R

isinoleaic Acid Derivates as Templates for Synthesis of Mesoporous

Silica Material based on Tetraethylorthosilicate and

3-Aminopropyltrimethoxysilane as CO-Structure Directing Agent

Andriyani

1*

, Marpongahtun

Y. Muis

1

1

Department of Chemistry, Faculty of Matematics and Natural Science, Universitas Sumatera Utara, Medan, Indonesia

Keywords: FT-IR, X-ray diffraction, scanning electron microscopy

Abstract:

The synthesis of mesoporous silica using sodium risinoleate as a template, 3-

aminopropyltrimethoxysilane as the structural directing agent and tetraethylortosilicate as a source

of silica was carried out. The reaction conditions are carried out by varying the amount of silence

before the aging stage. Mesopore silica obtained was characterized using FT-IR, X-ray diffraction

(XRD), scanning electron microscopy (SEM) and porosity analysis.

1 INTRODUCTION

Synthesis of silica material using tetraethyl

orthosilicate (TEOS) as a silica source takes place

through a sol gel process with several steps: (i)

hydrolysis and condensation of precursor molecules

and sol formation, (ii) gelatinization (gel sol

transition), (iii) aging and (iv) drying (Schubert &

Husing, 2005). The hydrolysis stage and

condensation to sol gel are affected by acid or base

conditions. Silica material which has pores is

obtained by adding organic components in the form

of supramolecules such as surfactants or

biomacromolecules which function as templates.

Pores in the material will be obtained after the organic

components are removed by calcination.

The formation of mesoporous silica material

which has a pore size between 2-50 nm using

surfactant as a template through the Cooperative self-

assembly route beginning with the formation of

nuclei in the liquid solution system of surfactants with

inorganic components, then the nuclei undergo

incorporation to form aggregates so that a solid phase

is formed which is separated from the liquid phase.

Furthermore, polymerization and condensation of

inorganic materials occur. Through the calcination

process mesopore material will form (Wan, 2007).

The interaction between organic matter

(surfactants) and inorganic materials (silica

precursors) greatly determines the pore

characteristics obtained. The use of anionic

surfactants with a negative charge on the head group

(S

-

) and cationic surfactants with a positive charge on

the head group (S

+

) in the formation of mesostructural

material is regulated through electrostatic

interactions. Interaction can occur directly in the form

of S

+

I

-

and S

-

I

+

(I inorganic components) or indirectly

using bridges with ion counterparts such as halogen

anions (X

-

= Cl

-

, Br

-

) with the interaction of S

+

X

-

I

+

and S

-

X

+

I

-

takes place in acidic and alkaline cations

(M

+

= Na

+

, K

+

with S

-

M

+

I

-

interactions in alkaline

conditions (Soler-Illia G J et al, 2002).

Mesostructural synthesis using anionic surfactant

with route (S-I +) produces hexagonal mesostructures

and lamellar copper oxides and by route (S

-

M

+

I

-

)

produces lamellar zinc oxide (Huo, 1994). The use of

anionic surfactants as templates is difficult to get

good interaction between silica and surfactants. The

use of organosilan as a co-structure-directing agent

(CSDA) to achieve good interaction between

surfactants and inorganic species has been proposed

by (Che, 2003). The structure of the organosilan

compound contains two sides of the alkoxilane which

can condense with silica precursors (TEOS) and the

organic side which can form electrostatic, covalent,

hydrogen bonds or π-π interactions with surfactant

head groups. Bridges of organic and inorganic species

will help self-organization into regular assemblies.

Synthesis of various mesoporous silicates

(AMSn) using N-lauryl glutamic acid and

aminopropyl triethoxysilane (APS) as co-structure

directing agents (CDSA) and tetraethyl orthosilicate

has been carried out (Gracia, 2005). Synthesis of

AMS 0.5 was carried out using sodium dodecyl

sulfate (SDS) in water / ethanol followed by the

1002

Andriayani, . and Muis, M.

Risinoleaic Acid Derivates as Templates for Synthesis of Mesoporous Silica Material based on tetraethylorthosilicate and 3-aminopropyltrimethoxysilane as Co-structure Directing Agent.

DOI: 10.5220/0010088410021007

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1002-1007

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

addition of a mixture of surfactants 3-aminopropyl

triethoxysilane (APTES) and tetraethyl silicate

(TEOS) (Yokoi, 2003).

Risinoleic acid (12-hydroxy-9-cis-octadecenoic

acid, C

18

H

34

O

3

) is an unsaturated fatty acid found in

the seeds of the Castor plant (Ricinus cmmunis L.,

Euphorbiaceae). Industrially, ricinoleic acid is

produced from safonification or fractionation

distillation from castor oil hydrolysis. Risinoleic acid

in the form of salt can be sodium risinoleate

(C

18

H

33

NaO

3

) in the form of pale white flour, while

in the form of methyl esters risinoleic acid (C

19

H

36

O

3

)

in the form of a paleyellow liquid. In previous studies

we have examined the effect of variations in 0.1N

hydrochloric acid in the synthesis of mesoporous

silica materials using sodium risinoleic salt as a

template (Andriani, 2013). In this paper, we will

report the synthesis of silica mesoporous material

using derivates of ricinoleic acid, namely sodium

risinoleate as a template by varying the amount of

silting time before the aging stage. Also synthesized

mesoporous silica material using methyl ester

risinoleate as a template by adding methanol as

cosolvent.

2 RESEARCH AND METHOD

2.1 Material

Tetraethylorthosilicate (TEOS, 98%) and 3-

aminopropyltrimethoxysilane (APMS) and

hydroclhoric acid were purchased from Sigma

Aldrich, sodium ricinoleic acid (C18H33NaO3)

obtained from VWR, and deionized water obtained

from pt sumber aneka karya abadi.

2.2 Material

Tetraethylorthosilicate (TEOS, 98%) and 3-

aminopropyltrimethoxysilane (APMS) and

hydroclhoric acid were purchased from Sigma

Aldrich, sodium ricinoleic acid (C

18

H

33

NaO

3

)

obtained from VWR, and deionized water obtained

from PT Sumber Aneka Karya Abadi.

2.3 Characterizations

The obtained products were then subjected to

characterization by using X-ray diffraction (Philip

PW 1710), Fourier transform infrared (Shimadzu IR-

Prestige-21), scanning electron microscope (JEOL

JSM-7000F and ZeissVPSEM1555), transmission

electron microscope (JEOL JEM-1400), and

adsorption desorption isotherm (Quantachrome Auto-

sorb).

2.4 Synthesis of Silica Mesopurus

Material using Sodium Ricinoleic

Acid as Template,

3-aminopropyltrimehoxysilane

(APMS) as CSDA,

tetraethylorthosilicate (TEOS),

Methanol and Variasi Pendiaman

(statically) Sebelum Pematangan

Sodium ricinoleic acid 2.072 g (6.47 x 10

-3

mol) and

210 ml deionized water was added into a two-neck

flask and stirred. Into the mixture was then added 8.4

g (7.06 x 10

-4

mol) HCl 0.1 M and stirred 1 hour at

room temperature (solution A). A mixture of 9.8 g

(0.047 mol) tetraethylorthosilicate and 0.7 g (0.022

mol) 3-aminopropyltrimethoxysilane in 0.7 g (0.022

mol) methanol were prepared in another beaker and

stirred for 15 minutes (solution B). The solution B

was added into solution (A) and stirred for another 2

hours at room temperature. The mixture was cured in

an oven at a temperature 80C for 45 hours. A white

precipitate was separated from the solution by

centrifuge and washed with deionized water and dried

at 50C. Surfactant was then removed by calcination

at 550C for 6 hours. The above process was repeated

with time variation of statically treatment at 1 and 2

hours and without statically. The obtained products

were then subjected to characterization by using X-

ray diffraction (XRD), FT-IR, SEM and TEM and

adsorption desorption isotherm (Quantachrome Auto-

sorb). The conditions reaction can be seen in Table 1

below.

Tabel 1: Condition of reaction with variation time

statically treatment before aging process.

Treatme

nt

Na-

risino

leic

(mol)

AP

MS

(m

ol)

TE

O

S

(m

ol)

HCl

(mol

)

Me

tan

ol

(m

ol)

Statica

lly

time(h

ours)

Run 8b 6.5 x

10

-3

3.9

x

10

-3

0.0

47

7.1 x

10

-4

0.0

2

-

Run 9b 4.7 x

10

-3

5.6

x

10

-3

0.0

34

1.5 x

10

-3

0.0

3

1

Risinoleaic Acid Derivates as Templates for Synthesis of Mesoporous Silica Material based on tetraethylorthosilicate and

3-aminopropyltrimethoxysilane as Co-structure Directing Agent

1003

Tabel 1: Condition of reaction with variation time

statically treatment before aging process. (cont.)

Treatme

nt

Na-

risino

leic

(mol)

AP

MS

(m

ol)

TE

O

S

(m

ol)

HCl

(mol

)

Me

tan

ol

(m

ol)

Statica

lly

time(h

ours)

Run 10b 4.7 x

10

-3

5.6

x

10

-3

0.0

34

1.5 x

10

-3

0.0

3

2

Run 11b 6 x

10

-3

7.3

x

10

-3

0.0

85

6 x

10

-3

- 2

3 RESULT AND DISCUSSION

3.1 Synthesis of Silica Mesoporous

Material using Sodium Ricinoleic

Acid as Template,

3-aminopropyltrimethoxysilane as

CSDA, tetraethylorthosilicate

(TEOS), Methanol and Variations

of Standing Time before the Aging

Treatment

Synthesis of mesoporous silica material using

tetraethylortosilicate, sodium risinoleate, 3-

aminopropyl trimethoxysilane with the addition of

HCl and methanol was carried out by varying the

static time before aging at 80C. The addition of

methanol serves as a co-solvent to homogenize the

reaction mixture and can also affect the formation of

sodium risinoleic micelles which serve as templates

(Wang, 2009).

Silica material at Run 8b before calcination is solid

with a soft yellowish white texture. The solids are

light yellow due to the mole template ratio of sodium

risinoleate and HCl large enough (9:1) and the mole

ratio of sodium risinoleate and methanol is quite low

(1:3), so that the methanol used is not enough to

dissolve excess sodium risinoleate. Solids obtained

after calcination are fine white, light and soft solids.

Whereas silica material at Run 9b before

calcination is obtained, white solids are slightly

harder than Run 8b and have homogeneous fine

grains. White solids are obtained due to an increase in

the mol ratio of sodium risinoleate to HCl (3: 1) and

the mole ratio of sodium risinoleate to methanol (1:

7), an increase in the amount of methanol can dissolve

excess sodium risinoleate. After calcination, it is

obtained a harder white solid and granular granules.

Silica material from Run 10b before calcination is

obtained with a soft soft white solid containing

granules or granules. After calcination, white solids

are obtained which are harder and have granules

larger in size than particles of Run 9b.

Silica material from Run 11b before calcination

obtained yellowish white solids and has smaller

granules than Run 10b. The solid color is slightly

yellow because it does not use methanol even though

the mol ratio of sodium risinoleate and HCl is greater

(2: 1). After calcination is obtained, a dry creamy

white solid has granules finer than Run 10b. All silica

materials were characterized using FT-IR, XRD,

SEM and porosity analysis.

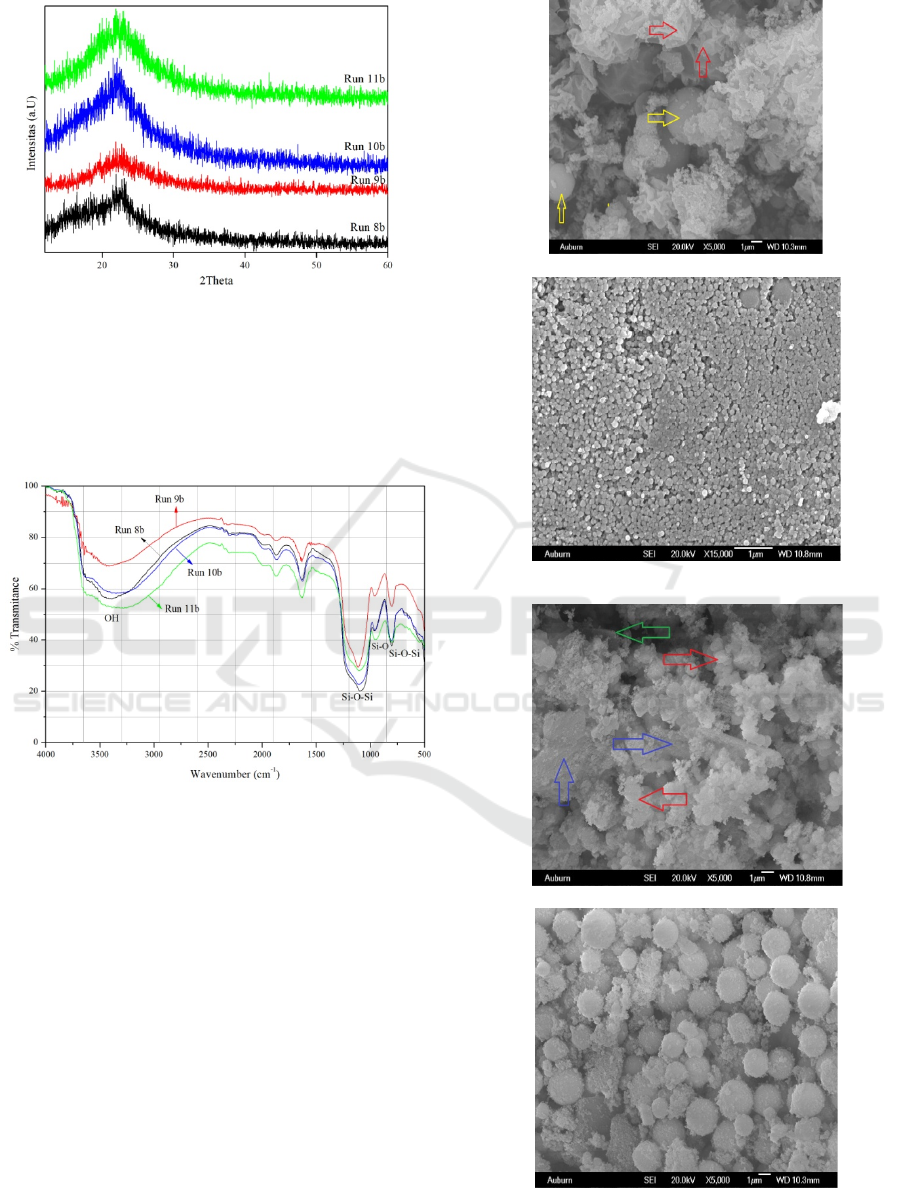

3.1.1 X-ray Diffraction (XRD)

Analysis of X-ray diffraction (XRD) of silica material

products Run-8b, Run-9b, Run-10b, and Run-11b can

be seen in Figure 2 below.

Diffractogram of XRD of mesoporous silica

material Run 8b, Run 9b, Run 10b and Run 11b

(Figure 1) at a 2 between 10 and 30 indicates that

all diffractograms have the same shape as a broad

peak around 24.0. This proves that the material is

amorphous and has nanoparticle size. This is

consistent with the data reported by previous

researchers (Li B, 2011)(Zao Q, 2011)(Zhang J,

2003)(Shah, 2009)(Khali, 2007)(Lin, 2010)(Park,

2006).

All silica material obtained in Run 8b, Run 9b,

Run 10b and Run 11b (Figure 2) shows the widened

absorption peaks between 3638 cm

-1

to 3167 cm

-1

,

this is due to the strain of OH (Si-OH) groups, while

at 965 cm

-1

to 951 cm

-1

is given by Si-OH asymmetric

group (

as

Si-OH). Other absorption peaks were also

seen at 1107 cm

-1

to 1094 cm

-1

which were sharp due

to the presence of Si-O-Si asymmetric group (

as

Si-

O-Si) and at 804 cm

-1

to 801 cm

-1

caused by the

presence of a Si-O-Si symmetrical group (

s

Si-O-Si).

Infrared spectrum data obtained for Run-8b, Run-9b,

Run-10b and Run-11b are all supported by literature

data (Khali, 2007)(Liu H, 2007)(AlOthman,

2010)(Zhao, 2011).

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1004

Figure 1: Diffractogram of XRD silica material Run

8b, Run 9b, Run 10b and Run 11b

3.1.2 FT-IR Spectroscopy

FT-IR spectrum of silica material from Run 8b, Run

9b, Run 10b, and Run 11b can be seen in Figure 2

below.

Figure 2: FT-IR spectrum for silica material Run 8b,

Run 9b, Run 10b and Run 11b.

3.1.3 Scanning Electron Microscope (SEM)

Morphological analysis of mesoporous silica material

Run 8b, Run 9b, Run 10b and Run 11b are carried out

with SEM photos with magnifications between

2000X to 25,000X. SEM images are shown in Figure

3 below.

(a) Run 8b (5000X magnification)

(b) Run 9b (15,000X magnification)

(c) Run 10b (5000X magnification)

(d) Run 11b (5000X magnification)

Figure 3: SEM image of silica mesopori material: (a)

Run 8b; (b) Run 9b; (c) Run 10b and (d) Run 11b.

Risinoleaic Acid Derivates as Templates for Synthesis of Mesoporous Silica Material based on tetraethylorthosilicate and

3-aminopropyltrimethoxysilane as Co-structure Directing Agent

1005

SEM image of silica material Run 8b (Figure 3a)

with 5000 times magnification shows the material has

a particle shape in the form of a mixture consisting of

dispersed spherical spherical particles ( sign) and

particles in the form of thin sheets that blend together

to form wrinkled roundabouts and multiples (sign ).

There are also particles that have thin skin / walls that

are susceptible to damage forming sheets (Liu H,

2010)

SEM photo of silica material Run 9b with a

magnification of 15,000 times (Figure 3b) shows

spherical particles of small size having a uniform

shape to form together to form a tight and compact

surface so that there are no gaps between particles. An

increase in the ratio of the amount of methanol added

seems to have an effect on particle size. The particle

size of Run 9b is smaller than the particle size of Run

8b. SEM image of silica material Run 10b with 5000

times magnification (Figure 3c) shows spherically

shaped particles forming an aggregate ( sign) and

also there is a particle shape in the form of large

chunks ( sign) and between particles there is a gap

( sign).

SEM image of silica material Run 11b with 5000

times magnification showing spherical particle shape

that is uniform in shape and dispersed with a more

perfect particle shape. Particle size is greater than

particle size Run 9b and Run 10b.

3.1.4 Adsorption-desorption Isotherm

Nitrogen

Porosity analysis of mesoporous silica material and

pore size distribution of Run 8b, Run 9b, Run 10b and

Run 11b were carried out by desorption nitrogen

analysis with isotherm at -196C. The isotherm

adsorption graph was calculated using the Brunauer-

Emmet-Teller (BET) method (Figure 4) and the pore

size distribution was calculated using the Barret-

Joyner-Halenda (BJH) method (Figure 5). Based on

Figure 4, the desorption isotherm adsorption chart

from Run 8b (black graph) shows a graph of

desorption of Type IV adsorption isotherms

according to the IUPAC classification, this is also

adjusted to the literature (Khalil, 2007). The type of

loop hysteresis is caused by the pores in the non-

turbulent aggregate of the particles which results in

slit-shaped pores according to the literature (Shah,

2009). While the desorption adsorption isotherm

graph from Run 9b (red graph) shows Type IV

desorption isotherm adsorption according to the

IUPAC classification is characteristic for mesoporous

material (Khalil, 2007). The existence of a hysteresis

loop is due to the narrow pore gap and includes the

pore of the micropore region, according to the

literature (Shah, 2009). The adsorption isotherm

adsorption graph from Run 10b (blue graph) shows

adsorption of Type IV isotherm according to the

IUPAC classification which is characteristic for

mesoporous material (Khalil, 2007). Pore adsorption

is a type of capillary condensation having a hysteresis

loop which can be caused by channels such as

cylinders or pores formed from coarse homogeneous

spheres forming tight agglomerates according to the

literature (Shah, 2009). Then the adsorption

desorption graph isotherm Run 11b (green graph)

shows adsorption of Type IV isotherm according to

the IUPAC classification which is a characteristic of

mesoporous material (Khalil, 2007). The presence of

a hysteresis loop can be caused by pores formed from

pore channels such as cylinders or pores from coarse

homogeneous sphere particles according to the

literature (Shah, 2009).

Figure 4: Adsorption desorption graph isotherm

nitrogen silica material from Run 8b, Run 9b, Run

10b and Run 11b.

Based on Figure 5, a graph of the pore size

distribution of silica material Run 8b (black graph)

shows a non-uniform pore size distribution in the

range between 1.44 nm to 9.53 nm, this is according

to SEM analysis. Mesopore silica material consists of

mixed particle forms so produced various pore

shapes. The pore size distribution chart of the silica

material Run 9b (red graph) shows that the pore size

distribution is not uniform from 1.43 nm to 9.53 nm.

This is in accordance with SEM photos that show the

form of particles that combine to form a compact and

tight surface. The particle size distribution chart of

silica material Run 10b (blue graph) shows a regular

pore size distribution (uniform) dominated by pore

size at 2.76 nm and 3.07 nm. This is consistent with

SEM photos where dominant particles are spherically

shaped in small sizes. The pore size distribution chart

for silica material Run 11b (green graph) shows a

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1006

uniform pore size and is dominated by 2.45 nm. This

is consistent with the results of SEM photos showing

the presence of spherical particles that have a uniform

and dispersed size.

Figure 5: Pore size distribution graph of silica

material Run 8b, Run 9b, Run 10b and Run 11b.

Porosity of mesoporous silica material Run 8b,

Run 9b, Run 10b and Run 11b such as diameter and

pore volume and surface area tabulated in Table 2

below.

Table 2: Diameter, pore volume and surface area of

mesoporous material from Run 8b, Run 9b, Run 10b

and Run 11b.

Treatm

ent

Pore

diameter

(nm)

Pore

Volume

(cm

3

/g)

Surface

Area

(m

2

/g)

Run 8b 1.5-9.5 0.02-0.22 54-301

Run 9b 1.4-9.5 0.02-0.16 58-240

Run

10b

3.1 0.04 66

Run

11b

2.5 0.05 113

4 CONCLUSIONS

Synthesis of silica mesoporous material from

tetraethylortosilicate (TEOS) as a source of silica,

sodium risinoleate as template and 3-

aminopropyltrimethoxysilane (APMS) as co-

structure directing agent (CDSA) was carried out.

The results of the FT-IR analysis proved that tissue

was formed (-Si-O-Si-) and the results of XRD

analysis were all amorphous material. The variation

of calming time before the aging stage produces silica

material with different morphology. Porosity analysis

of silica material which has a more uniform pore size

resulted from treatment with time of drying for 2

hours before the aging stage (Run 10b) and the

addition of methanol without the addition of

hydrochloric acid (Run 11b) with a pore size

distribution of 3.1 nm respectively and 2.5 nm.

ACKNOWLEDGMENT

The authors would like to thank to KEMENRISTEK

for the funding on the project of DRPM 2018, number

contract: 231/UN5.2.3.1/PPM/KP-DRPM/2018.

REFERENCES

Schubert U and Husing N 2005 Synthesis of Inorganic

Materials (Wiley-VCH Verlag GmbH & Co, KGoA,

Weinheim) p 308-309

Wan Yand Zhao D 2007 Chemical Rev. 7(107): 2821-2860

Soler-Illia G J et al 2002 Chem. Rev. (102): 4093-4138

Huo Qet al 1994 Nature (368): 317-321

Che S et al 2003 Nature Material (2): 801-805

Garcia-Bennett A E 2005 Angew. Chem. Int. Ed. (44): 5317

–5322

Yokoi T et al 2003 Chem. Mater. 15 (24): 4536-4538

Andriayani et al 2013 Advanced Material Research (789):

124-131

Wang W Q 2009 Journal of Colloid and Interface Science

(331): 156–162

Li B et al 2011 Journal of Colloid and Interface Science

(362): 42-49

Zhao Q et al 2011 Applaid surface Science (257):2436-

2442

Zhang J Z et al 2003 Self-Assembled Nanostructure

(Kluwer Academic Publishers, New York) p

Shah A T et al 2009 Journal of Colloid and Interface

Science (336):707-771

Khali K M S 2007 Journal of Colloid and Interface Science

(315):562-568

Liu H et al 2010 Journal of Colloid and Interface Science

(346):486-493

Park Y et al 2006 Journal of Colloid and Interface Science

(295):464-471

AlOthman Z A and Apblett A W 2010 Applied Surface

Science

(256):573-3580

Zhao Q et al 2011 Applaid surface Science (257): 2436-

2442

Liu H et al 2010 Journal of Colloid and Interface Science

(346):486-493

Khalil K M S 2007 Journal of Colloid and Interface Science

(315):562-568

Shah A T et al 2009 Journal of Colloid and Interface

Science (336):707-771

Gregg S J and Sing K S W 1982 Adsorpsi, Surface Area

and Porosit (Academic Press, Second Edition,

London (LDT) p

Rouqe-Malherbe R M A 2007 Adsorption and Diffusion in

Nanoporous Materia (CRC Press Taylor & Francis

Group) p

Risinoleaic Acid Derivates as Templates for Synthesis of Mesoporous Silica Material based on tetraethylorthosilicate and

3-aminopropyltrimethoxysilane as Co-structure Directing Agent

1007