pressure control loop and a three-element level controller. The pressure control

loop here proposed consists of a gain scheduling PID control strategy to operate on heat power in order to

keep the pressure at its desired value. The three-element level controller is a two-loop cascade control with

feed forward water aimed at correcting the mismatch between the demand (steam flow) and feed water flow:

level variation must be considered during this process because of the non-minimum phase behaviour of the

level. Due to switching behaviour of gain scheduling approach, an adaptive control rule is also investigated

in order to simplify the overall control structure and alleviate the adverse effects of the switching among many

controllers in industrial applications.

1 INTRODUCTION

Steam has unique properties that are extremely

important in many industrial processes, for a wide

variety of completely different applications. It can be

used to produce electricity but it can be directly used

in industrial processes for specific thermos-physical

transformation or for cleaning. Steam is basically

recycled, in a closed loop, from steam to water and

then back to steam again, all in a manner that is

nontoxic in nature. One of the most effective

parameters on ultimate cost of the end product is the

amount of heat required to produce the steam. This

heat must come from an energy source, and this varies

significantly, often based on the plant’s location in the

world (Everett B.Woodruff, 1998).

A boiler, or steam generator, is a closed vessel in

which water, under pressure, is transformed into

steam by the application of a suitable amount of heat.

to the references (Michael C. McGoodwin, 2016) and

(W.M. Rohsenow, J.P. Hartnett, Y.I. Cho, 1998) are

perfect sources to understand all the thermodynamics

concepts that are required in the present paper.

The first step before starting any procedure is to

have a description of the physical system. In this case,

a nonlinear dynamic model of the generic plant is

obtained. The most well-known nonlinear dynamic

control-oriented model for this kind of boilers is by

Åström and Bell model. The “Drum- boiler

dynamics” of Åström and Bell (K.J. Åström, R.D.

Bell, 2000) is a fundamental corner stone almost of

any studies in this field since it is a perfect

combination fidelity and simplicity.

The goal of this work is to develop a control

strategy to tackle the moderately complex non-linear

model that captures the key dynamical properties of

the steam drum boiler over a wide operating range

(K.J. Åström, R.D. Bell, 2000).

In order to improve plant performance and

flexibility as well as to reduce commissioning times,

nowadays, the trend is to exploit a reliable simulation

to design advanced control systems.

It may seem surprising that a traditional controller as

simple as PID controller can behave well enough, at

least so far (K.J Astrom, Tore Hagglund, 1995).

However, the market needs impose to improve

performance ever and ever.

As shown in (F.Morilla, march 2012), there is an

extensive works ongoing with boiler pressure and

level control systems. Mainly, they have been built up

Rastegarpour, S., Petretti, A., Ghanizadeh, Y. and Ferrarini, L.

A Multivariable Self-tuning Controller for a D-type Water Tube Industrial Boiler.

DOI: 10.5220/0006479203650372

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 365-372

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

365

as combination of conventional single variable

control loops and computation of variables that

cannot be measured directly (Balchen & Mumme,

1988). Advanced control techniques have also been

proposed to improve the performance of the control

system in comparison of a decentralized one (Tan, et

al., 2004). More complex and robust methodologies

such as LQG/LTR, H∞-control, predictive control,

and fuzzy control, have been also applied to improve

boiler performance (Tan, et al., 2005) in specific

cases. Based on (Sanjoy Kumar Chakraborty,

Nilotpal Manna and Surodh Dey, April 2014) the

importance of three-elements boiler drum level

control has been presented. From (Keyur Solanki,

Jalpa Shah, Nishith Bhatt, 2014), we can also prove

previous assumption on the level control scheme

based on the 3-element controller.

In this paper an adaptive control strategy will be

proposed to cope with nonlinearity of the boiler while

regulating its process characteristics on the desired

value. The whole procedure is done based on the

following pillars. First, a mathematical description is

provided through a nonlinear model for steam drum

of a D-type water tube boiler with natural circulation.

The model is derived from first principle modelling

method and is based on physical principles and

construction data. To validate the model, some real

data from a specific boiler have been considered and

used to tune the mdoel according to the classic grey-

box approach. Second, to compensate the

nonlinearities of the model, we divide the whole

operating range into several smaller ranges where the

process can be approximated by linear models. By

using system identification techniques, it is possible

to obtain many black-box models of the system,

linearized around various working conditions. Each

black-box model is only valid closed to its

corresponding operating point. Then, a specific

controller (a PID for compliance with the market) is

designed for each working point. Finally, two

adaptive techniques have been conveived and tested:

a gain-scheduling one and an adaptive one based on

interpolation approaches.

2 MODEL DESCRIPTION

2.1 D-type Water Tube Boiler

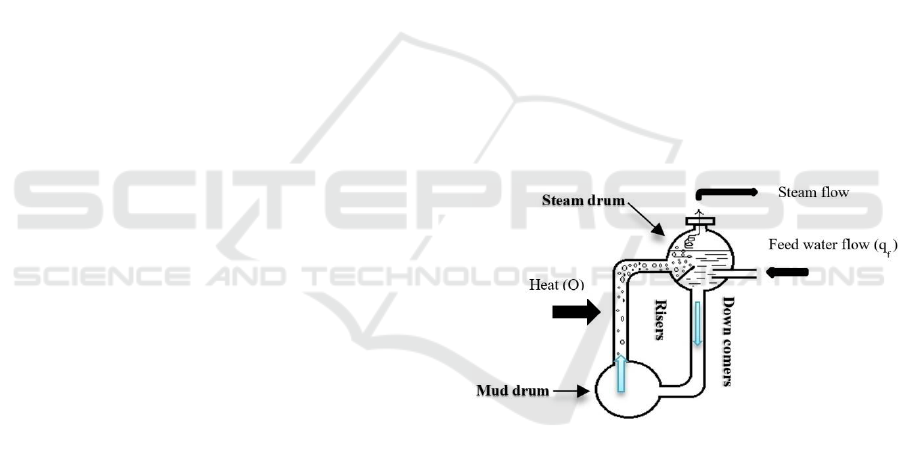

As a general working principles of D-type water tube

boiler, tubes are used to convey water and steam

through the boiler. The combustion gases flow pass

the outside surfaces of the tubes. The simplified

sketch of D-type water tube boiler configuration is

shown in Figure1. This boiler consists of a series of

tubes and two drums (upper and lower ones). Drums

distribute water to the tubes and these water tubes

connect the drums and form a wall around the

combustion area, where the heat is generated. Water

is transferred into the upper drum through a feed

water inlet line. The water tubes which is called

‘down comers’ and the lower drum is filled

completely with water and the upper drum is only

filled with water to a certain level to provide space for

the steam. The upper drum is called ‘steam drum’. As

fuel is burned in combustion area, heat is transferred

to the adjacent tubes named ‘risers’. Water circulate

from steam drum through down comers and into the

lower drum.

Lower drum is referred to as the ‘mud drum’.

From mud drum, water is distributed to the risers

surrounding the combustion area. Water in risers is

heated and steam-water mixture is produced and

enters the steam drum. Steam is separated from water

and goes to the steam outlet and eventually into the

plant.

Steam drum has a very complex mechanism and

it has a tricky behaviour. In this project, the main

focus is on the designing the suitable control system

for steam drum.

Figure 1: D-type water tube boiler.

2.2 Nonlinear Dynamic Model of Steam

Drum Boiler

A key property of boilers is that there is a very

efficient heat transfer due to boiling and

condensation. All parts of the system which are in

contact with the saturated water-steam mixture will

be considered in thermal equilibrium. Energy stored

in steam and water is released or absorbed very

rapidly when the pressure changes. This mechanism

is the key for understanding boiler dynamics. The

rapid release of energy ensures that different parts of

the boiler change their temperature in the same way

(K.J. Åström, R.D. Bell, 2000).

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

366

The model is derived from first principles of

thermodynamics laws, and is characterized by a few

physical parameters (K.J. Åström, R.D. Bell, 2000).

Variables subject to conservation laws are (Cooper,

2005): mass, energy and momentum.

Balance equations are then created by defining a

boundary around the process.

Note that level, temperature and process variables

other than those listed above are not conserved.

2.3 Mathematical Model

This section follows the Åström and Bell model

which is a nonlinear dynamic model for steam drum

of D-type water tube boiler with natural circulation.

By considering the schematic view of boiler in

Figure 1, let the main inputs be heat flow to the

system (Q), feed water mass flow rate (q

f

) and steam

mass flow rate (q

s

). Moreover, let the outputs be drum

pressure (P) and level variation (L).

Since first-principles dynamic model results from

the conservation equations, the balance equations are:

The global mass balance:

The global energy balance:

By substituting the internal energy ‘u’ with u=h-

, the global energy balance can be written as:

This equation represents the energy flow to the

system from fuel and feedwater and the energy flow

from the system via steam.

The total volume of the drum, down comers and

risers which is a constant value is:

By combining these equations with saturated

steam tables yields a simple boiler model which

describe only the behaviour of the drum pressure P to

manipulations of the inputs heat, feed water flow rate

and steam flow rate. But it cannot capture the

behaviour of the drum level. Eventually a model must

be obtained not only describe the behaver of the

pressure in the drum but also describe the distribution

of steam and water in the system.

The final form of model in format of state

equations are as below:

Where the coefficients e

ij

are as follows:

In addition, steam table are required to evaluate

h

s

, h

w

, ρ

s

, ρ

w

, t

s

, and partial derivatives with respect to

pressure at saturated pressure P.

The Table 1 and Table 3 summarize all the

parameters and their definitions.

Table 1: Parameters definition of the boiler.

Parameters

Definition

q

s

Steam mass flow rate

q

f

Feed water mass flow rate

q

sd

Steam flow rate through the liquid

surface in drum

q

dc

Down comer flow rate

q

cd

Condensation flow rate

q

ct

Total condensation flow rate

Q

Heat flow rate to risers (heat

supplied to the tubes)

V

t

Total volume

V

st

Total volume of steam

V

wt

Total volume of water

e

11

dV

wt

dt

+e

12

dP

dt

=q

f

q

s

e

21

dV

wt

dt

+e

22

dP

dt

=Q +q

f

h

f

q

s

h

s

e

32

dP

dt

+e

33

d

r

dt

=Q

r

h

c

q

dc

e

42

dP

dt

+e

43

d

r

dt

+e

44

dV

sd

dt

=

s

T

d

V

sd

°

V

sd

+

h

f

h

w

h

c

q

f

e

11

=

w

s

e

12

=V

st

s

P

+ V

wt

w

P

e

21

=

w

h

w

s

h

s

e

22

= V

st

h

s

s

P

+

s

h

s

P

+ V

wt

h

w

w

P

+

w

h

w

P

V

t

+ m

t

C

P

t

s

P

e

32

=

w

h

w

P

r

h

c

w

P

1

v

V

r

+

h

c

1

r

s

P

+

s

h

s

P

r

V

r

+

s

+

r

w

s

h

c

V

r

v

P

V

r

+ m

r

C

p

t

s

P

e

33

=

1

r

s

+

r

w

h

c

V

r

v

r

e

42

=V

sd

s

P

+

1

h

c

s

V

sd

h

s

P

+

w

V

wd

h

w

P

V

sd

+ V

wd

+m

d

C

p

t

s

P

+

r

1+

V

r

v

s

P

+

1

v

w

P

+

s

w

v

P

e

43

=

r

1+

V

r

s

w

v

r

e

44

=

s

A Multivariable Self-tuning Controller for a D-type Water Tube Industrial Boiler

367

Table 2: Parameters definition of the boiler (cont.).

Parameters

Definition

V

wt

Total volume of water

V

sd

Volume of steam under the liquid

level in the drum

V

wd

Volume of water under the liquid

level in the drum

V

sd

◦

Volume of steam in drum in

hypothetical situation when there is

no condensation of steam in drum

P

Pressure

m

t

Total mass of drum and metal tubes

Model assumptions are:

The two phases of the water inside the

system are in saturated thermodynamics

state everywhere.

There is an instantaneous and uniform

thermal equilibrium between water and

metal everywhere.

Steady state metal temperature is close to

saturation temperature and the temperature

differences are small dynamically.

In this model water has natural circulation.

3 GAIN SCHEDULING

CONTROL STRATEGY

Gain scheduling is a technique that deals with

nonlinear processes, process with time variations or

situations where the requirements on the control

change with the operating conditions. To use this

technique, it is necessary to find measurable

variables, called scheduling variables, that are well

correlated with changes in process dynamics.

This method is one possible scenario to design a

control system for drum boiler over the whole

operating conditions. A scheduling variable is first

determined. Its range is quantitated into a number of

discrete operating conditions.

The controller parameters are then determined by

automatic tuning when the system is running in one

operating condition. For each working point, as it has

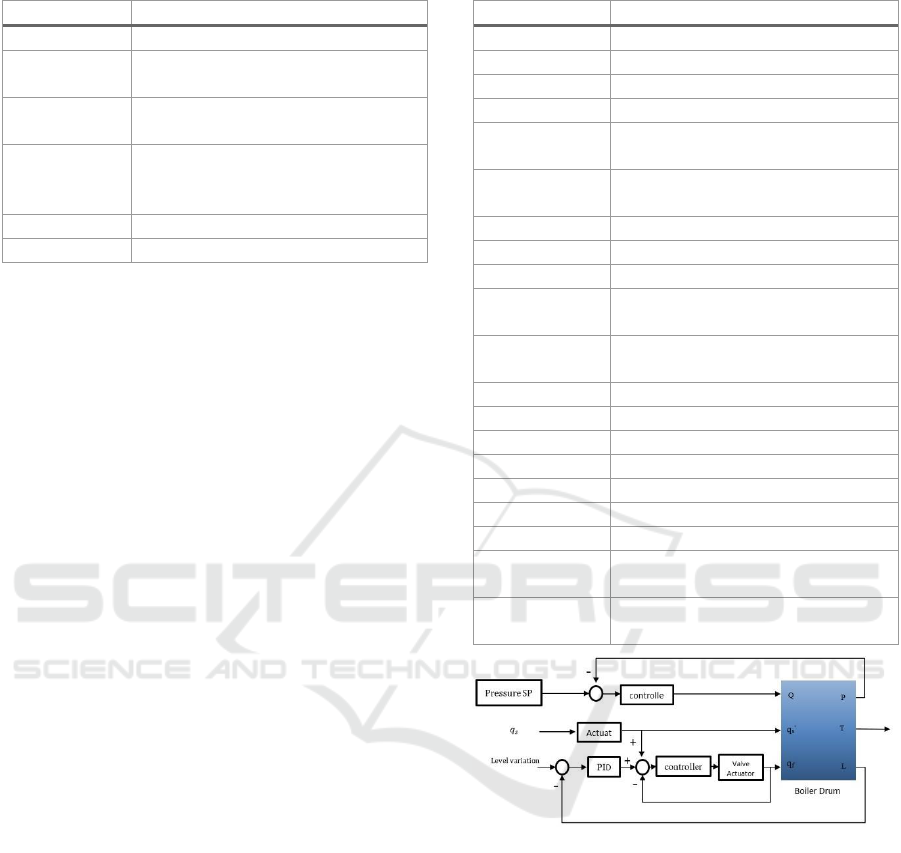

been shown in Figure 2, there are 3 PID controllers,

one for pressure loop on which the pressure is control

by heat and two for the two loops cascade control for

controlling the level variations.

Therefore, for each working points the PID controller

have been designed with the help of corresponding

estimated linearized models based on the black box

identification methods.

Table 3: Parameters definition of the boiler.

Parameters

Definition

ρ

w

Specific density of water

ρ

s

Specific density of steam

t

Temperature

h

c

Condensation enthalpy

h

s

Specific enthalpy of saturated

steam

h

w

Specific enthalpy of saturated

water

u

Internal energy

C

P

Specific heat of metal

L

Drum level

L

w

Level variation caused by changes

of the amount of water in the drum

L

s

Level variation caused by steam in

drum

L

r

Length of the risers

L

dc

Length of the down comers

A

Cross section of tube

A

d

Wet surface

α

m

Steam-mass fraction

α

v

Steam-volume fraction

α

r

Steam quality at riser outlet

ζ

Normalized length coordinate

along the risers

T

d

Residence time of the steam in

drum

Figure 2: Drum-Boiler control scheme.

3.1 Model Linearization

In this section, eight different working points have

been considered which result in eight various models

from identification and linearization methods. Since

in a nonlinear system there are so many option for

choosing the intended points, for the predefined

system the equilibrium points are consider at different

value of heat Q and pressure P corresponding to their

nominal values.

The model has been validated in various

equilibrium points presented in Table 4.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

368

Table 4: Various equilibrium points for Drum-Boiler.

According to the strong interactions between the

inputs and outputs of the steam-drum boiler model

(Figure 2), a linear MIMO system should be

estimated in each working point.

In this paper, the first 4 working points are just

considered to implement the control strategies. In this

case, the linearized models for the first 4 working

points can be summarized in the Table 5, Table 6,

Table 7 and Table 8:

Table 5: Linearized MIMO system in the 1st working point.

Table 6: Linearized MIMO system in the 2nd working

point.

Table 7: Linearized MIMO system in the 3rd working point.

Table 8: Linearized MIMO system in the 4th working point.

3.2 Gain-Scheduling Implementation

for Warm-up Condition

According to the control scheme given in Figure 2,

three PID controllers for each working point are

needed as following:

Pressure loop PID controller

Level loop cascade control scheme

(including 2 PID controllers)

To sum up, by now four sets of PID controllers

have been designed. A very initial condition has been

defined for the real existing drum boiler used as a test

case, at which the boiler start to work from pressure

equal to 4 bar to its nominal value which is 44.4 bar.

The value of initial condition is arbitrary chosen and

it is better not to be close to the cold start up

condition, i.e. 0 bar for long time.

The first aim is to start from predefined initial

condition and reach the first working point as the first

set point. The first operating condition is considered

as the initial condition of the next stage to reach the

next operating work till the last operating point which

corresponds to the nominal pressure.

According to the gain scheduling approach, the

PID can be tuned as follows:

)1(

11

)(

p

G

G

GG

ss

N

ss

K

sPID

where K and N can be chosen to act on the velocity

of the control loop and

p

is a high-frequency pole for

the controller feasibility. In Table 9: Gain-scheduled

controller parameters tuned parameters in different

working points have been shown.

Table 9: Gain-scheduled controller parameters.

By applying the gain scheduling method and set point

scheduling, it can be demonstrated that whether each

set of controllers can work properly during their

operating conditions and automatically switch to the

next operating point when the pressure reaches the set

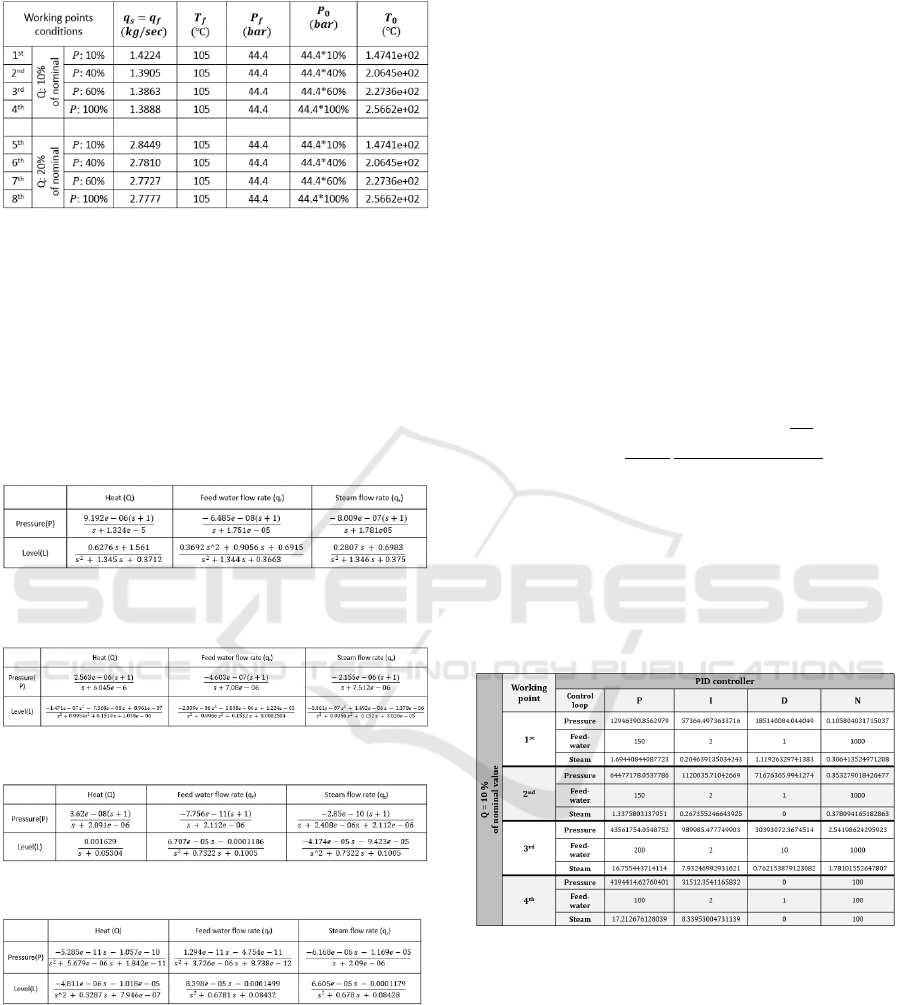

point value. Figure 3 shows the general definition of

this method.

As it can be seen in Figure 3, each set of

controllers works very well at their corresponding

working point. It means that the set point following

can be satisfied for the boiler model in nominal

pressure by implementing the gain-scheduled

A Multivariable Self-tuning Controller for a D-type Water Tube Industrial Boiler

369

Figure 3: Drum pressure in different working points based

on gain scheduled controller.

controller. This method is compared with a single set

of PIDs for the same set point. Figure 4 and Figure 5

illustrate this comparison for pressure and level

control loops.

Figure 4: Gain-scheduled controller on drum pressure loop

(desired value: 44.4bar).

Figure 5: Gain-scheduled controller on drum variation level

loop (desired value: zero variation).

4 SELF-TUNING CONTROL

SCHEME

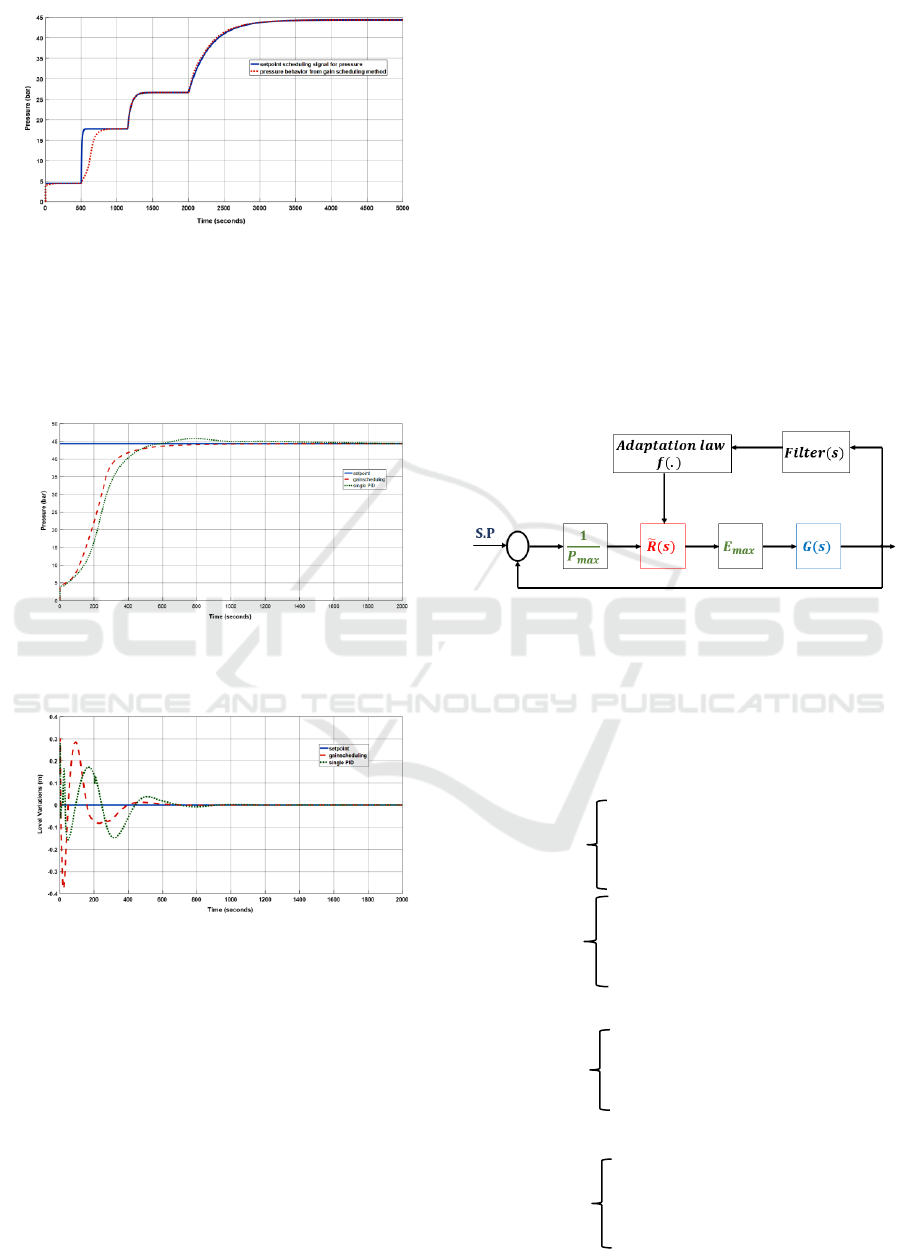

As it has been show in section 3, gain-scheduled

controller has better time domain characteristics, i.e.

faster, no overshoot and smother response. Although

it seems that gain-scheduled controller performs

numerically in a proper way, it will confront with

some limitation in practical application.

On the one hand, gain-scheduled method requires

a large effort to be implemented but when it combined

with auto-tuning, it will be very easy to use.

On the other hand, it will have adverse effects on the

industrial fields due to switching behaviour among all

controllers.

In this section, some interpolation approaches will

be used to design an adaptive function for each

control loop, i.e. pressure and level control loops.

In this case, the output of the system will be

filtered by a discrete filter to prepare an average value

rather than single one signal for the adaptive function.

After that the PID controllers will be retuned based

on the adaptive functions. The proposed adaptive

strategy is sketched in Figure 6 where

is the

maximum possible input for the boiler,

maximum output pressure, is the boiler dynamic

model and

is normalized controller.

Figure 6: Self-tuning control scheme.

Adaptive functions are designed based on the linear

interpolation of the given PID controllers in the gain-

scheduled method. So, the PID parameters will be

updated based on the following adaptive functions:

A. Pressure control loop

B. Level control loop – Outer loop

Derivative

gain

Integral

gain

Proportional

gain

Proportional

gain

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

370

C. Level control loop – Inner loop

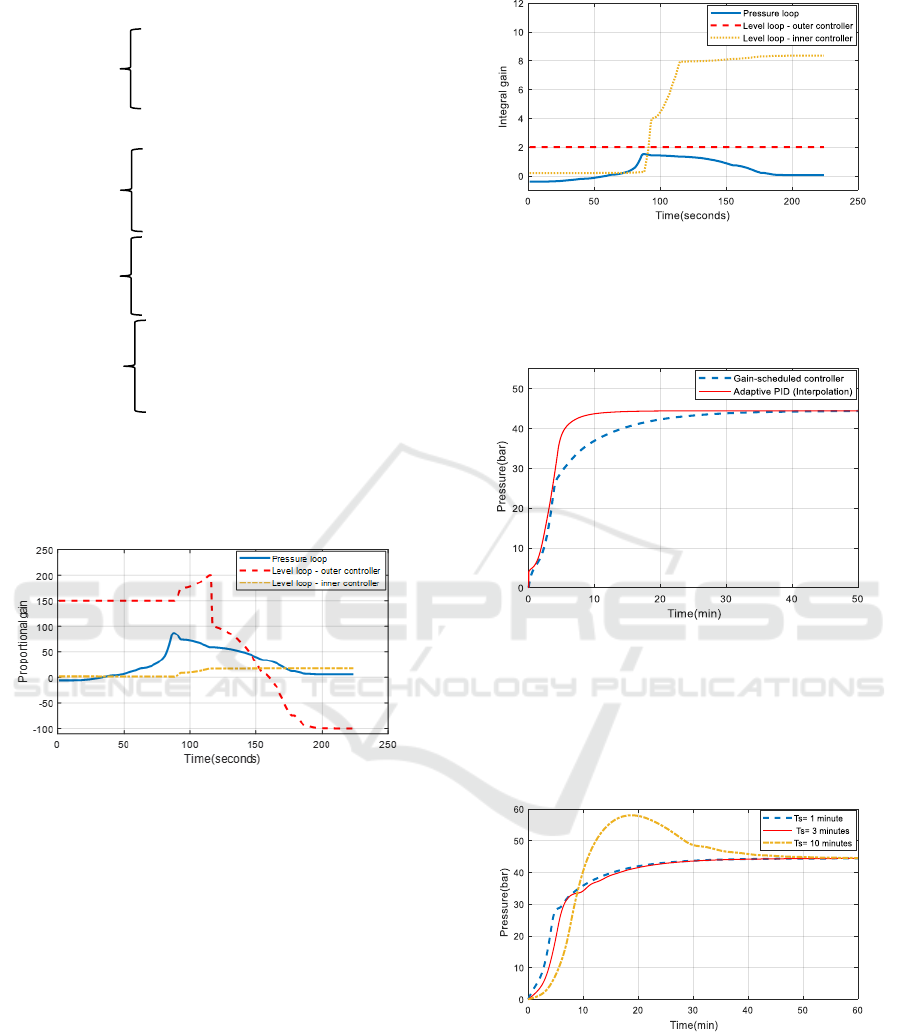

The PID coefficients profile have been shown in

Figure 7 and Figure 8. The updated PID is used in a

drum boiler initialized by 4 bar as the initial pressure

and 20 seconds as the filter time constant.

Figure 7: The PID coefficients profiles in adaptive control.

In this paper, a steam drum boiler endowed with a gain

scheduling control and an adaptive control scheme has been

considered for both control loops, i.e. pressure and level

control loops. As it has been shown in Figure 9 the gain

scheduled controller is a little bit faster, but as it mentioned

it has adverse effects in the practical application.

Simplicity, safety and accuracy are the most important

advantages of the self-tuning approach.

Figure 8: The PID coefficients profiles in adaptive control.

Although it is a bit slower than gain-scheduled

controller, it uses one adaptive PID controller rather

than a number of controllers.

Figure 9: Comparison between self-tuning controller and

gain-scheduled method.

Time constant of the filter is a crucial property of the

adaptive control scheme for boiler pressure control.

In Figure 10 the effects of different filter time

constant are evaluated.

Figure 10: Effect of filter time constant on pressure loop.

5 CONCLUSIONS

The aim of the paper is modeling and control of

medium-size industrial boilers (D-type water tube

boiler). Following the “Åström and Bell” model, a

Derivative

gain

Proportional

gain

Integral

gain

Derivative

gain

Integral gain: constant value equal to 2.

A Multivariable Self-tuning Controller for a D-type Water Tube Industrial Boiler

371

complex nonlinear dynamic model for natural

circulation of drum boilers has been derived. A real

drum boiler has been considered as a test case and the

model validated against the real case.

A single PID cannot cope easily with the system

nonlinear behavior.I It is more reasonable to extend

the number of working points and using the proper

controller for each linearized region. Each working

point has a set of PID controllers; one for pressure

loop and the other two for the two loops of the

cascade control based on the three elements level

control. Among all eight working points computed,

the first 4 have been chosen to represent the transient

behavior of the pressure till its nominal value.

Gain scheduling approach has been applied to

select the proper controller for each linearized model

in a discretized region. At the end an adaptive control

structure endowed by a linear interpolation function

has been considered to ease the control effort,

decrease the number of controllers and alleviate the

adverse effects of switching phenomena due to gain

scheduling methods. As it has been shown in the

simulation results, the implementation results had

satisfactory results.

Future directions include developing a better

tuning of the adapting technique (with more points

and finer interpolations) as well as integrating a more

complex decision rule. Also, robust control

techniques will be investigated.

REFERENCES

Balchen, J. G. & Mumme, K. I., 1988. Process Control:

Structures and Applications. New York: Van Nostrand

Reinhold.

Cooper, D., 2005. Practical Process Control. s.l.:Control

Station,Inc..

Everett B.Woodruff, H. B. T. F., 1998. Steam Plant

Operation. New York: McGraw-Hill.

F.Morilla, march 2012. Benchmark for PID control based

on the boiler control problem. brescia(Italy), s.n.

K.J Astrom, Tore Hagglund, 1995. PID controllers: theory,

design and tuning (2nd eddition). s.l.:instrument society

of america.

K.J. Åström, R.D. Bell, 2000. Drum-boiler dynamics.

automatica, 36(3), pp. 363-378.

Keyur Solanki, Jalpa Shah, Nishith Bhatt, 2014. Modeling

and Simulation of prototype of boiler drum level

control. IJMER(International Journal on Mechanical

Engineering and Robotics), 2(2).

Michael C. McGoodwin, 2016. engineering

thermodynamics, washington: s.n.

Sanjoy Kumar Chakraborty, Nilotpal Manna and Surodh

Dey, April 2014. Importance of three-elements boiler

drum level control and its installation in power plant.

International Journal of Instrumentation and Control

Systems (IJICS), 4(2).

Tan, W., Liu, J., Fang, F. & Chen, Y., 2004. Tuning of PID

controllers for boiler-turbine units. ISA Transactions,

43(4), pp. 571-583.

Tan, W., Marquez, H. J., Chen, T. & Liu, J., 2005. Analysis

and control of a nonlinear boiler-turbine unit. Journal

of Process Control, 15(8), p. 883–891.

W.M. Rohsenow, J.P. Hartnett, Y.I. Cho, 1998. hand book

of heat transfer. s.l.:McGrow-Hill companies.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

372