Optimization Parameters for Laser-induced Forward Transfer of

Al and Cu on Si-wafer Substrate

Mohammad Hossein Azhdast

1

, Hans Joachim Eichler

1

, Klaus Dieter Lang

2

and Veronika Glaw

2

1

Institute of Optics and Atomic Physics, Technical University of Berlin, Ernst-Ruska-Gebäude, Berlin, Germany

2

Institute of Electrical Engineering and Computer Science, IZM Fraunhofer, Gustav-Meyer-Allee 25, Berlin, Germany

Keywords: Laser, Material Processing, Laser Direct Writing, Nano Particle Deposition.

Abstract: The research goal is to perform a laser-writing study to deposition of micro/nano particles on the substrate

as interconnection usage. The threshold of laser energy, pulses per laser shot, as well as pulse overlapping is

crucial to achieve the best deposition results possible. The present study aims to the novel technique by laser

deposition of Aluminium and Copper nano particles on silicon wafer substrate. Thin µm films have been

deposited from one-side coated glass to Silicon wafers by sputtering nano particles using laser radiation.

Distance between donor film and substrate (ε) was up to several 100 µm and it has been optimized as 300

µm. A step-by-step optimization guide for deposition parameters were first developed and presented. The

identification of laser energy threshold, pulses per laser shot, in addition to pulse overlapping is essential if

the best deposition results are going to be drawn by laser direct writing method. This technique is regarded

as the most important direct-write alternative for lithographic processes in order to generate patterns with

high-resolution.

1 INTRODUCTION

The goal of this thesis is to perform a complete

study of Laser deposition, structuring, and adhesion

mechanism as one of the generative manufacturing

processes with laser radiation. One of the methods of

making thin films is sputter deposition. This

procedure is a process that particles will be ejected

from the material owing to bombardment of the

solid target by energetic atoms.

The deposition of nano particles is demonstrated

by the preparation of an Under Bump Metallization

(UBM); although, the laser sputtering technique may

be used for a multitude of other applications like:

bonding technology for microelectronics, as well as

micromechanical and micro-optical devices and

components (Craig, 2007 and Pique, 2008). Copper

and Aluminium based on their chemical properties

and different reflectivity, have similar reactions in

Infra-red laser for material processing and different

behaviour in other laser wavelengths (Azhdast, 2017

and Golnaz, 2008).

For large-scale manufacturing situations, where

the parallel creation of identical patterns is essential,

pattern-transfer techniques (PTT) are the most

economical choice. Here, the pattern of interest is

produced onto the substrate in one step at the same

time. Micro contact printing (MCP) as well as a

photolithography (PL) is considered the most widely

applied PTT. Especially photolithography benefitted

enormously from recent technological advances such

as the launch of extreme UV light sources, which

enabled the production of nano structures. However,

for both of these techniques, MCP and PL, a number

of disadvantages are to be taken into account.

This printing process includes three steps; (1) to

ablate material from donor glass with a focused laser

pulse. (2) Transition of ablated particles from

acceptor to receiver substrate. (3) Deposition of

transferring material to be adhered onto the acceptor

substrate (Bera, 2007 and Wartena, 2004).

2 PROCESS EXPLANATION

The procedure type which has been used in this

paper is to deposition nano metal particle by direct

laser radiation from one side coated glass as a donor.

Neither mask nor ultra- violet light source will be

used in nano particle printing, which is so expensive

and they are time consuming method. Compared to

228

Azhdast, M., Eichler, H., Lang, K. and Glaw, V.

Optimization Parameters for Laser-induced Forward Transfer of Al and Cu on Si-wafer Substrate.

DOI: 10.5220/0006627702280231

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 228-231

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

photo lithography techniques, main advantages

include higher flexibility, minimal number of

process steps and also no requirements of masks. An

Infra-red Nd:YAG laser with 8 picosecond pulse

duration and frequency doubled (λ=515 nm) are

used for tests. Photons are more energetic with

shorter laser wavelengths and they are easier to be

absorbed by the materials than photons with longer

wavelengths. To decrease the permeation of particles

in test substrate and to prevent the diffusion and

desorption stages in thin film production, additional

high density inorganic layer is used to control the

process in adsorption and absorption in deposition

level (Lianwei, 2014 and Salminen, 2013). High

laser power with short pulses cause very little

thermal influence on the substrate. As it can be seen

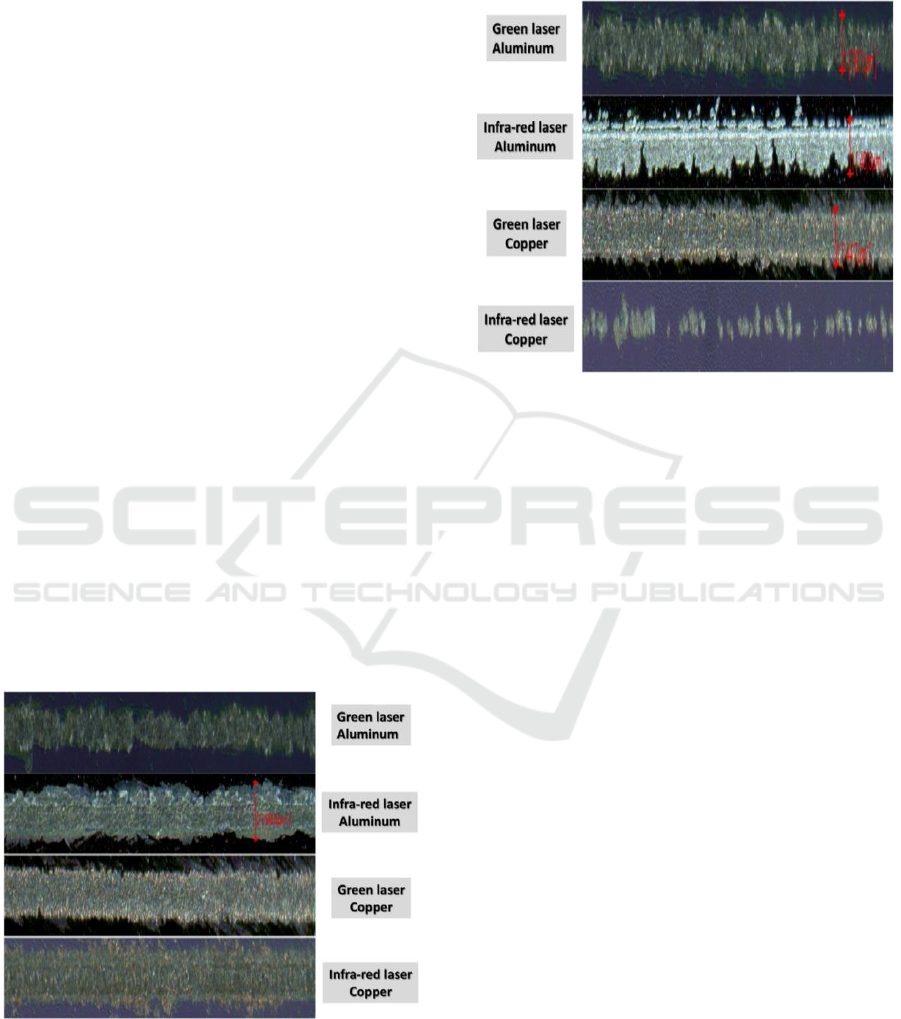

in Figure1 (a) and (b), four lines are made with laser

direct writing method. Distance between each laser

shot has been optimized by 10µm, 9 pulses per each

position and the 100 KHz repetition rate for left and

40 KHz for the right pictures. Pulse energy for both

lasers with 40 KHz repetition rate is measured as

137 µJ. The first line in the picture is made by

aluminium particles as donor with frequency

doubled laser (λ=515nm) which are deposited on the

substrate. In the second line infrared laser (λ=1064)

is used for aluminium particles as well. In the third

and fourth lines, copper is used for positioning of

nano particles with green and IR laser respectively.

The pulse energy of the IR laser for aluminium and

copper with 100 KHz repetition rate and 7W output

power is calculated as: 69.5 µJ. The laser intensity

with 1.064 µm wavelength for aluminium and

copper was: 245 KW/cm².

Figure 1(a): Deposition of Al & Cu by laser wavelengths-

100 KHz repetition rate.

The silicon wafer has passivized by silicon

nitride layer in order to decrease the permeation of

particles in Si-wafer substrates and to prevent

diffusion phenomenon. The coating thickness of

aluminium and copper was 500nm on a normal

glass with 250mm diameter and 1.1mm thickness.

Figure 1(b): Deposition of Al & Cu by laser wavelengths-

40 KHz repetition rate.

3 OPTIMIZING PULSES PER

SHOT AND OVERLAPPING

In this step pulses per laser shot are subject to

optimization. It was determined that a repetition rate

of greater than 80 KHz achieves good results

(Azhdast, 2015; 2016). Hence, a repetition rate of

100 KHz was used in this optimization step since the

overlapping has not been optimized yet, it is set to

80% for this step. The pulses per shot were changed

from 1 to 40 for deposition of Al on Si-wafer with

silicon nitride passivation. Al has a relatively high

and constant reflectance in the visible and infrared

wavelength range. Figure 2 (a) and (b) show the

results for pulses per shot in the range of 7 to 13. It

can be perceived that for less than 8 pulses per shot

the particles are not sputtered well on the substrate

in which case the samples later fail the adhesion tape

test. For 8 to 9 pulses a good deposition can be

observed. By increasing the number of pulses to

more than 15, the high energy leads to an impaired

layer on the substrate. The findings from Al can be

confirmed on Cu as optimal results are found for 8

to 9 pulses per shot as well.

Optimization Parameters for Laser-induced Forward Transfer of Al and Cu on Si-wafer Substrate

229

Figure 2(a): Pulses per shot in Aluminium.

Figure 2(b): Pulses per shot in Copper.

Finally the overlapping is subject to

optimization. Knowing from the previous step that 9

pulses per shot achieve good results, this parameter

setting was used in this step. The distance between

shots is changed from 1-40 µm.

Figures 3 illustrate that a distance of 10-11µm

produces perfect lines with smooth edges. The lines

are nickel plated in place of better coalescence. For

distances well above 20µm distortion on the edges

can be clearly noticed. The optimal distance between

shots for copper is very similar as shown in figure

3(b). It can be concluded that 80% overlapping

guarantees the production of perfect lines. With less

than 10µm distances between each laser shot, the

lines have more overlap which can be seen in the

pictures after nickel plating. The diffusion layer

occurs when the distances between each laser pulses

are too less.

Figure 3(a): Overlapping of laser shots; Aluminium.

Figure 3(b): Overlapping of laser shots; Copper.

4 CONCLUSIONS

A large number of techniques can be implemented to

precipitate a thin layer of film on a surface. Pulsed

laser energy should be higher than the threshold

energy in order to have the transmission of particles

from the coated side of the glass in/on to the target.

The chosen technique of thousand seeds, allow for

further investigation and additional optimization. It

has been found that the smallest features which are

ablated from a donor, obtained at a fluence level just

above the printing threshold for the sample. This

printing threshold is dependent on the sample

thickness, quality of focus, and duration of the laser

pulse as well as laser intensity. Copper in

comparison with aluminium, has a good wettability

for both different laser wavelengths. Nevertheless,

too high pulse energy at 40 KHz makes an uneven

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

230

implanted surface. It is obvious that the quality of

lines with lower intensity is not as well as higher

ones. The higher laser intensity would cause more

permeation of particles in the solid membrane and

makes desorption structure of the layer. The printing

threshold for the 500 nm thick donor sample for

copper and aluminium were found to be 83 µJ and

87µJ for the 8 ps pulses respectively.

REFERENCES

Azhdast M. H, 2017. Comparison of nano particle

implantation with picosecond lasers by concerning

different wavelengths from Aluminum and Copper on

Silicon wafer substrate, Conference on Lasers and

Electro-Optics, OSA Technical Digest.

Golnaz B. J., 2008. Investigation of the near surface

mechanical properties of Au-Ti thin films,” Master

thesis, Oklahoma State University.

Azhdast M. H., 2017. Deposition of Al and Cu

nanoparticles on Silicon Wafer using a Picosecond

Nd:YAG Laser: An Experiment-based Parameter

Optimization Guide, Conference on Lasers and

Electro-Optics, OSA Technical Digest.

S Bera S., 2007, Optimization study of the femtosecond

laser-induced forward-transfer process with thin

aluminum films, Appl. Opt. 46, 4650-4659.

Wartena R, 2004., Li-ion microbatteries generated by a

laser direct-write method, Nava research Laboratory,

Journal of Power Sources 126 193–202.

Lianwei C., 2014. Tuning Optical Nonlinearity of Laser-

Ablation-Synthesized Silicon Nanoparticles via

Doping Concentration, Journal of Nanomaterial,

National University of Singapore, Singapore.

Salminen T., 2013. Production of nanomaterial by pulsed

laser ablation, PhD thesis, Tampere University of

technology, Tampere, Finland.

Azhdast M.H., 2015. Arrangement for applying

conductive nanoparticles onto a substrate, Patent

publication number: WO2015117872A1.

Azhdast M. H., 2016. Adhesion mechanism between laser

sputtered Aluminum nano particles on Si-Wafer by

Nd:YAG laser, Conference on Lasers and Electro-

Optics, OSA Technical Digest.

Azhdast M.H., 2015. Nano particle production by laser

ablation and metal sputtering on Si-Wafer substrate,

Conference on Lasers and Electro-Optics, OSA

Technical Digest.

Craig B., 2007. Laser Direct-Write Techniques for

Printing of Complex Materials, MRS BULLETIN, Vol.

32.

Pique A., 2008. Laser Decal Transfer of Electronic

Materials with Thin Film Characteristics, Naval

Research Laboratory, 4555 Overlook Avenue, SW,

Washington, DC, USA 20375

Optimization Parameters for Laser-induced Forward Transfer of Al and Cu on Si-wafer Substrate

231