Contribution of Microsilica of Silica Sand on High Strength Concrete

J. Tarigan

1

, R. Karolina

1

and W. Muhammad

2

1

Lecturer of Department of Civil Engineering, University of Sumatera Utara, Jl. Perpustakaan, Medan, Indonesia

2

Department of Civil Engineering, , University of Sumatera Utara, Jl. Perpustakaan, Medan, Indonesia

Keywords: Concrete, Micro silica

Abstract: Various types of concrete have now been developed according to their needs, one of which is high strength

concrete. In designing high strength concrete, it should be noted that several factors will influence the

achievement of the quality of the plan, which are cement, water cement factor (FAS), concrete aggregates,

and appropriate admixtures. In engineering a natural mineral, it is important for an engineer to find alternative

materials to substitute Portland cement. So that the use of Portland cement can be reduced in the making of

high strength concrete that usually uses Portland cement in large quantities. In this research, micro silica

utilization as a substitute for Portland cement in concrete mixture is expected to create high strength concrete

that is environmentally friendly. The use of micro silica is accompanied by the use of Master Ease 3029 super

plasticizer. This research aims to compare high strength concrete variations of 0%, 5%, 10%, 15% and 20%

micro silica substitution of Bangka. From the results of research that has been done on 28 days curing showed

that normal concrete compressive strength / 0% variation is 61,296 Mpa while the concrete with substitution

variation of 15% micro silica is the most optimum with a compressive strength of 66,684 Mpa. For the value

of slump flow obtained from the five variations indicates that the higher the use of micro silica substitution,

the smaller the diameter value is.

1 INTRODUCTION

High Strength Concrete is a concrete that has

characteristics as a solid unit of material with a

compressive strength ranging from 55.5 to 200 Mpa.

This concrete allows the creation of a sleek,

lightweight concrete structure that can also save

energy and natural materials. High Strength Concrete

Density also gives the advantage of a high resistance

to the attack of dangerous liquid or gas. High Strength

Concrete is generally used in high-rise buildings and

bridges. In high buildings, High Strength Concrete is

used to conserve dimensions of columns and beams,

allowing wider space between columns to columns,

as well as between beams that affect the elevation of

each floor. The reduction of the structure component

dimension itself will reduce the weight of the

structure so that the load on the foundation becomes

lighter. In long bridges that generally use pre-cast

concrete, High Strength Concrete is required to

support larger span loads due to bridge spans and also

to overcome the possibility of precast concrete

damage that often occurs in the mobilization of the

precast concrete itself.

The need for these structural components leads to

the use of high strength concrete which includes

strength, durability, service life and efficiency. High

strength concrete is greatly influenced by the

constituent materials on the concrete. There are

several factors that influence the achievement of high

strength concrete compressive strength in its design.

The preparation of qualified ingredients is one of the

factors that can influence the manufacture of high

strength concrete. Factors affecting the quality of a

concrete are cement factors, cement water factors,

aggregate factors, Micro silica usage and admixture

materials usage.

The development of technology in the field of

construction is very rapidly presents new innovations

in the field of materials, one of them is concrete

materials. Several types of added materials are often

used for high strength concrete like Fly Ash and

manufactured micro silica such as Silica Fume. The

use of concrete added materials is intended to

improve the quality and strength of concrete, Because

the critical part of the concrete lies in the interfacial

zone area between the paste of cement and the sand

with a coarse aggregate, hence to increase the

Tarigan, J., Karolina, R. and Muhammad, W.

Contribution of Microsilica of Silica Sand on High Strength Concrete.

DOI: 10.5220/0010098103510355

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

351-355

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

351

adhesiveness of the interfacial zone, an idea arises by

using the most abundant natural materials in

Indonesia which is micro silica from Bangka silica

sand. The Micro silica is the result of fine processing

of silica sand in the Bangka region with the size of 0.1

to 1 micrometers and has a cementations property

because it has a content of Silicon Dioxide (SiO2)

greater than 96% which can play an important role to

the mechanical and chemical properties of the

concrete, of the mechanical properties, geometrically,

Micro silica can fill the cavities between the grain of

cement, causing the pore size distribution to decrease

as well as the total pore volume which is also reduced

so that it can directly improve the strength of the

concrete. Various levels of substitution of the most

optimum Micro silica variations on Portland Cement

Type I is starting from 0% - 20% (H. Mahyar, 2012)

Micro Silica is the well-performing natural

material for the performance of high strength concrete

compared to other materials such as silica nano, Fly

ash and bottom ash (Thusara Priyadarshana &

Ranjith, 2015)

The use of microsilica from the silica sand of

Bangka as a Substitution of Portland Cement in a

concrete mixture is an attempt to utilize the abundant

amount of natural materials in Indonesia. Besides, the

use of Microsilica from Bangka Silica sand as a

substitution to Portland Cement in concrete mixture

is expected to be a solution in achieving a high

strength concrete that is environmentally friendly

because it has the "Low Heat Hydration" feature that

is produced by the substitution of Microsilica from

Bangka Silica Sand at Portland Cement resulting in a

low hydration heat and reducing CO

2

emissions

because Microsilica from Bangka silica sand is a

natural material without a manufacturing process and

most importantly when applied in high strength

concrete, it can reduce the use of cement.

The use of microsilica in high strength concrete

mixture other than improving the quality of concrete

significantly, it also does not require a special

treatment such as Dry Air Curing or Steam Curing,

just do soaking in water like an ordinary concrete to

get the most optimum concrete quality (Md.

Safiuddin & Raman, 2007).

2 LITERATURE REVIEW

Microsilica of Bangka is the result of a fine processing

of silica sand which is one of the common materials

found in the earth's continental crust. This mineral has

a hexagonal crystal form made of a crystallized

trigonal silica. Micro Silica of Bangka is a smoothed

glass material and has a size with a diameter of 0.1 - 1

micrometers so if it’s viewed by the size of the small

particles geometrically, Microsilica of Bangka can fill

cavities between cement and aggregate particles so it

minimizes air cavity in order to increase the density of

concrete mixture.

Figure 1. Microsilica of Bangka

Micro Silica of Bangka has a very hard properties,

insoluble in water and has boiling point of 1715

O

C

and has white color, White Color is produced from its

high content of SiO

2

(Silicon Dioxide).

Table 1: Chemical contents of Microsilica of Bangka

Parameter Unit Result Method

Iron Trioxide

(Fe

2

O

3

)

% 0.03

SNI 15-

0346-1989

Alumunium

Trioxide (Al

2

O

3

)

% 0.17

SNI 15-

0346-1989

Calcium Oxide

(CaO)

% < 0.01

SNI 15-

0346-1989

Magnesium Oxide

(MgO)

% < 0.01

SNI 15-

0346-1989

Manganese

Dioxide (MnO

2

)

% < 0.01

SNI 15-

0346-1989

Chromium

Trioxide (Cr

2

O

3

)

% < 0.01

SNI 15-

0346-1989

Sodium Oxide

(Na

2

O)

% < 0.01

SNI 15-

0346-1989

Potassium Oxide

(K

2

O)

% 0.01

SNI 15-

0346-1989

Silicon Dioxide

(SiO

2

)

% 99.09

SNI 15-

0346-1989

Titanium Dioxide

(TiO

2

)

% 0.02

SNI 15-

0346-1989

Loss On Ignition

(LOI)

% 0.39

SNI 15-

0346-1989

Moisture Content

(MC)

% 0.06

SNI 15-

0346-1989

Source: Superintending Company of Indonesia,

Jakarta 2015

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

352

From above, it is seen that Microsilica of Bangka has

a very high content of silicon dioxide (SiO

2

). The

percentage of this content indicates that Microsilica

of Bangka can be made into added ingredients in high

strength concrete mixing. Thus, it is possible to utilize

Microsilica of Bangka as a filler and become a cement

substitution so as to reduce the use of cement in

concrete mixture.

3 RESULTS AND DISCUSSION

3.1 Slump Test

The test results of slump flow value for normal

concrete and concrete with the variation of

Microsilica of Bangka can be seen in the following

table.

Table 2: Test results of slump flow value of fresh concrete

Variasi

Diameter 1

(cm)

Diameter 2

(cm)

Average

(cm)

0% 76 73

74.5

5% 74 72

73

10% 71 69

70

15% 70 68

69

20% 65 63

64

From Table 2, it can be seen that the slump flow value

of the five concrete variations shows a significant

difference. High slump flow value is caused by the

use of Superplasticizer which serves to improve the

workability of fresh concrete.

Figure 2: Slump flow test

3.2 Concrete Absorption Test

The results of absorption test for normal and concrete

with the variation of Microsilica of Bangka can be

seen in the table.

Table 3: Test results of concrete absorption value

N

o

Varia

si

Umur

Beto

n

(Hari

)

Berat

Basah

(kg)

Berat

Kering

(kg)

Absorbs

i (%)

1

BN/0

%

28

3988 3974 0.35

2

BN/0

%

3982 3966 0.40

3

BN/0

%

3969 3954 0.38

4

5%

28

3699 3683 0.43

5

5% 3834 3821 0.34

6

5% 3716 3701 0.41

7

10%

28

3839 3823 0.42

8

10% 3752 3738 0.37

9

10% 3869 3853 0.42

1

0

15%

28

3879 3862 0.44

1

1

15% 3816 3798 0.47

1

2

15% 3848 3832 0.42

1

3

20%

28

3846 3831 0.39

1

4

20% 3833 3817 0.42

1

5

20% 3868 3851 0.44

From Table 3. it can be seen that the absorption value

of the five variations of concrete shows a not very

significant difference. The low absorption value is

due to the heterogeneous size of concrete materials so

that the concrete density is maximum.

Contribution of Microsilica of Silica Sand on High Strength Concrete

353

3.3 Compressive Strength of Cylinder

Concrete

The tests performed at 3, 7, 14, and 28 days curing,

and the results of the compressive strength listed on

the table are the result of compressive strength that

has been multiplied by correction factor for cylinder

with a diameter of 10 cm and a height of 20 cm which

is 1.04. The test is done based on SNI 1974: 2011, test

method of concrete compressive strength with

cylinder sample. Within 3 days the concrete reaches

a high compressive strength, and continues to

increase until 7 days curing, then the growth of

compressive strength begins to slow down to the 14

days curing, and reaches the maximum compressive

strength at 28 days curing. From the table of

compressive strength test results above, it is seen that

within 3 days the concrete reaches a high compressive

strength, and continues to increase until 14 days

curing and reaches the maximum compressive

strength at 28 days curing.

The compressive strength above shows that

within 3 days the concrete reaches a compressive

strength that is not too high compared to other

variations, and continues to increase until 14 days

curing and reaches the maximum compressive

strength at 28 days curing.

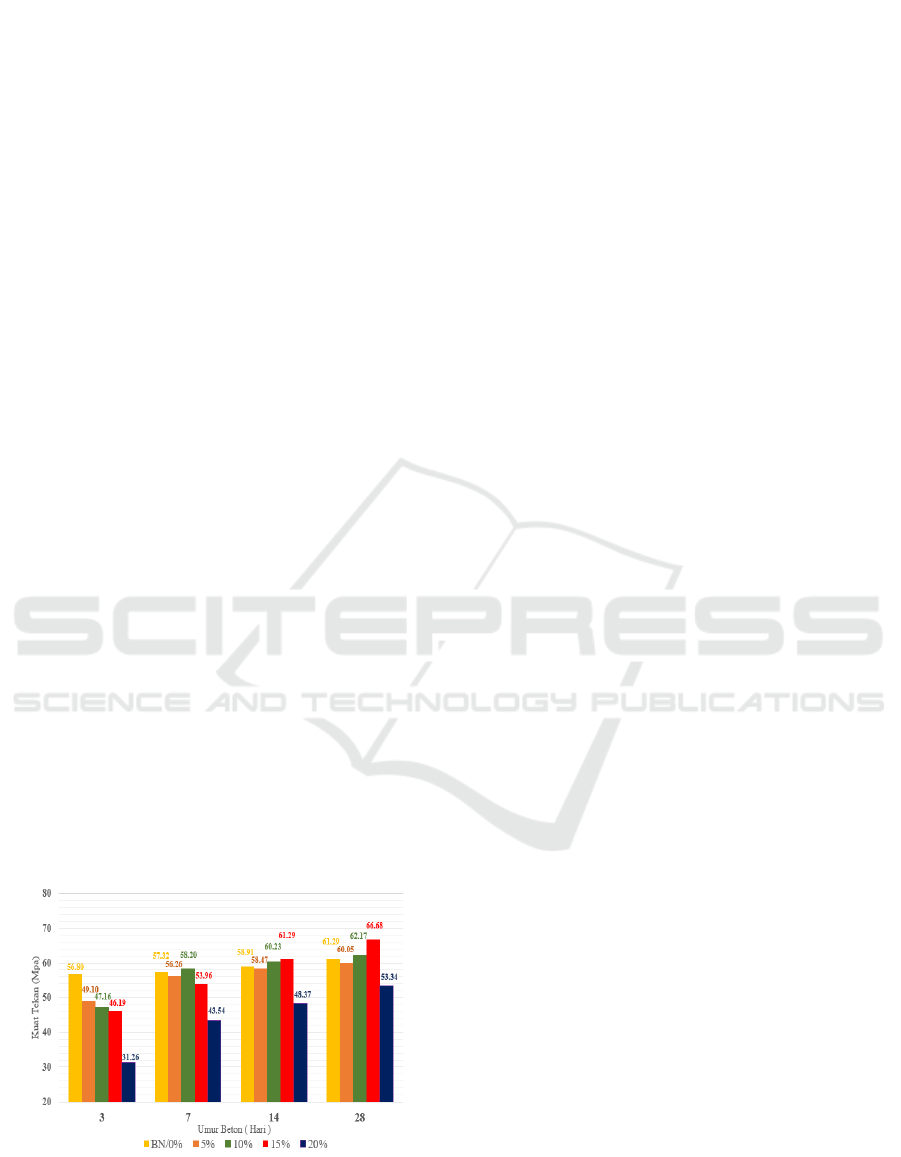

Of the five results of high strength concrete

compressive strength with variation substitution of

0%, 5%, 10%, 15% and 20% Microsilica of Bangka

to Portland Cement at a certain test age, the five

compressive strength test results can be compared

through Graph as follows.

Figure 3: Graphical comparison of concrete compressive

strength test results of Microsilica of Bangka Variations

From the results of concrete compressive strength test

of Microsilica of Bangka variation, it can be

concluded that high strength concrete with the

substitution variation of 15% Microsilica of Bangka

has the highest compressive strength compared with

the high strength concrete compressive strength of

other Microsilica of Bangka variations. With the

average compressive strength of high strength

concrete with substitution variation of 15% Micro

Silica of Bangka at 28 curing is 66,684 Mpa and the

compressive strength of high strength concrete with

substitution variation of 0%, 5%, 10% and 20%

Microsilica of Bangka at 28 days curing respectively

are 61.296 Mpa, 60,059 Mpa, 62,179 Mpa and 53,347

Mpa. Increased compressive strength of concrete with

substitution variation of 15% Microsilica of Bangka

is 8.78% of concrete substitution of 0% Microsilica

of Bangka variation.

4 CONCLUSIONS

Based on the research that has been done, it can be

concluded that:

1. The average diameter of Slump Flow of high

strength concrete substitution of 0%, 5%, 10%, 15%

and 20% Microsilica of Bangka variations to

Portland Cement respectively are 74.5cm, 73cm,

70cm, 69cm and 64cm. So it can be concluded that

the higher use of substitution of Microsilica of

Bangka variation to Portland cement, the lower the

Slump Flow value is.

2.The average value of high strength concrete

absorption substitution of 0%, 5%, 10%, 15% and

20% Microsilica of Bangka variations on Portland

Cement are 0.39%, 0.39%, 0.40%, 0.44% and

0.42%, respectively. So it can be concluded that the

higher use of substitution of Microsilica of Bangka

variation to Portland cement, the lower the

Absorption value is.

3.

The normal high strength concrete substitution of

0% Microsilica of Bangka variation to Portland

Cement at 3,7,14, and 28 days curing respectively

are 56,880 Mpa, 57,321 Mpa, 58,911 Mpa and

61,296 Mpa. Furthermore, the normal high strength

concrete compressive strength substitution of 5%

Microsilica of Bangka variation to Portland Cement

at 3,7,14, and 28 days curing respectively are

49,107 Mpa, 56,262 Mpa, 58,470 Mpa and 60,059

Mpa. Furthermore, the normal high strength

concrete compressive strength substitution of 10%

Microsilica of Bangka variation to Portland cement

at 3,7,14, and 28 days curing respectively are

47,164 Mpa, 58,205 Mpa, 60,236 Mpa and 62,179

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

354

Mpa. Furthermore, the normal high strength

concrete compressive strength substitution of 15%

Microsilica of Bangka variation to Portland cement

at 3,7,14, and 28 days curing respectively are

46,193 Mpa, 53,965 Mpa, 61,296 Mpa and 66,684

Mpa. Furthermore, the normal high strength

concrete compressive strength substitution of 20%

Microsilica of Bangka variation to Portland cement

at 3,7,14, and 28 days curing respectively are

31,266 Mpa, 43,543 Mpa, 48,357 Mpa and 53,347

Mpa. So it can be concluded that high strength

concrete substitution of 1% Microsilica of Bangka

variation to Portland cement at 28 days curing has

greater compressive strength than another high

strength concrete substitution variation.

4.

The use of Microsilica of Bangka as a variation of

substitution to Portland Cement on high strength

concrete is considered very effective because it

reaches the optimum compressive strength of

concrete at 28 days curing at 15% variation, thus

reducing a very significant use of Portland Cement

and it turns out 15% of Microsilica of Bangka

substitution makes the Interfacial zone are to be

better which is increasing the density between

aggregates and paste so that the binding ability

increases. This results is considered very good

compared to the previous research conducted by

V.Bhikshma, et al in 2009 which is the optimum

compressive strength on 28 days curing is on the

substitution of 12% of Microsilica (silica Fume)

variation to Portland Cement.

ACKNOWLEDGEMENTS

If any, should be placed before the references section

without numbering.

REFERENCES

ACI Committee. (1999). Building code requirements for

structural concrete:(ACI 318-99); and commentary

(ACI 318R-99). American Concrete Institute.

ASTM C.125-1995:61. 1995. Standard Definition of

Terminology Relating to Concrete and Concrete

Agregates.

Bhikshma, V., K. Nitturkar, and Y. Venkatesham.

"Investigations on mechanical properties of high

strength silica fume concrete." (2009): 335-346.

British Standart 3148. 1959. Test Water For Making

Concrete.

British and European Standart 12350 - 5. 2008. The Test

Flow Test For Fresh Concrete.

Dipohusodo, Istimawan. 1994. Struktur Beton Bertulang.

Jakarta: Gramedia Pustaka Utama.

Imran, Iswandi. 1997. Petunjuk Perencanaan Campuran

Beton Mutu Tinggi dengan Metode ACI, Laboratorium

Struktur dan Bahan, ITB.

Mahyar, H. 2012, Mikrosilika Sebagai Bahan Tambah

Untuk Meningkatkan Kuat Tekan Beton Mutu Tinggi,

REINTEK. Volume 7, No.1, ISSN 1907-5030.

Mahyar, H. 2013, Pemakaian Additive Micro Silica Dalam

Campuran Beton Normal Untuk Meningkatkan Kuat

Tekan Beton Normal, JURNAL PORTAL. Volume 7,

No.1, ISSN 2085-7454.

Mulyono, Tri. 2005. Teknologi Beton. Yogyakarta. ANDI.

Nawy, E.G. 1985. Reinforced Concrete a Fundamental

Approach. Sidney. Mac Graw- Hill Book Company.

Neville, A.M and Brook, J.J. 1987. Concrete Technology.

London. Longman Scientific and Technical.

[Nili, M., Ehsani, A., dan Shabani, K. 2010, Influence Of

Nano Silica and Microsilica on Concrete Performance.

International Confrence On Sustainable Construction

Materials and Technologies.. ISBN 978-4507-1484-4.

Nugraha, Paul. dan Antoni. 2007. Teknologi Beton dan

Material, Pembuatan Beton Kinerja Tinggi.

Yogyakarta: Andi Offset.

Pujianto, As’at. November 2011, Beton Mutu Tinggi

dengan Admixture Superplasticizer dan Aditif Silica

Fume. Semesta Teknika. Volume 14, No.2, 177-185.

Oktober 2016

Pujianto, As’at. November 2010, Beton Mutu Tinggi

dengan Admixture Superplasticizer dan Fly Ash.

Semesta Teknika. Volume 13, No.2, 171-180. Oktober

2016

Priyadarshana, T., Dissanayake, R., dan Mendis, P. 2015,

Effect Of Nano Silica, Micro Silica , Fly Ash and

Bottom Ash on Compressive Strength Of Concrete.

Journal Of Civil Engineering And Architecture 9. Pages

1146-1152.

Safiuddin, Md., Raman, S., dan Zain, M. 2007, Effect Of

Different Curing Method on the Properties Of

Microsilica. Australian Journal of Basic and Applied

Sciences. No. 1 (2). Pages 87-95. ISSN 1991-8178.

Standart Nasional Indonesia 03 – 6368 - 2000. 2000. Tata

Cara Perencanaan Campuran Tinggi dengan Semen

Portland dan Abu Terbang.

Standart Nasional Indonesia 03-6433 - 2000. 2000. Metode

Pengujian Kerapatan Penyerapan Dan Rongga Dalam

Beton Yang Telah Mengeras.

Standart Nasional Indonesia 1974:2011. 2011.Cara Uji

Kuat Tekan Beton Dengan Benda Uji Silinder.

Standart Nasional Indonesia 2847:2013. 2013. Persyaratan

Struktural Beton Untuk Bangunan Gedung.

Surat Keputusan Standart Nasional Indonesia T -15 – 1991

– 03. 1991. Tata Cara Perhitungan Struktur Beton

Untuk Bangunan Gedung.

Tjokrodimuljo, Kardiyono. 1996. Teknologi Beton.

Yogyakarta. Biro Penerbit Keluarga Mahasiswa Teknik

Sipil Universitas Gadjah Mada.

Contribution of Microsilica of Silica Sand on High Strength Concrete

355