Educating the Community in an Effort to Improve the Quality of

Rubber: A Case of Karang Intan Constituency in Banjar District of

South Kalimantan Province in Indonesia

Rizali Hadi

Universitas Lambung Mangkurat

rizalihadi@unlam.ac.id

Keywords: community rubber, community economy, image quality, latex, lump, and SIR.

Abstract: Though Banjar district is known as a city of diamond, it is an also famous for its community based rubber

production. According to BKPMD Kalsel (2015) 89.9% of rubber produced is from the local community. The

constituency of Karang Intan consists of 26 rubber producing villages which have existed since the Dutch era.

Rubber is the main income earning product for this community. The newly tapped Latex is thickened using

sap vinegar (formic acid or accident) to form lump. It is this lump which is then bought by its collectors from

local producers (tappers) and then sold to rubber processing plants in Banjarmasin, i.e.; SIR10 and SIR20 for

export. In accordance with the Dry Rubber Content (KKK) standards the price of wet rubber for each kilogram

ranges from Rp. 2,500.00 to Rp. 6,500.00. The price of dry rubber ranges from 10,000.00 to Rp. 13.000,00.

However, besides Karang Intan rubber, there is rubber from other areas such as Pleihari, Danau Salak, and

Hulu Sungai which is purchased by factories at a higher price. Rubber from Karang Intan is of low price

because of its poor quality. After an investigation, it has been established that during the processing of rubber,

the farmers use Urea NSP fertilizers (agricultural fertilizers) as thickener component. Using NSP fertilizer as

a thickener is not bad but it affects the quality of the rubber. In this case, farmers of Karang Intan need to be

educated about the importance of quality and how to produce quality rubber. They should know that good

quality rubber leads to better rubber prices. In this regard, the district department of industry and trading of

Banjar through groups has attempted to provide acid ant vinegar which helps in the thickening of rubber

however, continuous monitoring and education efforts are required to improve the image quality of Karang

Intan rubber.

1 INTRODUCTION

In South Kalimantan, 89.9% of rubber produced is

from smallholder rubber plantations (BKPMD,

2015). For Banjar district, the main income earning

sector is agriculture and plantation. In the past, for

this area agriculture was considered as an effort to

grow rice either in wetland rice fields, or in fields on

dry land. With time, there developed a culture of

planting in the formerly agricultural dry lands,

replacing rice with other crops such as rubber which

is a cash crop, then the farmers would look for another

more fertile land for their rice. The land planted with

rubber could then be called rubber plantation. In the

Dutch era South Kalimantan was famous for its

community rubber products. The community

economy grew strong, because basically they had

gardens as an investment that produced sustainably.

However, of recent the price of rubber has declined

and continues to dwindle its lowest due to (a) the

abundance of rubber products which has taken course

increasingly widespread rubber plantation areas, (b)

the rubber plant manufacturers have found mixtures

other than natural rubber or synthetic rubber. (C) the

decreasing quality of rubber tapped by the community

because of the wrong way of thickening from latex to

lump. The causes that is (a) and (b) are national

problems which must be solved through government

regulations. This research puts its attention on

problem (c) that is the low quality of rubber produced

by the community members.

Depending on the information obtained from the

field investigation, the author established that Banjar

district which was formerly famous for its diamond,

602

Hadi, R.

Educating the Community in an Effort to Improve the Quality of Rubber: A Case of Karang Intan Constituency in Banjar District of South Kalimantan Province in Indonesia.

In Proceedings of the 2nd International Conference on Economic Education and Entrepreneurship (ICEEE 2017), pages 602-606

ISBN: 978-989-758-308-7

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

it has all over a sadden turned into a famous district

for rubber production, mostly the constituency of

Karang Intan whose biggest population lives on

rubber farming. This constituency consists of 26

villages, and there are 20 villages that are mostly

planted with rubber, namely: Bi'ih, Sungai Besar Ulu,

Sungai Besar Ilir, Tangga, Mali-mali, Arpah River,

Habirau, Sungai Asam, Mandi Kapau, Carikan

Awang Bangkal Barat, Awang Bangkal Timur,

Padang Panjang, West Wind Bath, East Wind Bath,

Sirang Lake, Piris Stone, Nyiur Island, Babar and

Balau. Among the villages, Bi'ih's most extensive

village has a rubber plantation area. According to

Pambakal Bi'ih, H. Abdul Malik (2017) Bi'ih village

with population of 1,875 people (600KK) owns 900

rubber plantation and 400 ha of agricultural land.

There are many rubber gardens compared to usual

farmland. The people of Bi'ih Village not only have a

rubber plantation in their village, but also have

expanded their gardening to villages in the villages of

Karang Intan. This has led to a saying that the Bi'ih

people are synonymous with the nickname rubber

farmers, their work from generation to generation

right from the Dutch era, the Japanese era until now

is rubber production.

This research focuses on the image of rubber

produced in Karang Intan, especially from Bi'ih

village whose rubber is considered to be of very low

quality. According to Pambakal H. Abdul Malik, the

main reason is because of the way the thickening of

rubber from latex to lump is conducted. According to

the scientific guidance, the thickening of rubber

should use a mixture of acid ants, however, many

people do it in a conventional way. The conventional

manner in which the latex: (a) is precipitated mixed

with water, (b) mixed with leaves or juice of gadung

tubers, (c) mixed with alum, (d) mixed with Urea NSP

fertilizer. This method is easy and cheap, however,

though the lump appear to be much or big, inside, it

is full of pores that contain water.

There are several causes, it may be because: (a)

the local farmers do not understand the good practices

in thickening rubber, (b) there may be speculation

from the collectors who buy the product, (c) the

farmers may be less honest regarding quality. This

research was conducted in Karang Intan constituency

and purposively performed in the village of Bi'ih, in-

depth interviews with rubber growers, traders of

rubber, and collectors or village chiefs were

conducted.

2 LITERATURE REVIEW

The establishment of smallholder rubber plantations

in Kalimantan was a Dutch idea to utilize the formerly

communal land for the cultivation rubber. This idea

started in the village of Mangkatip (in Central

Kalimantan). The idea was put to implementation in

1860 by bringing rubber seeds from plantations in

Malaya and Singapore. This was after the Dutch had

observed the farming practice of people in

Kalimantan who used to shift from one cultivation

field to another looking for new fertile places. The

Dutch directed the communities to plant "care rubber"

which later turned to be "rubber" or "kararaba". The

experiment of planting on the formerly abandoned

land succeeded. Because of the practice of returning

to the previously abandoned land, the farmers were

then referred to as turn back cultivators or shifting

cultivators (Kurniawan, 2011). The community

members felt good and were happy because of having

rubber plantations which worked as a supplement to

their family income. In the process, Netherlands then

developed rubber plantations almost all over the

entire island of Borneo. According to Fradolin Ukur

(1994) "in an agricultural system, we can find

alternative forms of farming methods that can be

developed into approaches in the development of

farming communities. In Borneo the cultivators have

long developed a cyclical agroforestry system

alternately by planting former fields with rattan,

rubber, or other plants"

Rubber is an export commodity which is required

to meet the needs of factories in producing materials

made of rubber, such as vehicle tires, shoes, and

others. With the increasing demand for rubber

products, land clearing in Kalimantan continues to be

carried out by communities and companies. The

quality of rubber from smallholder farmers is difficult

to control, whereas the quality of a good product

determines the price and usually benefits.

According to Sannia, Ismono and Viantimala

(2013) in there research, they mention that the cause

of the low quality of smallholder rubber is due to: (a)

not using ant acids as latex thickeners into lumps; (b)

inserting other unfit components in the thickening

process. The commonly used parameter for latex

quality at the farm level is the rubber content. Lump

quality parameters used are visual parameters such as

color, elasticity, dirt level and odor or smell. With

these quality parameters, natural rubber can be

differentiated. Differences in quality make the prices

to be different. Improving the quality of rubber should

be perceived by the farmers in the form of value-

Educating the Community in an Effort to Improve the Quality of Rubber: A Case of Karang Intan Constituency in Banjar District of South

Kalimantan Province in Indonesia

603

added income with the increased quality of processed

rubber produced.

Napitupulu (2013) who also researched on the

quality of rubber established that the farmers are

aware of the low quality rubber.This means they have

full knowledge of what they do. This was discovered

through interviews that 79.05 percent of rubber

producing farmers intentionally mixed dirt and / or

unrecommended component into rubber latex during

the tapping process and in the post-tapping phase.

While the remaining 20.95 percent only insert the

mixture at the time of the first day of cutting in each

harvest cycle (3-5 days) to speed up the rubber sap

clotting and to avoid overflowing they mix water in

the sap together mostly during the rainy season.

3 RESULTS AND DISCUSSION

It is true that is South Kalimantan, the prices of rubber

vary person to person and from places to place

because of quality. For instance rubber from Danau

Salak can be bought at a higher price because of its

good quality. In Karang Intan because of low quality

rubber is usually purchased with a low price. Rubber

from Karang Intan is known as low quality rubber in

the whole of Banjar district. After investigation it

turned out the cause is due to the way the thickening

of latex into a lump is not in accordance with the

recommended steps.

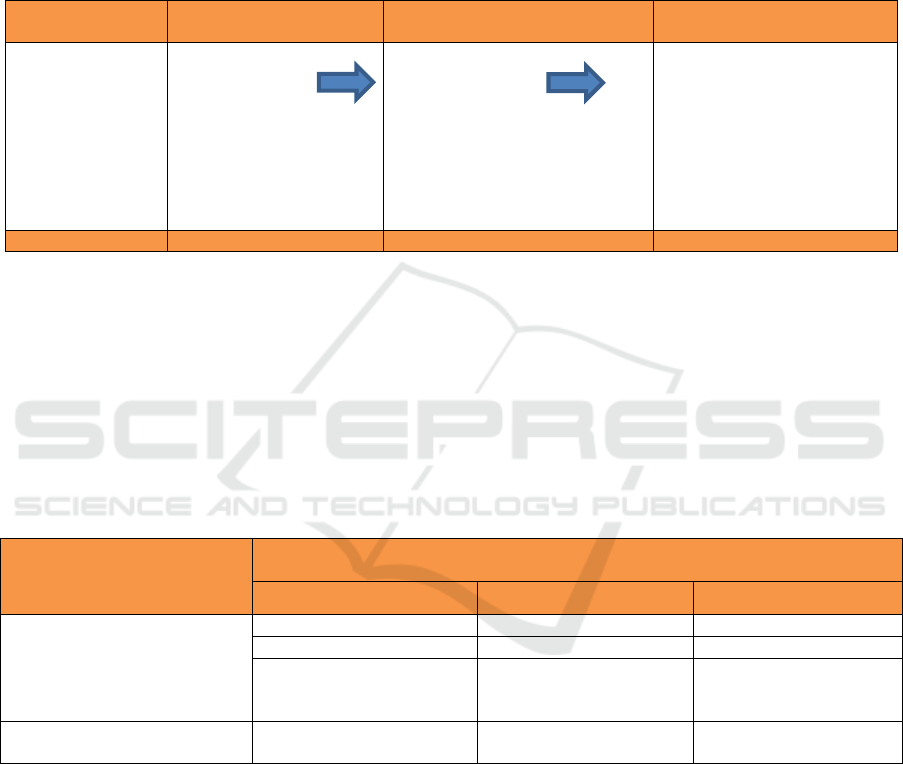

To discuss the economic benefits of using formic

acid as a thickener latex into a lump, it can be seen in

the displayed results of the research regarding

smallholder rubber farmers in the District of Tulang

Bawang, Lampung, and the calculation of rubber

profit obtained by farmers from Karang Intan

constituency in South Kalimantan.

3.1 A Study in the Constituency of

Tulang Bawang

Wiyanto and Nunung Kusnadi (2013) conducted a

research on the conventional rubber freeze conducted

in Tulang Bawang District, they established that there

those who follow the program and also those who do

not follow the program. To improve the quality of the

rubber there are programs that recommend to (a) use

ant acids, (b) keep the rubber from the dirt. A

fascinating outcome was obtained, after comparing

the two groups, it was discovered that those who

followed the program increased their profits by Rp.

500.00 per kg.

Prior to their efforts to improve the quality of the

use of formic acid village farmer who were accepted

in the program and non-program members

respectively obtained Rp. 24,785,206.00 and Rp.

28,409,250.00, after they had tried to improve the

quality of their farm products, they received an

increase amounting to Rp. 27,871,411.00 for the

village program and Rp. 28,871,090.00 for non-

program village members. This is reflected in table 1.

The study was conducted on two sample sites (A

and B), one location i.e. A sample which is

conventional rubber thickening method that does not

use ant acid, and one sample B that is in its location

have used acid ant. Recorded the sale of rubber

tapped for two days. In this location sample is then

carried out program of rubber quality improvement.

Afterwards, the sale of the two-day wiretapping

results to see the price increase after following the

rubber quality improvement program.

Table 1: Comparing sales of rubber after and before following the program.

Sample

Thickening of

Latex

Before the

Program

After the Program

Increase in

price

%

A

Not yet used acid

ants

24,785,206.00

27,875,411.00

3,090,205

12.47

B

After using acid

ants

28,409,250.00

28,871,090.00

461,840

1.63

3,623,994.00

14.10

Source: Wiyanto and Nunung Kusnadi (2013)

It is seen that there price increase for sample A

which previously did not use acid ant and after the

program is Rp. 3,090,205.00 or 12.47% indicating

that the use of ant acid and cleaning latex, the

proceeds of the sale rose to Rp. 3,090,205 or 12.47%.

For sample B the thickening method has been using

acid ant after the program, there is still an increase of

Rp. 461,840.00 because before the program has

received an increase of Rp. 3,623,994.00. This means

that sample B has received an increase of Rp.

3,623,994,00 + 461,840,00 = Rp. 4,085,834.00 or

14.10%. This increase is significant to increase the

income of rubber farmers.

ICEEE 2017 - 2nd International Conference on Economic Education and Entrepreneurship

604

3.2 Quality Problem of Karang Intan

Rubber

The collectors of rubber in Karang Intan buy from

their rubber farmers for two days then sell to a

processing factory in Banjarmasin. The price

benchmark is given by the factory, which is the

lowest and highest price. The would price of rubber

during the transaction is determined through

negotiations which also depend on quality of the

rubber being sold.

Table 2: Challenges faced by rubber producers in the constituency of Karang Intan.

Harvest for Two

Days

Tapper

Thickener

Crumb Rubber

Product

Commercial

Rubber System

Latex

Rubber farmers every

day tap rubber trees to

store latex to be thickened

into lumps, sold to

collectors

Lump :

Traders buy from rubber farmers,

rubber that has been thickened.

Saved two days later sold to

Crumb Rubber factory

SIR10 and SIR20

The factory processes the

rubber lumps into SIR10 and

SIR20 then shipped to the next

product processing plant,

either in locally or Overseas

Rubber collectors in Kecamatan Karang intan

recorded 12 people: Suri Adi, Rosehan, Ali, Baihaqi,

Aris, H. Abdul Wahid, Irwansyah, H, Juniansyah, H.

Jahri, Hairil, H. Bain and H. Munir. There is a

difficulty in obtaining data in numbers, because these

collectors have no written record. Representing

fellow collectors, Suri Adi gives an illustration that

the results of his purchase for two days brought to

Banjarmasin. Rubber there are three classes or

criteria, namely (a) dry rubber with the upper price (b)

mid-middle rubber with the middle price and (c) wet

rubber with the bottom price. They collect rubber

using pickup trucks loaded 1 ton per pick up. After

collected from rubber farmers enough 2 pickup they

take to the processing plant in Banjarmasin. Factory

or Crumb Rubber who bought rubber from the

collector is PT. Karya Sejati, PT. Balimas, PT Kapuas

and PT Sampit in Banjarmasin and surrounding areas.

Table 3: Factory price scheme.

Purchase 2 days thick wet

rubber

Criteria of quality and price assessment and weight

Dry

Semi Dry

Wet

Asal = 2.000 kg

@6.500,00 =

Rp.13.000.000,00

1.100 kg

1.400 kg

1,600 kg

@ Rp. 13,000.00

@ Rp. 11.900,00

@ Rp. 10,000.00

Rp. 14,300,000.00

Rp. 13,000,000.00

Rp. 16,600,000.00

Rp. 13,000,000.00

Rp.16,000,000.00

Rp.13,000,000.00

Profit

Rp. 1,300,000.00

Rp. 3,600,000.00

Rp. 3,000,000.00

It appears from this scheme the collectors prefer

to sell semi-dry and wet rubber, at a price of Rp.

11,900.00 and Rp. 10,000.00 per kg. A gain is higher

than dry rubber. This price scheme may be

situational, and the purchase price of thick rubber can

vary from Rp. 2,500.00 to Rp. 6,500.00.

Determination of the selling price to this factory also

depends on the negotiation, between the ranges of Rp.

10,000.00 to Rp. 13,000.00. The thick rubber that is

not good enough, will shrink more time to the factory.

The thick rubber that uses the acid of the ant is not

much shrinkage.

According to the village head, in fact it has been

often been done through counselling by district

department of industry and trading o about the

benefits of using acid ant, by showing scientific

studies. In addition, the collectors have also helped

supply the acid ants. But unfortunately the effort was

less successful.

Rubber that goes into the plant in-grade first, cut

into pieces using a circle machine to see the pores and

density. A thick rubber that uses acidic ants is usually

solid, whereas using other thickeners such as Urea or

NSP fertilizers, will look a lot of pores and in it there

Educating the Community in an Effort to Improve the Quality of Rubber: A Case of Karang Intan Constituency in Banjar District of South

Kalimantan Province in Indonesia

605

is water content. Rubber that looks a lot of this

porridge will drop the price, even less than Rp.

10,000.00. Rubber from Karang Intan which can

usually be estimated at Rp. 8,000.00 only per kg

while those from other regions such as from Sungai

Danau can be sold Rp. 10,000.00 or Rp.11,000.00.

Image that the rubber from Karang Intan constituency

as a low quality rubber is already attached. Collectors

will be easy to negotiate if the rubber is thickened

using acid ant, can approach the dry rubber with a

better price. The accumulated rubber in the factory is

then processed to become SIR10 and SIR20 rubber in

accordance with Standard Indonesia Rubber, which is

then sent to rubber product manufacturers, such as tire

factories, either domestically or exported abroad.

The question is why rubber tappers in the

constituency of Karang Intan not many of them want

to use acid ant. According to the Village Head Bi'ih,

H. Abdul Malik, who was also a collector, from

experience and observation, the less likely they are

being dishonest. The thought of tappers is: (a). They

see pricing and rubber heavy calculations are still

profitable, they just want to quickly make money and

not too much trouble; (B). Using agricultural

fertilizers, Urea NSPs, it's a quick condensed process

and fertilizer is easy to obtain, since they are

generally cultivated as farmers; (C). There are still

collectors who want to buy it, because there are also

factories who want to receive it, to be blended with

other rubber.

It seems that these rubber tappers considers the

conventional tapping process is not wrong, because

there are still collectors and crumb rubber factories

that receive it. They do not mind if the price is

reduced. They seem to have no interest in improving

the quality of rubber and that quality improvement is

only necessary, in accordance with government

programs. Farmers or rubber tappers in the

constituency of Karang Intan must also improve their

rubber quality, to improve their rubber quality image.

4 CONCLUSIONS

A fact that the quality of rubber in the constituency of

Karang Intan is lower than the quality of rubber the

surrounding area. The quality of this rubber is low

because the tappers do not use acid ant in the process

thickening their rubber product. This low quality

results in low cost. Bargaining a nice deal during

selling becomes difficult. However, rubber tappers

can generally accept this situation because they want

to quickly get money. It is unlikely that these rubber

tappers will intend to cheat, because they accept the

price cut proposed by the buyers. The industrial and

trading department of the district of Banjar has often

conducted counselling about the quality of this

rubber, but received less response from rubber

farming communities and other related parties.

It is suggested that the department should

establish a post for Field Extension Workers who

must be tasked by the responsibility of campaigning

and educating farmers to maintain the quality of

rubber in Karang Intan. Direct supervision can help to

educate farmers on to obtain good quality rubber by

using better rubber thickening acid ant. Given this

post, it is expected that this effort to improve the

quality of rubber will be successful.

REFERENCES

Aan Yuliono, Hamdani, Ahmad Yousuf Kurniawan. 2011.

Sistem Usaha Tani Perladangan Gilir Balik Masyarakat

Dayak Meratus Desa Haratai Kecamatan Loksado,

Kabupaten Hulu Sungai Selatan, Jurnal Agribisnis

Pedesaan, Volume 01 No.03.

Arkanudin, 2009. Sistem Perladangan dan Kearifan

Tradisional Orang Dayak dan Mengelola Sumber

Daya Alam.

http://arkandien.blogspot.co.id/2009/03/sistem-

perladangan-dan-kearifan.html. (Diakses 2/6/2017)

Belladina Sannia, R. Hanung Ismono, Begem Viantimala,

2013. Related the Rubber Quality to Income Additional

Farmers Village in Program and Non-Program) JIIA,

Volume 1 No 1.

Napitupulu, D. 2013. Tataniaga Karet Rakyat Kaitannya

dengan Mutu Bokar di Provisi Jambi

https://www.academia.edu/11666515/ (diakses

2/6/2017

Ukur, F., 1994. Makna Religi Dar Alam Sekitar Dalam

Kebudayaan Dayak, Dalam Paulus Florus (editor),

Kebudayaan Dayak, Aktualisasi dan Transportasi,

Jakarta: LP3S-IDRD dengan Gramedia Widiasarana

Indonesia.

Wiyanto, Nunung Kusnadi 2013. Faktor-faktor yang

mempengaruhi kualitas karet perkebunan rakyat,

Jurnal Agribisnis Indonesia (Volume 1 No 1, Juni

2013)

ICEEE 2017 - 2nd International Conference on Economic Education and Entrepreneurship

606