Laser Drilling of a 7-layer Flexible Printed Circuit Board using a

Pulsed Ytterbium Fiber Laser System

Chih-Chung Yang, Yi-Cheng Lin, Tzu-Chieh Peng, Kuo-Cheng Huang and Yu-Hsuan Lin

*

Instrument Technology Research Center, National Applied Research Laboratories, Hsinchu, Taiwan

Keywords: Laser Drilling, Trepanning, FPCB, Pulsed Fibre Laser.

Abstract: Recently, laser-processing industry is becoming increasingly popular because of its advantages of low cost,

fast and good energy efficiency. The electric circuit board manufacturers also began to import related laser

processing technology to improve the productivity. This paper presents the laser drilling process and quality

analysis of the 7-layer flexible printed circuit (FPCB). A laser drilling system pulsed Ytterbium fiber laser,

expander device, focal lens, galvanometric scanner and XY-axis manual stage was used to perform the hole

cutting of the multilayer-layer FPCB. This study succeeded in establishing a comparing procedure, which

enabled the characteristic comparison between the various experimental conditions. We believe that this

study provides a useful database for FPCB drilling technology.

1 INTRODUCTION

Laser is a kind of modern light source, which emits

light when a driving voltage is applied. The light is

amplified by a process of the stimulated emission of

electromagnetic radiation. The optical properties of

laser are monochromatic, coherent, collimated and

polarizable. In recent years, laser industry becomes

increasingly popular because of the demand of high

manufacturing efficiency for various products. Due

to the advantage of high power intensity, long

lifetime, low power consumption, good luminous

efficiency, faster switching and small size, the laser

technology has gradually replaced the traditional

optical lighting and mechanical processing.

Nowadays, laser has been widely used in optical

measurement, precision machining, bio-treatment,

image projection and versatile sample excitation

applications (Malcolm, 2000) (Winco, 2000) (Han-

Chao, 2015) (Surmann, 2003) (Seokbae, 2002).

Among them, the most popular is precision

machining. Due to the high collimation of the laser,

the focused spot can be very small. In other words,

the energy dose is quite high. The melting and

vaporization processing can be carried out in a small

area of the sample. It means that the resolution of

laser processing is very high. The laser processing

material is not limited to metal, and can be glass,

wood, ceramics, plastic and paper. For the cutting,

engraving or welding application, the typical lasers

are CO2 laser, Nd:YAG laser, semiconductor laser

and fiber laser etc. Recently, due to the rise of

mobile devices, the demand for laser-processing the

small circuit boards is rapidly growing. Therefore,

the electric circuit board manufacturers also began to

import related laser processing technology.

For the printed circuit board manufacturing

industry, laser direct cutting and drilling is the most

popular (Ching-Ching, 2017) (Hsin-Yi, 2016)

(Kestenbaum, 1990) (Avanish, 2008) (Winco, 2007)

(Reinhart, 2010) (Owen, 1998). Because the novel

printed circuit board has high conductive wiring

density, small holes and contacts, the resolution of

the traditional mechanical processing is obviously

insufficient. Also, mechanical cutting is also easy to

damage the printed circuit board. The most common

samples recently are soft-matter printed circuit board

and high density inter-connect (HDI) printed circuit

board. In order to improve the processing accuracy

and stability, laser ablation gradually replaced the

mechanical processing. Laser ablation has the

advantages of simple, high-resolution and rapid. It

cannot only accurately control the ablation depth and

the size, but also prevent overheat and maintain the

results quality. The type of laser light source can

determine the ablation characteristic. For example,

because the power of CO2 laser is very high, the

action of laser ablation is rapid. However, its long

wavelength leads to low resolution. Therefore, this

178

Yang, C-C., Lin, Y-C., Peng, T-C., Huang, K-C. and Lin, Y-H.

Laser Drilling of a 7-layer Flexible Printed Circuit Board using a Pulsed Ytterbium Fiber Laser System.

DOI: 10.5220/0006613801780184

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 178-184

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

kind of light source is only suitable for the

processing with a resolution greater than 100 μm.

On the contrary, although the UV laser has very high

resolution and low energy consumption, the light

source and related devices are extremely expensive.

Even if the resolution can be better than 50 μm, it is

a big burden for the manufacturer. For common laser

ablation, YAG laser is the relatively suitable light

source that well balance the resolution and

instrument cost. Through the appropriate optical

lens, the ablation resolution of the laser can achieve

between 40 to 100 μm. All the pattern formation is

performed by the galvanometer mirrors, so the

ablation speed is very fast. Various materials and

combinations of printed circuit boards have

individual laser processing parameters, so the

optimization procedure is very important. The

printed circuit board manufacturers have to master

the related know-how for the laser processing to

maintain the competitiveness of production.

This paper presents the pulsed laser drilling

process and quality analysis of the multi-layer

flexible printed circuit (FPCB). A scanning laser

drilling system composed of a pulsed Ytterbium

fiber laser, optical expander, galvanometric scanner

and XY-axis motorized stage was used to perform

the blind-hole cutting for the multi-layer FPCB. The

sample is a FPCB cross-stacked with black-oxide

copper, cupper and epoxy coated glass fabric. The

machining target is a perfect blind hole that has two

layers depth. This study succeeded in establishing a

comparing procedure of processing parameters,

which enabled the characteristic comparison

between the profiles of the drilled hole in various

conditions. The morphology of the laser-drilled

holes was measured by an optical microscope with

20X objective lens. By numerical analysis, the

proposed amendment to the laser drilling process is

able to achieve an optimal balance between process

efficiency and hole quality. The laser drilling system

was used to perform the hole cutting with hundreds

of processing parameters. With the optical

observation of experimental results, the morphology

and profile of each laser-drilled holes would exhibit

their individual characteristics. Following the

numerical analysis, the amendment to the laser

drilling process could be proposed to achieve a good

shape that has minimal carbonization and thermal

influence. We believe that this study provides a

useful database for FPCB drilling technology.

2 EXPERIMENTAL SETUP AND

SAMPLE PREPARTION

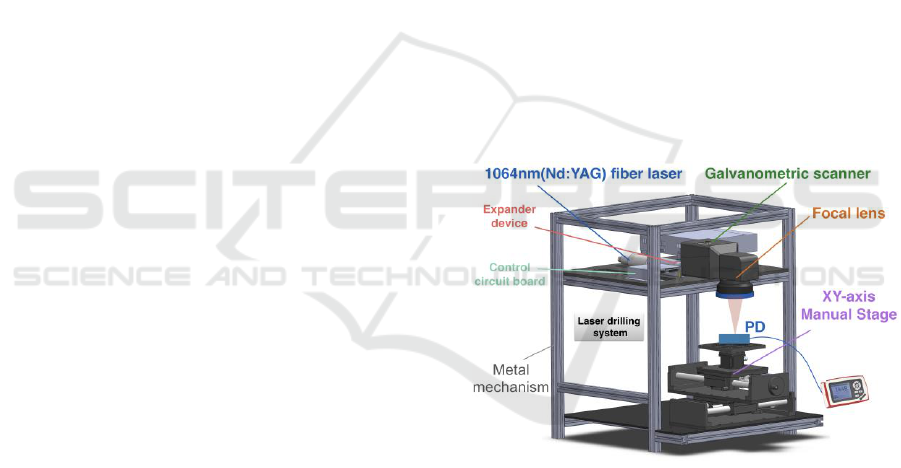

Figure 1 shows the experimental setup of the

scanning laser drilling system for the laser drilling of

multi-layer flexible printed circuit board. The system

composed of a pulsed Ytterbium fiber laser,

expander device, focal lens, galvanometric scanner

and XY-axis manual stage. The wavelength and

maximum power of the laser source are 1064 nm

and 30 W, respectively. The working distance of the

lens is 152.6 mm and the scanning range is 80 × 80

mm2. All optical and electronic components were

precisely positioned through the designed metal

mechanisms. The photodiode and power meter were

used to measure the average power of laser with

various parameters before conducting the drilling

process. The estimated value of spot size is about 81

μm, and the depth of field is about 4,256 μm. The

effective laser processing area could be directly

defined by the graph inputted into the software. A

laptop connected with the control circuit board was

used to interactively drive the laser to perform the

hole cutting of the samples.

Figure 1: Experimental setup of the laser drilling system.

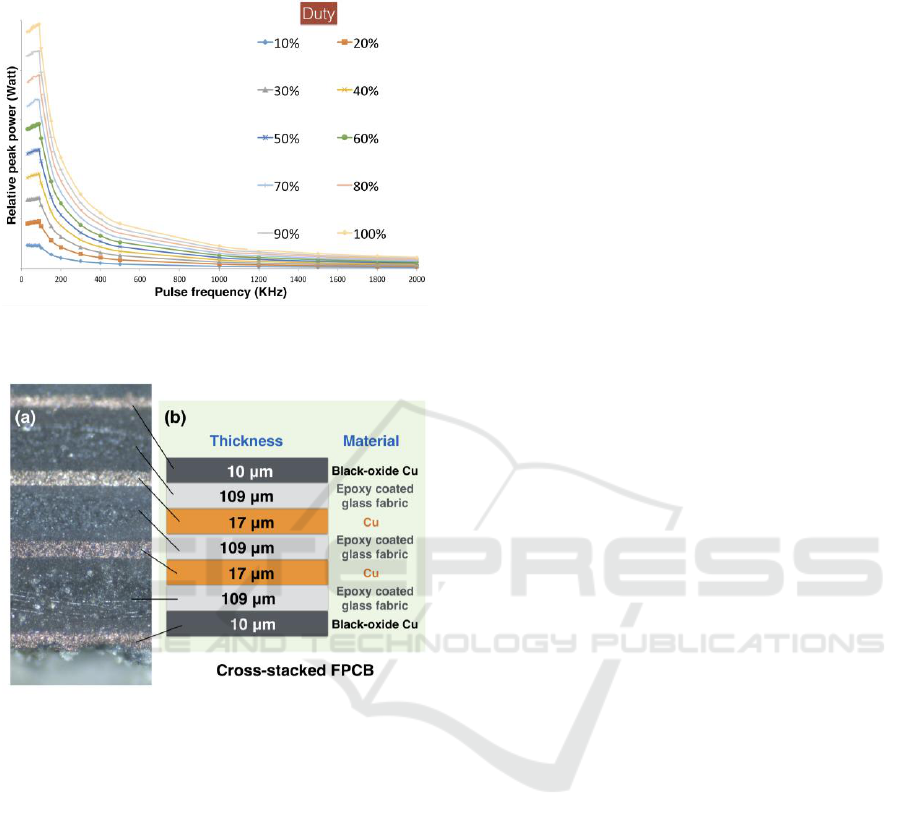

Figure 2 shows the relationship between the

pulse frequency and relative peak power of the laser

source. The values of peak power were calculated by

dividing the pulse frequency and time duration from

measured average power. The various duty cycles

for laser driving are represented by the various color

curves. From the figure we can see that the

maximum peak powers of the laser occur at the

pulse frequency of 90 KHz. The peak power is

rapidly attenuated from 90 to 1000 KHz, and the

difference is small after 1000 KHz. Also, the light

intensity is relatively unstable at pulsed frequency

Laser Drilling of a 7-layer Flexible Printed Circuit Board using a Pulsed Ytterbium Fiber Laser System

179

below 60 KHz. Therefore, the suitable parameters

for laser drilling are between 60 ~ 1000 KHz.

Figure 2: The relationship between the pulse frequency

and relative peak power of the laser source.

Figure 3: (a) The cross-sectional image and (b) Structural

diagram of the cross-stacked FPCB.

The sample for laser drilling was a FPCB cross-

stacked with black-oxide copper, copper and epoxy

coated glass fabric, as shown in figure 3. Figure 3(a)

is the cross-sectional image of the sample measured

by the optical microscopy. The thickness and the

material of the cross-stacked FPCB are shown in

figure 3 (b). The top and bottom layer are 10 μm

thick black-oxide copper. The dielectric layers are

109 μm thick epoxy coated glass fabrics. The inner

conductive layers between dielectric layers are 17

μm thick coppers. The cross section of the sample is

formed by the cutting of a diamond knife, therefore

the softer copper layer will be pulled and cause it to

look thicker in figure 3 (a). Also, the transverse

direction glass fabric can be seen at the bottom layer

of the dielectric layer. Before the laser processing,

the surface of the sample should be cleaned carefully

with alcohol. The particles on the sample surface can

lead to laser processing errors. As the sample is

softer, it is easy to warp and deformation. A mount

was made to effectively hold the sample and

maintain that the sample surface accurately located

on the focal plane of the laser. The stability of the

laser processing has been verified before the start of

the experiment.

3 RESULTS AND DISCUSSION

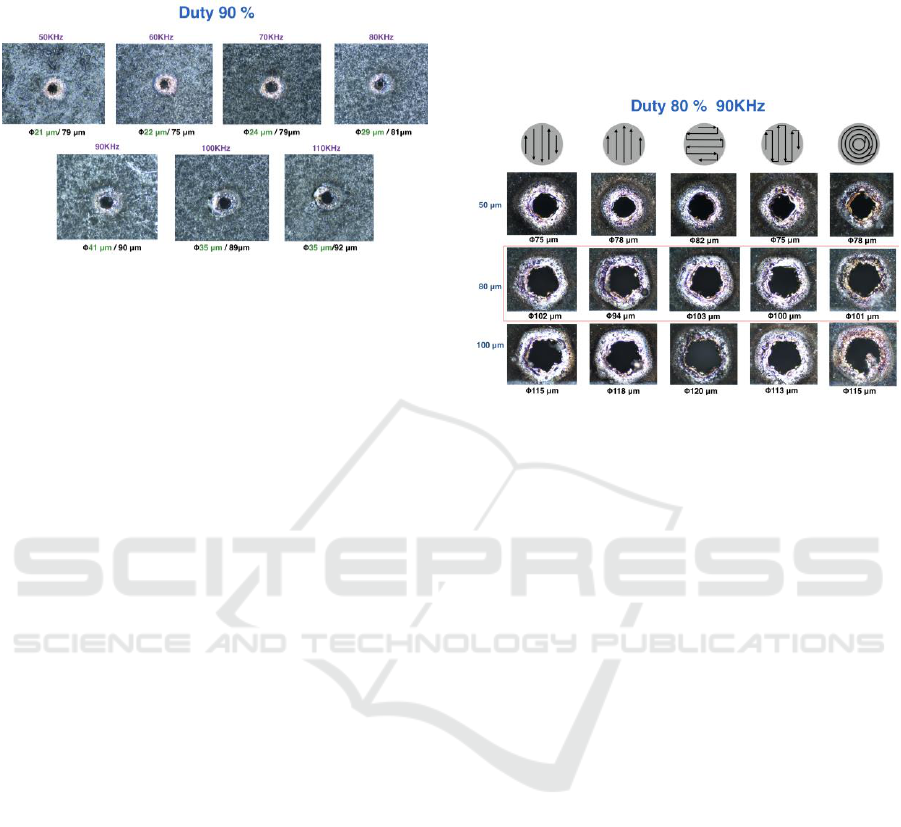

The parameters for laser drilling are very diverse,

including the duty cycle, pulse frequency, the

number of shots, the delay time and trepanning

speed, and so on. Each parameter will have an

impact on the machining process. Before starting

laser drilling, the laser focal plane must be

positioned on the surface of the FPCB to maximize

the efficiency of laser ablation. The adjustment of

the focal plane (z-axis) was achieved by the beam

expander in the system, rather than the use of a

mechanical movement stages. As the focal spot of

the laser is relatively small, so to achieve 100 μm

drilling must use the trepanning method. Before that,

we must first understand the relationship between

the size of the hole and the machining parameters

when the FPCB is directly drilled without

trepanning. Figure 4 shows the optical images of the

laser-drilled results. In order to achieve thru-holes,

the higher peak power of laser must be used. The

duty cycle of laser is 50%, the pulse frequency is 50-

110 KHz, and the number of shots is 1000 shots.

The green words indicate the aperture size of the

thru- hole, and the black words represent the surface

ranges of the FPCB affected by the heat damage.

Although the spot size of the laser is about 81um,

only the central part of the higher energy area can

effectively ablate the FPCB materials. It can be

found from Figure 3 that the laser processing energy

is highest at the frequency of 90 kHz. Corresponding

to Figure 4, the hole is relatively larger and the

diameter is about 41um. The farther the pulse

frequency from 90 KHz, the smaller the hole. It can

be estimated that the minimum thru-hole size drilled

by the system is about 20 μm. The processing

quality around the circumference of the hole also

needs to be concerned. If the heat damages are too

large, it will often cause the unpredictable problems

while the FPCB was used. After comparing the

contours of each hole, it could be found that the

better thru-hole which has balance ratio of inner and

outer diameter occur at the pulse frequency of 90

KHz. Although the smaller holes have better

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

180

resolution, the heat-affected regions did not

correspondingly become smaller.

Figure 4: Optical images of the holes by directly laser

ablation without trepanning.

In order to perform a 100 μm aperture laser

drilling, the trepanning procedure is required. The

correct trepanning method can effectively make the

hole size increase and maintain the circle shape. We

must first understand that whether the various

trepanning methods will have impact on the shape of

the hole. Figure 5 shows processing results using

five kinds of trepanning mode, including two-way,

one-way, lateral and vertical progressive scanning

and snail-like trepanning. In the software, the input

hole size images are 50 μm, 80 μm and 100 μm.

Because the actual drilled hole size is always greater

than the settings size, the input hole size images

should be less than 100 μm to achieve a just 100 μm

size hole. In order to achieve thru-hole, the higher

peak power of laser was used. The duty cycle of

laser is 80%, the pulse frequency is 90 KHz, and the

number of shots is 1000 shots. From the figure you

can see the holes are not perfect round. The reason is

that the surface of the black-oxide copper of the

FPCB is quite rough, and the glass fabric weaving in

dielectric layer is randomly distributed, so the

uniformity of laser processing cannot be perfect. In

figure 5, it could be found that the 50 μm hole size

image will form an actual hole with about 78 um

diameter, which is enlarged by 1.56 times. The 80

μm hole size image will form an actual hole with

about 100 μm diameter, which is enlarged by 1.25

times. That is also the hole size what we expect. The

100 μm hole size image will form an actual hole

with about 116 μm diameter, which is enlarged by

1.16 times. In other words, the larger the hole size

setting image will generate a hole which is closer to

the actual drilling hole size. This phenomenon may

come from the effect of the resolution of the laser

spot. In addition, the use of 50 μm hole size image

setting will generate a diamond-like shape. This

problem may come from the resolution limit of the

galvanometer mirrors. Therefore, using a larger hole

size image for laser drilling setting may easily

achieve a perfect round hole. However, the current

processing results only like a relatively round

pentagon.

Figure 5: Optical images of the holes drilled by various

trepanning modes and setting hole sizes.

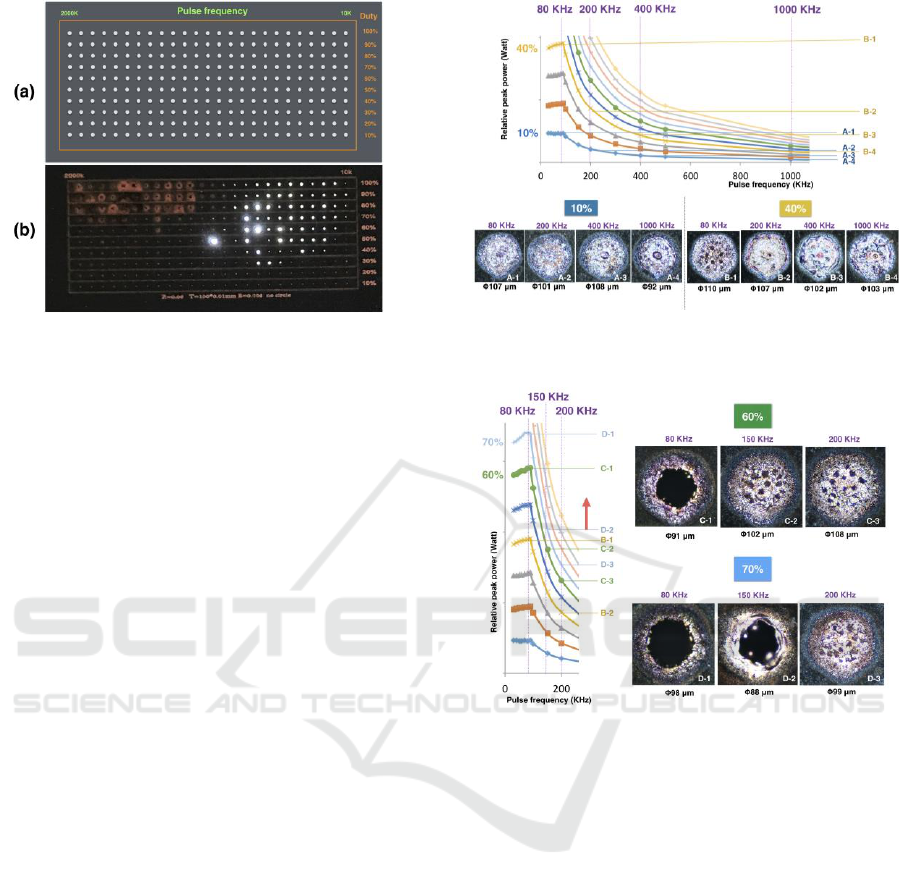

Theoretically, the higher the peak power will be

easier to penetrate through the FPCB. But in fact it

needs to match the trepanning speed and other

conditions. In order to quickly understand the

drilling results with using various peak power and

pulse frequency, a laser-drilling array method was

used to quickly help us to find the appropriate range

of parameters. Figure 6(a) shows the array pattern

with various parameters for image setting in the

system. The trepanning mode is snail-like and the

hole size is 80 μm. The vertical axis is the pulse

frequency from 10 to 2000 KHz, and the horizontal

axis is the duty cycle from 10 to 100%. Figure 6(b)

shows the actual hole array after laser machining. In

order to confirm whether the parameters can achieve

the thru-holes, in uniform white light was used to

illuminate the sample from the back. As long as the

FPCB has been penetrated, a light spot would be

observed. It can be found that the higher pulse

frequency part will cause serious thermal effect

around the holes. The external qualities of the holes

are totally bad. The formation of thru-holes falls in

areas of high peak power. Some holes have

particularly large light spot may not because the hole

size is larger. Because the sidewalls of the hole have

less scattering impurities (such as glass fabric

residues) will also increase the amount of

transmission light. The actual hole still needs a high

magnification microscope to directly observe and

qualify.

Laser Drilling of a 7-layer Flexible Printed Circuit Board using a Pulsed Ytterbium Fiber Laser System

181

Figure 6: Set pattern and actual hole array after laser

machining with various duty cycle and pulse frequency.

After selecting the hole size image of 80 μm for

setting, an actual hole size of about 100 μm can be

successfully formed. It is necessary to understand

the processing parameters that can form a thru-hole

or blind-hole, and whether the holes size will change

correspondingly after drilling. Figure 7 shows the

laser drilling results of FPCB using the previously

optimized parameters: snail trepanning with 80 μm

hole size image setting. The variables are the laser

duty cycle and pulse frequency. In order to easily

observe the actual peak power difference of the

laser, figure 3 is narrowed down and embedded to

the top of the Figure 7. The corresponding pulse

frequencies are marked by dotted lines. The actual

peak powers of the laser with 10% duty cycle are

labeled as A-1, A-2, A-3 and A-4 at pulse frequency

of 80, 200, 400 and 1000 kHz. The actual peak

powers of the laser with 40% duty cycle are labeled

as B-1, B-2, B-3 and B-4 at pulse frequency of 80,

200, 400 and 1000 kHz. The results show that the

drilled hole size can be controlled in the vicinity of

100 μm regardless of the value of the laser duty

cycle and pulse frequency. Due to the uncertainty of

the measurement and the non-uniformity of the

FPCB material, the deviation of about 10 μm should

be accepted. The peak power below the B-1 level

can ablated the surface of the black-oxide copper of

the FPCB, However, it cannot effectively achieve

broken copper of the first layer. Due to the effect of

the snail trepanning, the edge of the hole will have a

dark ring. It indicates that the areas were ablated

slightly. Although A-1 and B-3, A-2 and B-4 have

similar peak power, however the qualities of the

holes are totally different. The reason is that the

different pulse frequencies would cause different

drilling overlapping under a fixed trepanning speed.

Figure 7: Laser drilling results using 10% and 40% duty

cycle at pulse frequency of 80, 200, 400 and 1000 kHz.

Figure 8: Laser drilling results using 60% and 70% duty

cycle at pulse frequency of 80, 150 and 200 kHz.

Under the same drilling parameters, figure 8

shows the drilling results with higher duty cycle.

Since the pulse frequency above 400 KHz cannot

provide an enough peak power for thru-hole

generation, the pulse frequency parameters are

changed to be 80, 150, 200 kHz. The duty cycles are

raised to be 60% and 70%. Figure 3 is narrowed

down and embedded to the left of the Figure 7 and

the corresponding pulse frequencies are also marked

by dotted lines. The actual peak powers of the laser

with 60% duty cycle are labeled as C-1, C-2 and C-3

at pulse frequency of 80, 150, 200 KHz. The actual

peak powers of the laser with 70% duty cycle are

labeled as D-1, D-2 and D-3 at pulse frequency of

80, 150, 200 KHz. The results still demonstrate that

the drilled hole size can be controlled in the vicinity

of 100 μm regardless of the value of the laser duty

cycle and pulse frequency. With the validation of

microscopic images and backlighting observation,

100 μm thru-hole will generate when the laser peak

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

182

power is higher than D-2 (red arrow). A lot of tiny

pores were gradually formed on the hole surface if

the laser peak power is between B-1 and C-3. The

depths of these holes are about 1 to 2 μm only. It

means that only the surface of the black-oxide

copper is ablated away. The result also indicates that

using the laser with peak power higher than D-2

level and reducing the number of shots could

achieve the various blind holes. The laser with peak

power lower than B-1 cannot form the blind holes

even if the number of laser shots is increased.

Figure 9: The cross-sectional image of the drilled thru-

hole measured by an optical microscope.

Figure 9 shows the cross-sectional image of the

drilled thru-hole measured by the optical

microscope. The laser drilling parameters are: duty

cycle of laser is 80%, the pulse frequency is 90 KHz,

and the hole size image for setting is 80 μm. By

optical alignment using a digital microscope, the

diamond round knife can be precisely positioned on

the hole middle for cutting the hole in half. As the

mechanical cutting will pull copper layer, it will

cause hole shrinking in metal layers, as shown in the

green square area. Although the use of grinding

method can achieve a smoother cross-section of

FPCB, the time cost and failure rate are too high.

Figure 9 shows that the laser-drilled thru-hole has a

shape like a calabash. Because of the trepanning

processing, a lot of shots and the focal plane of laser

located on the surface of the FPCB, the heat will

concentrate on the first and second layer around the

hole region. The copper has better thermal

conductivity, therefore the glass fabric layer will

occur expanded ablation, as shown in the red square

area. The laser-drilled hole can be control as a 100

um size, however, the exit need to rapidly discharge

the scraps. The hole at the other side will burst and

form a larger hole. The size is about 1.6 to 2 times of

original hole. We believe that the quality of hole

sidewall can be further improved by turning the

better processing parameters. A better way should be

a gradual trepanning down process that can maintain

the hole size even in the different depth. For further

experiments, we will work in this direction.

4 CONCLUSIONS

This study succeeded in developing a simple, rapid

and relative accurate method for the quality analysis

of the laser-drilled hole on flexible printed circuit.

An laser drilling system system equipped with 1064

nm pulsed Ytterbium fiber laser, optical expander,

galvanometric scanner and XY-axis motorized stage

was used to perform the hole cutting with many

kinds of processing parameters. With the optical

observation of experimental results, the size and

shape of each laser-drilled holes would exhibit their

individual characteristics. Both the through and

blind holes can be successfully formed. Following

the numerical analysis, the amendment to the laser

drilling process could be proposed to achieve a ideal

hole shape, minimal carbonization and thermal

influence. This system is compatible with most

laser-drilling experiment and can be used for multi-

layer FPC. This study provides a useful database for

FPCB drilling technology.

ACKNOWLEDGEMENTS

The authors would like to express their appreciation

for financial aid from the Ministry of Science and

Technology, R.O.C under grant numbers MOST

105-2622-E-492-029-CC3. The authors would also

like to express their gratitude to the Instrument

Technology Research Center of National Applied

Research Laboratories for the support.

REFERENCES

Malcolm C. Gower, 2000. “Industrial applications of laser

micromachining”, Optics express, 7(2), 56.

Winco K.C Yung, J.S Liu, H.C Man, T.M Yue, 2000.

“355 nm Nd:YAG laser ablation of polyimide and its

thermal effect”, Journal of Materials Processing

Technology, 101(1-3), 306.

Han-Chao C., Yu-Hsuan L., Kuo-Cheng H., 2015. ”

Accurate laser skin perforation technique aimed at

promoting bleeding and reducing pain” Journal of

Innovative Optical Health Sciences, 8(6), 1550029-1-

8.

Laser Drilling of a 7-layer Flexible Printed Circuit Board using a Pulsed Ytterbium Fiber Laser System

183

Surmann, H., Nuechter, A., and Hertzberg, J., 2003. "An

autonomous mobile robot with a 3d laser range finder

for 3d exploration and digitalization of indoor

environments," Robotics and Autonomous Systems,

vol.45, no.3-4, 181-198.

Seokbae, S., Hyunpung, P., Kwan, H. L., 2002.

“Automated laser scanning system for reverse

engineering and inspection”, International Journal of

Machine Tools and Manufacture, 42(8), 889-897.

Ching-Ching, Y., Yi-Cheng, L., Chih-Chung, Y., Yu-

Hsuan, L., Kuo-Cheng, H., Keh-moh, L., Wen-Tse H.,

2017. “Laser-induced coloring of titanium alloy using

ultraviolet nanosecond pulses scanning technology”,

Journal of Alloys and Compounds, 715(25), 349-361.

Hsin-Yi, T., Chih-Chung, Y., Wen-Tse, H., Kuo-Cheng,

H., 2016. “Analysis of fabric materials cut using

ultraviolet laser ablation”, App. Phy. Mat. Sc. Process.,

10.1007/s00339-016-9815-2.

Kestenbaum, A., D'Amico, J. F., Blumenstock, B. J.,

DeAngelo, M. A., 1990. “Laser drilling of microvias

in epoxy-glass printed circuit boards”, IEEE

Transactions on Components, Hybrids, and

Manufacturing Technology, 13(4), 1055-1062.

Avanish, K. D., Vinod, Y., 2008. “Laser beam

machining—A review”, International Journal of

Machine Tools and Manufacture, 48(6), 609-628.

Winco, K. C. Y., Jun, W., T. M. Y., B. L. Z., C. P. Lee.,

2007, “Nd:YAG laser drilling in epoxy resin/AlN

composites material”, Composites Part A: Applied

Science and Manufacturing, 38(9), 2055-2064.

Reinhart, P., Wolfgang, S., Robert, S., 2010.

“Hydrodynamics of material removal by melt

expulsion: Perspectives of laser cutting and drilling”,

Physics Procedia, 5(A), 1-18.

Owen, M., E. Roelants, and J. Van P., 1998. "Laser

drilling of blind holes in FR4/glass." Circuit

World, 24(1), 45-49.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

184