Fully Automatic Faulty Weft Thread Detection using a Camera System

and Feature-based Pattern Recognition

Marcin Kopaczka

1

, Marco Saggiomo

2

, Moritz Güttler

1

, Thomas Gries

2

and Dorit Merhof

1

1

Institute of Imaging and Computer Vision, RWTH Aachen University, Aachen, Germany

2

Institut für Textiltechnik, RWTH Aachen University, Aachen, Germany

Keywords:

Automated Visual Inspection, Industrial Image Processing, Air-jet Weaving Machine.

Abstract:

In this paper, we present a novel approach for the fully automated detection of faulty weft threads on air-

jet weaving machines using computer vision. The proposed system consists of a camera array for image

acquisition and a classification pipeline in which we use different image processing and machine learning

methods to allow precise localization and reliable classification of defects. The camera system is introduced

and its advantages over other approaches are discussed. Subsequently, the processing steps are motivated

and described in detail, followed by an in-depth analysis of the impact of different system parameters to

allow chosing optimal algorithm combinations for the problem of faulty weft yarn detection. To analyze the

capabilities of our solution, system performance is thoroughly evaluated under realistic production settings,

showing excellent detection rates.

1 INTRODUCTION

Automated weaving is a key technology in modern in-

dustrial textile production. In weaving, a number of

parallel yarns (the so-called warp yarns) oriented and

tensioned in production direction is displaced verti-

cally by a mechanical frame. The most basic weav-

ing pattern, the plain weave, is formed by moving ev-

ery second warp yarn upwards while displacing the

other yarns downwards. The space between the dif-

ferently displaced warp yarns is the shed. The weav-

ing itself is the process of inserting a further yarn

thread, the weft yarn, into the shed perpendicular to

the warp yarns. After weft yarn insertion the positions

of top and bottom yarns are switched and the next

weft yarn is inserted. Among weaving machines, air-

jet weaving machines are widely used due to their su-

perior productivity of up to 1500 insertions per minute

and their high reliability. In air-jet weaving, the weft

yarn is inserted using compressed air. Additional air

ducts maintain a defined air flow along the whole shed

width, allowing the weft yarn to quickly move be-

tween the warp yarns. However, in some cases the

weft yarn may not reach its destination as it collides

with a warp yarn or its trajectory is altered by other

causes. In these cases, the weft yarn remains in the

shed and needs to be removed before weaving can

continue. Weaving faulty weft threads into the textile

would result in defects that affect the optical appear-

ance and mechanical properties of the fabric. To avoid

this problem, air-jet weaving machines are equipped

with a sensor that detects whether the weft yarn has

been inserted correctly into the shed. More precisely,

weft yarn defects are detected with photoelectric or

laser-based weft sensors such as (Wada, 1984) that

detect whether the weft yarn arrived correctly at the

receiving end of the machine. While currently ma-

chine or yarn status are not monitored using computer

vision systems, a large number of publications with

focus on inspection of the produced textile itself have

been published. The reasons behind fabric inspection

being such an active research area are two-fold: First,

textile inspection is currently often a manual proce-

dure performed by human workers, making it an ex-

pensive and time-consuming task. At the same time,

trials have shown that human performance in textile

inspection degrades quickly and that humans find no

more than 60% of defects in textile fabric (Karayian-

nis et al., 1999). This emphasizes the need for au-

tomated approaches that could help increasing defect

detection rates and decrease quality control expenses.

The second reason is that textile inspection is a prob-

lem that allows for a wide variety of approaches from

different computer vision disciplines. Therefore, a

broad range of algorithms has been developed and

adapted to allow localizing and identifying defects

124

Kopaczka, M., Saggiomo, M., Güttler, M., Gries, T. and Merhof, D.

Fully Automatic Faulty Weft Thread Detection using a Camera System and Feature-based Pattern Recognition.

DOI: 10.5220/0006591301240132

In Proceedings of the 7th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2018), pages 124-132

ISBN: 978-989-758-276-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

in textiles. Notable reviews include (Kumar, 2008),

where also a taxonomy of fabric inspection methods is

introduced, furthermore in (Ngan et al., 2011), where

the authors extend the range of algorithms to include

methods that allow defect detection in patterned fab-

rics, and most recently in the work by (Hanbay et al.,

2016), which also puts emphasis on the image acqui-

sition and imaging hardware. While the devices used

for weft yarn monitoring such as the laser sensors de-

scribed above can be defined as optical sensors, their

output signal is purely scalar and allows for no im-

age processing at all. If a faulty weft yarn is detected,

then textile production is stopped and an automated

weft yarn removal procedure is initiated. However,

while the error detection itself is highly reliable, the

faulty yarn removal succeeds only in 80% of the cases

where a defect is detected, making the system not ap-

plicable for industrial textile production.

To increase system reliability, we therefore intro-

duce a camera-based inspection system that allows to

check if a faulty weft yarn is present in the shed after a

weft yarn defect has been detected. A combination of

specialized imaging hardware and an image process-

ing pipeline developed especially for this task is pre-

sented. We analyze the effect of using different meth-

ods for image preprocessung that allow enhancing the

visual appearance of faulty weft threads in combi-

nation with image descriptors sensitive to structures

which can be found in our image data. The system

is described in detail and its performance on a real

industrial weaving machine is evaluated throughly,

allowing to define the optimal pipeline to solve the

problem of faulty weft yarn detection. To the best

of our knowledge, our approach is the first to allow

highly reliable weft yarn defect detection using com-

puter vision.

2 PREVIOUS WORK

A specific subgroup of approaches related closely to

our research area are systems for online (or, in this

specific context, onloom) analysis of woven fabrics

using a camera system attached directly to the loom.

An early approach has been presented by (Sari-Sarraf

and Goddard, 1999), where yarn density is measured

on the loom by applying Fourier transform to im-

ages acquired by a camera attached to the machine.

In (Stojanovic et al., 2001), the authors introduce a

system for onloom defect detection in woven fab-

rics that is tested on a loom mockup. The algo-

rithms use texture analysis to detect defects such as

holes in the textile. The currently most advanced sys-

tem has been introduced in (Schneider et al., 2014),

camerasystem

shed

reed

mounting structure

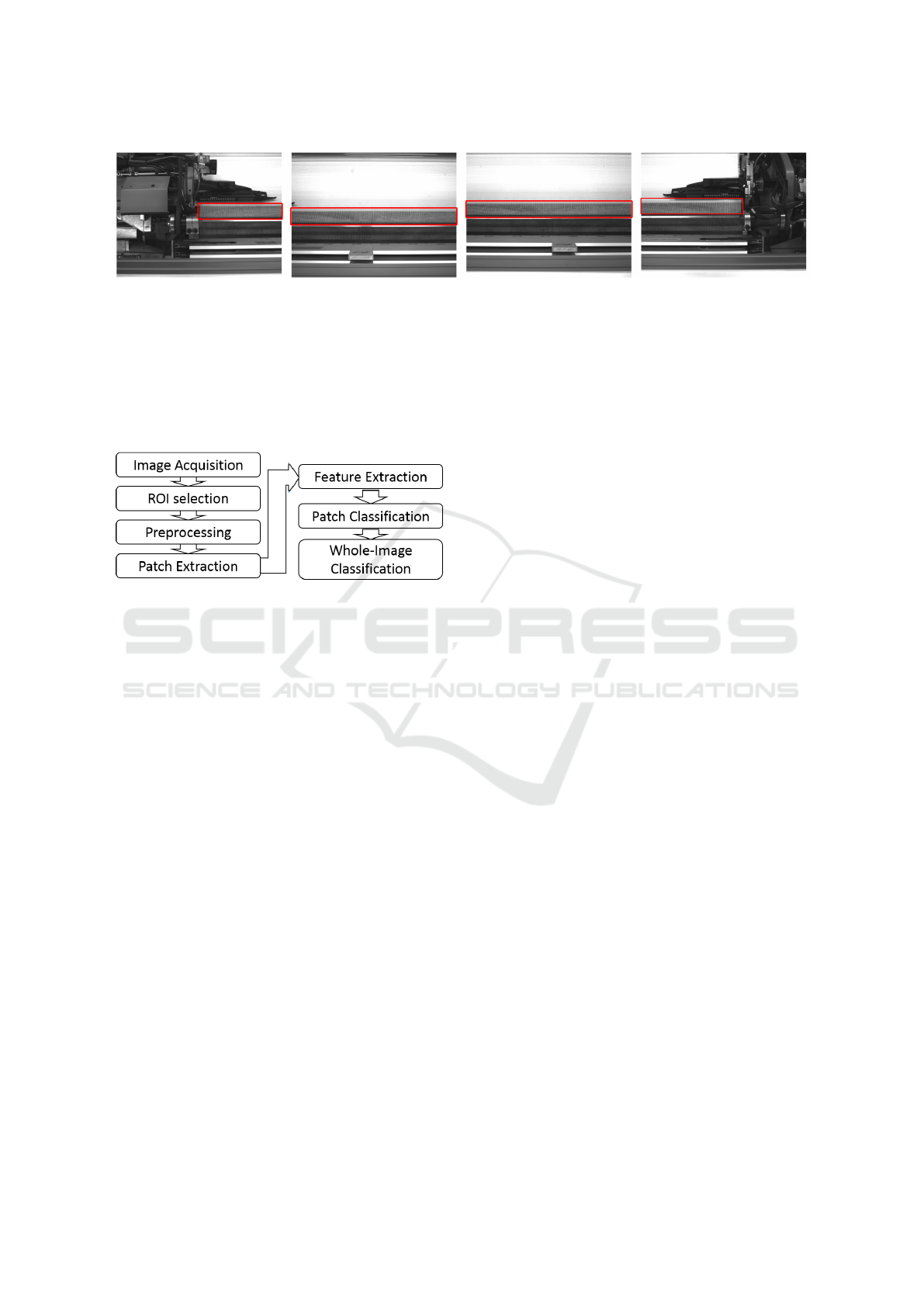

Figure 1: The visual inspection system mounted to an auto-

matic weaving machine.

where a vibration-stabilized high resolution camera

traverses along the loom and allows capturing images

with a spatial resolution of 1000 dpi. Real-time GPU-

enhanced image processing algorithms allow the pre-

cise localization of single yarns in the produced fabric

and thereby the detection of various types of challeng-

ing defects.

In contrast to previously published methods, our

method does not analyze the produced fabric, but in-

stead it focuses on the detection of faulty weft yarns

in the shed, allowing the operator to react and correct

the machine state before any defective fabric is pro-

duced. This approach is highly innovative as it allows

to increase product quality by avoiding defects caused

by weaving defective yarns into the product.

3 MATERIALS AND METHODS

This section gives detailed information on the devel-

oped methods. We start with a description of the

image acquisition setup and basic data preprocess-

ing steps, followed by our processing pipeline for im-

age enhancement, feature extraction and classifica-

tion. Finally, we describe the decision rule used to

compute the confidence if an alert should be raised or

not.

3.1 Overview

Fig. 3 shows an overview of our pipeline. Images

are acquired using a multi-camera array and subse-

quently processed in order to allow feature extraction

Fully Automatic Faulty Weft Thread Detection using a Camera System and Feature-based Pattern Recognition

125

Figure 2: Top view of the shed as captured by the four cameras. The used ROIs are outlined in red (high-resolution images,

best viewed in color on a computer display).

and classification of small image patches. Based on

the patch-based classification, a final per-image clas-

sification is implemented to automatically decide if

an image contains a faulty weft yarn. The following

subsections provide a more detailed description of the

implemented steps.

Figure 3: Overview of the implemented pipeline.

3.2 Camera Setup and Image

Preparation

Image acquisition was performed using an array of

four industrial cameras. The cameras were spaced

equidistantly in a sensor bar above the shed with the

cameras facing downward, allowing a clear view at

the shed’s contents at a resolution of 200 dots per inch

(dpi). Implementing an array of several cameras in-

stead of a single fixed or moving camera yields sev-

eral benefits:

• The system can be modified easily to fit different

machine widths by varying the number of cameras

used.

• Using several cameras allows to better match the

monitored area to the strongly elongated shape of

the shed.

• The cameras forming the array may have low res-

olutions whild still providing a high resolution

composite, allowing working without specialized

high-resolution cameras

• While the same benefits could have been gained

by using a single moving camera as in (Schnei-

der et al., 2014), constructing a traversing system

poses additional challenges such as camera posi-

tion retrieval and potentially motion blur that can

be avoided by using an array of cameras mounted

in fixed positions.

Since the area captured by the cameras was still larger

than the shed itself, fixed regions of interest (ROI)

were defined for each of the cameras in which all re-

gions except the shed were masked out. All image

analysis was performed on the ROIs only, ignoring

the non-shed parts of the image. Figure 2 shows full

images and the respective ROIs used for further pro-

cessing.

3.3 Preprocessing

With the images ready for further analysis, several

preprocessing steps aimed at enhancing defect ap-

pearance have been implemented. Since the domi-

nant structure in defect-free images is the repeating,

vertical pattern formed by the weft yarns and defects

break this regularity by introducing non-vertical com-

ponents, our implemented preprocessing steps aim at

increasing the contrast between defect and non-defect

areas by enhancing defect appearance. To this end,

we take advantage of the direction difference and use

orientation-sensitive preprocessing methods. A sam-

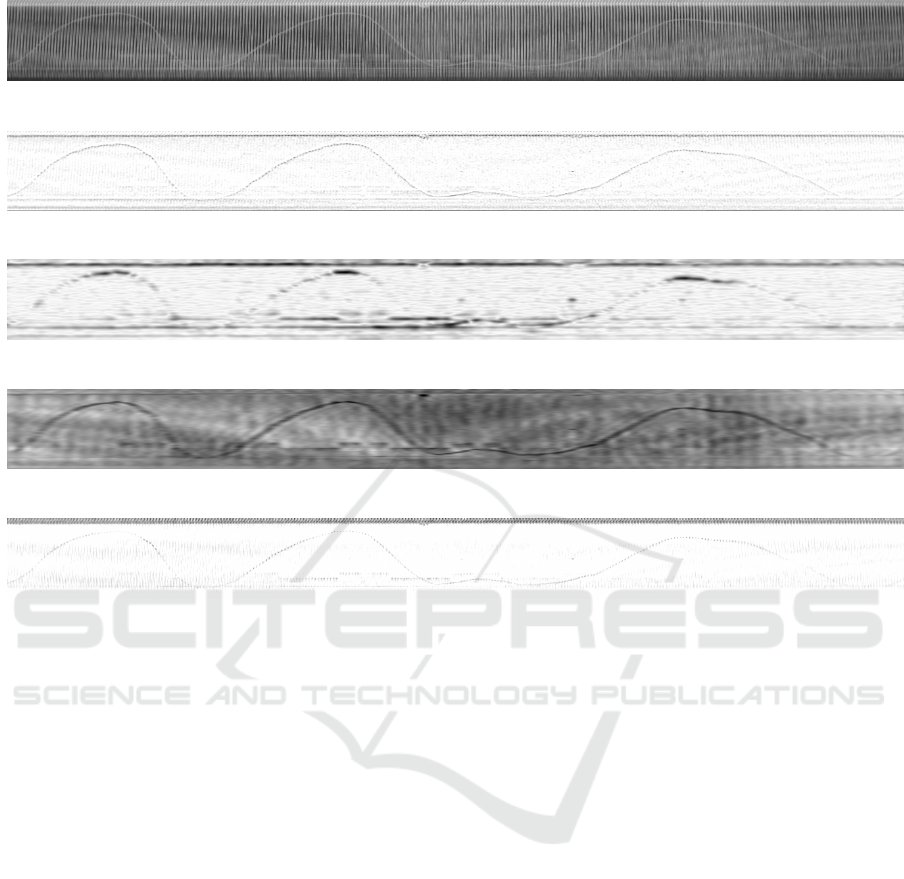

ple image and filter results are shown in Fig. 4. The

filters include:

• Basic edge and contour detectors, namely the

Sobel and Prewitt gradient operators. Computa-

tionally efficient, these basic filter kernels allow a

good enhancement of horizontal structures when

applied in their horizontal form. Since they are

known to be sensitive to noise and grain in the im-

age data, we also analyzed the impact of adding an

additional Gaussian smoothing filter before com-

puting the gradients. A sample result is shown in

Fig. 4b.

• Gabor Filters, a group of algorithmically de-

fined filter kernels that allow enhancing image

structures with a defined orientation and length

(Bovik et al., 1990). In contrast to the basic Sobel

and Prewitt filters, Gabor filters allow more fine-

grained control over the type of structure to be

enhanced thanks to their multiparametric nature.

ICPRAM 2018 - 7th International Conference on Pattern Recognition Applications and Methods

126

(a) Unprocessed original image

(b) Sobel filter after Gaussian smoothing

(c) Gabor filtering

(d) Directional lowpass using two-dimensional discrete Fourier transform (DFT)

(e) Directional unsharp masking by subtracting DFT result from original image

Figure 4: Visual appearance of the different preprocessing methods applied to the images in order to enhance defect visibility.

Preprocessing results are shown with inverted gray values to increase contrast for the reader.

While commonly used in groups as filter banks

for texture and image classification, in our pre-

processing implementation we use only horizon-

tal Gabor filters with a constant length to enhance

horizontal structures in the images as shown in

Fig. 4c.

• Spectral lowpass filters based on Discrete

Fourier Transform (DFT) that allow controlling

filter characteristics in a very fine-grained man-

ner. In our case, the filter is applied by comput-

ing the DFT of the image, centering the resulting

spectrum and multiplying it with a binary mask

designed to eliminate vertical structures in the im-

age while at the same time enhancing horizontal

patterns. The filtered image is the result of apply-

ing inverse DFT to the lowpass-filtered spectrum

(Fig. 4d). This approach can be extended to a

directional lowpass mask by subtracting the low-

pass result from the original image. In our case,

this solution eliminates the regular pattern formed

by the warp yarns and thereby allows further en-

hancement of the relevant weft yarns (Fig. 4e).

3.4 Feature Extraction and Image

Classification

Classification is performed by dividing the prepro-

cessed images into small patches, applying a feature

extraction method and feeding the resulting feature

vectors into a machine learning-based classifier. All

feature extractors and classifiers used in this work will

be described in this section. Since the classifiers ap-

plied are supervised learning methods, a method for

labeling each of the patches differently depending on

whether or not they show defective warp threads has

been developed as well. This section gives a detailed

overview of all steps involved in the classification

chain.

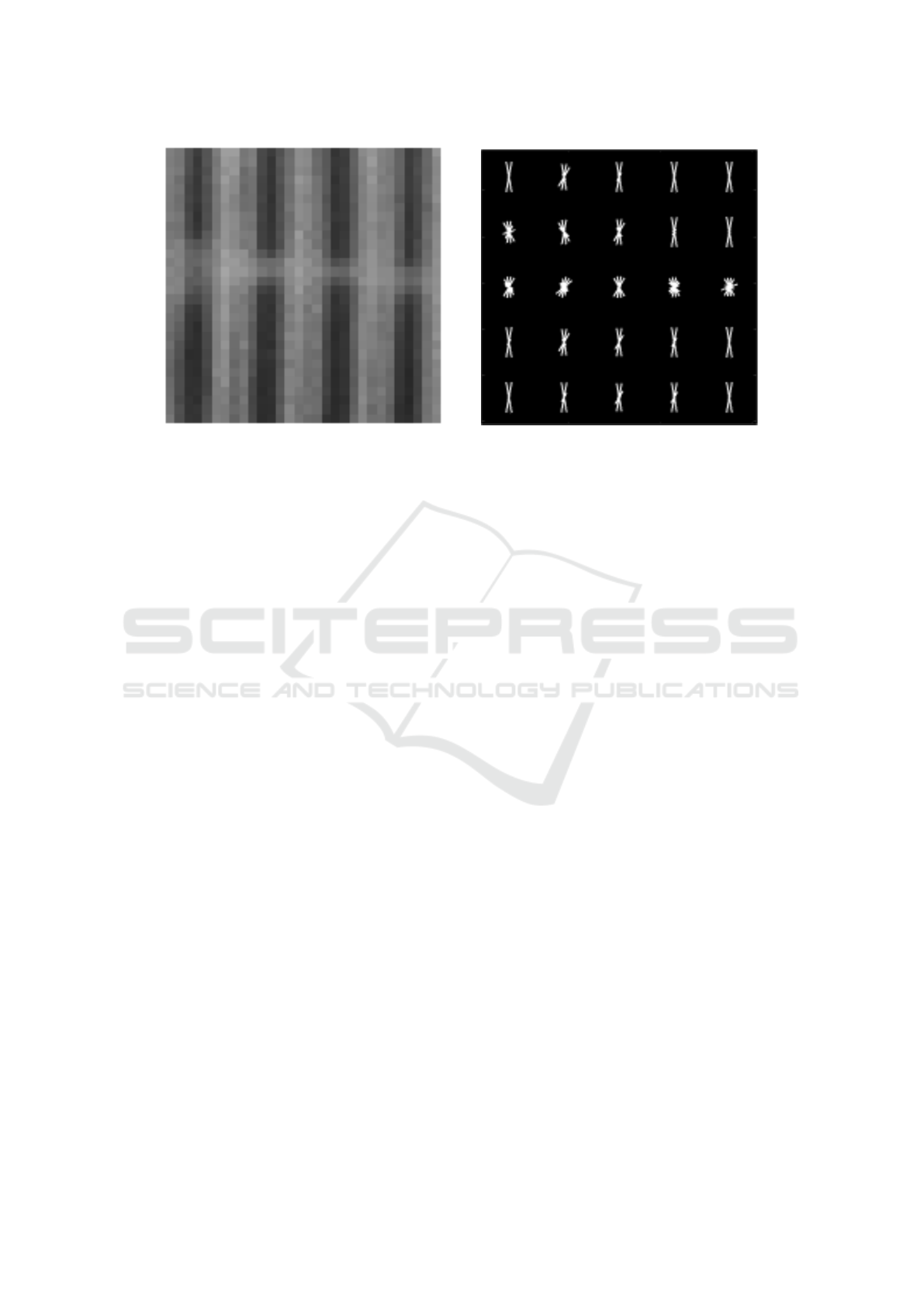

First, we extract small non-overlapping patches sized

30 × 30 pixels from the ROIs. Working on patches

instead of whole images yields several advantages:

First, we drastically increase the amount of training

data for the classifiers while at the same time reduc-

ing feature vector length, both being important factors

for successful training of classifiers with greater reli-

ability and faster classification speed. Furthermore,

Fully Automatic Faulty Weft Thread Detection using a Camera System and Feature-based Pattern Recognition

127

(a) Patch (b) HOG Visualization

Figure 5: Feature extraction is done on patches with 30 × 30 pixels

a classification based on small image fragments al-

lows a precise localization of defect warp yarns,

thereby allowing analysis of defect positions for fur-

ther processing. After patches have been extracted,

we assign a label to each patch depending on the

amount of defective thread visible in the center area of

the patch. Preliminary experiments were conducted

and we found that declaring a patch defective if it con-

tains at least 50 defective pixels is a well-performing

labeling rule.

After patches have been extracted and labeled,

feature extraction is applied to allow better descrip-

tions of the image data. We used three feature de-

scriptors that either have been proven to perform well

in textile image analysis tasks or have properties that

allow enhancing visual structures that are occur in our

data:

• The pixel intensity values themselves. Feeding

the image directly into the classifier requires no

additional computing time for feature extraction

and allows to analyze absolute intensities and lo-

cal structures (Fig. 5a), however the classifier can-

not benefit from gradient and neighborhood infor-

mation that extractors provide.

• Histograms of Oriented Gradients (HOG), a

descriptor that allows to extract local gradient in-

formation at the cost of discarding the intensity

data (Dalal and Triggs, 2005). As Fig. 5b shows,

a well-parametrized HOG operator allows to cre-

ate feature vectors that discriminate well between

defect and non-defect patches. An analysis of the

performance of different HOG variants is given in

Sec. 4.

• Local Binary Patterns (LBPs), another well un-

derstood method that extracts statistical neigh-

borhood information to form a texture descrip-

tor (Ojala et al., 2002). In our work, we use the

homogeneous LBPs, as they have shown better

performance than their rotation-sensitive counter-

parts (See Sec. 4).

The extracted feature vectors were subsequently

fed into a binary classifier to compute label predic-

tions for each patch. We tested the performance

of several widely used state-of-the art classifiers, in-

cluding the k-nearest-neighbors classifier (kNN), bi-

nary decision trees (BDT) and random forests (RF)

(Breiman, 2001). The key parameters of the classi-

fiers were varied systematically to determine optimal

values for our problem (Sec. 4). The final decision

whether a defect is visible in the image is computed

using a maximum a posteriori (MAP) approach as de-

scribed in (Bishop, 2006). MAP computes class prob-

abilities by multiplying a likelihood with a prior, with

the likelihood being the observation (in our case the

percentage of patches in an image reported as defec-

tive) and the prior the known base probability of an

image displaying a defect, i

˙

e

˙

the ratio of defect vs

˙

non-

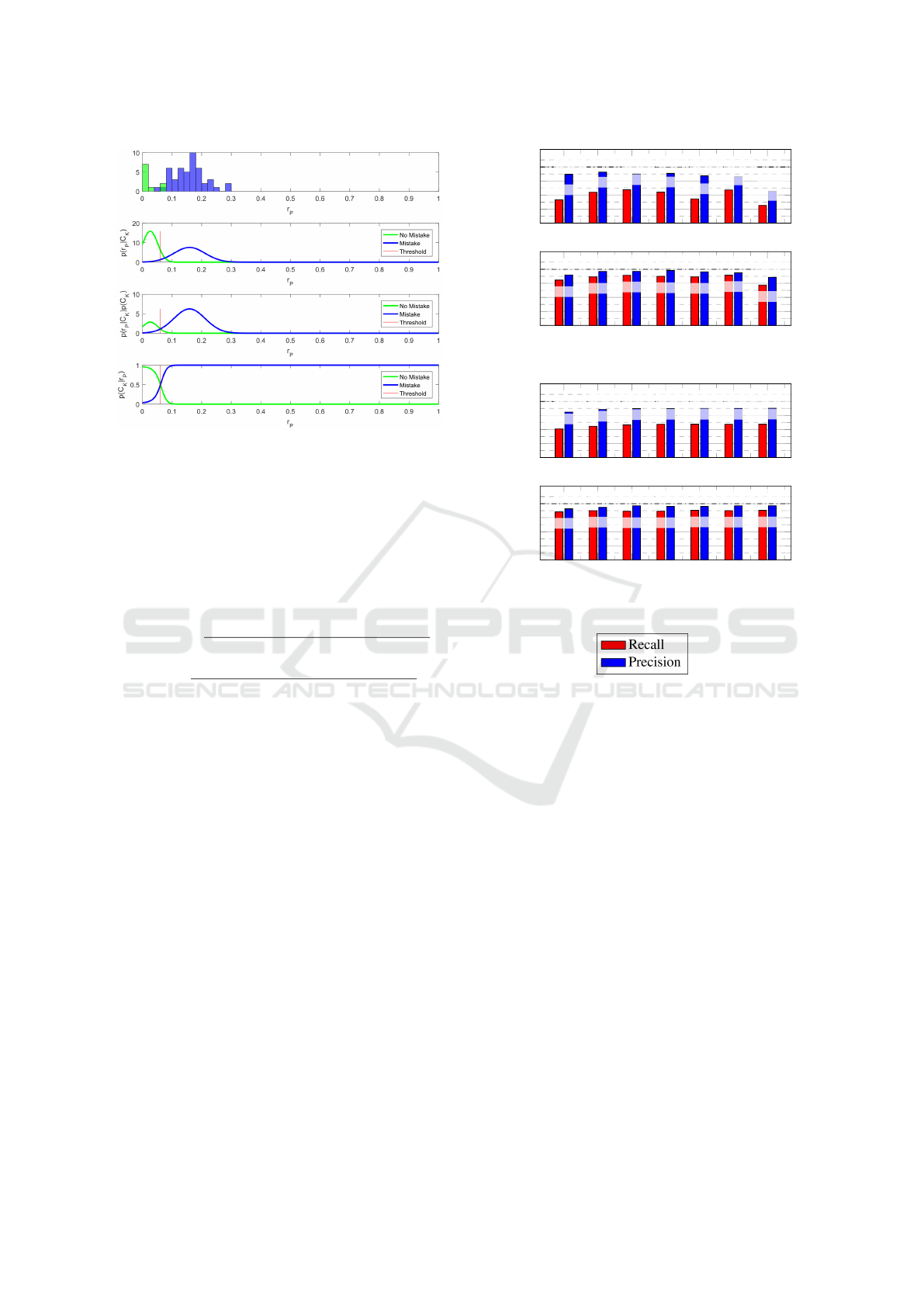

defect images. Fig. 6 shows the process in more de-

tail.

4 EXPERIMENTS AND RESULTS

The conducted experiments served two major goals:

Evaluation and optimization of the classifier perfor-

mance and validation of the developed algorithms on

realistic data. To this end, the system was mounted

on a modern industrial automatic weaving machine

(Dornier A1) and 75 sets of four images each were

acquired, with 60 sets showing a faulty warp thread

ICPRAM 2018 - 7th International Conference on Pattern Recognition Applications and Methods

128

Figure 6: MAP procedure. Top row: The percentage of

patches classified as defective is noted in a histogram. 2nd

row: Gaussian distributions are fitted to the data. 3rd row:

Both distributions are multiplied with a-priori knowledge

about the class distributions. Bottom row: The normalized

class probabilities. The decision boundary is located at the

intersection of the probabilities.

and the other 15 being defect-free. Key performance

indicators used to assess algorithm performance were

precision and recall, defined as

precision =

number of correctly detected defects

total number of detections

recall =

number of correctly detected defects

total number of defects

.

Since the classification pipeline consists of two steps

- patch-wise classification and image classification -

the performance of each step has been evaluated inde-

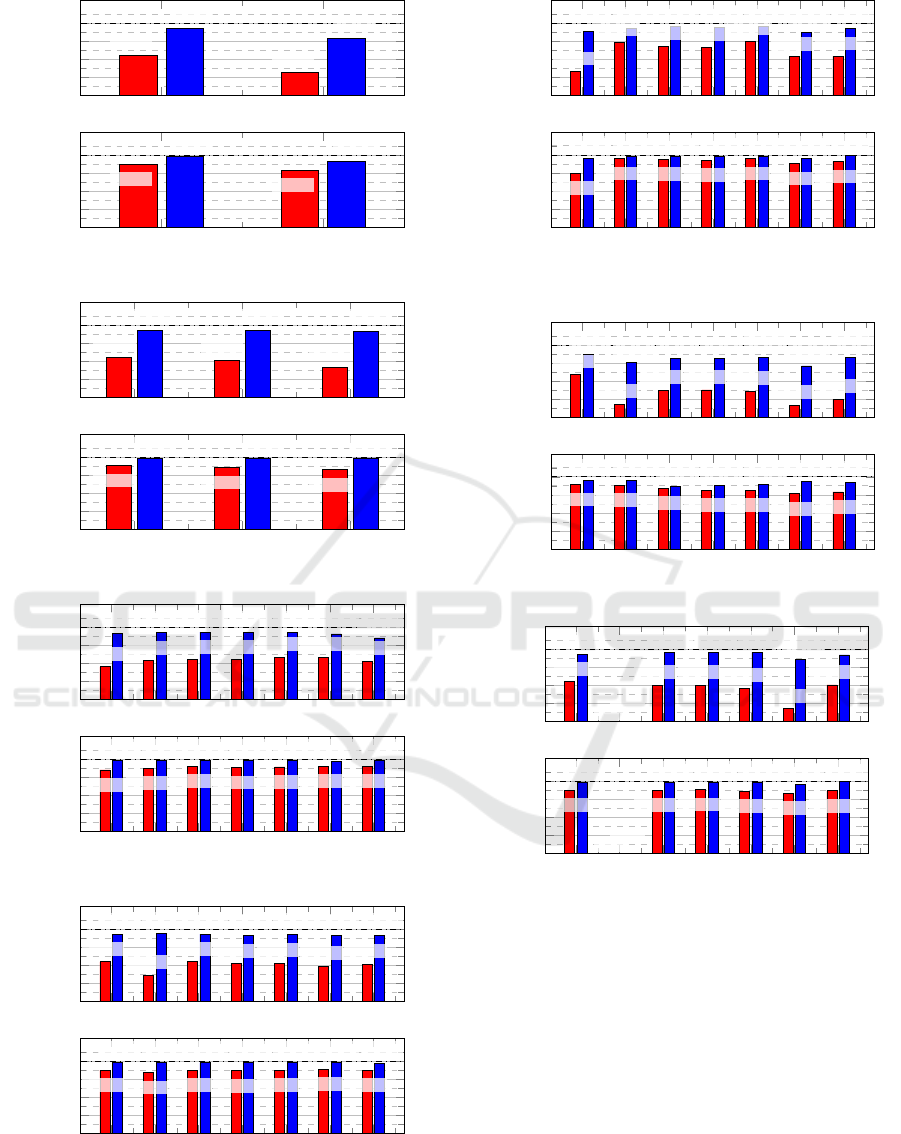

pendently. The following figures each show two bar

charts. The upper one presents the patch-wise classifi-

cation performance, the lower one presents the image

classification performance (Fig. 9). In a first trial we

evaluated the impact of descriptor type and parame-

ters on the classification result. All tests were per-

formed using the same classifier, namely a random

forest classifier with 30 trees, as this algorithm has

shown good overall performance and robustness to-

wards descriptor variations in preliminary tests. No

additional preprocessing was applied for these trials.

First, the HOG descriptor was evaluated, where cell

size and histogram bin count at a constant block size

of 1 × 1 have been analyzed. First, cell size has been

varied in a range from 3 × 3 to 30 × 30 pixels. As

shown in Fig. 7, classifier performance remains sta-

ble over a wide range of settings with only very small

and very large cell sizes having a negative impact on

the result. The impact of the histogram’s bin count

at a constant cell size of 6 × 6 pixels is shown in

Fig. 8. Again, the descriptor shows stable rates, yet

3 5 6

7

8 10 30

20%

40%

60%

80%

100%

53.1%

89.5%

63.9%

92.6%

67.5%

89.9%

64.2%

90.9%

54.6%

87.4%

67.2%

86.4%

45.2%

65.7%

3 5 6

7

8 10 30

20%

40%

60%

80%

100%

84.6%

91.9%

89.2%

96.8%

91.3%

96.9%

90.0%

98.2%

89.2%

96.4%

91.7%

94.8%

77.5%

88.6%

Figure 7: HOG: Quadratic cell size variation for 7 bins.

3 4 5 6

7

8 9

20%

40%

60%

80%

100%

60.7%

84.7%

64.5%

88.4%

66.6%

89.6%

67.3%

89.6%

67.4%

89.9%

67.3%

90.0%

67.6%

90.1%

3 4 5 6

7

8 9

20%

40%

60%

80%

100%

88.3%

92.6%

90.0%

94.7%

89.2%

96.8%

89.2%

96.0%

90.4%

96.0%

90.0%

96.9%

90.4%

96.9%

Figure 8: HOG: Histogram bin count variation for 6 × 6

cells.

Figure 9: Legend for bar charts. The upper charts of the fig-

ures present the patch-wise classification performance. The

lower charts present the image classification performance.

the rates increase slightly with increasing bin count.

For LBPs, we analyzed the impact of using rotation-

invariant versus conventional LBPs and the effect of

varying the number of neighbors as well as changing

descriptor radius and histogram cell size. As shown

in Figures 10, 11, 12 and 13, varying rotational vari-

ance or descriptor radius have a strong impact on the

classification performance, while the effects of vary-

ing cell size or the neighbor count are more subtle.

If not otherwise specified, cell size is 6 × 6, neigh-

bor count is 7, radius is 1 and the rotationally invari-

ant version is used. After analyzing descriptors and

choosing optimized parameter settings, we evaluated

the effects of the different implemented preprocess-

ing methods when classifying using either pixel in-

tensity values, HOG or LBP results as feature vectors.

The results are shown in Figures 14, 15 and 16. It

can be seen that preprocessing yields the biggest im-

provement when no additional descriptor is used, with

Gabor and Sobel-of-Gaussian filtering having the best

classification rate of 96.4%. The impact of prepro-

Fully Automatic Faulty Weft Thread Detection using a Camera System and Feature-based Pattern Recognition

129

invariant variant

20%

40%

60%

80%

100%

64.7%

94.4%

45.3%

83.5%

invariant variant

20%

40%

60%

80%

100%

89.6%

98.2%

83.3%

92.6%

Figure 10: LBP: Rotational variance.

1 2 3

20%

40%

60%

80%

100%

64.7%

94.0%

61.4%

94.1%

53.5%

93.7%

1 2 3

20%

40%

60%

80%

100%

90.4%

98.2%

88.3%

99.1%

85.8%

99.0%

Figure 11: LBP: Radius variation for cell size 7 × 7.

3 5 6

7

10 15 30

20%

40%

60%

80%

100%

56.3%

92.7%

62.8%

94.1%

64.2%

94.5%

64.2%

94.1%

66.7%

93.9%

67.0%

92.6%

62.6%

88.2%

3 5 6

7

10 15 30

20%

40%

60%

80%

100%

87.9%

98.1%

89.6%

98.6%

91.7%

98.2%

90.4%

98.2%

91.3%

98.2%

91.7%

97.8%

92.1%

98.2%

Figure 12: LBP: Quadratic cell size variation.

3 4 5 6

7

8 9

20%

40%

60%

80%

100%

64.0%

93.8%

49.1%

95.6%

64.1%

94.6%

61.9%

93.0%

62.4%

94.0%

59.0%

92.9%

61.4%

93.5%

3 4 5 6

7

8 9

20%

40%

60%

80%

100%

90.0%

98.2%

87.1%

98.6%

89.6%

98.2%

89.2%

98.2%

90.0%

98.6%

90.8%

98.2%

90.0%

97.7%

Figure 13: LBP: Neighbor count variation.

No

Gab

Prew

Sob SoG

DFT

Diff

20%

40%

60%

80%

100%

46.5%

91.3%

78.5%

94.0%

74.7%

95.9%

73.3%

95.7%

80.0%

96.4%

62.8%

89.5%

63.2%

93.7%

No

Gab

Prew

Sob SoG

DFT

Diff

20%

40%

60%

80%

100%

80.0%

96.5%

95.8%

98.7%

95.0%

98.3%

94.2%

98.7%

95.8%

98.3%

90.4%

96.4%

92.5%

99.1%

Figure 14: Different preprocessing methods for pixel inten-

sity feature vector.

No

Gab

Prew

Sob SoG

DFT

Diff

20%

40%

60%

80%

100%

67.5%

90.0%

34.5%

80.5%

50.0%

84.9%

50.4%

85.3%

48.9%

85.9%

33.5%

76.9%

40.1%

86.6%

No

Gab

Prew

Sob SoG

DFT

Diff

20%

40%

60%

80%

100%

91.3%

96.1%

90.4%

96.0%

87.5%

89.7%

85.4%

90.3%

85.0%

91.5%

81.3%

94.7%

83.3%

93.9%

Figure 15: Different preprocessing methods for HOG.

No

Gab

Prew

Sob SoG

DFT

Diff

20%

40%

60%

80%

100%

63.9%

94.6%

0.0%

0.0%

60.5%

96.1%

60.4%

96.1%

56.8%

96.5%

34.3%

88.6%

60.6%

93.7%

No

Gab

Prew

Sob SoG

DFT

Diff

20%

40%

60%

80%

100%

90.0%

98.2%

0.0%

0.0%

90.0%

98.6%

90.4%

98.6%

88.8%

98.2%

86.3%

95.8%

89.2%

99.1%

Figure 16: Different preprocessing methods for LBP.

cessing decreases when HOG is used as feature de-

scriptor. In this case, using no preprocessing outper-

forms the other methods with a whole-image classi-

fication rate of 96.1%. Gabor filtering and apply-

ing HOG delivers good whole-image classification re-

sults while at the same time showing slightly lower

patch-wise classification performance. Finally, LBPs

show a constantly high classification rate regardless

of the used feature vectors, peaking around 90% with-

out preprocessing as well as for the Sobel and Prewitt

filters.

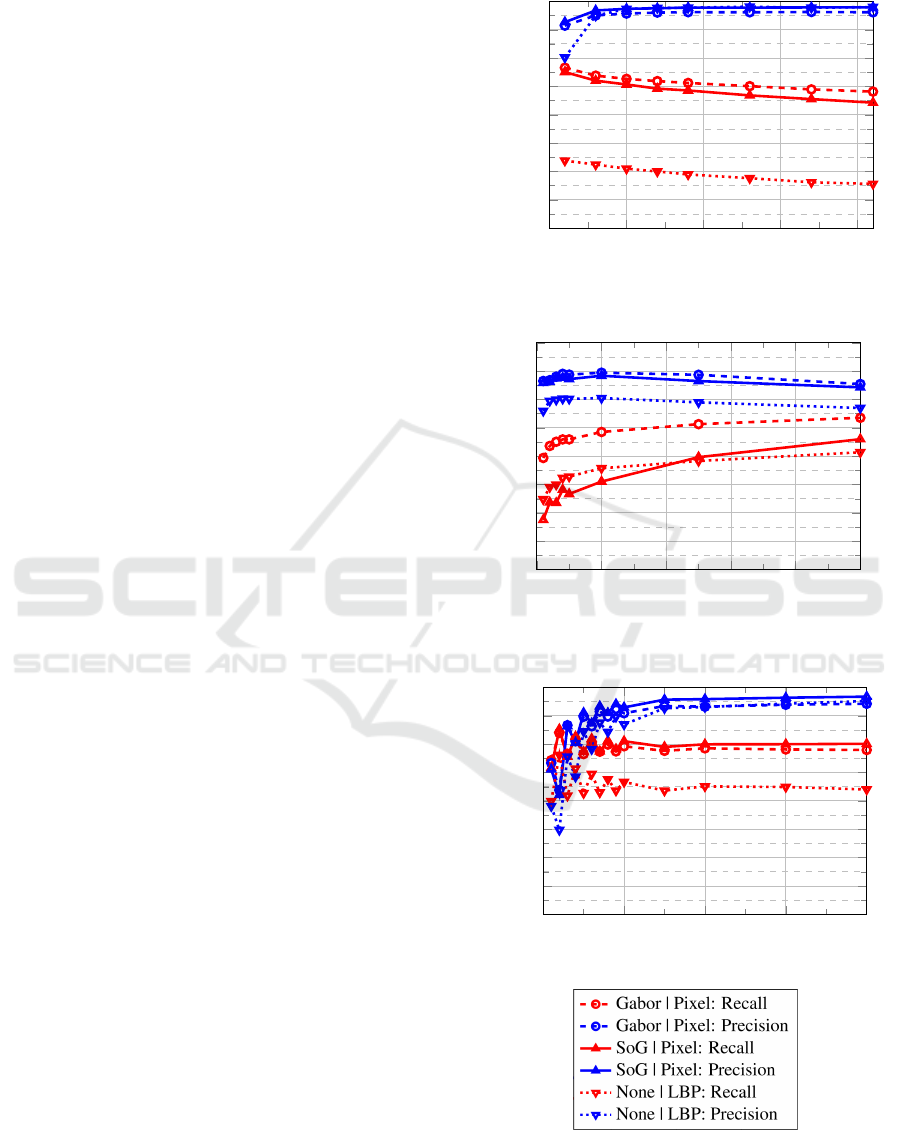

For testing the performance of different classi-

fiers and their settings, we have chosen three well-

performing preprocessing/feature descriptor combi-

ICPRAM 2018 - 7th International Conference on Pattern Recognition Applications and Methods

130

nations and analyzed how the classification rates

vary when applying different classifiers and vary-

ing their main parameters. The chosen combinations

are: Gabor filter and pixel intensity values, Sobel-of-

Gaussian and pixel intensity values, and finally ap-

plying LBPs to a non-preprocessed image (Fig. 20).

These are the three combinations that have shown the

best image classification rates. Since the image rates

were already high, we analyzed the patch rates under

the assumption that an increased patch-wise classifi-

cation rate corresponds to a higher classifier robust-

ness, thereby increasing chances of correctly classi-

fying new, more challenging patches.

The first inspected classifier is kNN. This algorithm’s

only adjustable parameter is the number of neigh-

bors k. The results in Fig. 17 shows that the choice

of k has only marginal impact on classification rates,

with the precision being constantly high even with

only one contributing neighbor, while the recall drops

continuously with increasing neighbor count.

An analysis of the binary decision tree (Fig. 18)

shows that less deep trees yield higher precision val-

ues while increasing the number of tree nodes in-

creases recall for all descriptors. In a subsequent step

we changed the number of trees in the random forest

classifier while leaving each tree’s depth at its default

value (Fig. 19). Results show that the classification

results increase with the number of trees until a num-

ber of about 15 trees is reached; from that point on the

classification rates remain constant.

Finally, the optimized per-patch results were used

to define a decision rule that allows detecting whether

a ROI contains a defective thread or not. To this end,

we analyzed the number of positives returned by the

classifiers (corresponding to the likelihood of a de-

fect being present in the image or not) for both de-

fect and non-defect ROIs and normalized it by image

size. Results have shown that defect and non-defect

images form two distinctive distributions. To find the

optimal decision rule, the likelihoods were multiplied

with the prior class distributions of the used image set.

Per-image classification rates are displayed in the bot-

tom bar charts of image 7 to to 16, showing that the

MAP approach allows to classify images with high

accuracy even by using results acquired from classi-

fiers with strongly varying patch-wise classification

performance.

5 DISCUSSION

Our results show that the problem of localizing de-

fective yarns is well solvable using computer vision

methods, however the different algorithm combina-

0

5

10

15

20

20%

30%

40%

50%

60%

70%

80%

90%

100%

Patch Classification

Figure 17: KNN: Variation of k.

0 200 400

600

800 1,000

20%

30%

40%

50%

60%

70%

80%

90%

100%

Patch Classification

Figure 18: BDT: Variation of depth.

0 10 20 30 40

20%

30%

40%

50%

60%

70%

80%

90%

100%

Patch Classification

Figure 19: RF: Variation of number of trees.

Figure 20: Legend for classification analysis.

Fully Automatic Faulty Weft Thread Detection using a Camera System and Feature-based Pattern Recognition

131

tions evaluated in this workstrongly differ in their per-

formance. Results show that preprocessing has a high

impact on classifier performance and that basic edge-

enhancing methods allow the best class separability,

outperforming direction-sensitive approaches such as

the Sobel-of-Gaussian or Gabor Filters. An interest-

ing fact is that the per-image classification rate gen-

erally remains constantly high and is generally robust

towards drops in the patch-wise classification perfor-

mance.

6 CONCLUSION

In this paper, we have described and thoroughly eval-

uated a solution for the fully automated detection of

faulty weft threads in automated weaving machines

using computer vision. First, we developed a robust

multi-camera setup capable of capturing the entire

shed area with high resolution. The resulting images

were divided into small patches and each patch was

classified independently. We described and evaluated

a number of methods for preprocessing, feature ex-

traction and feature-based classification. Parameter

variations of the extraction and classification methods

were analyzed and optimized settings were reported.

Finally, we introduced a maximum-a-posteriori-based

method for the final defect classification of a whole

image based on the detection distributions in positive

and negative test images. Results have shown that

our presented methods allow a reliable error detec-

tion with high classification rates, making the system

suitable for future industrial applications.

REFERENCES

Bishop, C. M. (2006). Pattern recognition. Machine Learn-

ing, 128.

Bovik, A. C., Clark, M., and Geisler, W. S. (1990). Multi-

channel texture analysis using localized spatial filters.

IEEE transactions on pattern analysis and machine

intelligence, 12(1):55–73.

Breiman, L. (2001). Random forests. Machine learning,

45(1):5–32.

Dalal, N. and Triggs, B. (2005). Histograms of oriented gra-

dients for human detection. In 2005 IEEE Computer

Society Conference on Computer Vision and Pattern

Recognition (CVPR’05), volume 1, pages 886–893.

IEEE.

Hanbay, K., Talu, M. F., and Ömer Faruk Özgüven

(2016). Fabric defect detection systems and meth-

odsâC”a systematic literature review. Optik - In-

ternational Journal for Light and Electron Optics,

127(24):11960 – 11973.

Karayiannis, Y. A., Stojanovic, R., Mitropoulos, P., Koula-

mas, C., Stouraitis, T., Koubias, S., and Papadopoulos,

G. (1999). Defect detection and classification on web

textile fabric using multiresolution decomposition and

neural networks. In Electronics, Circuits and Systems,

1999. Proceedings of ICECS’99. The 6th IEEE Inter-

national Conference on, volume 2, pages 765–768.

IEEE.

Kumar, A. (2008). Computer-vision-based fabric defect de-

tection: a survey. IEEE transactions on industrial

electronics, 55(1):348–363.

Ngan, H. Y., Pang, G. K., and Yung, N. H. (2011). Auto-

mated fabric defect detectionâ

C”a review. Image and

Vision Computing, 29(7):442–458.

Ojala, T., Pietikainen, M., and Maenpaa, T. (2002). Mul-

tiresolution gray-scale and rotation invariant texture

classification with local binary patterns. IEEE Trans-

actions on pattern analysis and machine intelligence,

24(7):971–987.

Sari-Sarraf, H. and Goddard, J. S. (1999). Vision system

for on-loom fabric inspection. IEEE Transactions on

Industry Applications, 35(6):1252–1259.

Schneider, D., Holtermann, T., and Merhof, D. (2014). A

traverse inspection system for high precision visual

on-loom fabric defect detection. Machine Vision and

Applications, pages 1–15.

Stojanovic, R., Mitropulos, P., Koulamas, C., Karayiannis,

Y., Koubias, S., and Papadopoulos, G. (2001). Real-

time vision-based system for textile fabric inspection.

Real-Time Imaging, 7(6):507–518.

Wada, Y. (1984). Optical weft sensor for a loom. US Patent

4,471,816.

ICPRAM 2018 - 7th International Conference on Pattern Recognition Applications and Methods

132