Study on Waste Heat Potential of Commercial Refrigerator

Condenser

Sulastri Panggabean

1

, Dewi Marina Sibarani

1

, Riswanti Sigalingging

1

and Adian Rindang

1

1

Agricultural Engineering, Faculty of Agriculture, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Waste Heat, Condenser, Commercial Refrigerator.

Abstract: The waste heat from the commercial refrigerator came out from the heat released by the condenser. The

released heat had the potential to be reused. The heat potential was suitable to be used for drying

agricultural products that do not require too high temperatures or sensitive to high temperature such as

materials containing volatile substances for example Curcuma rhizome. The amount of enthalpy and heat

potential presented in the waste heat before doing modification is 94.29 kJ.kg

-1

and 1.336 kJ.s

-1

. By doing a

little modification on the condenser such as moved the condenser to the backside and added partitions, the

enthalpy can be increased as much as 108.69 kJ.kg

-1

(increased up to 15.27%) as well as the heat potential

as much as 1.723 kJ.s

-1

(increased up to 28.92%).

1 INTRODUCTION

There are several factors that influence the

agricultural product processing activities as well as

other processing industry. One of them that holds

great impact is the availability of energy during

those activities take place. That energy can be either

thermal energy, electrical energy, chemical energy,

mechanical energy, and others, which derived from

various energy sources. Based on the source, the

energy can be classified into two groups namely:

fossil energy (diesel, petrol, kerosene or gas) and

non-fossil energy (wind energy, water energy,

biodiesel, biogas, bio-ethanol, etc). For the time

being, fossil energy is still the main choice in the

processing industry in Indonesia, although the latter

not less than the first and has started to increase in

utilization. Among the energy sources that have

been mentioned earlier, there are other sources of

energy that can still be exploited but tend to be

ignored because they are considered no longer

useful, which is the energy that derived from waste

or by-product of the utilization of fossil and non-

fossil energy when it is converted to another form of

energy or when used for a process. Among the

energy that comes from a by-product of a production

process is wasted heat which is the unused output

from a production process and usually discharged

into the environment.

Utilization of waste heat into a source of energy

that can be reused for another process has several

positive impacts on the environment. First, the heat

that usually discharged to the environment which is

at a temperature above the ambient temperature,

could be one of the factors that led to the increase of

the environment temperature, can be reduced

because the heat was used for other processes before

discharged. Secondly, the aforementioned energy

usage savings, which are certainly along with cost

reductions for energy inputs. Thus, we can reduce

the cost of production because some energy required

comes from the waste that was previously about to

be disposed of. Third, it has good environmental

impacts, especially on the effects of fossil fuel

exploration.

With the enormous benefits of reusing waste

heat, it certainly has a new impact on future industry

development. However, a more in-depth study of

waste heat recovery is needed, such as: the quality of

heat that can still be utilized, the type of activity that

can exploit the heat potential possessed from waste

heat, additional measures that must be done so that

the waste heat can be utilized optimally, and how

much benefit is gained by wasted heat recovery.

There are some activities that produce heat as a

by-product, such as heat generated due to processing

at the factory, heat emitted by vehicle radiators, and

heat released by the condenser in the cooling system.

The amount of waste heat from the factory is high

Panggabean, S., Sibarani, D., Sigalingging, R. and Rindang, A.

Study on Waste Heat Potential of Commercial Refrigerator Condenser.

DOI: 10.5220/0010071700090013

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages 9-13

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

9

because usually, the heat comes from the

sterilization or the steaming process at very high

temperatures while the waste heat of motor vehicles

(such as cars or tractors) is classified as average. In

addition to both types of heat, there is still a low

waste heat from the condenser in the cooling system.

The heat from a cooling system derived from the

cooling cycle as a heat discharged to the

environment as a result of rising temperatures due to

the compression process of the compressor. The

cooling cycle includes: compressing refrigerant into

the condenser by the compressor, discharging the

heat from the condenser to the environment,

throttling by the expansion valve, and absorbing the

heat from the surrounding by the evaporator and

then come back to the compressor, thus the cycle of

the cooling system occurred. Based on the purpose,

the cooling system could be divided into several

types, such as air conditioner (AC) for cooling room

and refrigerator for maintaining the freshness of

food or drinks (for cold storage purpose). The

refrigerator itself is divided into two types, namely

domestic refrigerator and commercial refrigerator

also known as showcase refrigerator.

The waste heat of an air conditioner and a

domestic refrigerator has been studied before

(Suntivarakon, et.al., 2009; Shinde, 2014;

Rahmanto, 2011; and Momin, 2014), but not for a

commercial refrigerator. Based on previous studies

(Suntivarakon, et.al., 2009; Shinde, 2014;

Rahmanto, 2011; and Momin, 2014), the potential of

heat that can be utilized is quite satisfactory. Given

that the objectives of a commercial refrigerator

(showcase) are slightly different from domestic

refrigerators, thereby resulting heat generation may

have different potential values. Therefore, a more in-

depth review of the potential for waste heat in the

showcase refrigerator is required.

The purpose of this paper was to get the heat

potential value that was still held by the heat of the

condenser and to propose the type of activity that

was suitable based on the potential.

2 METHODOLOGY

The research was conducted on a one-door

commercial refrigerator AGATE-300 model with

R600a refrigerant type. The initial data on the

refrigerator before and after modification were taken

during 6 hours. Preliminary data required include

refrigerant temperature leaving the condenser,

temperature and RH of air around the condenser, the

temperature in the cold region of the refrigerator,

and the temperature and RH of the environment. The

data will be used to calculate the potential value of

waste heat, compression work, refrigeration effects

and coefficient of performance before and after

modification. Modification was made to the

condenser to concentrate the condenser waste heat

so that the heat can be utilized more centrally.

3 RESULTS AND DISCUSSIONS

The cooling process in the refrigeration machine

occurs when heat from one region is absorbed by the

refrigerant and releases the heat to another region.

This refrigeration process runs with the help of

refrigerant passing through the coil. This process

begins with the flow of the refrigerant with the aid

of a compressor from the evaporator (conducting

heat absorption) to the condenser (releasing the heat)

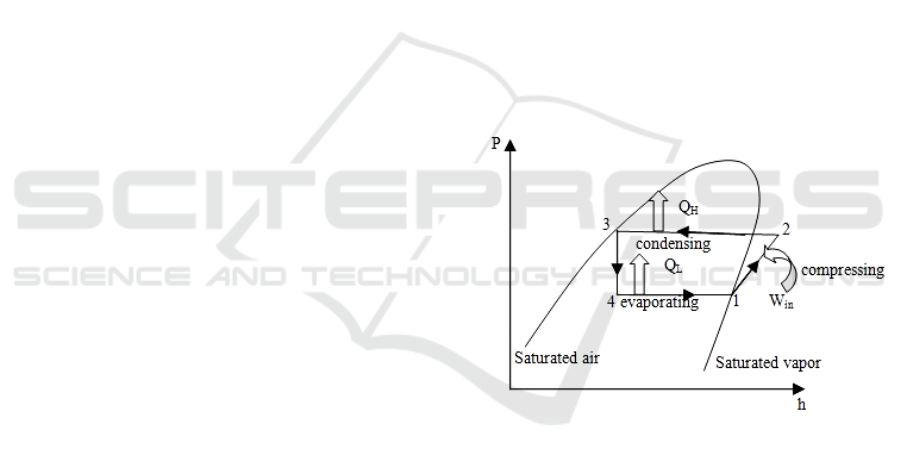

(Ashby, 2006). This process can be understood more

clearly with the aid of pressure-enthalpy diagrams of

the vapor refrigeration compression cycle (Figure 1)

(Stoecker and Jones, 1987).

Figure 1: The standard vapor compression cycle in the

pressure-enthalpy diagram.

There are some important parameters in

refrigeration system that need to be known, such as,

the refrigeration effect, the compression work, and

the coefficient of performance (COP).

How much compression work during the

ongoing refrigeration cycle is described as (Stoecker

and Jones, 1987):

(1)

The effect of the refrigeration system is

expressed in how much heat is released during the

refrigeration cycle and described as (Stoecker and

Jones, 1987):

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

10

(2)

The coefficient of performance (COP) signifies

the achievement value of the vapor compression

cycle is described as (Stoecker and Jones, 1987):

(3)

The waste heat from the condenser has the

potential to be exploited. For example waste heat

from an air conditioner used for drying clothes with

COP between 2.66 to 3.45. Hot temperatures dispose

of condensers vary between 41.9 to 42.6

o

C. Drying

rate of 1.1 kg.h

-1

without an additional fan and 2.26

kg.h

-1

with an additional fan. The heat potential

output of its air conditioner was 12,648 BTU.h

-1

or

equivalent to 3.71 kJ.s

-1

(Suntivarakon, et.al., 2009)

and for drying potato chips with COP of 2.64 to

3.26. Hot air temperature of 33.88

o

C to 44.05

o

C.

The air conditioner cooling capacity was about

2.734 ± 0.023 kJ.s

-1

(Rahmanto, 2011). The waste

heat of domestic refrigerator condenser can also be

used to heat water up to 47

o

C (Shinde, 2014) to

52

o

C (Momin, 2014).

Analysis of the heat potential of condenser

output begins with the measurement of the

temperature and humidity of the output air from the

refrigerator condenser as well as the environmental

air that described as (ASABE, 2006):

e

o

(T) = 0.6010 exp

17.27 T

T+237.3

(4)

Pv = e

o

(Twet) – γpsy (T – Twet)

(5)

RH = 100 x (Pv / e

o

(T)

(6)

In this case: e

o

(T) is saturated vapor pressure at

air temperature (kPa), Pv is actual vapor pressure

(kPa), e

o

(Twet) is saturated vapor pressure at wet

bulb temperature (kPa), Twet is wet bulb

temperature (

o

C), T is dry bulb temperature (

o

C),

γpsy is the psychrometric constant (0.06738 at

1atm), and RH is relative humidity of air.

Air specific humidity is described as (Cengel and

Boles, 2002):

ω = 0.622 x

(7)

In this case: ω is specific humidity (kg.kg

-1

), and

P is the atmospheric air pressure (kPa).

The enthalpy of air before and after passing

through the condenser is described as (Cengel and

Boles, 2002):

h = 1.005 T + ω(2501.3 + 1.82 T)

(8)

In this case: 1.005 is specific heat of dry air at 1

atm (kJ.kg

-1

), 2501.3 is air coefficient, and 1.82 is

specific heat of air (kj.kg

-1

K

-1

).

The specific volume of air passing through the

condenser is described as (Singh and Dennis, 2009):

(9)

In this case: Vs is the specific volume of air

(m

3

.kg

-1

).

Airflow rate pass through the condenser is

described as (Cengel and Boles, 2002):

V = v x A

(10)

In this case: V is air flow rate (m

3

.s

-1

), v = air

velocity (m.s

-1

), and A is surface area (m

2

).

The potential heat of the condenser is described

as (Cengel and Boles, 2002):

Q =

V

V

s

(11)

In this case: Q is heat (kJ.s

-1

), h

2

is the enthalpy of

air after passing through the condenser (kJ.kg

-1

), and

h

1

is the enthalpy of air before passing through the

condenser (kJ.kg

-1

).

3.1 Waste Heat Potential of

Commercial Refrigerator

Condenser

Based on observation, the following data (Table 1)

were obtained:

Table 1: Initial observation data (before modification).

Parameters

quantity

T ambient db

28.78

o

C

T ambient wb

26.96

o

C

T air from condenser db

33.39

o

C

T air from condenser wb

29.25

o

C

RH of air from condenser

73.57 %

Velocity of air leaving condener

5 m.s

-1

Study on Waste Heat Potential of Commercial Refrigerator Condenser

11

From the potential value obtained from

observation and calculation, it is advisable to utilize

the heat potential for the drying process of curcuma

chips. Given that, to dry the curcuma requires a

temperature between 40

o

C – 60

o

C (Sapei, et al,

2017). This is due to the presence of essential oils in

those rhizomes that would be lost if dried at high

temperatures.

Based on Table 1 and by using Equation 8 and

11, the enthalpy and the waste heat potential from

commercial refrigerator condenser could be

calculated and obtained respectively 94.29 kJ.kg

-1

and 1.336 kJ.s

-1

. This amount of energy can be used

for draying agricultural product such as curcuma

rhizomes. If all of the energy used for draying in 6

hours then the amount of curcuma chips that can be

dried as much as 13.2 kg, with the assumption that

all of energy used for drying or there are no energy

loss during drying process (efficiency is 100%),

90% of initial water content, and 7% of desired

water content.

The waste heat potential can be raised if a

modification is made to the condenser. In addition,

this modification can also increase the number of

activities that can use the waste heat. Furthermore,

this needs to be done because in the default

condition the direction of the waste heat (air leaving

the condenser) leads to the front of the refrigerator,

making it quite difficult to exploit the heat potential.

In addition, the heat tends to spread in all directions.

The modification done by moving the condenser

position to the back of refrigerator and adding some

partitions outside the condenser. Adding partitions

could reduce the air velocity leaving the condenser

but it also increased the air contact time with the

condenser surfaces. Here are the data obtained after

modifications (Table 2)

Table 2: Observation data after modification.

Parameters

quantity

T ambient db

28.78

o

C

T ambient wb

26.96

o

C

T air from condenser db

42.12

o

C

T air from condenser wb

32.09

o

C

RH of air from condenser

50.28 %

Velocity of air leaving condenser

1.6 m.s

-1

After modification the enthalpy and the waste

heat potential respectively 108.69 kJ.kg

-1

and 1.723

kJ.s

-1

. The enthalpy can be increased as much as

15.27% and the the waste heat potential can be

increased as much as 28.92%.

With this amount of energy, then 16.7 kg of

curcuma chips will be able to be dried, with

assumptions that all of energy used for drying or

there are no energy loss during drying process

(efficiency is 100%), 90% of curcuma water content,

and 7% of desired water content.

Although this modification could improve the

quality of heat that can be utilized, this also changed

the value of COP, compressor work and

refrigeration effect.

3.2 Work of Compressor, Refrigeration

Effect, and COP

The work of a compressor from a refrigeration can

be calculated using Equation1 and using properties

of refrigerant R600a (ASHRAE, 2009). From the

calculation, the work of compressor before and after

modification obtained as follows (see Figure 2):

Figure 2: The work of compressor.

The refrigeration effect of a commercial

refrigerator can be calculated using Equation 2. Here

is the refrigeration effect before and after

modification (see Figure 3).

Figure 3: The refrigeration effect.

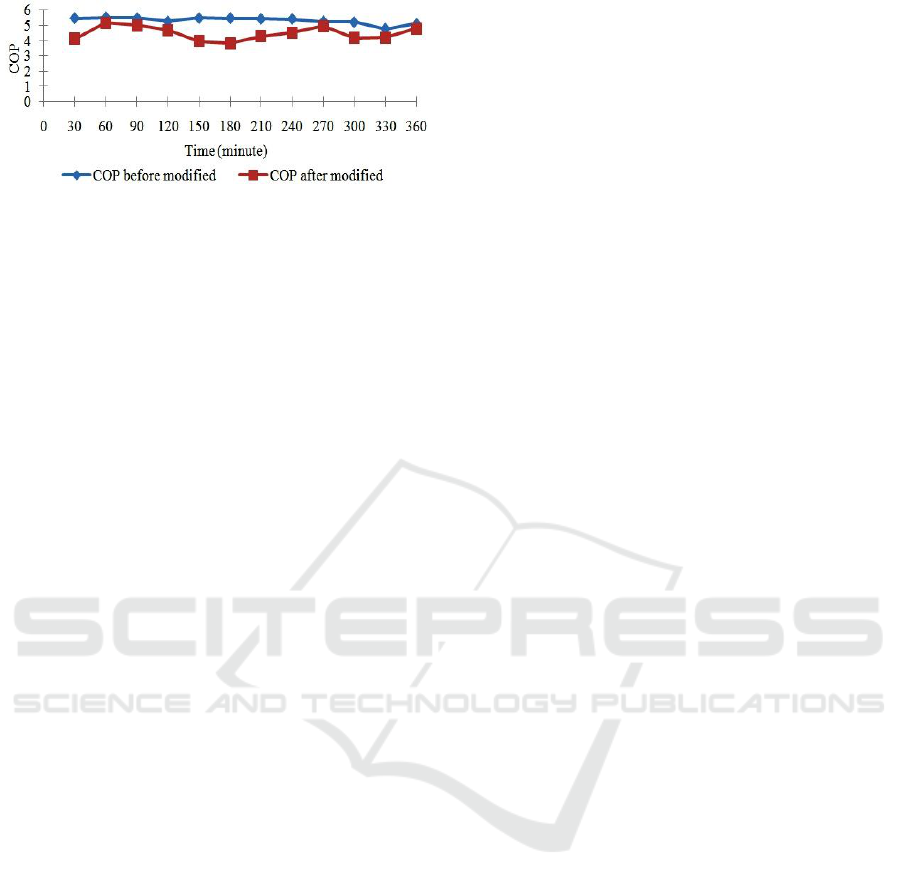

The COP of a commercial refrigerator can be

calculated using Equation 3. Here is the COP before

and after modification (see Figure 4).

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

12

Figure 4: The coefficient of performance (COP).

The COP after modification (Figure 4) was lower

than before modification. This happened because the

work of compressor (Figure 2) has been increased

after modification although the refrigeration effect

(Figure 3) was almost constant. Nevertheless, the

average of COP was still relatively high, which was

above 4. The increase in the work of compressor

could occur due to modification made to the

condenser position and the partitions added on the

outside of the condenser which resulted in a reduced

air velocity passing through the condenser. Thus

made the compressor work more even though the

refrigeration effect was almost constant. This

illustrates the considerable influence on the

performance of irreversible heat transfer between the

refrigerant on the cold and warm region.

4 CONCLUSIONS

From the observation, it can be concluded that the

waste heat of a commercial refrigerator had potential

to be utilized for another process such as for drying

process. The potential heat also can be improved by

doing some modification in to the system. The

enthalpy and the potential heat presented in the

waste heat before doing modification respectively

was 94.29 kJ.kg

-1

and 1.336 kJ.s

-1

. Modifications

done to the condenser such as moved the condenser

to the backside of refrigeration and added partitions

on the outside of condenser. By doing modifications,

the enthalpy could be increased as much as 108.69

kJ.kg

-1

(increased up to 15.27%) as well as the

potential heat as much as 1.723 kJ.s

-1

(increased up

to 28.92%).

ACKNOWLEDGEMENTS

This research was funded by Universitas Sumatera

Utara in accordance to TALENTA of Universitas

Sumatera Utara, Research Contract of Fiscal Year

2018 No. 38 / UN5.2.3.1 / PPM / KP-TALENTA

USU / 2018 on March 16, 2018.

REFERENCES

ASABE. 2006. Measurement and Reporting Practices for

Automatic Agricultural Weather Stations. ASAE.

Ashby B. H. 2006. Protecting Perishable Foods During

Transport by Truck. USDA, Washington

ASHRAE, 2009. The 2009 ASHRAE Handbook:

Fundamentals. American Society of Heating,

Refrigerating and Air-Conditioning Engineers Inc,

Atlanta

Cengel, Y. A., Boles, M. A., 2002. Thermodinamics an

Engineering Approach. McGraw Hill. New York.

Momin, G. G., Deshmukh, S. R., Deshmukh, M. T.,

Chavan P. T., Choudhari, P. P. 2014. COP

Enhancement of Domestic Refrigerator by Recovering

Heat from the Condenser. International Journal of

Research in Advent Technology

Rahmanto, D. E., 2011. Design and Performance Test of

Drying Chamber by Using Air Conditioning

Condenser Rejected Heat (Case Study of Potatoes

Chips Drying). Thesis IPB. Bogor.

Sapei, L., Tarigan, E., Hwa, L., Halim, V. P., Soebiantoro,

F. A., 2017. Drying Kinetics of Curcuma xanthorrhiza

Roxb. NRLS Conference Proceedings, International

Conference on Natural Resources and Life Sciences

(2016), KnE Life Sciences,

Shinde, T. B, Dhanal, S. V., Mane, S. S., 2014.

Experimental Investigation of Waste Heat Recovery

System for Domestic Refrigerator. International

Journal of Mechanical Engineering and Technology

(IJMET).

Singh, R. P., Heldman, D. R., 2009. Introduction to Food

Engineering. Academic Press, INC. New York.

Stoecker, W.F., Jones, J.W., 1987. Refrigeration and Air

Conditioning. McGraw-Hill Book Company, New

York.

Suntivarakorn, P., Satmarong S., Benjapiyaporn, C.,

Theerakulpisut, S., 2009. An experimental Study 0n

Clothes drying Using Waste Heat from Split Type Air

Conditioner. International Scholarly and Scientific

Research & Innovation.

Study on Waste Heat Potential of Commercial Refrigerator Condenser

13