Optimizing Storage Capacity of Retailers in Stochastic Periodic

Inventory Routing Problem

Ehsan Yadollahi

1,2

, El-Houssaine Aghezzaf

1

, Joris Walraevens

2

and Birger Raa

1

1

Department of Industrial Systems Engineering and Product Design,

Faculty of Engineering and Architecture, Ghent University, Gent, Belgium

2

Department of Telecommunications and Information Processing (TELIN),

Faculty of Engineering and Architecture, Ghent University, Gent, Belgium

Keywords: Safety Stock, Storage Capacity Limitation, Stochastic Demands, Inventory Routing Problem.

Abstract: A challenging question in Stochastic Periodic Inventory Routing Problem (SPIRP) is how to deal with

stochastic demand rates, while minimizing the costs (transportation, inventory, and storage) and finding the

best routing system. In this paper, we reformulate the SPIRP model to a safety stock-based SPIRP where the

inventory storage capacity at the retailers are considered as variables and retailer’s demand rate is stochastic.

The supply chain planner needs to find the best routing system to replenish the retailers with the most optimum

level of inventory, while the service level is satisfied in a long term planning horizon. Four different policies

for storage capacity optimization are presented, evaluated, and compared in an illustrative example. The

impact of storage capacity limitation is considered based on the defined policies to measure their compatibility

for different situations.

1 INTRODUCTION

Inventory-Routing Problem (IRP) integrates

inventory management and vehicle routing decisions

over several periods and has received increased

attention in recent years (Aghezzaf, 2007, Bertazzi et

al., 2013, Yadollahi et al., 2017, Federgruen and

Zipkin, 1984, Bell et al., 1983). Bell et al., (1983) are

one of the first researchers who used VRP and

inventory management together to deal with the case

where only transportation costs are included, demand

is stochastic, and customer inventory levels must be

met. Demand stochasticity means that shortages may

occur since the supplier only knows a probabilistic

distribution of demand for the retailer. To avoid

having stock-outs, a penalty is imposed whenever a

retailer runs out of stock, and this penalty is usually

paid with the unsatisfied demand (negative

inventory). Unsatisfied demand is either considered

as lost-sale or backlogged. More explanation about

IRP and SPIRP can be found in (Coelho et al., 2014a,

Coelho et al., 2014b).

Variability of service, uncertainty in demand, and

delay are the well-known characteristics of SPIRP.

The trade-off between costs (transportation and

inventory) and products’ availability makes SPIRP a

hard problem to solve. Even though there is a

noticeable body of literature about IRP and SPIRP,

only few studies have involved capacity limitation as

constraints. Stacey et al., (2007) are one of the

pioneers in specifying the significance of storage

capacity on both the routing and inventory decisions

in the context of inbound transportation. They have

evaluated the benefits of applying storage constraints

at different levels by developing two new heuristics

that sequentially take into account the inventory level

and routing decisions.

Pujawan et al., (2015) have proposed a new

method to integrate operational and strategic decision

parameters, namely shipment planning and storage

capacity decision under uncertainty. Their objective

is to provide a close to optimal solution to find the

best balance for logistics cost and product

availability. The authors develop a simulation model

to investigate the effects of various indicators on costs

and service levels in a distribution system. The model

mimics the transportation and distribution problems

of bulk cement, consisting of a silo at the port of

origin, two silos at two ports of destination, and a

number of ships that transport the bulk cement. The

outcome of their model clarifies the significant effect

of the number of ships deployed, silo capacity,

Yadollahi, E., Aghezzaf, E-H., Walraevens, J. and Raa, B.

Optimizing Storage Capacity of Retailers in Stochastic Periodic Inventory Routing Problem.

DOI: 10.5220/0006620302170223

In Proceedings of the 7th International Conference on Operations Research and Enterprise Systems (ICORES 2018), pages 217-223

ISBN: 978-989-758-285-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

217

working hours of ports, and the dispatching rules of

ships on both total logistics costs and service level.

Finding the appropriate storage capacity is one of

the main objectives of SPIRP that desires more

investigation. The comparison between small and big

storage capacity can be assessed from several

different aspects such as costs, service level, silo

availability, product’s perishability, etc. In addition,

different options for storage capacity at the retailers

with different costs makes it more challenging for the

supply chain decision maker to find the most

optimum solution.

The idea of having the capacity optimized is a new

concept in SPIRP and has not been treated completely

in the literature. In this paper by involving storage

capacity constraints into SPIRP, we develop the

solutions to deal with stochasticity in demand rates

and costs minimizations while service level is

satisfied. Four different policies for storage capacity

allocation are considered in this paper. The strategies

are evaluated and compared by implementing them

on an illustrative example based on two indicators

namely costs and computation time. The outcome of

these solutions are discussed in details for the short

and long term planning horizon in order to have a

better insight of their influence on the whole system.

The rest of the paper is organized as follows;

section 2 presents the Safety Stock-based SPIRP

together with the different approaches for the capacity

optimization. In section 3, we explain all the

approaches and discuss the advantages and dis-

advantages.

2 SAFETY STOCK-BASED SPIRP

MODEL WITH STORAGE

CAPACITY LIMITATION

POLICIES

The inventory routing system studied in this paper

consists of a single depot and a set of geographically

scattered retailers. The retailers are indexed by ,

(where is the total number of retailers)

and the depot is indexed by . Each retailer has a

stochastic independent demand rate of

per unit of

time, that is assumed to be approximately based on

Gamma distribution . Let be the set of

retailers indexed by and ; and

.

Let be the planning horizon

indexed by and

be the planning

horizon that includes period . Let

be the size

in time units of each period , for example eight

working hours per day. For the deliveries, a fleet of

vehicles

each with a capacity of

is available. The supplier and each retailer agree to

a service level (

) based on a predetermined

inventory violation rate of

during each period and

retailer, and

. Let be

the number of available silos for each retailer .

Additional parameters of the model are as follows:

: the fixed handling cost (in euros) per delivery at

location

(retailers and depot) in period .

: the per unit holding cost of the product at

location (in euros per ton) in period ;

: the fixed operating cost of vehicle (in

euros per vehicle per use);

: travel cost of vehicle (in euros per km);

: average speed of vehicle (in km per hour);

: duration of a direct trip from retailer

to

retailer

(in hours);

: the initial inventory levels at each retailer in

period zero;

The cost of using a silo for each retailer , in

period

: maximum capacity of each silo , for

retailer

The variables of the model are defined as follows:

: the quantity of product remaining in vehicle

when it travels directly to location

from

location

in period . This quantity equals

zero when the trip () is not on any tour of the route

travelled by vehicle in period t;

: the quantity delivered to location in period

;

: the inventory level at location by the end of

period ;

: a binary variable set to 1 if location

is

visited immediately after location

by vehicle

in period , and 0 otherwise;

: a binary variable set to 1 if vehicle is being

used in period , and 0 otherwise;

: a binary variable set to 1 if silo is being

used for retailer in period , and 0 otherwise;

The minimization objective function is:

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

218

(1)

Subject to:

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

The objective function (1) shows the variables to

minimize the level of costs in this replenishment

system. It includes five cost components, namely,

total fixed operating cost of using the vehicle(s), total

transportation cost, total delivery handling cost, total

inventory holding cost at the end of each period, and

total cost of renting silos at the retailers.

Constraints (2) assure that each retailer is visited

at most once during each period. Constraints (3)

guarantee that a vehicle moves to the next

retailer/depot after serving the current one.

Constraints (4) prevent that the time required to

complete each tour does not exceed the duration of

the period. The quantities to be delivered to each

retailer are determined by constraints (5). These

constraints also avoid sub-tour from occurring.

Constraints (6) are capacity constraints induced by

the vehicles capacities. Constraints (7) determine the

delivered number of products from period 1 to

together with the initial inventory to be equal to the

expected demand’s values from period 1 to , safety

stock, and remaining inventory at the end of period

for each retailer . Constraints (8) insure that the level

of inventory at the end of last period is equal or larger

than initial inventory. Constraints (9) determine the

optimum number of required silos for each retailer

during each period. Finally, constraints (11) specify a

vehicle cannot be assigned to serve retailers unless

the related fixed cost is payed.

Eq. (11) presents the safety stock calculation

model to be used in constraints (7).

As is specified by equation (11), safety stock is a

function of service level parameter (

), number of

time periods (), and standard deviation of demand

(

for each retailer ). The parameter

is the

service factor determined by retailer’s requested

service level (

%) gained by the level of

. It is

used as a multiplier with the standard deviation and

number of time periods to calculate a specific

quantity (as safety stock) to meet the pre-set service

level.

(11)

Optimizing Storage Capacity of Retailers in Stochastic Periodic Inventory Routing Problem

219

3 DIFFERENT APPROACHES

FOR STORAGE CAPACITY

ALLOCATION

We propose 4 different policies in this study. These

policies are suggested based on the requirements in

short/long term planning horizons and high

variability in demand rates to evaluate their

applicability in distribution systems. Different

industries have different preferences in renting a silo.

Therefore, presenting various strategies for silo

allocation could help the decision maker to decide

wisely. In the reminder four proposed policies for silo

allocation are modelled and described.

3.1 Fixed Number of Silos

This is the basic policy that allocates a certain number

of silos to the retailers during the whole planning

horizon. Equations (1)-(10) formulate the Safety

Stock-based SPIRP for this policy. Number of silos

are fixed from period 1 to the last period. It means the

maximum required silos need to be rented in the

beginning of the planning horizon based on the

expected level of inventory from the optimization

model.

In some distribution centres where the variability

of demand rates is high, and high level of service is

promised to the customers, it is better to rent a certain

number of silos for the whole planning horizon.

Therefore, there is less risk of having limited space

for the inventory during the planning horizon. The

calculated number of silos is based on the maximum

expected level of inventory, meaning there are some

periods that some silos are not full, but the rent must

be paid. The allocation of the silos to the retailers are

based on the rental fee, and the trade-off between

inventory/silo costs and transportation costs.

3.2 Fixed Cumulative

Fixed-cumulative approach optimizes the silo

allocation mechanism, in order to use the maximum

capacity of rented silos during the periods with low

inventory level at the retailers. In other words, the

cumulative level of inventory from the beginning to

period is taken into account instead of the level of

inventory for period . To have this strategy applied

in the Safety Stock-based SPIRP, constraints (9)

needs to be replaced by constraints (13). In

constraints (13) the inventory level for all the periods

from 1 to need to be smaller or equal to storage

capacity in one period multiplied by . Retailers with

higher variability in demand rates and/or long term

planning horizon are more convenient to have this

strategy for renting the silos, since for those retailer

the risk of having excess inventory/demand in long

term is compensated by other periods with lower

demand rate.

3.3 Flexible Number of Silos

In this policy the retailers are allowed to have

different number of silos for each period. It means the

number of silos are different during the planning

horizon, but 1the decision for each period is made

only based on the inventory for that period. It makes

the inventory costs as low as possible since there is

no need to pay the rent when the silo is not used.

Equation (12) involves this flexibility in the objective

function by summing up the silo fee costs for each

period. Therefore, the model selects the number of

silos for each period differently based on the

maximum inventory level on that period. Equations

(2-10) and (12), present the Safety Stock-based

SPIRP model with flexible storage capacity.

All these decisions are made before the planning

horizon, therefore this mechanism may cause risks for

the retailers in terms of stock-out occurrence.

Generally, the retailers with lower coefficient of

variation with short term planning horizon are more

preferred to apply this policy.

3.4 Flexible Cumulative

This mechanism is similar to Fixed-cumulative, with

this difference that in this policy the retailer does not

(12)

(13)

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

220

need to keep a certain number of silos for the whole

planning horizon. The idea is to be flexible in renting

the silos as well as involving the variability in

inventory level among the periods to minimize the

costs. Equations (2-8), (10), (12), and (13) present the

Safety Stock-based SPIRP model with flexible-

cumulative approach for silo allocation.

4 ILLUSTRATIVE EXAMPLE

We consider a distribution centre with 8 retailers.

There is a fleet of vehicles with 2 available vehicles,

each one with the capacity of 40 tons. The vehicles

work 8 hours per day with an average speed of 50

km/h. Fix and variable costs of the vehicles are

presented in table 1. The retailers are scattered

randomly around the warehouse. Distances between

retailers themselves and warehouse are shown in table

3.

Table 1: Some elements.

Notation

Parameter

Cost

Delivery costs

25

Inventory holding

costs per unit per period

0.5

Travel costs for

vehicle in Euro per KM

1

Fix operating cost

of vehicle

30

Average speed of

vehicle

50

The demand rate for each retailer is considered

stochastic and follows Gamma distribution and all the

stock-outs are fully backlogged. Table 2 presents the

demand rates for 8 hours (1 period) and standard

deviations as well as their coefficient of variations.

The rest of the parameters of this example are

provided in table 1. We use CPLEX 12.5.1 for solving

all models. All the computations are performed on a

3.60 GHz Intel® Xeon® CPU.

Table 2: Demand rate parameters per period.

Retailers

Average

demand

(ton/day)

Standard

deviation

(ton/day)

CV

()

()

1

1.507

1.228

0.81

1.507

1

2

0.979

0.989

1.01

0.979

1

3

0.498

0.706

1.41

0.498

1

4

3.455

1.859

0.53

3.455

1

5

11.596

3.405

0.29

11.59

1

6

0.497

0.705

1.41

0.497

1

7

3.278

1.811

0.55

3.278

1

8

5.747

2.397

0.41

5.747

1

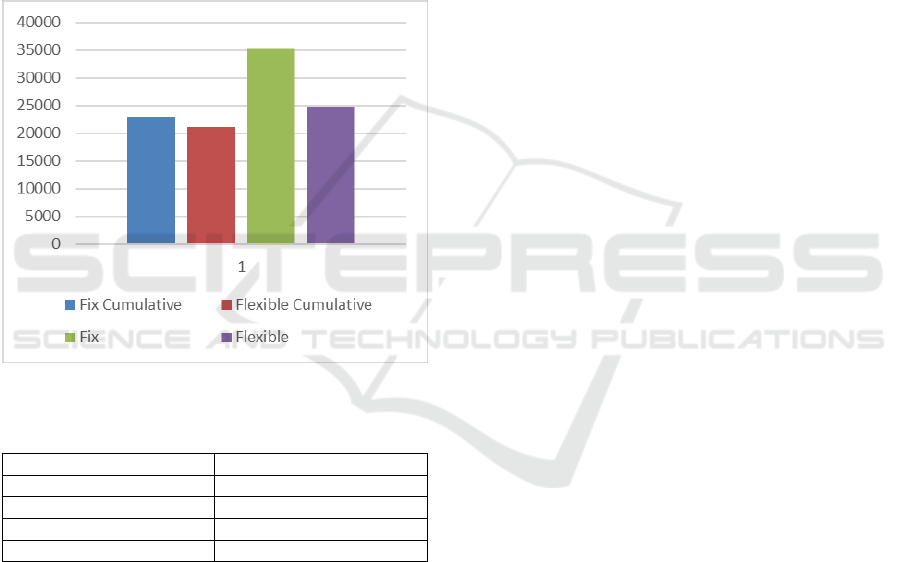

5 RESULTS AND DISCUSSION

The two indicators considered in this study are cost

level and computation time. Both indicators have

been measured and evaluated for the defined policies

in this example to clarify the differences. Figure 1

shows the expected costs for each policy during the

whole planning horizon. As mentioned in equations

(1) and (2), these costs are fixed and variable costs of

transportations, silos, and inventory. Figure 11 clearly

indicates the low level of cost for flexible cumulative

strategy while fixed strategy is the highest. Flexible

cumulative strategy has saved 40% of the expected

costs in this model, while flexible strategy reduces the

costs by almost 30%. The cumulative approach shows

a big improvement compared to periodic approach,

by allocating the silos and trucks properly as well as

minimizing the inventory level at the retailers among

the periods.

Table 3: Duration of a trip from retailer

to retailer

(in hour).

warehouse

c1

c2

c3

c4

c5

c6

c7

c8

warehouse

0

0.5001

0.9621

0.5155

0.3106

0.4601

0.5536

0.986

0.8472

c1

0.5001

0

1.3152

0.676

0.7533

0.2581

0.9052

1.4541

1.3465

c2

0.9621

1.3152

0

1.436

0.6586

1.0973

1.3068

1.4446

0.7826

c3

0.5155

0.676

1.436

0

0.7823

0.82

0.3225

0.9552

1.0698

c4

0.3106

0.7533

0.6586

0.7823

0

0.6161

0.7071

0.9266

0.644

c5

0.4601

0.2581

1.0973

0.82

0.6161

0

0.9775

1.4446

1.2525

c6

0.5536

0.9052

1.3068

0.3225

0.7071

0.9775

0

0.6329

0.7992

c7

0.986

1.4541

1.4446

0.9552

0.9266

1.4446

0.6329

0

0.4826

c8

0.8472

1.3465

0.7826

1.0698

0.644

1.2525

0.7992

0.4826

0

Optimizing Storage Capacity of Retailers in Stochastic Periodic Inventory Routing Problem

221

We also consider computation time for each

policy in order to verify the applicability of the

strategy, particularly for larger models. Table 4

presents the computation time per policy for the

whole distribution system. Fixed and flexible silo

allocation models need the minimum time among the

other strategies, while when the model is cumulative

in storage capacity allocation, the required time

becomes larger. Fixed cumulative approach needs 87

seconds to achieve the optimized solution, while it is

even more with Flexible Cumulative approach with

106 seconds. Higher computational time specifies the

model complexity level and computation difficulty

that results in lower interest to apply the complex

solutions for large systems.

Figure 1: Overall costs for each policy.

Table 4: Computation time per policy.

Policies

Time (seconds)

Fixed

20

Fixed cumulative

87

Flexible

23

Flexible Cumulative

106

According to the results of the illustrative

example, flexible approach has got the most

reasonable results for both computation time and cost

reduction. But if the model is small in size, the fix

cumulative approach seems more reasonable, since it

is more logical to rent a silo for the whole planning

horizon.

6 CONCLUSIONS

In this paper we considered Stochastic Periodic

Inventory Routing Problem with storage capacity

limitation. The proposed safety stock-based SPIRP

model involved storage capacity as a constraint in the

model to optimize it with regard to cost minimization.

Four different policies are proposed to deal with

storage capacity limitation at retailers. The

advantages and disadvantages of these approaches

have been discussed in this paper. Finding the balance

between transportation and inventory costs together

with the storage costs (silo rent) is the most important

factor in SPIRP model. Definitely it depends on the

value of product itself, silo fee, promised service

level, demand variability rate at the retailers, length

of the planning horizon, etc., to allocate silos to the

retailers. The illustrative example presented in this

paper has revealed the advantages of flexible model

among other policies. In addition for smaller

distribution centres, fixed cumulative approach seems

to be an appropriate strategy to optimize the storage

capacity. As for future research, the applicability of

these approaches will be evaluated in some

experimental cases with design of various

experiments based on the variables. In addition, their

impact on service level, inventory and transportation

costs, and computational time will be measured and

discussed.

REFERENCES

Aghezzaf, E. H. 2007. Robust distribution planning for

supplier-managed inventory agreements when demand

rates and travel times are stationary. J Oper Res Soc, 59,

1055-1065.

Bell, W. J., Dalberto, L. M., Fisher, M. L., Greenfield, A.

J., Jaikumar, R., Kedia, P., Mack, R. G. & Prutzman, P.

J. 1983. Improving the Distribution of Industrial Gases

with an On-Line Computerized Routing and

Scheduling Optimizer. Interfaces, 13, 4-23.

Bertazzi, L., Bosco, A., Guerriero, F. & Laganà, D. 2013.

A stochastic inventory routing problem with stock-out.

Transportation Research Part C: Emerging

Technologies, 27, 89-107.

Coelho, L. C., Cordeau, J.-F. & Laporte, G. 2014a.

Heuristics for dynamic and stochastic inventory-

routing. Computers & Operations Research, 52, Part A,

55-67.

Coelho, L. C., Cordeau, J.-F. & Laporte, G. 2014b. Thirty

Years of Inventory Routing. Transportation Science,

48, 1-19.

Federgruen, A. & Zipkin, P. 1984. A Combined Vehicle

Routing and Inventory Allocation Problem. Operations

Research, 32, 1019-1037.

Pujawan, N., Arief, M. M., Tjahjono, B. & Kritchanchai, D.

2015. An integrated shipment planning and storage

capacity decision under uncertainty A simulation study.

International Journal of Physical Distribution &

Logistics Management, 45, 913-937.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

222

Stacey, J., Malini, N. & Charles, S. 2007. The storage

constrained, inbound inventory routing problem.

International Journal of Physical Distribution &

Logistics Management, 37, 484-500.

Yadollahi, E., Aghezzaf, E. H. & Raa, B. 2017. Managing

inventory and service levels in a safety stock‐based

inventory routing system with stochastic retailer

demands. Applied Stochastic Models in Business and

Industry.

Optimizing Storage Capacity of Retailers in Stochastic Periodic Inventory Routing Problem

223