Characteristics and Durability of K-300 Concrete Mix

for Earthquake-resistant Housing Infrastructure in Indonesia

Fahrizal Zulkarnain

1*

, Syaiful Bahri

2

1

Department of Civil Engineering, Faculty of Engineering

2

Posgraduate Director,University of Muhammadiyah Sumatera Utara, Medan, Indonesia

Keywords: Durability of Concrete, Composition of Concrete Mix, Concrete Strength, Earthquake-Resistant Housing

Abstract: This study investigated the performance of the properties of Ordinary Portland Cement (OPC) and Additive

Bond Crete in housing infrastructure. Additive Bond Crete is commonly used to increase the compressive

strength of concrete material and for economic concerns. In determining the strength of K-300 concrete mix

that is suitable for earthquake-resistant housing infrastructure, it is necessary to research the materials to be

used for proper quality and quantity so that the mixture can be directly applied to the resident's housing, in

the quake zone. In the first stage, the examination/sieve analysis of the fine aggregate or sand, and the sieve

analysis of the coarse aggregate or gravel will be carried out on the provided sample weighing approximately

40 kilograms. Furthermore, the specific gravity and absorbance of aggregates, the examination of the sludge

content of aggregates passing the sieve no. 200, and finally, examination of the weight of the aggregate

content. In the final stage, a compressive strength test of the K-300 experimental mixture is carried out, and

subsequently the composition of the K-300 concrete mixture suitable for one sack of cement of 50 kg is

obtained for the foundation of the proper dwelling. The composition is consists of use of Cement, Sand,

Gravel, and Water.

1 INTRODUCTION

Concrete can be used in several applications such as

pavement, building, foundation, pipeline installation,

dam, and other civil building infrastructure

(Piyamaikongdech, 2007; Zulkarnain and Ramli,

2011). One alternative to the mixture of concrete

components is to use lightweight concrete while

maintaining the compressive strength of the existing

concrete, so this becomes the solution for the existing

concrete mixture. Huang's research (2009) indicates

that lightweight concrete can be used as structures in

residential buildings by the addition of stiff fibers to

concrete mixtures. This is to add strength especially

on columns and also beams on building structures to

withstand loads. Some researchers have tested in

particular to increase the compressive strength of

concrete versus normal concrete, as did Zulkarnain et

al. (2016), by addition of paper and also foam to

increase the compressive strength of concrete.

Research conducted by Kuehn (2010) in Canada

shows that particles of 10 μm in size can be used for

concrete mixtures in building structures. It can be

argued that the results of the study are close to the

results obtained with ash for concrete mixtures, so the

basis of that research is well suited for use in disaster

areas. Furthermore, a study by Zulkarnain (2011)

suggests that concrete mixtures can be increased in

strength by adding silica powder, especially for

lightweight concrete that can be used for houses in

disaster areas with relatively fast processing and does

not require a high cost for each building produced.

Previous research by Karolina et al. (2014) concluded

that the volcanic ash from Mt. Sinabung could be one

of the aggregates in the concrete mix.

A study by Zulkarnain (2015) on the strength of

concrete with the addition of volcanic ash indicates

that this addition can increase the strength of the

concrete in such a way that it is possible to reconstruct

the earthquake-damaged housing around Mount

Sinabung.

The innovation of the research in 2016-2018

produced a new K-300 concrete mix for earthquake-

resistant housing infrastructure in Indonesia, which

can be directly applied to the earthquake area. For the

area of North Sumatra, for example, this is

appropriate for housing around the safe area of Mount

Sinabung, both for short-term and long-term.

162

Zulkarnain, F. and Bahri, S.

Characteristics and Durability of K-300 Concrete Mix for Ear thquake-resistant Housing Infrastructure in Indonesia.

DOI: 10.5220/0010039901620167

In Proceedings of the 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and Technology (ICEST 2018), pages 162-167

ISBN: 978-989-758-496-1

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reserved

2 LITERATURE REVIEW

Preliminary study by Zulkarnain et al. (2014) said that

a mixture of palm oil can also be used for lightweight

concrete mixtures. In this research, the increase of

compressive strength value of concrete is obtained

which can also be used for housing in disaster area.

The results have been published in the Journal of

Civil Engineering Research 2014.

In Proceedings of the 3rd International

Conference on the Geohazard Information Zonation

and 5th Seminar & Short Course of HASTAG (GIZ

2014-HASTAG 5), p. 90-98, Karolina et al. (2014)

presented the results of research on ash of eruption of

Mount Sinabung with the following conclusions: (1)

It is found that the water cement factor is so high that

it affects the compressive strength of the concrete

produced. (2) The visual observation results show

that the surface of the brick has the same shape as the

particle equation, thus the surface of the brick

becomes flat. (3) The use of brick material from the

ash of Mount Sinabung resulted in the increase of

absorption which in the study by 4.142%. (4) Based

on the resulting compressive strength, the addition of

10% ash will result in a compressive strength of

211.01 kg/ cm

2

with treatment and presence of SiO

2

dominance in concrete mixture. (5) From the

research, it is found that Mount Sinabung ash can be

used in the mix for brick making.

The use of ash of eruption of mount Sinabung in

concrete mix will increase the compressive strength

of concrete at 28 days of testing. The results of the

compressive strength test at 28 days were 166.90

kg/cm

2

using no mixture (0%), the compressive

strength at 28 days was 173.72 kg/cm

2

by 5%

mixture, the compressive strength at 28 days was

207.14 kg/cm

2

by 10 % mixture, and the compressive

strength at 28 days was 130.97 kg/cm

2

by 15%

mixture. Other chemical compositions are: SiO

2

=

74.3%, AL

2

O = 3.3%, CAO = 1.79% (Karolina et al.,

2014).

Zulkarnain F. (2015), through internal research in

Muhammadiyah University of North Sumatra

(UMSU), has examined the strength and resilience

characteristics of concrete mixtures using silica

powder for housing development. Thus, the

preliminary study for this research is very supportive

and can be the basis for research of K-300 concrete

mix for earthquake-resistant housing infrastructure in

Indonesia.

Inspection of materials becomes the decisive

factor in increasing the compressive strength of the

tested sample. Selection of materials and techniques

or ways of mixing is also a matter of priority before

samples are tested. Samples will be tested with cube

and cylinder molds for each planned age of up to 28

days. From the test results will be obtained a good

value and used as a reference for the mixture of

concrete in the disaster area.

In the last section, the composition of the concrete

mix for every 1 sack of 40 kg cement can be

determined based on the volume of the mixture for 1

sack of 40 kg cement. Comparison of volume of

mixture for 1 sack cement of 40 kg and final

composition of cement: sand: gravel: water can be

achieved for earthquake-resistant housing

infrastructure in Indonesia.

3 METHOD OF

IMPLEMENTATION

Primary data is data obtained from the results of

research conducted in the laboratory which, among

others, are:

a) The materials prepared in the study for mixing of

concrete, among others, are: sand, aggregate and

Bond Crete supplements. Examination of the

materials in the preparation of the study are:

Sieve analysis or filtration of coarse aggregate,

sieve analysis or filtration of fine aggregate or

sand, specific gravity and aggregate absorbance,

mud content of aggregate or passing sieve no.

200, and the weight of the aggregate content.

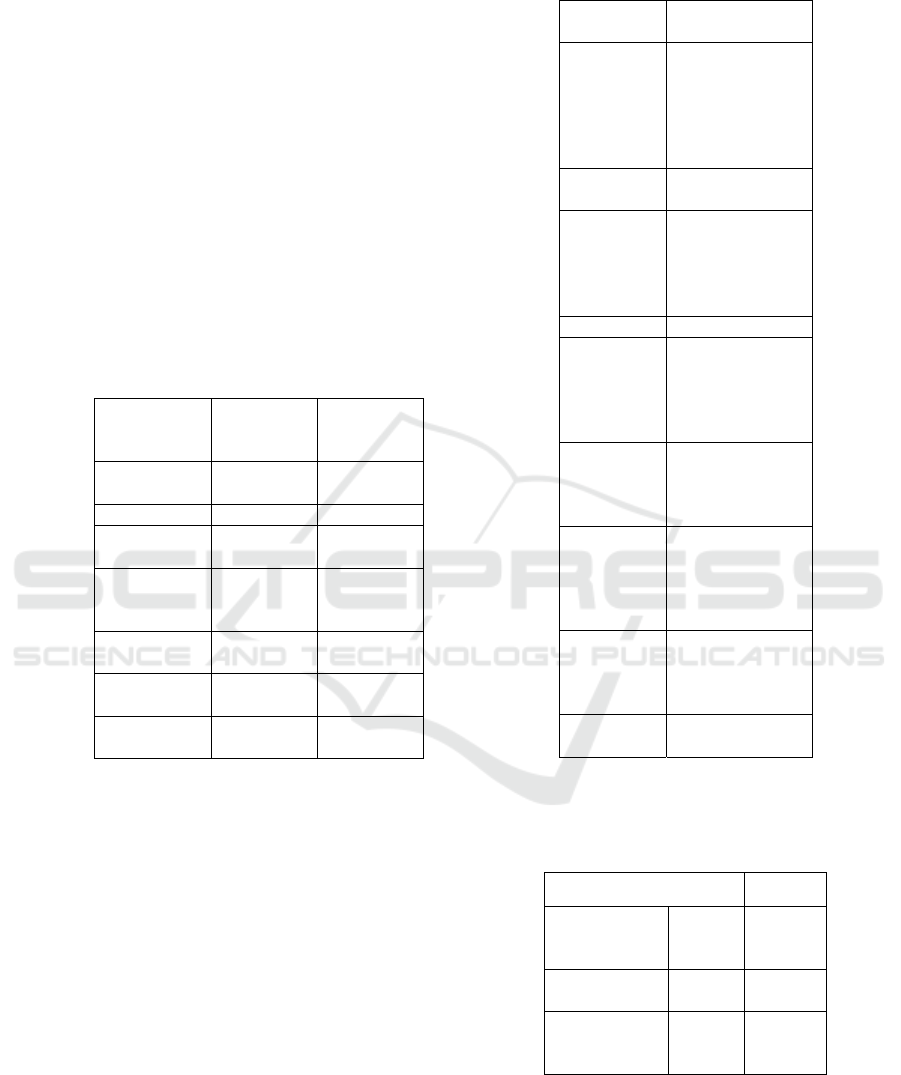

Figure 1. Materials for testing

b) Planning of Concrete Mix design using the DoE

Method that has been adapted to the conditions

of Indonesia.

c) Several types of alternatives are used for the

preparation and making of cylindrical test objects

which include:

Planning used for development or

construction of residential houses. The

Characteristics and Durability of K-300 Concrete Mix for Earthquake-resistant Housing Infrastructure in Indonesia

163

material used is Andalas cement, weighing

± 40 kg per sack.

The schedule of activities undertaken in this

study include: Characteristic examination,

Planning of the composition of the mixture,

Preparation of experimental mixture at the

initial stage of this study (3 cubes of 15 cm

x 15 cm, and 3 cylinders of 15 cm in

diameter and height of 15 cm), Quality

Inspection of Experimental Concrete Mix

with 7 days of age.

In general the resume of design of concrete

mix is as follows:

1. Data on Ingredients

40 kg Bosowa Cement.

Additive Bond Crete.

Water at Public Laboratory of Medan.

Aggregates as follows:

Aggregate

examination

Fine

aggregate

Coarse

aggregate

- Type

Natural

san

d

Natural

g

ravel

- Gradation Zone 2 BS -

- Maximum

d

iamete

r

- 40 mm

- Specific

gravity of

SSD

2.58 2.61

-

Absorbance

2.17 % 0.93 %

- Mud

content

1.69 % 0.52 %

- Weight of

content

1426.86

K

g

/m

3

1472.47

K

g

/m

3

1. Data for Planning:

1) Quality of K-300 concrete.

2) Planned slump of 6-9 cm.

3) Planned standard deviation of 50

kg/cm

2

.

4) The planning method of DoE has been

adapted to the conditions of Indonesia.

2. Results of Planning:

Composition of mixture per 1 m

3

of concrete

(Aggregate in state of SSD).

1) Cement = 448.72 kg

2) Fine aggregate (sand) = 614.70

kg

3) Coarse aggregate (gravel) = 1141.58 kg

4) Water =175.00 Littre

3. Making of Experimental Mixture:

Day/Date

Monday/August

7, 2017

Site

Civil

Engineering

Laboratory of

Public

Polytechnic of

Medan

Type of

Mixture

K-300

Object Test

3 cubes of 15 x

15 cm and

3 cylinders of

= 15 cm, height

of 15 c

m

Additive Bond Crete

Water

content of

fine

aggregate

(san

d

)

5.82 %

Absorbance

of fine

aggregate

(

san

d

)

2.17 %

Water

content of

coarse

aggregate

(gravel)

0.72 %

Absorbance

of coarse

aggregate

(

g

ravel

)

0.93 %

Slump

obtaine

d

8.17 cm

4. The results of examination of the compressive

strength of experimental concrete at age 7 days

(estimated 28 days)

5.

7 days

Average

compressive

strength

Kg/cm

2

369.48

Standard

d

eviation

Kg/cm

2

5.99

Characteristic

compressive

strength

Kg/cm

2

459.67

6. Recommendations:

1) Based on examination of experimental

mixtures, the resulting mixture composition

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

164

according to the planning can meet the

required quality.

2) In the implementation is required to conduct

supervision of the quality of the materials of

mixture and the quality of concrete by way

of sampling according to the provisions and

conduct testing of samples in the laboratory.

3) For the purpose of correction of moisture

content of the mixture, the examination of

the moisture content of the aggregate shall

be carried out prior to mixing.

Figure 2. The compaction process uses a vibrating engine

on all samples.

4 RESULTS OF TESTING

4.1 Design of K-300 Concrete Mix

The data and materials used during the research

process are as follows:

a. Quality of concrete : K-300

b. Planned slump : (6 – 9) cm

c. Materials

Fine aggregate:Type = natural sand

Specific gravity of SSD = 2.58

Absorbance = 2.17%

Gradation = zone 2 BS

Coarse aggregate : Type = natural gravel

4.2 Planning of Cement Water Factor

(CWF)

Estimation of compressive strength of concrete

(kg/cm

2

) with CWF of 0.5 corresponds to type of

cement and aggregate using Table 1.

Table 1. Planning of Cement Water Factor (CWF)

Type of

Cement

Type of

Aggregate

Compressive Strength

(kg/cm

2

)

3

days

7

days

28

days

91

days

Ordinary

Portland

Cement

(Type I)

Natural

(Not

destroyed)

200 280 400 460

Crushed

stone

230 320 450 530

Based on the graph of the relationship between

Compressive Strength with Cement Water Factor, the

CWF value of 0.52 is obtained. Maximum value of

CWF for this planning is limited to 0.39 so that the

CWF value used is 0.39.

4.3 Planning of Concrete Free Water

(Liter/m

3

)

Estimates of the amount of free water (kg/m

3

)

required for different levels of work can be

determined using Table 2.

Table 2. Plannin of Concrete Free Water (Liter/m

3

)

Aggregate

Planned Value of

Slump (mm)

Diameter

max.

(mm)

Type

0

–

10

10

–

30

30

–

60

60

–

180

20

Natural 135 160 180 190

Crushed

stone

170 190 210 225

40

Natural 115 140 160 175

Crushed

stone

155 175 190 205

The rough aggregate used is a natural type with a

maximum diameter of 40 mm and a natural fine

aggregate. With planned value of slump of 6-9 cm, it

Characteristics and Durability of K-300 Concrete Mix for Earthquake-resistant Housing Infrastructure in Indonesia

165

is planned to use free water as much as 175.00

liters/m

3

of concrete.

4.4 Planning of the Amount of Cement

Based on the smallest CFW value and Free Water

then the planned use of cement is as much as:

Total Cement =

=

.

.

= 448.72

kg/m

3

4.5 Maximum Cement Level

The minimum cement quantity for this planning is set

at 400 kg/m

3

. Thus, the amount of cement used is the

calculated amount of cement which is equal to 448.72

kg/m

3

.

4.6 Adjusted Cement Water Factor

Since the amount of cement used does not change, the

value of CWF does not need to be adjusted so that the

CWF value remains at 0.39.

4.7 Estimated Aggregate Composition

From the graph of the relationship between the

maximum size of coarse aggregate (30 mm), the

gradation of fine aggregate (Zone 2 BS), planned

value of slump (10 2 cm) and CWF = 0.42 then the

composition is obtained:

Fine aggregate : Coarse aggregate = 35% : 65%

4.8 Estimated Weight of Concrete

Content

From the graph of the relation between the relatively

specific gravity of the dry aggregate of the surface

and the amount of free water, it is estimated that the

weight of the wet concrete content is 2380 kg/m

3

.

4.9 Calculation of the Composition of

the Concrete Mixture

From the above planning steps for the mixture, the

composition per mixed m

3

(aggregate in a state of

SSD) is obtained as follows:

Cement : 448.72 kg

Fine Aggregate (Sand) : 614.70 kg

Coarse Aggregate (Split) : 1141. 58 kg

Water : 175.00 liter

4.10 Calculation of Correction of the

Mixture for Various Water Content

The composition of the mixture per m

3

of concrete in

step 8 above is based on the assumption that the

aggregate used is in the state of SSD (saturated

surface dry). For aggregates not in the state of SSD,

the correction of the mixture is carried out as follows:

Cement : Fixed

Fine Aggregate (Sand) : Sand of SSD +

(Water Content of sand Degree of Saturation of

sand) Sand of SSD

Coarse Aggregate (Split) : Gravel of SSD

+ (Water Content of gravel Degree of

Saturation of gravel) Gravel of SSD

Water : Water of SSD Sand Correction

Gravel Correction

With the description of the research road map

above, the results we will achieve in the research will

be as expected. This has been done by previous

researchers, with the same methods and workings, but

the number of molds is increased overall, so a better

result is obtained to determine the strength of

columns and beams on the main housing/settlement

structures. And this can be used in the reconstruction

of housing in the vicinity of Mount Sinabung, North

Sumatra.

The subsequent process after consideration is to

test the compressive strength of each specimen, so

that the strength of the sample is known. Testing of

compressive strength is also performed on the

cylinder by using a cover on the top, so that the flat

portion is obtained for more accurate data resulting

from the test.

5 CONCLUSIONS

Some results are obtained from testing for both cube

and cylinder sample forms according to the age of the

plan, including:

1. Based on examination of experimental

mixtures, the composition of the mixture as a

result of planning can meet the requested

quality.

2. The K-300 mix with additive of 1% Bond

Crete can be used for earthquake-resistant

housing infrastructure in Indonesia.

3. In the implementation is required to perform

quality control of materials of mixture and

quality of concrete by way of sampling

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

166

according to the provisions and conduct

testing of samples in the laboratory.

4. For the purpose of correction of moisture

content of the mixture, the examination of the

moisture content of the aggregate shall be

carried out prior to mixing.

ACKNOWLEDGMENTS

The research was conducted with the assistance of the

Ministry of Research and Technology, Higher

Education of the Year 2016/2017 through the Applied

Product Research scheme (PPT).

REFERENCES

Huang, Y.J. (2009). Fiber-Reinforced Syntactic Foam. A

Dissertation Presented to the Faculty of the Graduate

School, University of Southern California. In Partial

Fulfilment of the Requirements for the Degree Doctor

of Philosophy (Materials Science).

Karolina R, Syahrizal, Putra M.A, Prasetyo T.A. (2014).

The Use of Vulcanic Ash of Mount Sinabung Eruption

as the Substitution of Fine Agregate in Making Batako

(Mass-Produced Brick). Proceedings of the 3

rd

International Conference on the Geohazard Information

Zonation and 5

th

Seminar & Short Course of HASTAG

(GIZ 2014-HASTAG 5), p. 90-98.

Kuehn, S.C, & Froese, D.G. (2010). Tephra from Ice

A

Simple Method to Routinely Mount, Polish, and

Quantitatively Analyze Sparse Fine Particles. Microsc.

Microanal. 16, p. 218-225.

Piyamaikongdech, A. (2007). Ductile Lightweight

Concrete for Lightweight Structural Application. M. S.

Thesis, The University of Texas at Arlington.

Zulkarnain, F. (2011). Strength and Durability Properties

of Lightweight Foamed Concrete for Housing

Construction, PhD Thesis, Universiti Sains Malaysia.

Zulkarnain, F. (2011). Strength and Durability Properties

of Lightweight Foamed Concrete for Housing

Construction, PhD Thesis, Universiti Sains Malaysia.

Zulkarnain, F, dan Ramli, M. (2011). Performance of

Foamed Concrete Mix Design with Silica Fume for

General Housing Construction,European Journal of

Technology and Advanced Engineering Research, Issue

2.

Zulkarnain, F, Sulieman M.Z, Serri E. (2014). The Effect of

Mix Design on Mechanical and Thermal Properties Oil

Palm Shell (OPS) Lightweight Concrete, Journal of

Civil Engineering Research, Vol.4, No. 3-A, 2014.

Zulkarnain, F. (2015). Karakteristik Kekuatan dan

Ketahanan Campuran Beton dengan Penambahan

Serbuk Silika untuk Pengembangan Perumahan, APB

Universitas Muhammadiyah Sumatera Utara, Mei

2015.

Zulkarnain, F, Sulieman M.Z, Fadila R. (2016). The

Potential Usgae Paper Fiber Reinforced Foam

Concrete (PFRCFC) Wall Paneling System As An Idea

Building Material. International Journal Of Advanced

Research (IJAR), Vol. 4, Issue 2, 201

Characteristics and Durability of K-300 Concrete Mix for Earthquake-resistant Housing Infrastructure in Indonesia

167