The Method to Measure Si Thickness for Bond Line Thickness

YangSub Park, KilBum Kang, Sangyun Yun and SeongSoo Kim

Advanced Technology Inc, Incheon, Korea

Keywords: BLT, Bond Line Thickness, Si Thickness, TSV.

Abstract: Today, many semiconductor products are manufactured through the TSV process. At this time, It is

important to manage the Bond Line Thickness because all of the stacked dies must be discarded due to a

single contact failure. If we can measure the thickness of the silicon, the BLT in the wafer level package

process can be estimated. In this paper, we propose a method to measure the thickness of silicon by using

infrared ray. We designed the infrared light source to select the path of the incident light to the objective

lens. And this optical system has a characteristic of moving in the opposite direction according to a change

in height. By using this optical system, it is possible to calculate the correct in-focus position. By doing this,

we present a method to measure BLT by measuring the distance between the top and bottom of Si surface.

1 INTRODUCTION

The Bond Line Thickness (BLT) is one of important

measurement items for 3D Integrated Circuits (IC)

(Patti, 2006) using Through Silicon Vias (TSV)

(Topol et al, 2006) because each chip in the product

is directly connected in the vertical direction. When

the distance between the layers is increased, The

defects such as a head in pillow (HIP) (Liu et al,

2010) (Son et al, 2016) may occur. These types of

defects may weaken the electrical connections and

reduce the reliability of the product. While it is

almost impossible to observe bond joint between

bump and pad, many semiconductor production

plants manage the BLT to ensure die attach quality

and reliability. However, even this method is

impossible in the Wafer Level Package (WLP)

process. Because it is difficult to measure the BLT

sideways because of the neighboring dies.

Therefore, we propose a method to measure the

thickness of Si without destroying the mass

production products. And the BLT in WLP can be

measured using this method.

2 METHOD

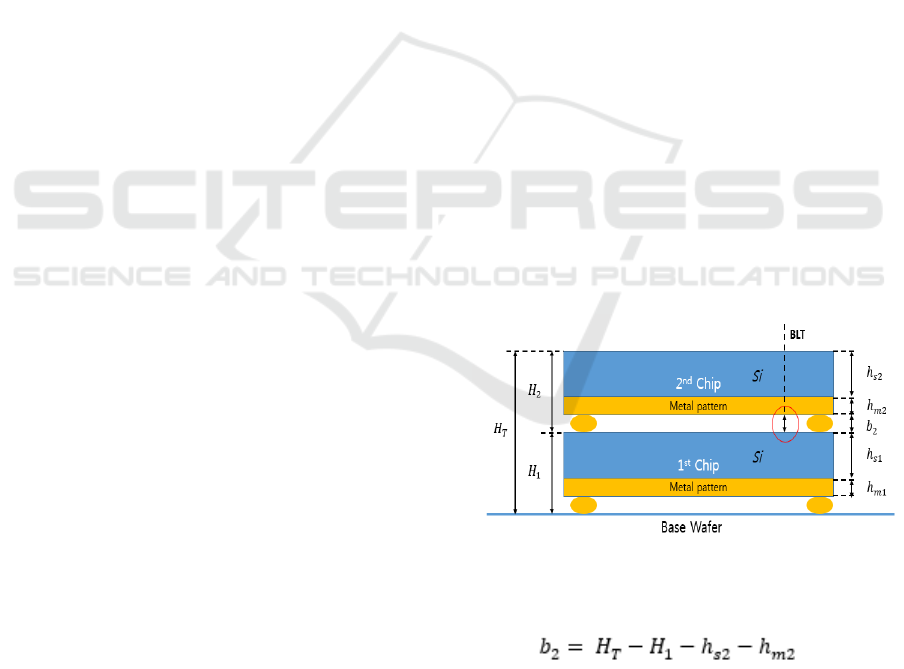

Figure 1 is the cross-section diagram of chips

stacked on the base wafer. The chip consists of a Si

layer and metal layers. H is the height of the chip

from the base wafer or a previous chip. h_m is the

thickness of metal layers of H and h_s is the Si

thickness of H. b_2 is BLT and it means the space

between chips. The height of chip is sum of Si layer,

the height of metal layers and the thickness of bond

line. It is possible to calculate b. Generally, the

thickness of metal layer is almost the same as the

design value. And there are many methods to

measure H. Therefore, The BLT in WLP can be

estimated by accurately measuring the Si thickness.

Figure 1: The cross-section diagram of chips stacked on

the base wafer.

(1)

2.1 The Design of Optic

We designed an infrared optical system to measure

the thickness of Si without damaging the wafer and

chips. Infrared ray has good light transmission

property for silicon, so we can get the images

Park, Y., Kang, K., Yun, S. and Kim, S.

The Method to Measure Si Thickness for Bond Line Thickness.

DOI: 10.5220/0006525502730275

In Proceedings of the 7th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2018), pages 273-275

ISBN: 978-989-758-276-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

273

reflected by the opposite metal pattern through Si.

The light incident on the silicon is divided into a

signal reflected from the silicon surface and a signal

reflected after passing through the silicon. The

thickness of the silicon can be measured through the

path difference between these two signals.

However, if the thickness of the chip is very large,

the gap between the two signals becomes large and it

is difficult to measure them simultaneously. And in

the opposite case, it is also not easy to measure the

distance between these two signals because they

overlap each other.

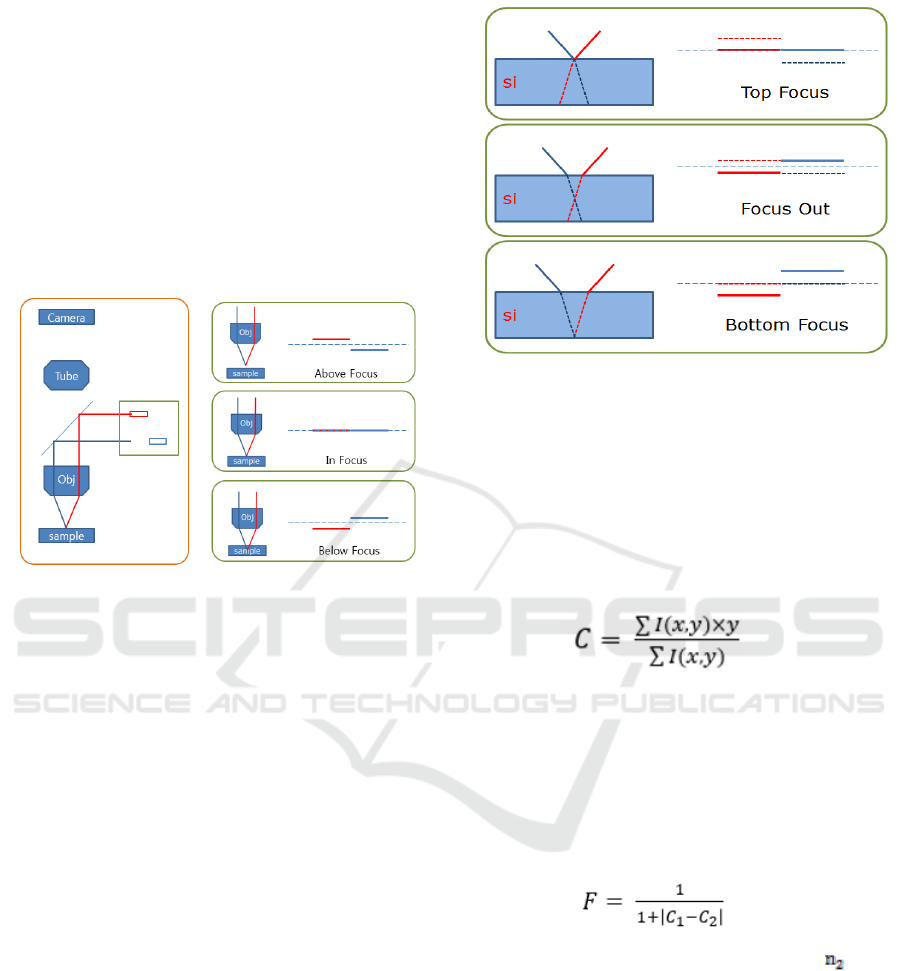

Figure 2: Left: a schematic diagram of an infrared optical

system, right: the light paths with focus change.

To solve these problems, we designed optical paths

of the light incident on the objective lens as shown

in Figure 2 left. This optical system has the

capability of confirming the position of the objective

lens and focus state.

Figure 2 left is a schematic diagram of the optical

system. It is possible to get the signals that move

inversely to each other when the focus change. The

results are shown in Figure 2 right. In the in-focus

state, the light of the two paths is met at one point.

However, when the focus changes up and down, it

moves away from each other.

2.2 Measurement of Si Thickness

Figure 3 is a schematic diagram of image acquisition

in silicon using the optical system of Figure 2. Since

the infrared light source penetrates the silicon,

infrared light be focused both the top surface of the

silicon and the bottom of it. D is the distance

between two different in focus position. h

s

can be

estimated by multiplying D and the coefficient of

refraction of silicon and the angle of incidence of the

beam.

Figure 3: The path of light with different focus position.

Figure 3 is an image acquired at regular intervals in

the height direction using the optical system of

Figure 2. I(x,y) is the brightness value at the (x, y)

pixel position of the image. And C is the y position

of the straight line existing in the image. In order to

measure C, we calculated the line profile in the y

direction and find the center of gravity using the

brightness of the image as the weight.

(2)

There are two straight lines in the image. C_1 is the

position of the straight line calculated in the area on

the left side and C_2 is the position of the straight

line calculated in the right image. F means how the

two straight lines match. This can be obtained from

equation (3). At this time, let P be the position where

F is the maximum value. This P means the position

of in focus.

(3)

n

1

is the refractive index in the air, and is the

refractive index of the silicon. P

t

is the point where F

is the maximum on the silicon top surface and P

0

is

the point where F is the maximum on the silicon

bottom surface.

ICPRAM 2018 - 7th International Conference on Pattern Recognition Applications and Methods

274

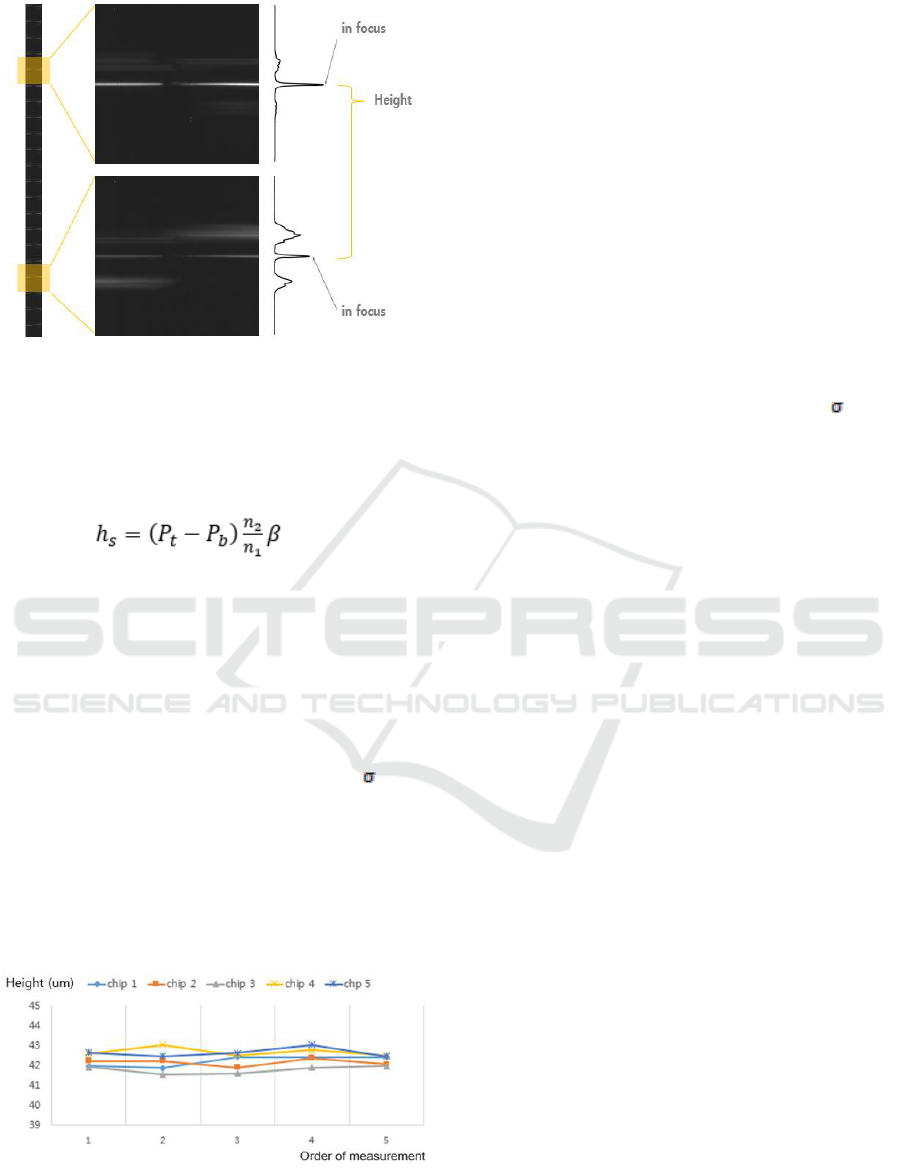

Figure 4: The image acquired from real sample.

And β is a coefficient according to the incident angle

of the beam. This is easily measurable using samples

already known in height. Therefore, the height of

silicon can be obtained via equation (4).

(4)

3 EXPERIMENT RESULTS AND

ANALYSIS

In order to measure repeatability, the same positions

were measured five times on each chip. Then, we

calculated the variance of these values, and multiply

this value by 3 to evaluate it on the 3 . The

repeatability average for these five chips is 0.67μm.

In order to measure the accuracy, We measured the

specific location of the chip five times. Then, the

position was measured with a high resolution

microscope and compared. The average accuracy

from 5 chips was confirmed at 0.32μm. This result is

shown in Figure 5.

Figure 5: The results of measurement.

4 CONCLUSIONS

An infrared optical system was used to measure the

thickness of silicon without destroying the wafer.

Infrared illumination was investigated so that the

path of light incident on the objective lens could be

selected and the focus state could be confirmed.

Then, the position of in-focus was calculated by

adjusting the height so that the left and right lines

match with the image acquired using this optical

system. These operations were performed from the

upper and lower surfaces, respectively, and the

height difference was calculated, and the actual

thickness was measured by multiplying this value by

the coefficient corresponding to the refractive index

of silicon and the incident angle of the beam. The

repeatability of the thickness of the silicon measured

in such a process is 0.67μm on the 3 . The

measurement accuracy was confirmed on average

0.32μm.

This value is three times better than the production

process control standard 2μm. Therefore, by using

the method proposed in this paper, it is possible to

manage BLT process of wafer level package

products.

REFERENCES

Patti, R.S. "Three-dimensional integrated circuits and the

future of system-on-chip designs", Proceedings of the

IEEE, Vol.94, Iss.6, pp. 1214- 1224

A. W. Topol, D. C. La Tulipe, Jr., L. Shi, D. J. Frank, K.

Bernstein, S. E. Steen, A. Kumar, G. U. Singco, A. M.

Young, K. W. Guarini, and M. Ieong, “Three-

dimensional integrated circuits,” IBM J. Res.

Develop., vol. 50, no. 4/5, pp. 491–506, Jul.–Sep.

2006.

Yan Liu; Pamela Fiacco; Ning-Cheng Lee “Testing and

prevention of head-in-pillow” 2010 5th International

Microsystems Packaging Assembly and Circuits

Technology Conference

Ho-Young Son; Tackeun Oh; Joo-Wan Hong; Byeong-Do

Lee; Ji-Hyuk Shin; Sung-Ho Kim; Nam-Seog Kim

“Mechanical and Thermal Characterization of TSV

Multi-chip Stacked Packages for Reliable 3D IC

Applications” 2016 IEEE 66th ECTC

The Method to Measure Si Thickness for Bond Line Thickness

275