A Heuristic for a Rich and Real Two-dimensional

Woodboard Cutting Problem

Claudio Arbib

1

, Fabrizio Marinelli

2

, Andrea Pizzuti

2

and Roberto Rosetti

2

1

Dipartimento di Scienze/Ingegneria dell’Informazione e Matematica, Universit

`

a degli Studi dell’Aquila,

Via Vetoio, Coppito, I-67010 L’Aquila, Italia

2

D.I.I., Universit

`

a Politecnica delle Marche, Via Brecce Bianche, I-60131 Ancona, Italia

Keywords:

Cutting Problem, Heuristics, Manufacturing.

Abstract:

Cutting operations in manufacturing are characterized by practical requirements and utility criteria that usually

increase the complexity of formulations or, even worse, are difficult to be modeled in terms of mathematical

programming. However, disregarding or just simplifying those requirements often leads to solutions consid-

ered not attractive or even useless by the manufacturer. In this paper we consider a rich two-dimensional

cutting stock problem that covers the whole specification of a family of wood cutting machines produced by

a worldwide leader in industrial machinery manufacturing. A sequential value correction heuristic is imple-

mented to minimize the employed stock area while reducing additional objective functions.

1 INTRODUCTION

The CUTTING STOCK PROBLEM (CSP) is a well-

known model of real-world optimization problems

arising in manufacturing. This difficult problem has

a very simple statement: find an efficient way of cut-

ting small objects from large ones.

A wide literature investigates the basic CSP and

its variants, see (W

¨

ascher et al., 2007) for a com-

prehensive survey. Indeed, variants exist to fill the

gap between theory and practice, and a variant is re-

garded of interest for the academia as far as it requires

a non-standard model and/or a novel methodological

approach.

Unfortunately, it is often hard to encapsulate re-

ality into a single elegant mathematical formulation.

Moreover, it is generally recognized that the success

of an optimization method depends on the concur-

rency of transversal skills: one is indeed mathematical

modeling, but it is not the only one. A fundamental

role is for instance played by the bi-directional inter-

face that must be developed to feed the model with

data and to present the solutions to decision-makers:

a development that normally requires more IT than

math skills.

On the other hand, the more a model is close to op-

erational decision, the more attention is to be devoted

to process details. Disregarding such details (which is

often done in research papers in order to capture the

mathematical essence of the problem) would simply

cause the software product not to work, and the man-

agement not to buy it. For example, edge trimming

is generally neglected in CSP models; but a cutting

pattern that does not take it into account, may not be

realizable in practice.

While a specification on edge trimming can eas-

ily be dealt with after prototype development, this

is not the case of other apparently irrelevant issues.

For example, blade thickness expressed in fractions

of millimeters can increase the precision required of

the packing algorithm, with important effects on its

efficiency if, as usual, it has pseudo-polynomial time

complexity.

A twofold challenge has therefore to be addressed:

• On software design. Technical issues — be they

expressed as constraints or utility criteria — have

both a local impact on the feasibility of cutting

patterns (number of stages, item rotation etc.) and

a global one on the cutting plan as a whole (num-

ber of patterns, cut sequence etc.). Pattern gener-

ation algorithms can differ a lot from each other

in order to take care of the former issues, and the

latter can affect the whole software architecture.

• On decision making. A hierarchical problem de-

composition based on the various utility criteria

(e.g. first minimize trim-loss, then setups, then

open stacks) can output low-quality or even infea-

Arbib, C., Marinelli, F., Pizzuti, A. and Rosetti, R.

A Heuristic for a Rich and Real Two-dimensional Woodboard Cutting Problem.

DOI: 10.5220/0006534500310037

In Proceedings of the 7th International Conference on Operations Research and Enterprise Systems (ICORES 2018), pages 31-37

ISBN: 978-989-758-285-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

sible solutions. On the other hand, combining dif-

ferent objectives into a single goal may produce

solutions not appreciated by all the involved deci-

sion makers.

We here propose to address this challenge by a

single architectural choice in which patterns are gen-

erated via Sequential Value Correction heuristics and

then used to provide a collection of non-dominated

solutions.

Problems with a level of detail that covers indus-

trial specification as a whole and puts the solution

method in a condition to operate in the plant, are

called rich. In this paper we consider a rich Multiple-

stock-size two-Dimensional CSP (M2D-CSP) com-

pliant with the specification of a family of wood cut-

ting machines produced by SCM Group (SCM, 2017).

The M2D-CSP is a variant of the CSP that can

be presented as follows. Let I be a set of n distinct

rectangles (part types). Each i ∈ I has length l

i

and

height h

i

, and must be cut in d

i

copies from a stock

set J of m different (and larger) rectangles. Each j ∈ J

has length L

j

and height H

j

, and is available in b

j

copies. The cut should be done so as to minimize

used stock area; other objectives — such as reduction

of employed stocks, setup minimization etc. — can

however be selectively or entirely considered.

Our problem has these main features:

• Cuts proceed parallel to stock item from edge to

edge (guillotine cut).

• Items (either produced or in stock) can be orthog-

onally rotated.

• 2 and (simplified) 3-stage cuts are possible: in a

first stage, a configuration c = hstock type, first

cut orientation (horizontal or vertical)i is selected,

and multiple cuts are done orthogonally to orien-

tation; then the stock item is rotated by 90

◦

and

the stage is repeated.

• Precut is possibly allowed as a pre-processing

step.

Part types admit overproduction if explicitly indi-

cated, but demand is in general to be fulfilled exactly.

Indeed, relaxing demand constraints by overproduc-

tion can yield solutions with very small trim-loss; but

a substantial number of excess items are cut, increas-

ing too much the necessary amount of stock items and

consequently production costs.

2 LITERATURE REVIEW

Real cutting processes often deal with heterogeneous

stock types. The relevant M-CSP is handled in var-

ious ways. In (Belov and Scheithauer, 2002) an

exact cutting plane approach is proposed for one-

dimensional CSP with multiple stock lengths. The

same problem is solved heuristically in (Poldi and

Arenales, 2009). In (Yanasse et al., 1991), the two-

dimensional CSP in the wood industry is addressed

and a heuristic algorithm is proposed for the multiple

stock sizes case.

Trim-loss minimization is not the only criterion

considered in an industrial cutting process: indeed,

setup costs and the number of stacks maintained open

throughout the process can affect process quality as

well. Examples of CSP seeking both setup minimiza-

tion and open stack limitation can be found in (Belov

and Scheithauer, 2007), where a sequential heuris-

tic for the one-dimensional case is proposed, and in

(Non

˚

as and Thorstenson, 2000), where the problem

is formulated as a non-linear concave minimization

problem and solved through global or local proce-

dures. Metaheuristics and an exact approach that sep-

arately address the CSP with setup minimization are

reported respectively in (Umetani et al., 2003) and

(Aloisio et al., 2011); moreover CSP with open stack

limitation is considered in (Arbib et al., 2016) and

(Yanasse and Lamosa, 2007).

Although industrial applications require consider-

ation of several practical issues, these are taken into

account by very few papers; and in those cases, very

few additional issues are regarded simultaneously.

Here is a list of exceptions (to the best of our knowl-

edge):

• (Malaguti et al., 2014) describes a truncated

Branch-and-Price algorithm to solve an M2D

guillotine CSP in woodboard cutting industry,

where orthogonal rotation of items and boards is

allowed, and stacked boards can be cut concur-

rently. The objective is to minimize a weighted

combination of stock usage, number of cutting cy-

cles and of 3-stage cuts.

• (Varela et al., 2008) presents a 1D-CSP arising in

a plastic manufacturing facility, with five objec-

tive functions hierarchically ranked, some tech-

nical parameters related to the employed cutting

machines and order priorities. A GRASP algo-

rithm with a call to a sequential heuristic proce-

dure is implemented.

• (Chu and Antonio, 1999) proposes a mathemat-

ical formulation for a rich 1D-CSP in the metal

industry. The various technical constraints taken

into account significantly affect the total cost

and involve trim-loss, material reusability and cut

time. Approximation algorithms based on dy-

namic programming are devised.

In conclusion, it is worth quoting sequential heuris-

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

32

tics. Instead of a rigorous (but slow) solution of the

pricing problem with exact dual prices, algorithms

of this type use pseudo-prices to sequentially (and

quickly) compose each single patterns, and in this

way can achieve good solutions. Various implementa-

tions have been proposed for 1D bin packing and CSP

(Belov and Scheithauer, 2007), (Varela et al., 2008),

and 2D bin-packing and CSP (Cui et al., 2015), (Chen

et al., 2016).

3 A SEQUENTIAL VALUE

CORRECTION HEURISTIC

The basic idea behind the sequential value correc-

tion scheme consists in assigning a value (the pseudo-

price) to each part type and generate cutting pattern

sequentially, each one with the parts not yet allocated

that maximize the total value of the pattern. After a

solution has been computed, pseudo-prices are con-

veniently updated and the process reiterated in order

to fill a pool of non dominated solutions. Dominance

relationship are based on the following minimization

criteria: total used stock area, total trim-loss, number

of used stocks, number of distinct setups, and total

number of precuts (Notice that used area, trim-loss

and number of used stocks measure distinct perfor-

mance due the overproduction features and the pres-

ence of stocks of different sizes).

The whole procedure is composed by three main

steps, each one optimizing a distinct performance in-

dicator by resorting to Algorithm 1, which is a se-

quential value correction heuristic (SVC).

The algorithm can be summarized as following:

• Step 1: SVC solves the M2D-CSP with non-

batched demand, seeking used area minimization.

• Step 2: The second step tries to reduce the number

of setups by demand rounding. In particular, the

demand of each part type is aggregated by increas-

ing batch dimension (parameter size) and SVC is

called to find solutions with reduced number of

setups. Starting from size = 2, the procedure is

iterated for increasing values of size, chosen as

the largest integer in [size + 1,max

i∈I

d

i

] that mini-

mizes the area associated to the residual demand

r

0

. Step 2 terminates when SVC does not find any

new non-dominated solution.

• Step 3: in this phase SVC searches for solutions

with reduced number of precuts. A suitable op-

portunity threshold δ is used to trigger decreasing

chances of employing a precut. The procedure it-

erates by updating δ until new generated solutions

have no precut.

Algorithm 1: Sequential value correction heuristic.

1: procedure SVC(d,size,δ)

2: λ

i

← S

i

3: cuts ← 0

4: for i ← 1. .. N do

5: g ← random(1,ρ)

6: r ← d

7: s = Ø

8: repeat

9: d

0

←

r

size

10: r

0

← r mod size

11: while d

0

> 0 do

12: P = Ø

13: for c ∈ C do

14: p[c] ← getPattern(c, λ,δ, d

0

)

15: P = P ∪ {p[c]}

16: end for

17: (a,cuts) ← getBestPattern(P)

18: f illingPattern(a,cuts)

19: s ← a

20: h ← random(1/g,g)

21: λ ← updatePrices(a,λ,h)

22: end while

23: r ← r

0

24: size = 1

25: until r > 0

26: patternSeq(s,cuts)

27: if notDominated(s) then

28: Sol = Sol ∪ {s}

29: end if

30: end for

31: end procedure

3.1 SVC Heuristic

The SVC heuristic is the core of the algorithm and is

implemented to build the CSP solutions.

Let I

0

be the set formed by the items of I and

their rotated counterparts. In its general framework,

SVC starts by defining a price λ

i

for each part type

i ∈ I

0

. Each price is initialized at the item area S

i

.

Part type demand is batched by size, that is, stock

items are stacked and each pattern is activated at mul-

tiples of size. A partial CSP solution is obtained

by sequentially building patterns through subroutine

getPattern: the subroutine attempts to solve sub-

problems where the sum of prices is maximized un-

der bounded knapsack and compatibility constraints.

For each configuration c = hstock type, first cut

orientationi in the set C of all possible configurations,

a cutting pattern is generated and added to a set P.

The most profitable pattern a ∈ P is then selected us-

ing getBestPattern, which also set the corresponding

A Heuristic for a Rich and Real Two-dimensional Woodboard Cutting Problem

33

activation level cuts. The f illingPattern function is

implemented to insert unplaced items in empty sec-

tions, given the residual demand and the value of cuts

of the chosen pattern. Subsequently, prices λ

i

are up-

dated by promoting items with high current demand

d

0

i

and small multiplicity in a. A complete CSP so-

lution s is finally obtained by combining the partial

solution computed for demand d

0

with the one found

for the residual demand r

0

.

In general, open stacks are not an objective to be

minimized, but are limited by the number of unload-

ing stations that equip the cutting machine. Although

the pattern generation procedure already respects the

limited availability of unloading stations, an attempt

at reducing the stacks opened by the current solution

s is made by the patternSeq procedure. The function

patternSeq implements a simple pattern sequencing

heuristic that compares each pattern with all the sub-

sequent ones, and swaps pattern pairs that allow the

largest decrease of open stacks.

The current solution is added to a pool (Sol) if it

fulfills all the constraints and is not dominated by any

other. The process is iterated a prescribed number N

of times unless certain halting conditions hold (e.g.,

user stop or minimum used area reached). Finally, the

pool Sol is filtered and reduced to a frontier of non-

dominated solutions.

It may happen that Sol consists of partial solu-

tions only, due to insufficient stock availability. In that

case, non dominated solutions are limited to those that

fulfills the largest demand.

For the sake of conciseness, in the following we

shall assume c = h j,Hi, i.e., the cut of the first stage is

always parallel to the height H

j

of the stock item: the

arguments presented maintain validity when replac-

ing ”horizontal” with ”vertical” and ”H

j

” with ”L

j

”.

3.2 Patterns Generation and Selection

For a given configuration c = h j,Hi ∈ C, function get-

Pattern creates a pattern that depends on the current

prices λ and demands d

0

. First, for each part type i ∈ I

0

a vertical section of width l

i

is defined, and a bounded

integer knapsack problem is solved. The knapsack ca-

pacity is set equal to the stock height H

j

and element

sizes correspond to the heights h

i

of the part types

selected. Clearly, only part types k ∈ I

0

with l

k

≤ l

i

,

demand d

0

k

> 0 and prices λ

k

> 0 are considered. Ac-

tually, each knapsack element describes a horizontal

strip containing a single item k (2-stage patterns), or

multiple copies of the same part-type (3-stage pat-

terns) wide at most l

i

. In the latter case, the maxi-

mum multiplicity m

k

is given by

b

l

i

/l

k

c

, and prices

are computed accordingly.

Let Q

c

be the set of sections generated so far, each

one provided with a certain activation level defined

with respect to the current part type demand d

0

. The

pattern is obtained by solving a further bounded knap-

sack problem that optimally selects sections in Q

c

. In

particular, the knapsack capacity is equal to L

j

and

knapsack elements correspond to sections, where the

size and value of element q are respectively equal to

the width and price of section q (the price of a sec-

tion is the sum of the prices of items it contains).

The resulting solution provides a subset of sections

¯

Q

c

that may present overproduction. In order to preserve

the structure of the knapsack problem, only activation

levels of the elements (sections) are explicitly con-

sidered, whereas part type multiplicities in sections

are neglected; moreover, the simultaneous presence

of part types and rotated part types is not accounted

for. It follows that part types overproduction is not

prevented and a post-processing may be required to

exactly fulfill part type demands. Sections q ∈

¯

Q

c

are

sorted by non-increasing order of the ratio

V

q

S

q

, where

V

q

and S

q

are respectively the price and the area of

section q.

Sections are possibly added to the pattern p fol-

lowing the prescribed order, and demand d

0

is accord-

ingly updated. In particular, a section is discarded

if it causes demand overproduction, or overflow of

the allowed limit on open stacks. In that case, the

resulting pattern p may present a residual stock area

of length R

j

that can be further filled. Therefore the

whole procedure, i.e., sections generation and selec-

tion, is repeated in order to generate a sub-pattern for

the configuration c = h

¯

j, Hi ∈ C, where stock item

¯

j

has length R

j

and height H

j

. The sub-pattern is placed

next to p and merged with it, and the process reiter-

ated until the residual stock area cannot be filled any

longer. Pattern p is then added to the set P.

Once patterns are generated for each c ∈ C, the

procedure getBestPattern selects the most profitable

pattern a ∈ P, that is, a pattern that maximizes the

total price of the sections it contains. Pattern a is fi-

nally added to the partial CSP solution s with acti-

vation level cuts, computed according to the current

demand d

0

and stock items availability. The pattern

generation process is iterated until the whole demand

is fulfilled.

Since the presence of real-valued prices, all the

above bounded integer knapsack are solved by en-

coding the integer variables as binary variables and

then by using an own implementation of the algorithm

for the 0-1 knapsack described in (Martello and Toth,

1990).

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

34

3.2.1 Precut Policy

For each pattern p, function getPattern generates also

a pattern p

0

that contains a precut, and then evaluates

the opportunity of replacing p with p

0

. For a given

pattern p, the algorithm scans all the cuts of the sec-

ond stage (those required to separate strips), choosing

one whose quota h is closest to the middle of H

j

, see

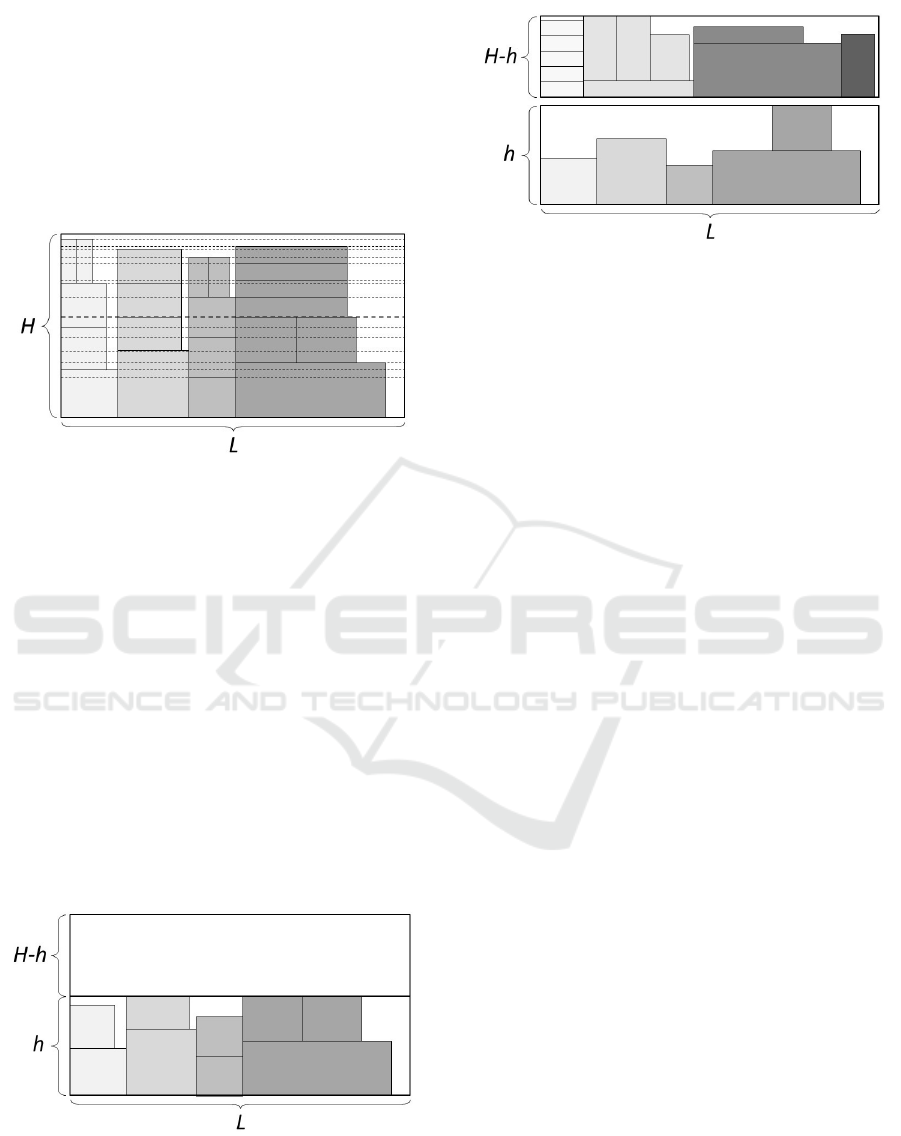

Figure 1.

Figure 1: Dotted lines indicate the potential cuts of the sec-

ond stage. The bold line refers to the cut closest to the mid-

dle of the stock height H

j

.

Stock item j (and pattern p) is split into new stock

items j

l

and j

u

(sub-patterns p

l

and p

u

) of sizes h×L

j

and (H

j

− h) × L

j

, respectively; the items that cross

quota h are removed and the sub-pattern p

u

deleted,

see Figure 2. Stock item j

u

is used to build a new

pattern p

0

u

(by the same procedure described above),

and a pattern with precut p

0

is obtained by merging

p

0

u

and p

l

, see Figure 3. If the difference between

the reduced costs of p and p

0

is larger than a given

threshold δ, then the pattern with precut is selected;

otherwise getPattern selects p.

The value of δ is set to zero in Steps 1 and 2 of

the heuristic, and is progressively increased in Step 3,

where the algorithm aims at producing solutions with

a decreasing number of precuts.

Figure 2: Sub-pattern p

l

.

Figure 3: Sub-patterns p

l

and p

0

u

.

4 COMPUTATIONAL RESULTS

The SVC was implemented in C++ and experiments

were performed on a Intel

r

Core2 Duo E8500 3.16

GHz with 8Gb RAM. The SVC heuristic has been

tested on ten real instances provided by SCM Group,

with n ∈ [58,972] and ρ = 1.15. The results have

been compared to those provided by the software pre-

viously adopted by the company and developed by a

national software house devoted to the design of cut-

ting optimization software. In order to be consistent,

the non-dominated solution using the minimum total

stock area has been promoted to the best solution and

compared to the single solution provided by the com-

pany own software.

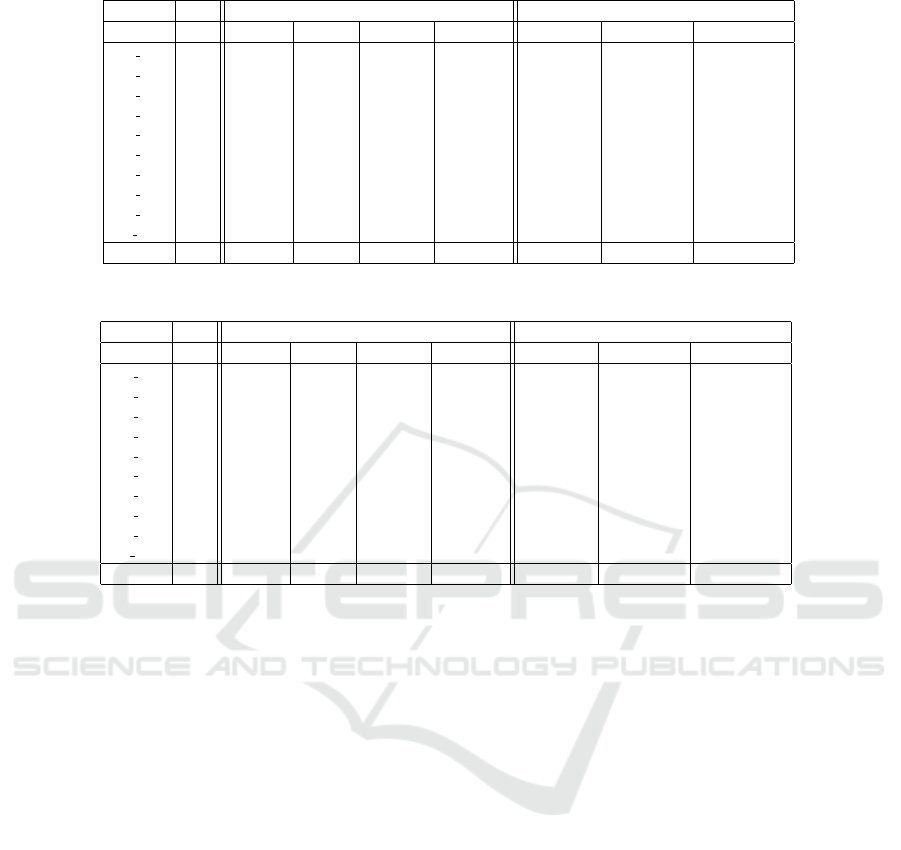

Table 1 and 2 show the results for the case with

disabled and allowed precut, respectively. For each

instance, the SVC performance is evaluated in terms

of total used stock area (Area), number of used stocks

(#stocks), total number of patterns (#patterns) and

CPU time. The last three columns show the percent-

age gaps with the results obtained by the company

software (positive values mean an improvement ob-

tained by SVC; the symbol ‘-’ means that the CPU

time limit of three hours has been reached by the com-

pany software).

On average, the SVC heuristic reduces the total

used stock area by 2.34% without precuts (1.42%

with precuts), while the percentage trim-loss is re-

duced by a factor between 1.5 and 4. The number

of used stocks is also reduced by 7.62% (1.19 %) on

the mean. When precut is disabled, an average re-

duction of 3.61% in the number of distinct patterns

is achieved, although a meaningful mean increase of

11.02% arises when precut is allowed. However, such

worsening is mainly due to the greater material usage

efficiency attained by the SVC best solution: in most

of the cases, SVC computes non-dominated solutions

requiring comparable used material and less number

of patterns. The CPU time required to solve real in-

A Heuristic for a Rich and Real Two-dimensional Woodboard Cutting Problem

35

Table 1: Results without precut on ten real instances.

SVC heuristic Company software

Name n Area #stocks #patterns CPU time ∆Area (%) ∆stocks (%) ∆patterns (%)

I 1 58 2403.12 304 69 26.69 1.31 1.32 2.90

I 2 83 1454.8 251 102 6.67 1.19 1.20 -6.86

I 3 141 1512.21 508 165 121.14 1.58 1.57 0.61

I 4 500 221.32 29 29 103.52 2.40 34.48 34.48

I 5 500 273.84 36 36 - - - -

I 6 747 3158.81 620 546 634.72 2.13 1.94 -14.65

I 7 759 495.92 96 96 760.08 5.45 5.21 5.21

I 8 869 2923.78 563 269 972.06 - - -

I 9 951 354.72 67 67 34.63 - - -

I 10 972 903.11 179 178 494.59 - - -

Average - 1370.16 265.30 155.70 350.46 2.34 7.62 3.61

Table 2: Results with precut on ten real instances.

SVC heuristic Company software

Name n Area #stocks #patterns CPU time ∆Area (%) ∆stocks (%) ∆patterns (%)

I 1 58 2403.12 304 80 5.92 1.64 1.64 -18.75

I 2 83 1454.8 251 105 34.55 0.79 0.80 -6.67

I 3 141 1509.24 507 152 332.28 1.18 1.18 -8.55

I 4 500 220.78 29 29 139.09 - - -

I 5 500 273.3 36 36 471.14 - - -

I 6 747 3158.27 620 524 632.56 2.08 1.13 -10.11

I 7 759 494.83 96 96 104.28 - - -

I 8 869 2908.4 566 264 549.39 - - -

I 9 951 354.72 67 67 84.11 - - -

I 10 972 903.33 179 177 1332.55 - - -

Average - 1368.08 265.50 153 368.587 1.42 1.19 -11.02

stances is about 6 minutes on the mean, with just few

instances that exceed 10 minutes.

The heuristic was also tested on 52 benchmark

instances with n ∈ [10,250]. With the precut option

disabled (enabled) the algorithm reduces trim-loss in

17.3% (15.4%) of the cases. By using the continuous

lower bound of the total requested area, the optimal-

ity of the best solution with respect to the material

usage has been certified in the 80.8% (82.7%) of the

cases. Independently of the precut policy, in 17.3%

of the cases a solution with one pattern less is found,

and only 1.9% of the instances require an additional

pattern.

5 CONCLUSIONS AND FUTURE

WORK

Mathematical programming is a powerful tool that

can be used to model many relevant industrial prob-

lems. However, those mathematical formulations are

often challenging and, in some cases, real process

constraints are hard to be modeled. This is also true

for many CSP variants that try to simplify resolution

by encoding just a restricted number of real-world

constraints. Software applications based on those

CSP formulations may then happen to be inappropri-

ate, and companies are continuously looking for tools

able to deal with the whole process features and spec-

ification.

This paper addressed such an issue and presented

an SVC heuristic to solve a rich M2D-CSP that ful-

fills the specification of a family of wood cutting ma-

chines produced by SCM Group. The objectives of

used stock area minimization and of additional crite-

ria, as well as the fulfillment of open stack constraints,

were considered. Computational tests demonstrated

the improvement achieved on the previous software

solution, in terms of both solution quality and CPU

time requirements.

Further research is needed to include additional

optimization criteria, e.g., the minimization of cut-

ting times and the management of left-overs, and

to provide an exact formulation of the pricing prob-

lem when the whole set of specification is consid-

ered. Also, cutting processes are strongly affected

by operations scheduling: the formulation of a bi-

objective rich M2D-CSP that simultaneously mini-

mizes a scheduling function (such as the maximum

lateness or the weighted sum of tardiness) should then

deserve investigation.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

36

ACKNOWLEDGEMENTS

We gratefully acknowledge dr. eng. Federico Ratti,

Stefano Oliva and Simone Cera of SCM Group for

the fruitful discussions and constructive remarks that

helped us design and refine the algorithm described in

this paper.

REFERENCES

Aloisio, A., Arbib, C., and Marinelli, F. (2011). On lp re-

laxations for the pattern minimization problem. Net-

works, 57(3):247–253.

Arbib, C., Marinelli, F., and Ventura, P. (2016). One-

dimensional cutting stock with a limited number of

open stacks: bounds and solutions from a new inte-

ger linear programming model. International Trans-

actions in Operational Research, 23(1-2):47–63.

Belov, G. and Scheithauer, G. (2002). A cutting plane algo-

rithm for the one-dimensional cutting stock problem

with multiple stock lengths. European Journal of Op-

erational Research, 141(2):274 – 294.

Belov, G. and Scheithauer, G. (2007). Setup and open-

stacks minimization in one-dimensional stock cutting.

INFORMS J. on Computing, 19(1):27–35.

Chen, Q., Cui, Y., and Chen, Y. (2016). Sequential value

correction heuristic for the two-dimensional cutting

stock problem with three-staged homogenous pat-

terns. Optimization Methods and Software, 31(1):68–

87.

Chu, C. and Antonio, J. (1999). Approximation algorithms

to solve real-life multicriteria cutting stock problems.

Operations Research, 47(4):495–508.

Cui, Y.-P., Cui, Y., and Tang, T. (2015). Sequential heuris-

tic for the two-dimensional bin-packing problem. Eu-

ropean Journal of Operational Research, 240(1):43 –

53.

Malaguti, E., Durn, R. M., and Toth, P. (2014). Ap-

proaches to real world two-dimensional cutting prob-

lems. Omega, 47:99 – 115.

Martello, S. and Toth, P. (1990). Knapsack Problems: Al-

gorithms and Computer Implementations. John Wiley

& Sons, Inc., New York, NY, USA.

Non

˚

as, S. L. and Thorstenson, A. (2000). A combined

cutting-stock and lot-sizing problem. European Jour-

nal of Operational Research, 120(2):327 – 342.

Poldi, K. and Arenales, M. (2009). Heuristics for the one-

dimensional cutting stock problem with limited mul-

tiple stock lengths. Computers and Operations Re-

search, 36(6):2074–2081.

SCM (2017). SCM group. https://www.scmgroup.com. Ac-

cessed: 2017-06-30.

Umetani, S., Yagiura, M., and Ibaraki, T. (2003). One-

dimensional cutting stock problem to minimize the

number of different patterns. European Journal of Op-

erational Research, 146(2):388 – 402.

Varela, R., Vela, C. R., Puente, J., Sierra, M., and Gonz

´

alez-

Rodr

´

ıguez, I. (2008). An effective solution for a real

cutting stock problem in manufacturing plastic rolls.

Annals of Operations Research, 166(1):125.

W

¨

ascher, G., Haußner, H., and Schumann, H. (2007).

An improved typology of cutting and packing prob-

lems. European Journal of Operational Research,

183(3):1109 – 1130.

Yanasse, H. H. and Lamosa, M. J. P. (2007). An inte-

grated cutting stock and sequencing problem. Euro-

pean Journal of Operational Research, 183(3):1353 –

1370.

Yanasse, H. H., Zinober, A. S. I., and Harris, R. G. (1991).

Two-dimensional cutting stock with multiple stock

sizes. Journal of the Operational Research Society,

42(8):673–683.

A Heuristic for a Rich and Real Two-dimensional Woodboard Cutting Problem

37