Nanoscale Non-Contact Laser Measurement of Precision Machine

Tooling and Optical Surfaces

Schubert Soãres

Ultrafast Sensors, 6774 E 123

rd

Ave, Brighton, CO 80602, U.S.A.

Keywords: Non-Contact Nano Metrology, Laser Triangulation, Optical Scatter, Machine Tool Error, Surface

Topography, Edge Structure, Defect Geometry, Thin Films.

Abstract: Optical and semiconductor products are fabricated utilizing industrial technology that is steadily progressing

to nanometre accurate operations. Reliable non-invasive contact-free sensors and techniques are required to

monitor in situ manufacturing parameters in parallel with product formation. The real-time evaluation and

analysis of precision fabrication processes could lead to intelligent, computerized, sensor-actuated

implementation, with automated compensating feedback loops to facilitate nanometre accuracy and

consistently provide high quality products in abundant yield. Laser triangulation is demonstrated herewith

as a versatile solution to simultaneously measure machine tool components and monitor the product in

process. Optically levered reflection resolved on a nanometre resolution displacement sensor, enables the

analysis of spindle axial and rotational error, stage linear error, the impact of these error-motion components

on a diamond tool edge and its progression to wear, while inspecting the compliance of the product to the

desired surface finish and shape. Scanning optical scatterometry is utilized to image and analyse edges,

surfaces, defects, and thin film structure. This sensor technology is highly adaptable, and may be utilized in

scales ranging from small µm-size to large meter-size products manufactured from a variety of materials.

1 INTRODUCTION

A variety of industrial and consumer products such

as laser optics, mirrors, crystals, thin films, fibre

optic devices, camera optics, semiconductor wafers,

precision aircraft and automotive engine

components, and progressive-focus optical lenses

are routinely manufactured to accuracies, ranging

from a few 100’s to a few nanometres. The

manufacture of these products is implemented with

rigid process control, often utilizing separate

systems for metrology, in uncoordinated

independent procedures. There is vital requirement

in these diverse industries for versatile, integrable,

contact-free, non-destructive, optical sensor

technology to accurately monitor in situ all

dynamics of the fabrication process, machine tool

operating parameters, cutting tools, and product

quality. The measurements range from rotational

(spindle) and linear (stage) error motion, cutter

condition vis-à-vis edge quality and evolution during

usage, machined surface quality and shape

conformity, defects, and manufacturing

repeatability. The potential for co-ordinated

concurrent sensor measurements and computer

assisted parametric control of the manufacturing

process could result in consistent nanometre quality

products with significantly improved yield.

Conventional contact-free techniques such as

capacitive and inductive probes rely on relatively

large sampling areas, and may be inadequate in

terms of convenience, calibration, sensitivity, and

cost for a variety of product materials, shapes, and

sizes. These systems were developed originally for

conductive materials; the non-invasive measurement

of optics or doped semiconductors poses additional

challenges. Shape is another restriction with

calibration posing significant hurdles for spherical,

aspheric, or free form surfaces, restricting usage to

planar products. Other techniques such as

ultrasonics, air pressure, and phase analysis involve

greater hardware complexity and lack nanometre-

level resolution. The measurement of the shape of a

diamond cutting tool, or the structure of a thin film,

or a defect for example, is virtually impossible

utilizing any of these technologies. Since all of

these sensor types require extensive electronic

24

Soãres, S.

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces.

DOI: 10.5220/0006539900240035

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 24-35

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

processing and amplification, noise and linearity are

major limiting factors to accuracy and resolution.

Laser triangulation sensing offers a simple,

compact, feasible, micro-to-macro scale solution to

track operating parameters in a variety of industrial

environments, to monitor, evaluate, and analyse the

manufacturing process, and also to measure a

multitude of precision products fabricated from a

variety of materials. Optical-lever metrology, in

which laser reflection and scatter are scanned on a

nanometre-resolution solid state sensor, is

investigated in this paper. This technology is

utilized to easily resolve 100-nm tool displacement,

250-nm error motion, cutting tool shape and wear,

machined surface quality and tolerances, defects,

and composite thin films. The versatility of this

technology resides in simple calibration processes,

easy multi-channel expansion into ordinary data

acquisition and computer systems, and turnkey

integration with precision machine tools.

2 OPTICAL METROLOGY

There are several well established techniques for

optical metrology utilizing the energy (wavelength),

the coherence, and the polarization properties of

laser beams, in electromagnetic interaction with

surfaces and media, derived from the physics of

optical reflection, diffraction, or transmission. The

optical signals are monitored with sensors or

cameras, recorded on data acquisition systems, and

analysed and decoded with software to produce

calibrated metrics for evaluation and quality control.

The foremost of these methods is interferometry

wherein a pair of coherent beams, originating from

the same source (via wavefront or amplitude

division, forming reference and probe beams)

interact when combined after sampling to produce

fringe energy redistributions, which are monitored

singly, sequentially, or collectively to decode a

variety of parameters. The signal could be related to

and utilized to measure, for example, displacement,

three-dimensional (3D) shape, spectral content,

optical properties, and the internal structure of

optically transmissive media. The reflection and

transmission properties of polarized light incident on

near-perfect surfaces, interfaces, and film layers

provides additional opportunities for metrology

based on ellipsometry, Brewsters angle, principal

angle, critical angle and total internal reflection

(Azzam, 1999, Heavens, 1955). These techniques in

fact may be utilized, by comparative analysis of

polarization state, amplitude evanescence, and phase

shift, to measure real and complex optical properties

of media, examine sub-surface structure, or detect

anomalous behaviour at interfaces.

Optical triangulation and scatter, operating with

nanopositioning, are additional options available to

directly evaluate position, displacement, and motion,

and to image surface topography, sub-surface

structure, anisotropies, artefacts, defects, and thin

films.

2.1 Laser Reflection and Scatter

Our primary focus is on laser reflection and scatter

from smooth surfaces in optical components,

precision-machined surfaces, Si wafers and similar

products from various high-technology industries.

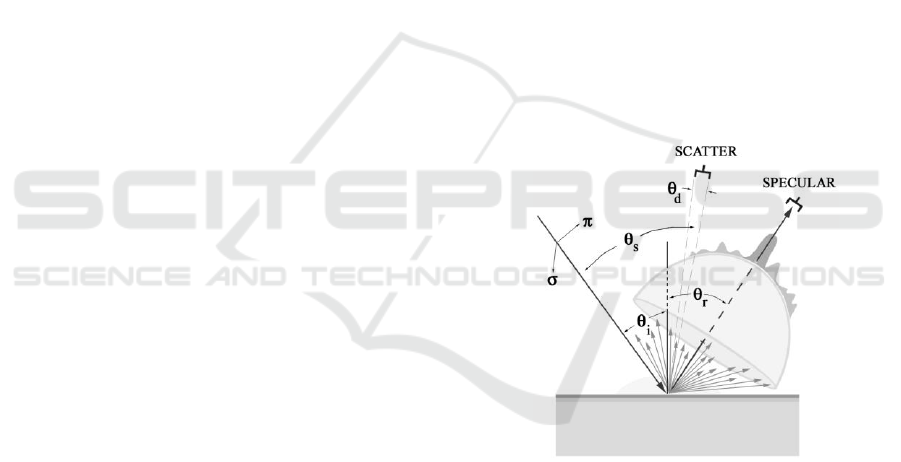

Any smooth surface with residual nanoroughness

(Figure 1) will produce specular reflection and non-

specular diffractive scatter from an incident optical

beam, which is preferably made diffuse to eliminate

its coherence and minimize speckle. The specular

beam is produced by the flat-smooth surface (zero-

order roughness), and is governed by the vector

Fresnel relations, which are polarization specific.

Figure 1: Geometry of optical scatterometry. Specular

reflection is from the smooth surface. Low to high spatial

frequency microstructure scatters proportionally

decreasing power at wide angles. The omni directional

low-intensity haze is produced by microstructure.

Residual structure in the surface, corresponding

solely to the roughness component of the

topography, can be modelled in a multi-dimensional

Fourier integral (or alternate) analysis, as composed

of sinusoidal (or basis) functions within a continuous

and distributed spread of spatial frequencies (or

components), each with adjustable amplitude and

phase shift, which converges approximately, in the

mean-square, to the surface profile (Church, 1979,

Longuet-Higgins, 1957, Stover, 1995).

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces

25

The far-field (Fraunhofer) distribution of

scattered optical power from this surface at angle

s

,

from an incident beam inclined at

i

, measured on a

detector subtending solid angle

d

, ranges from its

maximum at the angle of specular reflection

r

,

decreases gradually but not necessarily uniformly or

symmetrically, in ~ 2-steradians oriented (for

detection) in spherical coordinates about the axis of

the reflected beam, centred at the point of reflection

(Figure 1). Since for practicality,

i

is usually not

normal, the spot on the surface is not circular, and

must be accounted for if illuminated structure or

defects are large in comparison. The scatter power

measurement at non-normal angles is compensated

by a factor of (Cos

s

)

-1

to normalize the orientation

of the detector to the plane of the surface. The

altitudinal and azimuthal variation of the scattered

optical power about the specular axis need not

necessarily be regular or asymptotic, and in fact may

contain additional artefacts such as multiple

secondary maxima superimposed with power

fluctuations, uniform haze, and other variations.

The defect size, , and the roughness dimension,

',scaled in comparison to the wavelength,

determine the corresponding total 3D scatter

distribution (Bohren, 1998, Stover, 1995). There are

five zones of scaling, namely:

(І)

(І)

(І)

(І)

and

(І)

These can be restricted

to a few categories for precision surfaces. Scatter

from low spatial-frequency roughness (several

multiples of the optical wavelength; ') is present

in angular proximity to the specular reflection.

Microstructure containing higher spatial frequencies

(') scatters power at wider angles away from the

reflected beam. The scaling determines if the optical

path of scatter radiation is by direct reflection from

the surface or by instances or orders of multiple

reflections within the roughness, prior to impinging

on the detector. The power of the scattered

radiation, if scales with the sixth power of the

dimension of defects, and varies as

-4

. The non-

specular radiation at oblique angles is essentially

Rayleigh scatter produced by randomly oriented

sub-wavelength

(І)

defects, surface, and sub-

surface structure, and studied extensively by Church,

1979, and Stover, 1995. Indeed, scatter produced by

nanostructure, where ' is relatively minor (at multi-

lattice constant or multi-molecular dimensions) in

comparison with , is distributed uniformly over the

entire hemisphere, much as a Lambertian source,

and forms a noise-power baseline. The total power

distribution function may also contain Mie scatter

components from fractional to multi-wavelength

dimension defects (

(І)

), Rayleigh scatter from

sub-wavelength defects (), and a wide range of

features which additionally may be present on the

surface as texture, device patterns, debris, or damage

in a sub-surface region within an optical wavelength.

The remaining critical variables in defect and

artefact detection are the beam incidence angle and

its polarization, the scattering cross section, the spot

profile and size, and the detection arrangement. -

polarized light incident on a defect generates a

symmetric lobular altitudinal pattern oriented

orthogonal to the field, while-polarized light

illuminating a defect produces a uniform altitudinal

scatter distribution but is azimuthally lobular, i.e. a

90-degree rotation of the field. The beam

orientation and the positioning of detectors for

defect detection in the scattering plane is an

empirical art critically based on the selection of the

polarization of the incident beam to enhance high

defect-to-background contrast. For example, the

normal component of –polarization in near normal

incidence could be utilized to probe embedded

defects or voids with narrow oblique detection.

Similarly,-polarization may be useful to detect a

particle on a surface, where oblique incidence is

combined with wide normal detection. Additional

variables to consider are the specific defect shape

(usually not spherical), the defect material, whether

the defect resides on a dielectric or a conducting

surface, and the corresponding image charge

distributions. The operating wavelength may be

judiciously selected if the background surface, the

defect material, and the scatter thus produced are

reasonably well understood. The angular

distribution of scatter also suggests the utilization of

Fourier spatial filtering to distinguish scatter profiles

of a particular roughness range, device footprint, or

defect type, a technique widely in use in the

semiconductor industry to identify undesirable

defects on processed wafers.

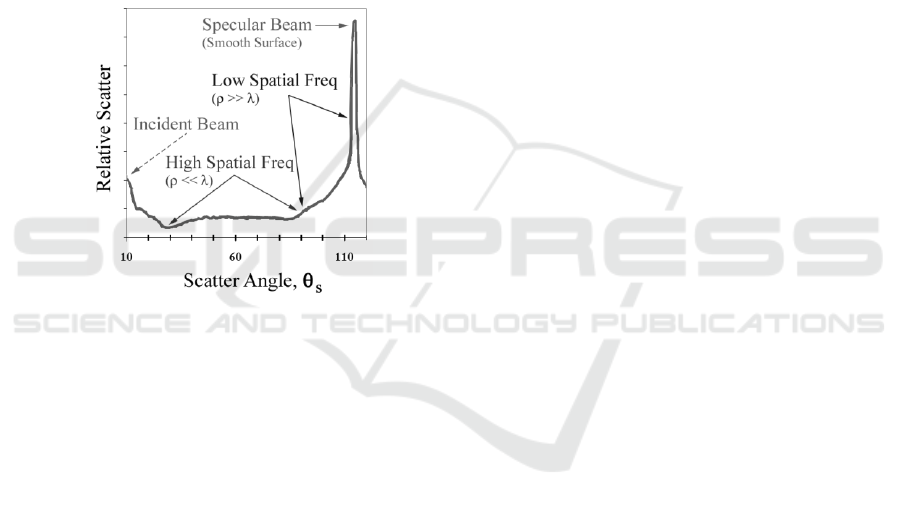

Figure 2 shows representative angle-resolved

optical scatter data acquired at 633 nm on a polished

quartz optic, in which the logarithm of the relative

scatter produced is plotted versus the detector

(scatter) angle, which is varied from the incident

beam towards the specular reflected beam. The data

follows our discussion in the previous paragraph,

and the scatter power in relation to the surface

roughness spread is as indicated. The dynamic

range from the specular maximum power (flat

surface) to the scatter minimum power

(nanoroughness) is approximately 73 dB. The

specific scatter power for a defined roughness spread

at a prescribed angle could be resolved by

deliberately machining the corresponding structure

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

26

onto a surface to enable a calibration reference in

this measurement or vice versa. The scatter

produced by an ideal near-perfect smooth flat

reflecting surface would consist of only two

components: the specular beam which would be an

almost mirror image of the incident beam, with an

infinitesimal fraction of the power transferred to

omni directional uniformly distributed Rayleigh-

scatter haze produced at the crystalline level,

establishing the noise threshold. A polished optic, a

precision diamond turned mirror, or a polished Si

wafer are considered ideal surfaces, satisfying

conditions of spatial frequency ergodicity, and

sampling at a single point would produce a perfectly

symmetrical scatter profile, which would be

representative of the entire surface.

Figure 2: The angular optical scatter distribution (at 633

nm / ) measured on polished quartz. The dynamic signal

range is 73 dB. The scatter power is proportional to the

roughness scaled to the wavelength, as indicated.

Another useful figure of merit for comprehensive

surface quality is the normalized total integrated

scatter (TIS), which is produced by the entire

functional structure of the surface and sub-surface,

comprising all roughness and defect-array

constituents with the exclusion of the specular beam

(corresponding to the zero-order smooth surface),

which is filtered from the data. The TIS value may

be utilized to monitor a surface and provide a rapid

measurement of overall quality, during the grinding,

the lapping, and the polishing processes to produce a

smooth flat surface on an optic or a Si wafer. It can

also be utilized to sample defect density per unit area

by common mode comparison of the TIS for a

smooth surface to a surface with distributed defects.

A surface may also be scanned in a TIS system to

provide area-wide metrics for a more exact figure of

merit. An associated figure of merit could be

established by profiling the specular beam for

comparison with the profile of the incident beam to

deduce spatial frequency components of the surface.

Precision industrial environments where optical

components, devices, semiconductor wafers, and

metal parts are manufactured require rapid real time

evaluation and analysis of parameters such as

machine error motion, surface topography, local and

global surface roughness, sub-surface damage,

contamination, shape, thickness, and defects. This

goal is achieved if some of the technical

complications, details, and analysis of scatterometry

(Figure 1), associated with factors such as the angle

of incidence, polarization, beam profile, interaction

with media, coherence, etc., may be circumvented.

A simple in-plane non-invasive linear optical system

consisting of a low power plane polarized laser input

beam with a symmetric profile and a passive,

suitably oriented, uniaxial sensor can be devised to

produce results within constraints of ease of

calibration, expense budget, and low complexity.

Low spatial frequency variations in surface

topography or motion cause well-defined deflections

in the specular reflected beam, and produce

proportional signal fluctuations. If additional

sensors are positioned to measure scatter in

predetermined non-specular angles

s

it is possible to

detect and deduce various surface parameters related

to high spatial frequency content and defects. If the

sensor is capable of resolving minute power

variations, its corresponding sensitivity to surface

features and defects is proportionally enhanced.

2.2 Optical Sensing

Optical sensors with wide dynamic response are

available to track position, and measure

displacement and motion, producing a signal, which

is proportional to the relative distance between two

objects, or range to a moving surface; coordinates

are established by sensor geometry and mounting

configuration, with illumination which can be direct

beam incidence or triangulation. These sensors are

available as single element units or as multi-element

/ dual-dimensional arrays. The sensing element

could be a PIN photodiode, or a CCD or CMOS

sensor, and require external bias and amplification.

Optical sensing circumvents the limitations of

various other non-contact technologies in

measurements of planar and non-planar geometries,

in a smaller footprint, with improved performance,

reliability, and integration.

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces

27

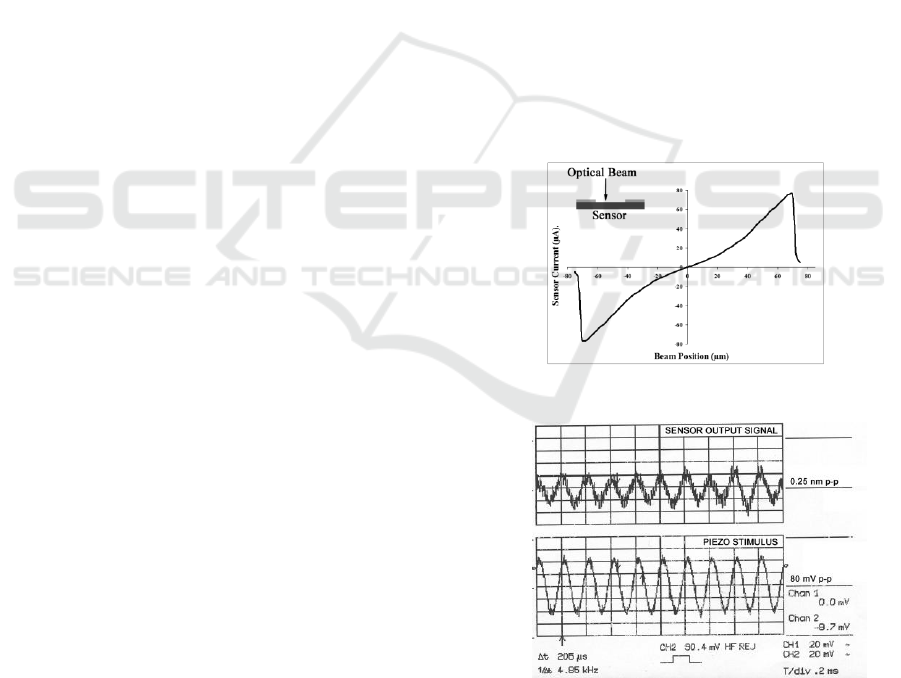

2.2.1 A Displacement Tracking Sensor

A planar multi-dimensional silicon sensor was

demonstrated in which Schottky contact pairs were

deposited and oriented laterally, with the

photosensitive area delimited by the contacts as seen

in the inset in Figure 3. The active area is

illuminated with an optical source, preferably though

not necessarily, in the profile of a collimated or

focused laser beam. The optical radiation is

absorbed in the sensor, inducing excitons, which

instantly diffuse radially away from the point of

injection, electrons dispersing more rapidly than

holes, establishing a steady state charge distribution

centred at the point of injection (Sze, 1981). This

sensor operates on the cascading internal structure of

ambipolar electrical fields, arising from the disparity

in the diffusion distribution geometries of high-

mobility electrons in the conduction band, and low-

mobility holes in the valence band. This field

arrangement modulates the intrinsic fields within the

depletion region at the contacts, and induces a beam

position weighted self bias at each contact, with

unidirectional current flow on average that is

uniquely proportional to the injection point of the

optical beam relative to the contacts (Sze, 1981).

The sensor itself may be presumed to be self

deconvolved and essentially noiseless, since in its

passive mode internal currents, in the absence of

optical input, are symmetrically opposing. If the

beam profile is asymmetrical, or geometrically

irregular with distributed internal power variations,

then this versatile sensor could identify the

weighted-average position of the “maximum” power

of the beam, suggesting applications in sensing

textured or patterned geometries. The sensor signal

is proportional to the position of the beam maximum

within the contacts, as well as to the input optical

power, and also to the relative position between the

plane of the active surface and the source, yielding

resolvable 3D-sensitivity for a variety of

applications in optical systems. The output signal

may be made arbitrarily large to circumvent any

level of input noise available at an amplifier; the

ultimate limitation however being the shot noise in

the optical source, which in effect can also be

minimized by lock-in techniques, feedback control,

and thermal stabilization (Horowitz and Hill, 1989).

2.2.2 Static and Dynamic Sensitivity

This sensor was evaluated for static sensitivity and

dynamic response; representative results are shown

in Figures 3 and 4. In the static mode a 1-mW HeNe

(633 nm) laser source was collimated into a 10X

microscope objective; the beam spot was estimated

at approximately 5 µm. The sensor with 150-µm

active area was fixed to a micropositioning stage.

The stage driver was computer controlled, and the

voltage across the stage was gradually ramped,

sweeping the sensor across the stationary optical

beam from one contact to the opposite contact.

The functional dependence of the signal from the

sensor versus the beam position traversing between

the contacts is measured and processed with low

noise electronics (Figure 3). This signal is shown to

peak in bipolar fashion at the contacts with a null at

the geometric centre. There is piecewise linearity in

the signal, possibly associated with a non-uniform

beam profile, shielding of the optical beam as it

traverses the contact, and non-linear interaction

between the ambipolar field distribution and the

contact fields. Several displacement references are

available for purposes of calibration; the most basic

being that the manufacturer certifies the stage with a

displacement per applied voltage specification. In

addition, the sensor has a lateral active area

dimension, which could also serve as a rigid

reference.

Figure 3: Tracking response of a displacement sensor.

Figure 4: Frequency response of the sensor to a 4.85-kHz

oscillation imposed on the optical beam.

The dynamic response of the sensor was

evaluated utilizing a lock-in technique to explore

low amplitude detectivity and the noise floor. The

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

28

laser was coupled into optical fibre and the fibre was

fixed to a narrow tube piezoceramic with 3 nm/V

displacement calibration. A 50-µm sensor was

attached to a mechanical stage and positioned within

the optical beam in the near field. The spot size was

estimated less than 30 µm full width half maximum.

The lock-in amplifier provided a 4.8-kHz, 80-mV p-

p stimulus to the piezo, and the sensor signal was

simultaneously monitored and measured by lock-in

at 10

5

gain. The stimulus corresponds to a spatial

beam oscillation of approximately 0.25 nm across

the active area of the sensor, and was resolved with

approximately 20% noise (Figure 4). This would

indicate a detection threshold of approximately 0.05

nm, well below the lattice constant of Si. It is

apparent that 1-nm resolution could routinely be

achievable without any constraint.

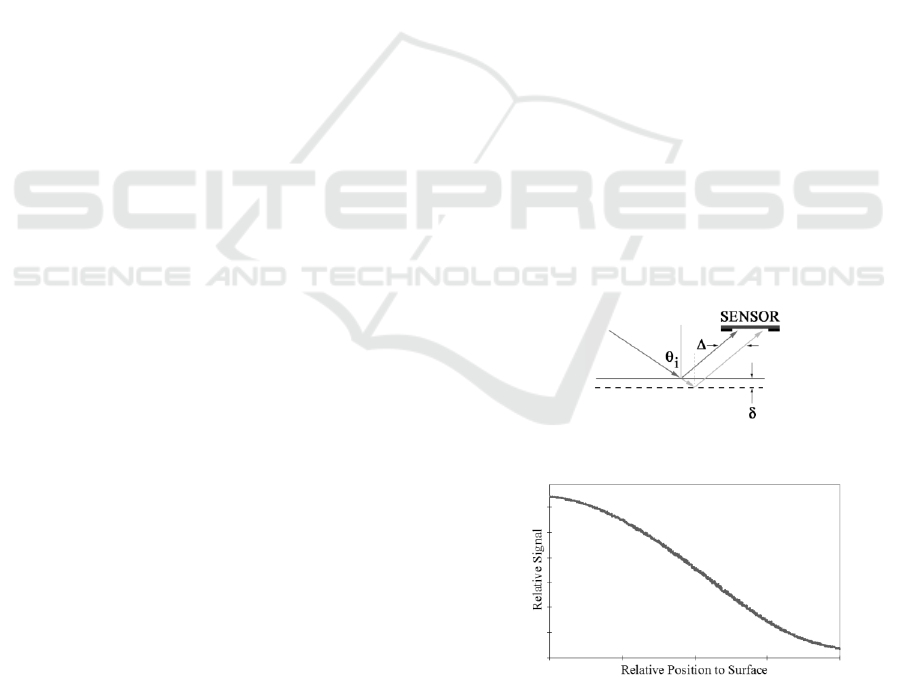

2.3 Metrology by Laser Triangulation

The technology described above is now integrated

and utilized in a computerized system to measure

and evaluate a variety of manufacturing assets,

operating parameters, and precision products. These

range from basic tool position and displacement

sensing, rotary and linear motion sensing, thermal

effects, inertial imbalance, and examination of the

machining operation, to sophisticated inspection of

diamond cutting tools required to fabricate optics,

and imaging of precision machined surfaces, defects,

and thin films. The metrology and imaging system

consists primarily of a stable laser source, a

displacement sensor, a piezo stage with triaxial

scanning capability of 50 µm x 50 µm x 50 µm,

typically with 100-nm pixel resolution, ultra-low

noise electronics, data acquisition, signal processing,

and software analysis. The 785-nm laser is fibre

coupled, and the sensor and the fibre tip are mounted

adjacent, in plane on a base, with adjustments to

enable the applications and measurements detailed

below. The beam spot is typically under 0.1-mm

diameter, and can be adjusted to the application as

necessary. The optical beam and the sensor

arrangement are shown in Figure 5a. This geometry

of optical triangulation is optimal for sensing and

imaging applications, wherein the sensor and the

optical source are mutually aligned at an angle such

that the source beam reflects from the target surface

into the sensor, forming a plane of incidence which

is orthogonal to the surface.

The displacement and motion sensitivity is as

follows: if the plane of the surface moves a parallel

distance away from its reference position (Figure

5a), the optical beam is translated to a new position

on the surface, laterally displacing the reflected

beam across the sensor by a dimension, , producing

a proportional sensor signal. For a triangulation

angle

i

of π/4, the displacement of the beam is

optically levered by a factor of twice the

displacement of the surface; equivalence is

established at ~ π/7. This could be considered a

practical lower limit whereby the formation of a

Wiener wave distribution would not perturb the

sensor, in near-field measurements. The vertical

response (normal to the target surface) of this

configuration over a perpendicular scan of 50 µm is

shown in Figure 5b. The linear response of the

system in the central region is ideal for various

sensing applications, which are explored in the

following sections. The imaging capability of this

system resides in its sensitivity to contrast in scatter

measurements, in a lateral scanning process. Scatter

is measured by positioning a sensor apart from the

specular beam, and adjusting its altitudinal and

azimuthal positions to detect spatial roughness or

defect types, as shown in Figures 1 and 2, and

described in Section 2.1. This system utilizes

software-processing routines to operate scanning

algorithms, interpret signals, and enhance sensor

response to scatter. Evaluations of various

machining parameters and examinations of surfaces,

geometric artefacts (edges), defects, and thin film

layers in 3D measurements are presented in the

following sections, which demonstrate the versatility

of this technology.

Figure 5a: Optical triangulation geometry.

Figure 5b: Response of the sensor-beam arrangement to

displacement, perpendicular to the surface plane.

2.3.1 Torque Offsets and Thermal Analysis

Ultra-precision machine tools are designed as

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces

29

integrated systems in gravitationally levelled,

vibration isolated, and temperature controlled

environments for rotational and translational

stability, approaching multi-100 nm error motion. A

typical machine tool will operate with pressurized

fluid-lubricated bearings supporting the spindle and

the track to maintain uniform motion for high

accuracy. These tools are provided with operational

routines and techniques to match their specifications,

and it is beneficial for the operator to periodically

measure and monitor performance to maintain

repeatable product integrity and yield.

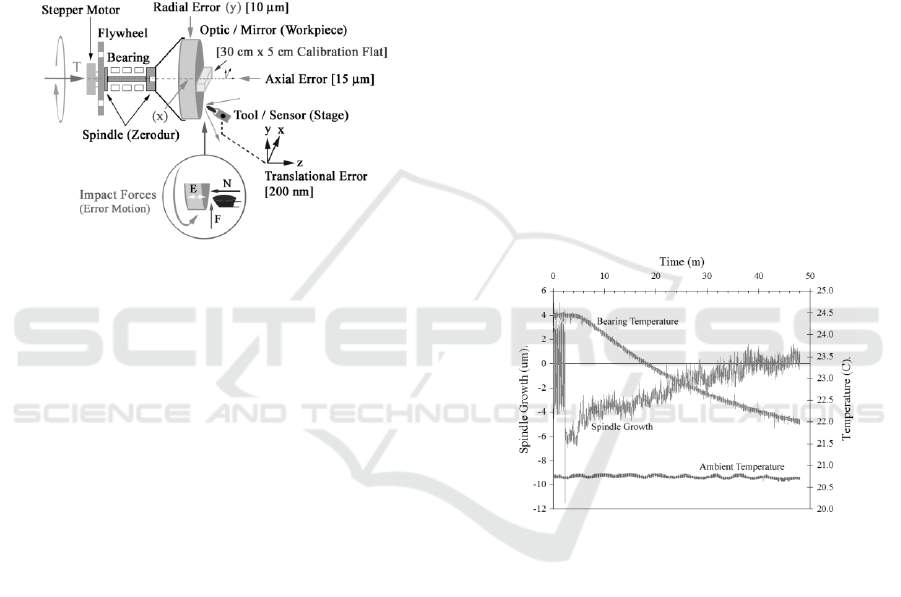

Figure 6: Axial and radial error measurement geometry on

the workpiece, and translational error on the cutting tool

holder stage. The calibration flat replaces the optic.

The measurement configuration for axial, radial,

and translational error motion is shown in Figure 6.

A cylindrical work piece is clamped to the spindle in

an appropriate manner to ensure rigid coupling, with

static preadjustment of its relative position to “true”

its surfaces to the spindle and to the tool holder, and

thereby reduce error. Typically the front planar

surface and the circumferential cylindrical surface

are then pre-machined (few µm of removal) to

conform workpiece geometry in roundness and

planarity to the dynamic circular motion of the

spindle and linear motion of the cutting tool,

respectively. The cutting tool and the sensor are

mounted on a holder stage with translational

freedom and nanopositioning capability as required.

Mechanical and thermal characteristics of the

spindle air-bearing assembly, and translational and

rotational accuracy of a precision machine tool were

examined in the triangulation-sensing configuration

(Figures 5a and 5b) to study the performance of the

tool and the sensor. A sensor was placed on axis,

parallel to the spindle, which operates free running

(100 rpm for approximately 30 min) to stabilize

thermally. The vibratory axial error motion on this

unit in operation is approximately 3 µm (Figure 7).

The rotating spindle exerts paraxial torque, which

preferentially repositions the spindle within the

bearing encasement, in an unstable axial position, in

the direction of the torque vector.

The spindle rotation was next instantly powered

down, and the sharp transition in the data at 3 min.

indicates rapid deceleration associated with loss of

power, and an axial torque-free realignment of the

spindle position within the air bearing encasement.

The spindle dynamic-to-static torque offset is 6 m

equivalent to the amplitude of the spindle axial error

motion. It now commences resting passively,

balanced axially and radially within the bearing with

uniform air suspension. The bearing temperature

was 24.5 ºC during the rotational phase, cooling off

gradually to 22 ºC, and compressing over tens of

minutes, commencing after shut down. The heat

from the bearing assembly is gradually transferred to

the spindle, which “grows” back to its position

during rotation, as the entire spindle-bearing

assembly cools and stabilizes in the environment.

This thermal growth error is slightly larger than 6

m, equivalent to the dynamic axial error, and the

torque offset. The ambient air temperature remains

steady at 20.7 ºC during these measurements.

Figure 7: Thermal analysis of a precision spindle.

2.3.2 Cutting Tool Holder-stage Accuracy

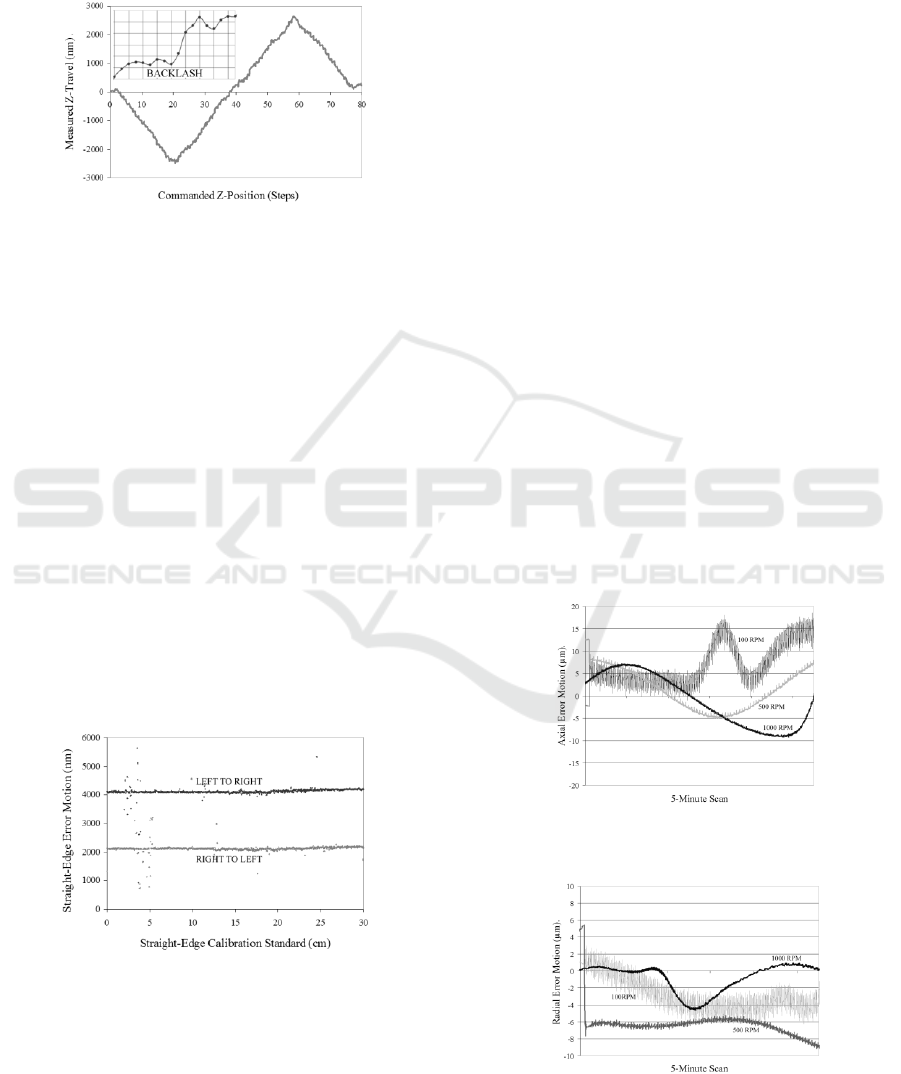

The on-axis translational accuracy and hysteresis of

the tool stage was evaluated by clamping a

commercially available 30 cm x 5 cm polished

calibration flat to the spindle chuck (Figure 6),

mounting a sensor to the tool holder, and measuring

the signal as the sensor tracks the motion of the tool

holder in a sequence of 20 steps, 125-nm each, first

retracted away from the flat, next 40 steps, 125-nm

each, moving toward the flat, and finally 20 steps,

125-nm each, retracted from the flat, back to its

original resting position. These results are shown in

Figure 8, with a detailed view in the inset. The

translational backlash (in the inset) is apparent as

progressive motion commands are given to the tool.

The overall translational motion is linear with

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

30

marginal error of a few 100’s nm. With the tool

traversing 10-m total roundtrip translation, from its

original resting position, through the 80-step

sequence, and returning to it, the total round-trip

hysteretic error is under 30 nm.

Figure 8: Sensor response to 80x125-nm step pattern. The

inset displays the backlash as the tool is advanced.

The translational accuracy of the tool stage,

perpendicular to the spindle axis (in the radial

direction) was also examined (Figure 9). The sensor

in this measurement was first translated across the

entire 30-cm length of the calibration flat, then offset

2 m below the original track, and next translated

back to its original position. This data indicates very

high repeatability of the tool positioning system with

error in the few 100’s nm as in the previous on-axis

measurements. A fraction of this error contains

inaccuracies of the flat and possible contamination

of the reflective surface, as is evident in the spurious

signals in the first 5 cm measurement range. The

flat also appears to have an upward bend beginning

at 18 cm, where there is an incremental trend in the

data of approximately fewer than 200 nm total.

Integrating these measurements, the triaxial x-y-z

tool-holder stage motion is shown to be accurate to

less than 200 nm with negligible hysteresis.

Figure 9: Bi-directional tracking measurements,

translating across a 30-cm calibration flat.

2.3.3 Spindle Error Motion

The dynamic axial and radial error motions of a

spindle work piece were analysed next, over a 5-

minute period of steady state rotation. The axial

measurement data set is shown in Figure 10,

evaluated at 100, 500, and 1000 rpm. The 100-rpm

axial data has rapid positional fluctuations composed

of periodic and aperiodic elements, across the entire

measurement duration, in amplitude under 6 µm,

combined with gradual axial error variation

extending to 15 µm over several minutes. The

spindle is observed to settle as the rotational speed is

increased to 500 rpm, where the rapid error noise is

reduced to less than 1 m, combined with 15-m

gradual instability over extended time. It stabilizes

much further at a speed of 1000 rpm, where the

instantaneous positional fluctuation is reduced to

less than 500 nm but the long-duration large 15-m

axial variation is persistent in the data. Radial

spindle error measurements at 100, 500, and 1000

rpm demonstrate equivalent behaviour, as seen in

Figure 11. The radial noise is comprehensively

lower than axial noise, which indicates that the

spindle as expected is radially more stable within the

bearing. The 100-rpm data has rapid periodic and

aperiodic fluctuations in the 3-µm amplitude range

combined with a slower variation of under 10 µm,

extending over duration of several minutes. The

stability improves at 500 rpm and the fast error noise

reduces to less than 1 µm. The gradual drift is less

than 5 µm over the measurement time span, or about

25% of the axial instability. The spindle, rotating at

1000 rpm, registers under a miniscule 250 nm of

high frequency noise, with 5 m of radial instability.

Figure 10: Measurements of axial error motion at 100,

500, and 1000 rpm made over a 5-minute duration.

Figure 11: Measurements of radial error motion at 100,

500, and 1000 rpm made over a 5-minute duration.

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces

31

2.3.4 Ramifications of Spindle Error Noise

The above complement of measurements can be

integrated into an overall figure of merit of the

precision fabrication capability of this machine tool,

to estimate and project the quality of a finished

product and manufacturing yield. The limiting

factors are as outlined below, focusing on the

manner in which spindle error motion produces wear

on the cutting tool, which then induces roughness

and shape error in the machined surface. The

undesirable rotational instabilities in Figures 10 and

11, particularly approaching the 1-µm level and

larger (to 15 µm) may be associated with a

combination of factors such as torque variations

inherent in drive-motor speed inconsistencies and

spindle non-uniformities (material, warpage),

spindle inertial imbalance, unstable suspension-fluid

pressure distribution in the bearing, bearing

acoustics, multiple resonances, frictional forces,

energy transfer of the spindle to the casing,

insufficient machine tool vibration isolation,

gravitational level imbalance, thermal gradients and

non-uniform heat dissipation, and various other stray

factors. An associated factor is that instability at a

given point along the inertial axis of the spindle may

in reality be smaller in amplitude than the

measurement at the workpiece, where it is

mechanically levered to a larger amplitude - at a

pivot point along the axis within the bearing. Some

of these errors can be partially corrected since most

precision machine tools do have rebalancing

flywheels with passive adjustment to nominally

damp non-circular motion; the spindles may also be

constructed from low-expansion Zerodur to limit

thermal creep. However, a sensor-driven active

adjustment and damping system could dynamically

reduce the 15-µm slow error to less than 100 nm.

Intuitively, the best measurement areas for rotating

spindle analysis are on the workpiece, and not

directly on the spindle. All of these factors could

serve as a case study for future analysis to attain the

goal of true nanometre manufacturing.

Referring to Figure 6 (inset), the 15-µm axial and

10-µm radial spindle slow error motions represent

equivalent periodic and aperiodic error forces with

proportional counter-normal impact (E), originating

in torque error (T), and friction (F) transmitted

through the workpiece directly to the edge of the

cutting tool, which exerts normal force (N) during

the machining process; the translational error of the

tool-holder stage, and the rapid spindle error

motions (100 – 500 nm) are significantly smaller in

comparison. These combined forces (E, F, & N)

generate high friction, thermal spikes, and acoustic

shock, which produce extremely high localized

energy transfer to the cutting tool edge point-of-

contact, resulting in wear patterns in the edge profile

and its contour, limiting its usable lifetime. The

evolution of the edge profile of a cutting tool will be

explored in detail in the following section 2.3.5.

Qualitatively, the error noise data indicates that a

flat mirror surface, machined utilizing this spindle

and a fresh cutting tool, would have radially oriented

local roughness texture of depth dimension equal to

the axial fluctuations (Figure 10) of the spindle, with

relatively smaller contributions from lower radial

noise components (Figure 11), which occur in the

plane of the surface. The tool positioning error on

the order of 100 nm (Figures 8 and 9) is negligible in

comparison with the multi-m level axial and radial

fast and slow error noise of the spindle. If the

surface is a curved mirror or a lens, machined to a

pre-determined contour, the dynamic axial and radial

error-motion could result in proportional roughness

and shape variations caused by the instability of the

spindle. The axial error would induce radially

oriented roughness in the finished surface, while the

radial error could modulate this roughness texture.

These two error factors would combine and

contribute localized geometric modulations to the

shape of the surface as the contour is machined. As

with any large mechanically driven periodic system

at low-rpm operation, the axial and radial data

exhibit considerable inertial imbalance and potential

low frequency resonances in the tool. These

instabilities are damped at much higher rotational

rates, producing a relatively smooth cutting

operation. The machining of precision mirrors,

lenses, and flats requires careful consideration of

multiple factors, and evaluation of tool performance

at various speeds to determine the most suitable

operational parameters for the highest quality optical

products.

This complement of measurements and analysis

has additional applications: it can be utilized for

evaluating and optimising spindle and stage design,

implementing motion stability, damping resonances,

streamlining bearings, improving vibration isolation,

and reducing thermal gradients – all important

factors in the design and manufacture of nanometre

precision machine tools. It can also be utilized to

determine the optimal operating points for spindle

rotation, bearing fluid pressure, cutting tool depth

and feed, coolant flow, temperature, and machine

tool stability, and thus shorten the decision making

process leading to nanometre surface and shape

quality with high yield.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

32

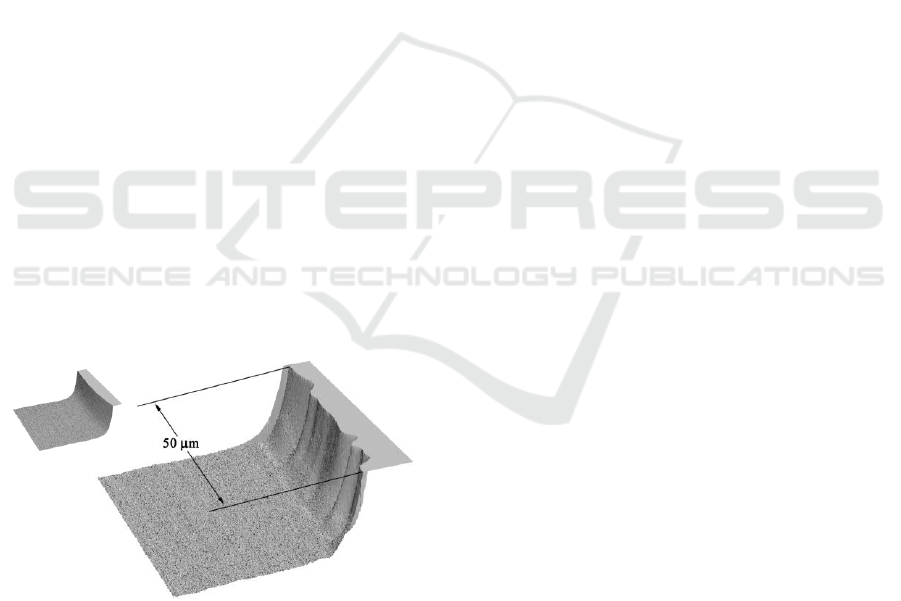

2.3.5 Diamond Cutting Tool Edge Profile

The next measurement in our evaluation sequence is

the cutting tool profile, and the progression of wear

during the machining operation. We focus

particularly on precision single-point diamond

turning (SPDT), utilizing commercially available

diamond cutting tools, for the fabrication of

precision mirrors and optics. These tools are

specified in terms of their contour (nose) radius,

cutting point transverse edge radius, edge roughness,

edge roundness, edge straightness, cutter angle, and

rake angle. The primary measurement of interest in

SPDT is the edge contour, as related to the nose

radius, since edge wear is directly correlated to

finished surface quality. Among various tool

parameters, contour wear is a good figure of merit,

and is directly dependent on usage duration, cutting

depth, spindle and stage error motions, thermal

gradients originating in frictional forces in the

cutting process, machining parameters such as

rotational speed and feed rate, surface material

properties, and the quality of the diamond crystal.

Edge contours on diamond tools were examined, one

freshly manufactured and another measured after its

utilization to form multiple lenses. The two tools

had zero rake angles, edge radius on the order of < 2

µm, 60-degree cutter angle, and contour radius of

0.2 mm. These diamond tools are fabricated by

polishing with progressively finer diamond particles

in controlled processes. They may contain intrinsic

crystalline defects and sub-surface damage induced

during fabrication.

Figure 12: Contour of a used diamond tool showing wear

grooves across the edge. The inset is a fresh tool.

The fresh tool was measured at the cutting point,

and the data shown in Figure 12 (inset) indicates

pristine edge quality, and smooth rake. The local

radius conforms to the manufacturer specification of

0.2 mm with minimal edge roughness and no visible

edge defects. The edge straightness also appears to

be uniform, without any manufacturing artefacts

such as polishing striations across the edge. The

tool utilized in manufacturing optical lenses has

multiple features of interest, resulting from wear,

including a modulated edge-contour profile

descending into deep furrows which span from the

rake face downwards, into the base. The regions of

modulation, have dimensions of a few to 10 µm,

superimposed on the original edge. The multi-µm

waviness of the edge contour indicates that spindle

error motion (which is of equivalent multi-µm

oscillation) is a major contributing factor in this

degradation. In SPDT, the error motion induces

equivalent periodic high impact forces on the cutting

tool edge within its microscopic area of contact with

the surface, typically on the order of 2-µm (width) x

10-µm (cutting arc) or less (Figure 6, inset). These

error-noise forces in combination with frictional

forces, acoustic shock, and thermal gradients during

machining perturb and damage the cutting tool edge

at its points of weakness: defect sites, its polish

roughness structure, and its subsurface damage. The

wear regions along the contour appear to have

become progressively deeper with usage, rendering

the cutting edge unusable. This cutting tool will

inevitably leave these imprints on the machined

surface, resulting in a poor quality product with

noticeable optical imperfections and local shape

irregularities. In combination with all of the

measurements and discussion in Section 2.3.4 the

overall quality of a machined surface utilizing this

cutting tool, at low rpm, would not result in optical

quality surfaces and shapes.

2.3.6 Surface, Defect, and Thin Film Data

Optical scatter is routinely utilized to examine

smooth surfaces and to identify defects in the optics

and the semiconductor industries, including thin

films, and multi-layer and photoresist-patterned

substrates. The geometrical arrangement to perform

these functions is shown in Figure 1. A detector is

positioned to the surface, oriented to capture scatter

radiation in a solid angle, defined by the angle of

incidence and the polarization of the input beam.

Since non-specular scatter is typically of low

intensity for smooth surfaces, the detector is coupled

to low noise, high gain electronics, and may also

include capability to select a particular polarization

to enhance feature-to-background sensitivity. The

nanometre scanning stage combined with software

processing can produce contrast-enhanced images of

surface structure and roughness, defects, and sub-

surface damage. Figure 13 shows the scatter image

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces

33

of a diamond-turned Si surface in a 50m x 50m

field. In the machining process, the spindle operated

at 1000 rpm, and a 1.5-mm diamond tool was

advanced in 3-µm steps/rev, with 1.3-µm removal,

and impressed corresponding indentations on the Si

surface in a regular pattern; the total surface area of

the Si-wafer section was 1 cm

2

and the tool edge

profile was unknown. The surface is linear along

the y-axis but has large irregular shape inaccuracy,

on the order of 10 - 25 µm, along the x-axis,

perpendicular to the grating, equivalent to and

perhaps caused by error motion as the cutting tool

traverses the surface (See discussion in Section

2.3.4). This data indicates that if a large optic or

mirror was manufactured utilizing this machine and

cutting tool combination, µm-scale surface and

shape irregulaties would undoubtedly occur in the

finished product. In general, to quantify similar

surface errors, the cutting tool and a sensor could be

mounted on identical arcuate positions on the holder

(Figure 6). It would then be possible to first cut the

surface, and then measure its contour to determine

its accuracy within limits of the error noise of the

machine tool.

Figure 13: 50m x 50m scatter image of diamond-turned

Si showing local cutting tool indentations and overall

shape error.

Perfectly smooth planar polished surfaces were

also measured but displayed no interesting features

related to microstructure and defects, beyond a

simple flat field in the data indicating that the entire

scatter profile was confined to the specular region

with minimal Lambertian haze and no detectable

offset scatter components. This data was verified by

AFM measurements and analysis in the identical

vicinity of the surface.

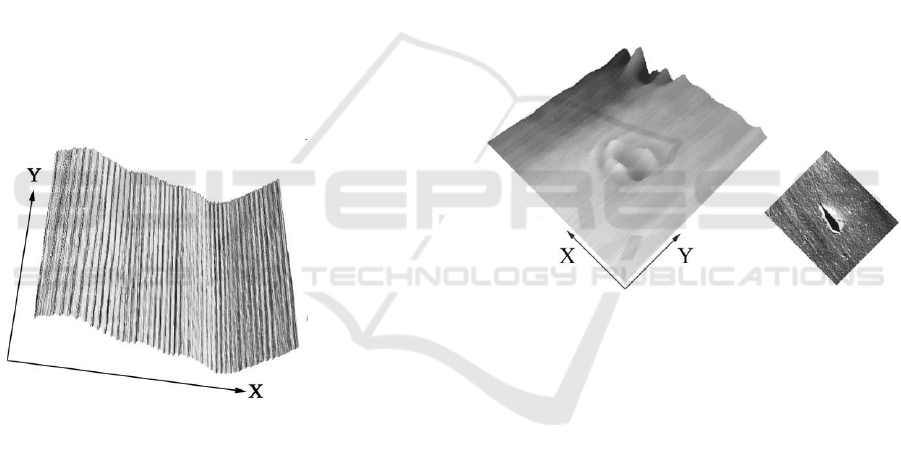

We progress to examining the scatter features of

a defect. A commercially available polished quartz

blank was scanned with the same parametric

settings, and the data is shown in Figure 14. The

data contains several observable features: low

frequency wave-like roughness oriented

perpendicular to the x-axis of spatial period about 10

µm in the foreground. Towards the rear of the

sample the structure appears to be two-dimensional,

oriented randomly along both axes of 5-10 µm

dimensions, and includes peripheral geometry of a

second defect in the far corner. The defect pit

(identified in the semiconductor industry as a crystal

originated pit or COP; see inset for AFM image) in

the centre is approximately 15 µm in diameter, and

produces scatter, which indicates the presence of

some shallow vertical projections in the range of a

few micrometers forming concentric rings. The

inner ring has wavelike rim structure, while the

surrounding ring appears somewhat regular and

shallow. The defect also appears to have an internal

bridge, spanning the pit bisecting it parallel to the y-

axis.

Figure 14: Defect on quartz surface (50m x 50m)(L).

The surface structure appears to be composed of wave like

patterns with particular orientation. AFM image of a

similar defect and surface structure on the same sample is

shown (R).

In a final measurement, a composite 200-nm (50-

nm Cr and 150-nm Au), 75 µm x 75 µm thin film

pad, deposited by e-beam evaporation on a Si wafer,

was imaged to examine the scatter produced by the

structure of the film, the edges, and the corner. The

data is shown in Figure 15 and reveals

compositional information about the film, in greater

detail than could be observable by diffraction-

limited high-resolution optical microscopy. The

200-nm total film thickness is identifiable, as

indicated on the data, despite scaling to

approximately only 25% of the wavelength of

optical beam, and indicating very good depth

sensitivity of the scatterometer-triangulation

technique. The darker base region of the film is very

likely low-reflectivity Cr material, while the brighter

scatter data in the upper region is associated with

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

34

highly reflective Au. The surface of the film

appears to have randomly oriented two-dimensional

fine grain structure in the spatial frequency range of

a few micrometers laterally but extending only a few

10’s of nanometres in roughness vertically,

remarkably just under 3% in dimensional

comparison with the sensing wavelength. These

appear to be islands of molecular nucleation forming

crystallite fractals of the Au material, generated

progressively as the film is deposited. Some of this

structure may also include the underlying structure

of the Cr film.

Figure 15: 200-nm Cr-Au film on Si. The film thickness is

as shown, and the surface of the film appears to indicate

structure formed by nucleation.

There is a uniform ridge along the upper

peripheral edges of the film, related to the

photoresist-mask pattern utilized in the lithographic

lift-off fabrication process. Similar dielectric and

metal thin films are routinely deposited on optics

(anti-reflection coatings) and semiconductor wafers

(device connections and contacts), whose structure

and function could be examined by this technique.

3 CONCLUSIONS

Laser triangulation combined with detection by a

sub-nanometre resolution sensor is presented as a

versatile, contact-free, non-invasive method to

monitor and evaluate ultra-precision machine tool

operation, and to examine the surface and shape

quality of µm-size to meter-size optical and

semiconductor products to accuracy of less than 200

nm, and potentially approaching 10 nm. The

thermal stability, axial torque displacement, spindle

“growth”, tool holder stage error and hysteresis, and

the axial and radial error motion of a precision

machine tool spindle were resolved with this

apparatus in the range of < 100 nm to several m. A

diamond cutting tool edge had 10-µm wear patterns,

which developed after multiple usage cycles,

originating in spindle error motion. An SPDT Si

surface was shown to have indented lines equivalent

to the machining settings, with large overall 10 - 25

µm shape variations. This set of measurements and

analysis could be utilized to design nanometre

precision machine tools, optimise critical

components like the spindle and the bearing,

facilitate vibration isolation, and select operating

parameters to fabricate products with high quality

and large yield. Textured surface structure with

defects and internal defect structure were identified

on a quartz optical flat. Finally, a thin Cr-Au film

was examined, and the 200-nm thickness of the film

is easily identifiable together with approximately 20-

nm fractal nucleation structure on the surface of the

film. We have demonstrated the versatility,

adaptability, and reliability of this technology for

use in the manufacture of optical, semiconductor,

and other industrial products manufactured from a

multitude of materials, regardless of size.

ACKNOWLEDGEMENTS

Financial and/or technical assistance for this work

was provided from several sources at various times,

including the US Naval Research Laboratory,

California Institute of Technology, US Air Force,

NASA – Jet Propulsion Laboratory, the Livermore

Laboratory, the National Research Council, and E.F.

and B.F. Soãres.

REFERENCES

Azzam, R., and Bashara, N., 1999. Ellipsometry and

Polarized Light, Elsevier.

Heavens, O., 1955. Optical Properties of Thin Solid Films,

Dover.

Church, E., Jenkinson, H., and Zavada, J., 1979.

Relationship between Surface Scattering and

Microtopographic Features, Optical Engineering 18

(2).

Longuet-Higgins, M., 1957. Statistical Properties of an

Isotropic Random Surface, Phil. Trans. A, 250.

Stover, J., 1995. Optical Scattering, SPIE Optical

Engineering Press. Washington, 2

nd

edition.

Bohren, C., and Huffman, D., 1998. Absorption and

Scattering of Light by Small Particles, John Wiley.

Sze, S., 1981. Physics of Semiconductor Devices, John

Wiley, 2

nd

edition.

Horowitz, P., and Hill, W., 1989. The Art of Electronics,

Cambridge University Press, 2

nd

edition.

Nanoscale Non-Contact Laser Measurement of Precision Machine Tooling and Optical Surfaces

35