A Comprehensive Study of Sea Wave Tidal Power Plant (PLTPS)

E. Warman

1

, W. Armi

1

, and F. Fahmi

2

1

Department of Electrical Engineering, Faculty of Engineering, Universitas Sumatera Utara

2

Centre of Excellence Sustainable Energy and Biomaterial, Universitas Sumatera Utara,

Jl. Almamater, Kampus USU Medan 20155 INDONESIA

Keywords: Tidal, Sea wave, Power plant.

Abstract: The use of fossil fuel sources to power plants is a major problem in many countries in the world today. Among

power plants that use water as an energy source, tidal energy is one alternative of renewable energy sources.

This paper discusses all matters relating to tidal power plants (PLTPs) of the type, generation process,

advantages and disadvantages as well as the subject of this study discussed three case studies of generators of

two types of conversion, i.e., tidal range and tidal stream to see the characteristics of each plant. From the

result of the case study, it can be seen that the prospect of the implementation of marine energy development

especially the tidal energy is good enough to be seen from the potential of Indonesia sea that has the range

and speed of current that fulfill the provisions, especially in some straits in eastern Indonesia

.

1 INTRODUCTION

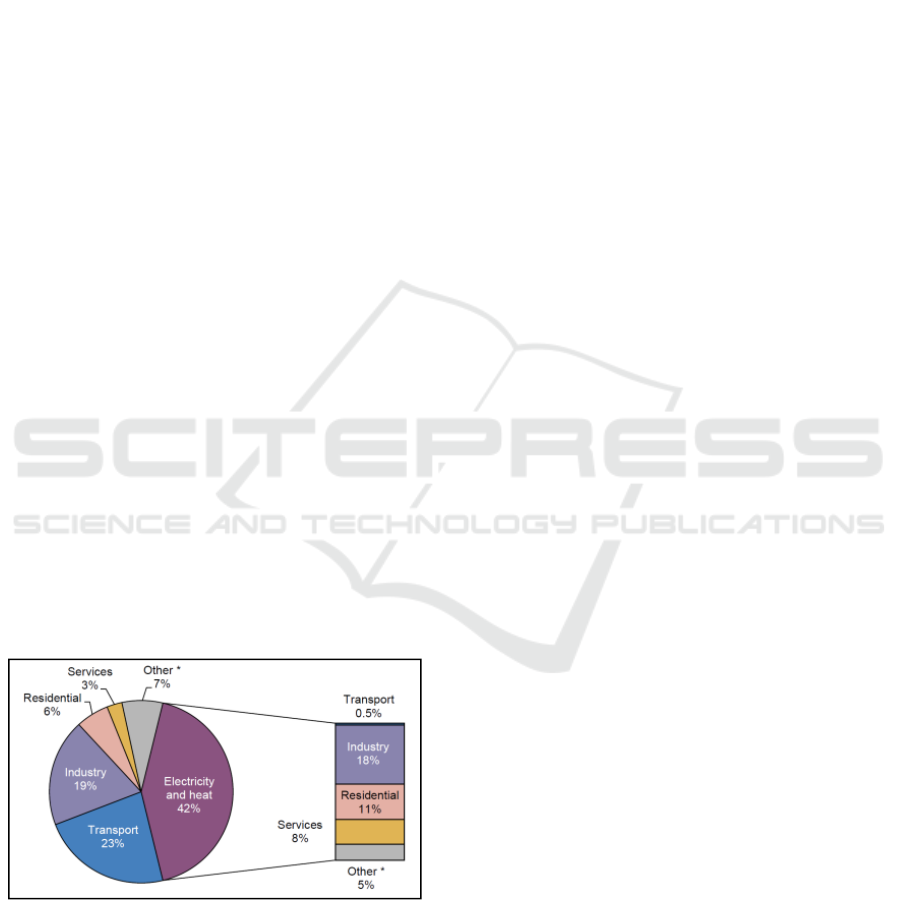

Energy use indirectly contributes to the high

concentrations of CO2 in the atmosphere that have

increased significantly over the last century. From

some sectors of energy users, the electricity and heat

generation sectors are the most widely used energy

sources so as to be directly proportional to CO2

emissions into the atmosphere as shown in Figure 1

(IEA, 2015).

Figure 1: CO

2

emissions from various sectors in 2013

The use of fossil fuel for power plant has been an

inevitable problem. Because of the negative effects

caused by the release of CO2 into the atmosphere and

the depleting supply of non-renewable sources of

energy while the use of electric energy is increasing,

then the use of renewable energy sources began to

promote.

Tidal energy is one alternative source of

renewable energy. The working principle is the same

as hydroelectricity, where water is used to rotate

turbines and generate electrical energy. Energy is

derived from the utilization of sea level variations

contained in the tidal mass transfer of water.

2 MATERIAL AND METHODS

2.1 Tidal Energy Conversion System

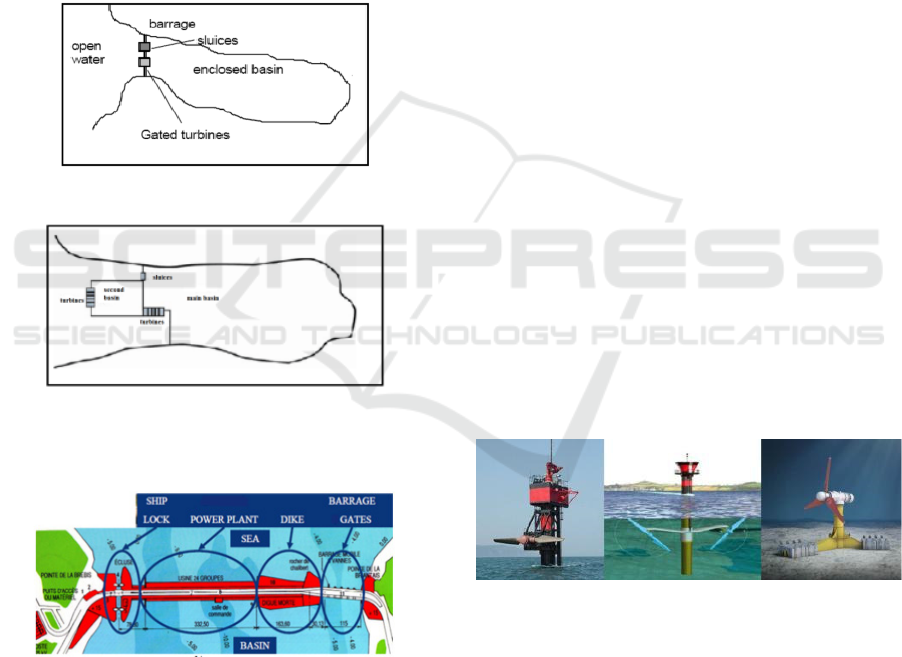

Tidal Barrage is a tidal utilization technology using

barrage or dam. Energy is produced from the

difference in sea tidal height. Electricity is generated

through a turbine placed at the dam.

The dam extracts tidal energy from the height

difference between water in the Dam and at sea.

When the tide, water will enter into the Dam until

certain conditions the water will be retained and

released back through the water turbine when the

water receded. From the process of tidal movement of

water that moves the turbine in the Dam then, the

electrical energy can be obtained.

280

Marwan, E., Armi, W. and Fahmi, F.

A Comprehensive Study of Sea Wave Tidal Power Plant (PLTPS).

DOI: 10.5220/0010085302800286

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

280-286

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

There are two main types of tidal reservoirs:

single-basin and double-basin systems. Single Basin

consists of one basin and requires a dike that cuts

down the estuary or bay. There are three operating

patterns in this system such as tidal generation, tidal

generation and two-way generation as in Figure 2.

Double Basin system requires the construction of two

barrages, core and additional. The main basin is

basically the same as the receding mode in a single

basin system. The difference is that in this case some

of the energy produced is used to pump water into the

second basin. For this reason, the second dam acts as

a storage element, extending the time period in which

the dam can generate electricity as illustrated in

Figure 3.

Figure 2: System Single Basin

Figure 3: System Double Basin

Figure 4 describes the barrage type PLTPs

component.

Figure 4: The layout of PLTPs type barrage component

Some components and its function as follows:

1. Gate: The gate controls the flow of water between

the sea and the basin.

2. Substation: Ground generator to raise the voltage

and interconnect to the network.

3. Basin: Water reservoir area at high tide and return

water to the sea at low tide (low tide).

4. Inactive dike: Separation barrier.

5. Powerhouse: Generally, power plants use bulb

turbines as their initial drivers.

6. Lock: The structure built between the sea and the

basin that allows the ship or boat to pass.

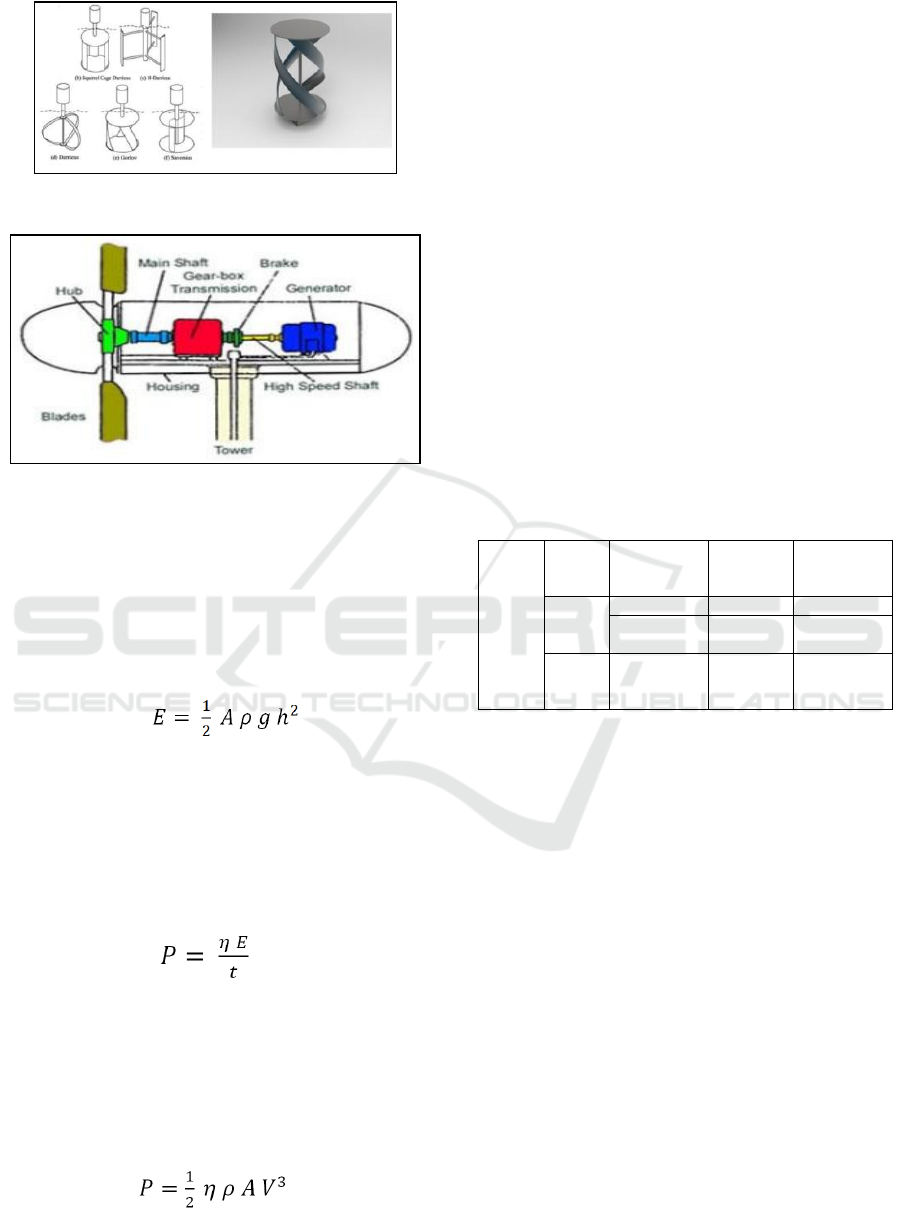

2.2 Tidal Stream

Tidal Stream or tides that is the movement of

seawater due to the tidal cycle, creating kinetic

movement. The potential of this current is usually

located near the coast; especially there is inhibiting

the topography, such as inter-island straits. Turbines

used in this technology are often called Free Flow

Tidal Turbine (FFTT), have the same form and

working principle with a wind turbine. The large

density of seawater makes the current drive strong so

that the FFTT can generate large electrical energy.

Currently, there are two types of turbines,

horizontal axis turbine, and a vertical axis turbine. In

the horizontal axis turbine (HAT), the blades are

designed in the opposite direction with the direction

of ocean currents due to the current velocity and

direction of the current causing the turbine blades to

rotate as in Figure 5. Turbine blades are below the

rotating water surface on the horizontal axis parallel

to the direction of the water flow. The optimum

operating point of this turbine is at a current velocity

between 4 and 5.5 mph (Khaligh, 20018). At the

current velocity, a 15-meter turbine is capable of

producing energy comparable to a 60-meter wind

turbine. The strategic location of power plant

placement with this type of turbine is near the coast at

a depth of 20-30 meters.

(a) (b) (c)

Figure 5: (a), (b) 2 blades; (b) 3 horizontal blades

Vertical axis turbine (VAT) is designed perpendicular

to the direction of ocean currents as shown in Figure

6. VAT has greater efficiency but is unstable, and the

resulting vibration is higher. Another advantage is

that the size of the blade on a VAT type turbine can

be increased without any restrictions as in the HAT

turbine type. Figure 7 describes the PLTPs

component of the stream type.

A Comprehensive Study of Sea Wave Tidal Power Plant (PLTPS)

281

Figure 6: (a) vertical axis turbine; (b) gorlov turbine

Figure 7: Component of PLTPs

2.3 Power on Turbine

To calculate the estimated power output of this

turbine PLTPs used the following formula:

2.3.1 PLTPs System Dams (Barrage)

The capacity of a barrage type tidal turbine can be

calculated by Equation 1 (Araquistain,-):

(1)

With: E = potential energy (J), A = the horizontal area

of the dam (m

2

), ρ = density of water (1025 kg/m

3

) /

(1021-1030 for seawater), g = the force of gravity of

the earth (9.81 m/s

2

) , h = the water level at the dam

(m).

From Equation 1, we can calculate the power which

can be generated using Equation 2:

(2)

With: P = Energy raised (W), η = turbine efficiency,

t = time of operation (s)

2.4 PLTPs Flow Tide System (Stream)

Tidal current turbine capacity can be calculated by

Equation 3 (Royal Academy of Engineering,-)

(3)

With: P = Energy raised (W), η= turbine effiency, ρ =

density of water = 1025 kg/m

3,

A = turbine

coverage area (m

2

), V= speed of water flow (m/s)

The literature review study was conducted by a

systematic search on electronic databases: Web of

Science, British Hydropower Associates (BHA),

Indonesian Energy Outlook and several other

publications. The search is then continued by

scanning a list of references from relevant

publications so that explanations of case studies can

be more widely elaborated. The aspects reviewed

include the following: location of construction,

structure, and components, tidal potential, type of

turbine, working cycle, generation capacity, and

annual energy.

The case study discussed in this paper are 3 tidal

power generation units. The three power generating

units represent two types of tidal power and tidal

current tidal ranges. The 3 units are La Rance, Sihwa,

and Strangford Narrow as shown in Table 1.

Table 1: Case studies of PLTPS

Sea

Tidal

Power

Plants

Gener

ator

Type

Generator

Name

Location

Year of

Developme

n

t

Tidal

Range

La Rance F

r

ance 1966

Sihwa

South

Korea

2010

Tidal

Curre

n

t

Strangford

Northern

Ireland

2008

3 RESULTS

3.1 La Rance Tidal Power Plant, France

La Rance Tidal Power Plant is a tidal power plant

built in the estuary of the river Rance in Brittany,

France as illustrated in Figure 8. With a capacity of

240 MW and built in 1966 making it the oldest and

second largest PLTPs in the world and generating an

annual capacity of 540 GWh (BHA, 2009). With a

tidal height of 8.2 m which is the largest tidal range

in France the plant supplies electrical energy to a 225

kV national transmission network and illuminates ±

1300,000 homes annually.

The background of the construction of PLTPs at

the mouth of this river includes the height of the

largest tidal range including in France with an

average of 8.2 m to a maximum of 13.5 m. The

reservoir volume is 184,000,000m3, with more than

20km to the headwaters (22km2 basin area) and only

750 m wide by the mouth of the estuary.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

282

a. Structure and Components

1. Powerhouse

Bulb turbines are placed on a 332.5m powerhouse

dam.

2. Dam

Dyke or embankment on La Rance power plant has a

length of 163.6m. with a barrage length of 145.1 m, 6

gates or a water gate with a height of 10 m, a width of

15 m and a maximum water flow of 9600 m

3

/s with a

basin area of 22 km

2

as illustrated in Figures 9 and 10.

Figure 8: Location La Rance tidal power plant

Figure 9: Construction dyke at La Rance tidal power plant

Figure 10: Construction Barrage at La Rance

b. Electric Supplies

In the La Rance tidal power plant, there are 24 x 10

MVA alternators operating in 2bar (28.44psi)

pressurized air absolute pressing; AI 3.5kV. There are

6 units of operation with each 4 bulb turbine complete

with supporting components for turbine and

alternator adjustment. 3 transformer units (3.5 / 3.5 /

225kV) with 80MVA power, with OFAF cooling

system and 225kV network connection using oil-

filled cables under pressure.

c. Working Cycle

The work cycle on the La Rance tidal power plant is

shown in Figures 11 and 12.

1-way generation (Tidal generation)

2-way generation (Tidal generation and

generation on the rising tides)

Figure 11: A 1-way work cycle at La Rance tidal power

plant

Figure 12: A 2-way work cycle at La Rance tidal

d. Turbine

The characteristics of turbine bulb used in La Rance

PLTPs are 5.35 m diameter, weight: 470 t, Rated head

5.65 m, discharge at rated head 275 m

3

/s, output 10

MW, rotation speed 93.75 rpm, max. over speed: 260

rpm, 4 blades (inclination: -5° to +35°), 24 guide

vanes, minimum head: 3 m and maximum head: 11

m.

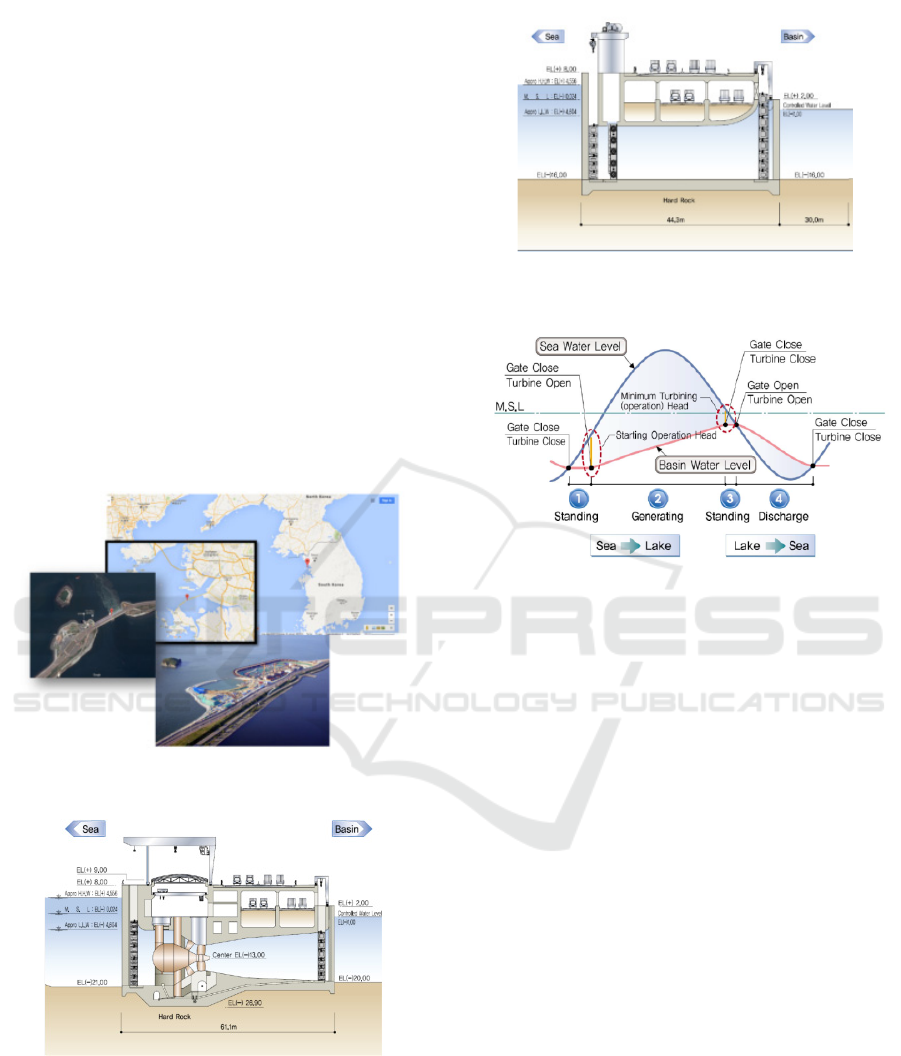

3.2 Sihwa Tidal Power Station, South

Korea

Sihwa Lake Tidal power station is located 4 km from

Siheung town in Gyeonggi Province South Korea As

illustrated in Figure 14. With a capacity of 254 MW

makes the Power plant is the largest PLTPs today.

Power is generated by utilizing the rising tidal flow

into a 30 km

2

basin using 10 turbine bulb units of 25.4

MW capacity. 8 water gates placed to release water

from the barrage to the sea. This project cost $ 355.1m

and was built between 2003 and 2010 generating an

annual capacity of 552.7 GWh (Schneeberger, 2008).

A Comprehensive Study of Sea Wave Tidal Power Plant (PLTPS)

283

a. Structure and Components

The construction of the Sihwa Lake tidal power plant

is similar to the first case study, La Rance tidal power

plant. For size, specifications can be seen in Figures

15 and 16.

b. Turbine

Technical Data for turbines used in Sihwa lake tidal

power station is 10 bulb turbine diameter runner 7.5

m with output of 25.4 MW and output generator 26.8

MVA, Rated speed 64.3 rpm, Rated head 5.82 m,

Rated discharge 482.1 m³/s, voltage rating 10.2 kV,

current rating 1515 A, annual energy production is

around 550 GWh.

c. Working Cycle

This power plant cycle uses a 1-way generation cycle

that is a tidal generation, meaning that the flow of

water used to turn turbines is a tidal stream. With data

of basin area 56 Km2. This unit operates 2x in a day

as illustrated in Figure 17.

Figure 14: Location Sihwa tidal power plant

Figure 15: Construction of the powerhouse Sihwa tidal

Figure 16: Construction dyke Sihwa tidal power plant

Figure 17: Sihwa tidal power plant work cycle

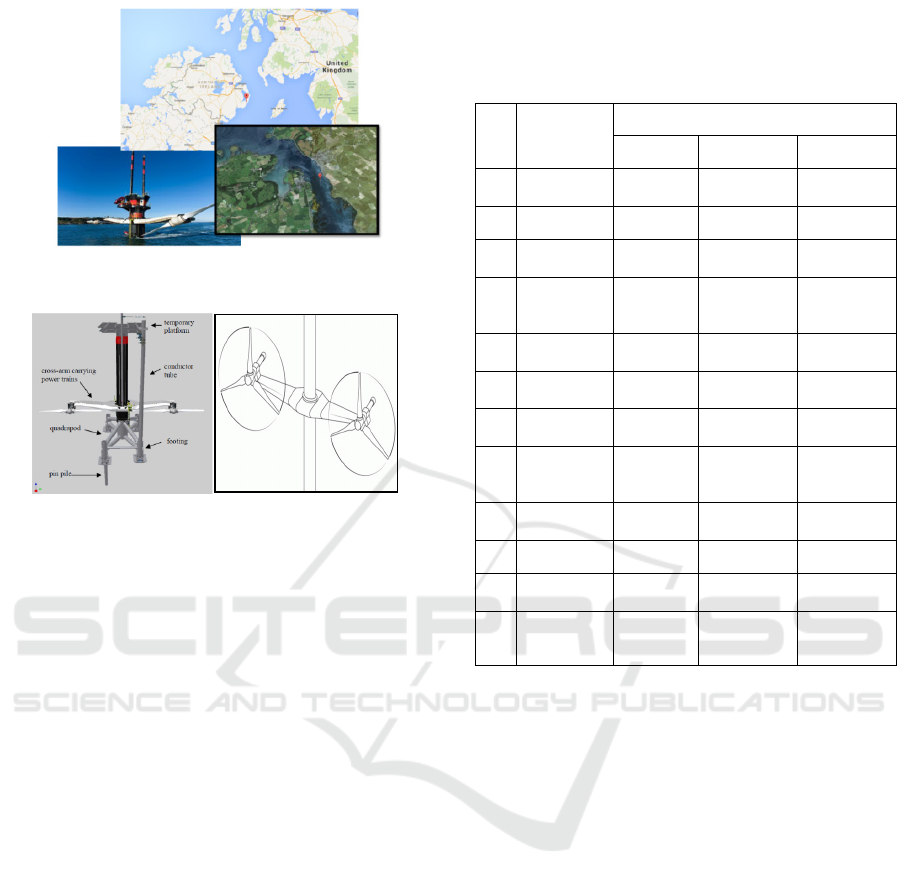

3.3 Strangford Narrows MCT, Northen

Ireland

Seagen is the first large-scale commercial tidal power

plant in the world. The first seagen was installed at

Strangford Narrows between Strangford and

Portaferry in Northern Ireland, England in April 2008

and connected to the grid in July 2008. The turbine

generates 1.2 MW between 18 and 20 hours a day

when tides rise and exit from Strangford Lough

through a pronged cleft (Narrow) As shown in Figure

18. SeaGen S 1.2MW system is capable of generating

up to 20MWh of energy per day in Strangford, whilst

totaling 6,000MWh per year. This equals the average

energy generated from the 2.4 MW wind turbine

(MCT, 2013). The seagen turbine weighs 300t; each

turbine drives the generator through a gearbox such

as a water turbine or wind in general. This turbine has

a feature where both blades can rotate up to 180

degrees allowing them to operate in both directions -

on tidal and flood tides. The rotor can be lifted up

through the water surface to anticipate when the

current is too strong beyond the limit of the rotor's

ability. Its feature design allows the S-turbine tidal

stream turbine system to achieve 48% efficiency at

various current velocities as illustrated in Figure 19.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

284

Figure 18: Location of Seagen S tidal Stream Turbine

Figure 19: (a) Seagen S tidal Stream Turbine component;

(b) visualization of the turbine sweep area

4 DISCUSSION

Comparing the two types of La Rance, France and

Sihwa Korea generators, there are differences and

similarities, that is, La Rance was built approximately

45 years earlier than Sihwa, obviously the

development of technology makes it easier to build a

similar power plant with a larger capacity where La

rance capacity 240 MW with 24 turbines of 10 MW

while Sihwa power plant uses 10 turbine units with a

capacity of 25.4 MW. The diameter of the turbine

sihwa is greater that is 7.5m while La Rance 5.35m.

with half the cost of La Rance developer sihwa tidal

power can build a plant with a better capacity of €

580m or equivalent to the US $ 656.44m, while the

cost of building a tidal power plant of US $ 355.1m.

it is because the existing embankment construction at

Sihwa lake has been previously made for agricultural

purposes. Another difference is seen from the work

cycle in which the La Rance power plant works in two

directions, the generation whereas the tidal power

plant works in one direction where we know that in

some places the tidal generation is less effective as

the tidal generation because the water discharge is

likely to be out of control. For tidal stream turbine

type generation in accordance with the theory that the

greater the area of turbine sweep with the same

current velocity yields greater energy as attached in

Table 2.

Table 2: Comparison between PLTPS

No

.

Aspect of

Review

PLTPS Unit

La Rance Sihwa Strangford

1 Location France

South

Korea

Northern

Ireland

2. Year 1966 2011 2008

3

Tidal

heigh

t

8,2 m 6.3 m -

4

Tidal

current

velocity

- - 2,4 m/s

5

Conversion

system

Barrage barrage stream

6

Type of

turbine

Bulb Bulb

Horizontal

axis

7

D-runner

turbine

5.35 m 7 m 16 m

8

Number of

turbines

24 unit

@10

MW

10 unit @

25.4 MW

2 unit @

600 kW

9

Working

cycle

2 ways 1 way 2 ways

10 Capacity 240 MW 254 MW 1.2 MW

11

Annual

energy

540 GWh 552.7 GWh 6 GWh

12

Developme

nt costs

US$ 656.

44m

US$

355.1 m

€ 3.6 m

5 CONCLUSION

From the results of the discussion we obtained the

following conclusions:

1. PLTPs are subdivided according to their energy

extraction method, i.e., potential energy that is

vertical water movement associated with the ups and

downs of tidal and kinetic energy which is the result

of the horizontal motion of water which is also called

as tidal current.

2. The prospect of the implementation of the

development of marine energy utilization, especially

tidal energy is good enough to be seen from the

potential of Indonesia sea that has the range and speed

of current that meet the requirements, especially in

several straits in eastern Indonesia.

3. Location determination, selection of turbine

type, and type of duty cycle are determined by the

characteristics of the location itself either from its

topology, tidal range, and its tidal current velocity.

A Comprehensive Study of Sea Wave Tidal Power Plant (PLTPS)

285

REFERENCES

Araquistain, T.M., Tidal Power: Economic and

Technological Assessment. Department.

British Hydropower Association (BHA), 2009. La Rance

Tidal Power Plant, Liverpool.

International Energy Agency (IEA) Statistics, 2015. Key

Trends in CO

2

Emissions Excerpt from CO

2

Emissions

From Fuel Combustion.

Khaligh A;” Energy Harvesting.” Illinois Institute of

Technology 2008.

Marine Current Turbine (MCT), 2013. Seagen-S 2MW,

Proven, and Commercially Viable Tidal Energy

Generation.

Schneeberger M., 2008. Sihwa Tidal – Turbines And

Generators For The World‘s Largest Tidal Power

Plant, Andritz Va Tech Hydro, Bristol.

The royal academy of engineering, Wind Turbine Power

Calculations RWE power renewable, Mechanical, and

Electrical Engineering Power Industry.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

286