Multi-Concerns Engineering for Safety-Critical Systems

Philipp Lohm

¨

uller, Andrea Fendt and Bernhard Bauer

Institute of Computer Science, University of Augsburg, Universit

¨

atsstr. 6a, 86159 Augsburg, Germany

Keywords:

Safety-Critical Systems, Dependability, Tradeoff Analysis, Multi-Criteria Decision Analysis, Multi-Concerns.

Abstract:

Modern cars are equipped with a large number of electronic assistance systems such as Adaptive Cruise Con-

trol (ACC) to improve road safety and driving comfort. These systems require a complex cross-linking, both

inside and outside the vehicle, e.g., by means of bus systems or wireless interfaces like Bluetooth. Thus, safety

of road users can endangered if the communication between these systems failed. Communication failures can

be affected by hacking attacks, e.g., delayed decelerating of an ACC system, thereby presenting a security and

timing vulnerability endangering safety of road users. Hence, in this paper safety is considered as primary

goal. Goals that contribute to achieve the primary goal can be in contradiction to each other under certain

circumstances. Therefore, an approach is proposed to model Safety, Security and Timing (SST) constraints to

guarantee maximum safety. Furthermore, a preventative risk assessment of the individual concerns including

a tradeoff analysis is performed to enable the development of Safety-Critical Systems (SCS).

1 INTRODUCTION

The development of safety critical embedded systems

involves the consideration of certain requirements and

objectives. Objectives include essential safety, secu-

rity and real-time demands, which do not only vary in

their importance, but usually are even partially con-

flicting. Consequently, amendments made on behalf

of a safety or security target possibly introduce or in-

tensify other threats. Thus, fixing a safety or security

vulnerability might introduce significant safety prob-

lems. For instance, modern vehicles are equipped

with various wired and wireless interfaces. According

to the automotive industry, wireless communication

of vehicles will increase tremendously in the future by

introducing car-to-car and car-to-infrastructure com-

munication. By broadcasting most current and very

important information to neighboring vehicles, e.g.,

hazard warnings, weather conditions or traffic news,

road safety can be increased significantly. Wireless

communication comes at the cost of a massive risk of

hacking attacks, representing a severe issue for secu-

rity as well as safety, since the majority of car func-

tionalities are highly safety critical. Even a minor

interference can result in serious consequences, due

to strong functional interdependencies [Nilsson et al.,

2008]. Although wireless car-to-x communication

can provide a significant safety improvement it also

introduces new security and safety issues by increas-

ing the vulnerability for hacking attacks. Amend-

ing the problem by using a secure encryption for the

wireless communication might jeopardize timing con-

strains, since encryption comes at the cost of addi-

tional processing load. When confronted with such

conflicting SST objectives, it is most important to an-

alyze proposed solutions comprehensively and to take

all potential side effects of a particular design into

account. This might reveal unresolvable contradic-

tions, affording a transparent and traceable tradeoff

analysis. In the course of this paper an approach is

presented to analyze SST issues systematically, struc-

turing them hierarchically and performing a tradeoff

analysis on them.

2 APPROACH

The Multi-Concerns Engineering (MCE) process is

relevant in the design phase of SCS, when important

design decisions regarding unresolvable contradicting

SST issues have to be evaluated. In this paper we pro-

pose a comprehensive process of trading off conflict-

ing SST requirements:

1. Devise potential alternative system designs

2. Identify and structure SST objectives

3. Perform a Failure Mode and Effects Analysis

(FMEA)

4. Apply an MCDA to find the safest solution

504

Lohmüller, P., Fendt, A. and Bauer, B.

Multi-Concerns Engineering for Safety-Critical Systems.

DOI: 10.5220/0006631705040510

In Proceedings of the 6th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2018), pages 504-510

ISBN: 978-989-758-283-7

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

When confronted with contradicting SSTs in the

design phase of an SCS, several competing system

models are developed. This approach helps to evalu-

ate the alternative solutions regarding potentially con-

flicting SST issues, to identify the best tradeoff and

to reveal individual vulnerabilities of a solution. For

instance, when trying to find the best solution for

a vehicle’s ACC, one might consider several sensor

types, data encryption mechanism or maximum al-

lowed cruising speeds.

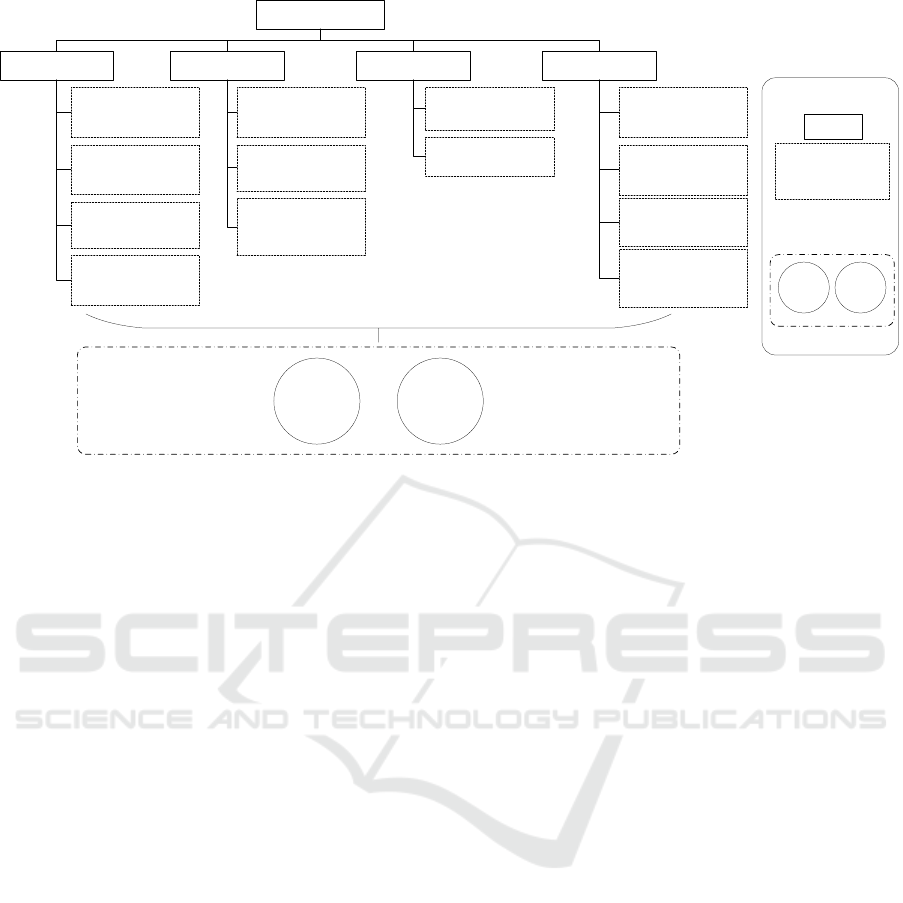

Subsequently, these insights are transferred into

a standardized Safety Goal Hierarchy (SGH), which

builds the basis for the actual FMEA risk assessment.

For a clear graphical representation, the SGH makes

use of the Goal Structuring Notation (GSN) as pro-

posed by Tim Kelly and Rob Weaver in [Kelly et al.,

2004]. The strength of GSN is to present the goals

while preventing various possible failures in a stan-

dardized, structured and understandable manner, em-

phasizing their relationships and revealing potential

goal conflicts.

A promising approach for resolving goal conflicts

in the design of safety critical systems is to rate safety

as primary goal and considering security and tim-

ing objectives as subordinated goals that might affect

safety concerns. Therefor an SGH is always initiated

with a top-level goal: Assuring that the system is ac-

ceptably safe which has to be decomposed into more

concrete subgoals regarding the system under devel-

opment, usually including security requirements and

real-time constraints.

Based on the definition of different solutions the

potential risks of failure for each alternative have to

be identified by means of the FMEA. The FMEA is

a well accepted method for identifying and prevent-

ing or reducing potential risks of failure associated

with an arbitrary system or process preemptively. [Liu

et al., 2016] It’s first step is to answer the following

questions: ”What can go wrong?”, ”Why did this fail-

ure occur?” and ”What would be the impact of the

identified failure?” After having identified potential

failure modes and their causes, they are integrated

into the SGH already prepared. Possibly the SGH

designed in advance has to be extended to include

aspects that have not been considered so far. That

means, refining the SGH until each potential failure

mode is represented by a goal on the lowest level (1).

Note that the goal structure can be arbitrarily complex

and nested, while always ending at the Single Point of

Failures (SPOFs).

Afterwards the risk associated with each SPOF

has to be evaluated. The FMEA measures this risk by

three factors, denoted as OSD in the following: the

Occurrence (O) is the likelihood of a failure to oc-

System is

acc. safe

Prevent

SPOF 1

Prevent

SPOF 2

Subgoal 1 Subgoal 2 Subgoal 3

Subgoal 2.1

Subgoal 2.2

Prevent

SPOF 3

Prevent

SPOF 4

Prevent

SPOF 5

Prevent

SPOF 6

Prevent

SPOF 7

Prevent

SPOF 8

Prevent

SPOF 9

Figure 1: Exemplary SGH.

cur, the Severity (S) the impact a failure can have and

the Detection (D) denotes the probability that a fail-

ure will be detected. Each of these criteria is assigned

an integer value between 1 and 10, whereas 1 stands

for the lowest probability of occurrence, the lowest

impact or the highest probability of detecting the fail-

ure (vice versa for 10). The detailed ratings and their

interpretations can be looked up at [Bundesminis-

terium des Inneren, 2017]. Then the risk evaluation of

OSD is aggregated to a Risk Priority Number (RPN)

by multiplying the ratings: RPN = O × S × D. Al-

though this simple aggregation has been reasonably

criticized, e.g., in [Bowles, 2003], the RPN evalua-

tion is a compulsory requirement of software devel-

opment for the automotive industry. A more sophisti-

cated aggregation mechanism will be presented in 3.1.

According to the RPN potential failures are classified

into risk levels. For RPNs of 50 or more, actions on

behalf of risk mitigation or risk reduction are manda-

tory, this usually means to change the system design

or exclude potentially dangerous use cases. These

changes might introduce new threats or intensify ex-

isting ones. Therefore the whole FMEA has to be

repeated to assure that the amended system accom-

plishes an acceptable risk level. [Bundesministerium

des Inneren, 2017]

In order to identify the safest, realizable imple-

mentation, an adapted version Saaty’s Analytic Hier-

archy Process (AHP) [Saaty, 1990] is applied to the

SGH. The AHP is a Multi-Criteria Decision Analy-

sis (MCDA) method, that calculates the best compro-

mise based on a structured goal hierarchy and com-

parison matrices, that asses the relative importance of

the goals for their common super-ordinated objective.

Creating a comparison matrix (also called pairwise ra-

tio matrix) means to rate the relative importance for

every pair of subgoals, when they are directly com-

pared to each other. The AHP proposes to set ratings

between 1 and 9, where 1 means that the two com-

pared subgoals are equally important and 9 means that

the objective rated with 9 is extremely more important

for it’s super-ordinated goal than the other one [Saaty,

1990]. Inconsistent ratings can be introduced eas-

Multi-Concerns Engineering for Safety-Critical Systems

505

ily, for example by setting non-transitive comparison

judgments. However, the ratings are not required to

result in a fully transitive judgment, since this can

hardly be achieved for more than three subgoals by

human decision making and usually is impossible for

the whole number of ratings. Therefor, only a certain

degree of consistency is required, the so called Con-

sistency Ratio [Saaty, 1990]. In literature several al-

gorithms for identification of inconsistent ratings can

be found, e.g. [Harker, 1987].

Based on the pairwise comparison matrix, local

priorities, i.e., the importance of subgoals contribut-

ing to their super-ordinated objective, can be calcu-

lated using the eigenvector of the matrix AHP. These

local priorities are used to calculate the global priori-

ties of the single points of failure, meaning the abso-

lute importance of the objectives on the lowest level

for reaching the top-level safety goal. In the next step

we have to determine how well the alternative solu-

tions fulfill the objectives of preventing SPOFs. Since

this has already been evaluated with the FMEA, hav-

ing ratings between 1 and 10 for failure OSD, FMEA

judgments only have to be transfered into suitable

AHP pairwise comparison ratios which can be done

automatically. Two suitable transformation meth-

ods, namely RPN Comparison Method (RCM) and

Pairwise Comparison Method (PCM), will be pre-

sented. Thereby RCM directly uses the RPN calcu-

lation. Therefor, the FMEA ratings of alternative so-

lutions are compared by normalizing their inverse ra-

tios. The resulting local priorities in form of percent-

ages of importance, can be used directly by the AHP

to calculate global priorities for proposed alternative

solutions. The result is a weighted prioritization of the

alternative solutions, identifying the one which best

fulfills the SST objectives.

O S D RPN

S

1

o

1

s

1

d

1

r

1

S

2

o

2

s

2

d

2

r

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

S

n

o

n

s

n

d

n

r

n

For RCM, a vector of RPNs a = (r

1

, r

2

, ..., r

n

) is ex-

tracted from the matrix above. Subsequently, the in-

verse vector of a is created: a

−1

= (r

−1

1

, r

−1

2

, ..., r

−1

n

).

Then, a

−1

is normalized by the formula: α =

1

∑

i=n

i=1

r

−1

i

.

Finally, the local priorities π(S

i

) for every alternative

solution S

i

are derived by: π(S

i

) = r

−1

i

· α.

The RCM directly reflects the RPN values in the

tradeoff analysis and its calculation is quite simple,

whereas PCM is much more related to AHP. More-

over, it does not depend on the flawed RPN calcula-

tion, as it is directly based on OSD ratings, whereas

PCM allows a much more flexible and accurate con-

sideration of FMEA judgments. For the PCM, first of

all the FMEA ratings for OSD of the potential fail-

ure modes have to be judged in their relative impor-

tance for the criticality of a failure. Therefor we de-

fine a so called OSD-Matrix, that is kept constant for

all SPOFs. It is a simple judgment matrix comparing

the importance of OSD on behalf of safety. By de-

fault it is an all-one matrix, which would imply that

OSD are considered equally important. In a second

step, the FMEA ratings for the alternative solutions

have to be transformed into judgment matrices. Since

the values of OSD are multiplied with each other to

determine the RPN, higher ratings result in exponen-

tially higher RPNs. To reflect this characteristic in the

matrices of pairwise ratios a cubic function is used to

transform OSD ratings: Let X be one of the ratings

X ∈ {O, S, D} and x

i

∈ {o

i

, s

i

, d

i

} for i ∈ {1, 2, . . . , n},

then each rating is transformed by x

0

i

= x

3

i

for all x

i

.

By raising the rating to the third power, the multipli-

cation that would have been made when calculating

the RPN is approximated. Again the inverse ratios

of the transformed judgments have to be used, since

higher OSD ratings represent a higher risk of failure

and though a worse, i.e., a lower, AHP judgment. The

three pairwise ratio matrices are calculated as follows:

S

1

S

2

·· · S

n

S

1

1

x

0

2

x

0

1

·· ·

x

0

n

x

0

1

S

2

x

0

1

x

0

2

1 ·· ·

x

0

n

x

0

2

.

.

.

.

.

.

.

.

.

.

.

.

S

n

x

0

1

x

0

n

x

0

2

x

0

n

·· · 1

Prevent SPOF

Occurrence Severity Detection

Solu-

tion 1

Solu-

tion p

Solu-

tion 2

. . .

Figure 2: PCM: Goal Hierarchy Extension.

Obviously, this is a consistent reciprocal matrix. To

determine the local and global priorities with the

AHP, the goal hierarchy has been extended at every

SPOF (2). The regular AHP algorithm can be ap-

plied on this extended goal hierarchy to find the safest

tradeoff between evaluated alternative solutions.

3 EVALUATION

In this section the position paper brings a real ap-

plication example that includes the whole approach

MODELSWARD 2018 - 6th International Conference on Model-Driven Engineering and Software Development

506

of the tradeoff analysis more closer. Furthermore,

a szenario based evaluation is performed that cov-

ers three szenarios applying the approach presented

in this paper.

3.1 Application Example

The tradeoff analysis is operated by means of a self-

developed Eclipse plugin enabling automated calcu-

lations and graphical visualizations. The work flow

presented in 2 thereby serves as a basis. It is analyzed

which kind of ACC system, the ACC with a maxi-

mum permissible speed of 210 km/h or 160 km/h,

complies the safety requirements more. With com-

mon sense it can be concluded that the ACC with a

maximum permissible speed of 160 km/h is safer than

the other one. Thus, the alternative solutions are ex-

tended to an ACC (210 km/h) with Radar + Camera

and 256 bit Encryption as well as an ACC (160 km/h)

with Radar and 128 bit Encryption. The next step in-

cludes designing (sub-)goals and SPOFs for an ACC

being acceptably safe. For that purpose subgoals are

designed aiming at correctly working sensors, actua-

tors, software and the communication between them.

All these subgoals are split in two or more SPOFs.

For instance, in case of subgoal ACC Actuators are

working correctly there are two SPOFs: Brake fail-

ure is sufficiently mitigated as well as Engine failure

is sufficiently mitigated. The complete goals as well

as all associated SPOFs (marked with the individual

concerns) are illustrated in a GSN hierarchy (3) where

each of the SPOFs is connected with the two afore-

mentioned alternative solutions.

For each SPOF, it is mandatory to perform FMEA

risk assessments, i.e., RPN values must be calculated

based on OSD probabilities. The exemplary assess-

ment of the SPOF Missing an obstacle can be ruled

out with sufficient certainty is listed in 1. All deter-

mined RPN values can be found in 3 assigned to the

respective SPOF. Since there are SPOFs with associ-

ated RPNs values that will endanger safety risk sig-

nificantly, improvements according RPN calculations

have to be performed.

Table 1: FMEA risk assessment of the SPOF.

O S D RPN

ACC 210 km/h 1 9 6 54

ACC 160 km/h 2 8 6 96

With the completion of the risk assessments it is

necessary to rate (sub-)goals and SPOFs by their im-

portance according to the AHP algorithm in [Saaty,

1990]. The AHP rating of the top goal can be seen

in 2. It can be observed here that ACC communica-

tion is acceptably reliable is more important than all

the other goals. Hence the local priority for the com-

munication (Comm. in 2) is better than for the sen-

sors, actuators (Act.) and software (SW). Since the

resulting maximum consistency ratio has not been ex-

ceeded, no further improvements are required.

Table 2: AHP rating of the goal ACC is acceptably safe.

Act. SW Sensor Comm.

Act. 1 1 1

1

2

SW 1 1 1

1

2

Sensor 1 1 1

1

2

Comm. 2 2 2 1

Local Prio. 20% 20% 20% 40%

Consis. Rat.: 0%

Finally, the tradeoff analysis can be done compar-

ing local priorities of the RCM and PCM method (4).

By applying the PCM the judgments of OSD were

changed according to 3.

Table 3: OSD Matrix of the PCM.

O S D Local Priority

O 1 2 5 58,2%

S

1

2

1 3 30,9%

D

1

5

1

3

1 10,9%

The results show that the ACC (210 km/h) with

Radar + Camera and 256 bit Encryption is safer than

the ACC (160 km/h) with Radar and 128 bit Encryp-

tion. As can be seen there is no significant difference

between the two methods.

Table 4: Global priorities of the alternative solutions.

Alternative Solution RCM PCM

ACC 210 km/h 54,4% 56,2%

ACC 160 km/h 45,6% 43,8%

3.2 Szenario based Evaluation

Three additional scenarios are evaluated:

1. The approach is also compatible with other risk

assessment methods than FMEA. Therefore,

Fault Tree Analysis (FTA) has been analyzed.

2. Changes on the system model effect changes on

the approach. Therefore, the ACC system is com-

plemented by a Lane Assist (LA) system. It is

evaluated which parts are concerned and how to

solve upcoming problems.

Multi-Concerns Engineering for Safety-Critical Systems

507

ACC is acceptably safe

ACC Sensors are working

correctly

ACC Software is working

correctly

ACC Actuators are

working correctly

ACC communication is

acceptably reliable

Brake failure is sufficiently

mitigated (SA)

27 27 88,9%

Engine failure is sufficiently

mitigated (SA)

21 21 11,1%

Results are correct. Errors

are sufficiently mitigated.

(SA)

90 90 40,0%

Results are calculated in

time. Delays are sufficiently

mitigated. (TI)

100 100 40,0%

Software acceptably secure

against manipulation and

hacking attacks (SE)

162 81 20,0%

Missing an obstacle can be

ruled out with sufficient

certainty (SA)

54 96 38,8%

Distance to the obstacle is

acceptably accurate (not too

short) (SA)

48 90 8,0%

The probability of detecting

an obstacle in time is

acceptable. (TI)

80 70 38,5%

Detecting a non existing

obstacle can be ruled out

with sufficient certainty (SA)

45 45 14,7%

Communication is

acceptably secured against

data theft (SE)

180 90 10,0%

Communication is

acceptably secured against

manipulation (SE)

72 144 30,0%

Messages arrive in time with

acceptable reliability (TI)

48 48 30,0%

Messages are transferred

correctly with acceptable

reliability (SA)

48 48 30,0%

ACC (210 km/h)

with Radar +

Camera, 256 Bit

Encryption

ACC (160 km/h)

with Radar, 128

Bit Encryption

any Goal

any SPOF

RPN ACC 160 km/h

RPN ACC 210 km/h

Local Priority

Legend

Note: Solutions relate to

all SPOFs

any

Solution

any

Solution

2

(SA) Safety

(SE) Security

(TI) Timing

Figure 3: Abstract goal hierarchy of the application example.

3. The approach is scalable as required, i.e., the SGH

and alternative solutions are expandable. For eval-

uation alternative solutions will be modified.

The fundamental difference between FMEA and FTA

is that FMEA lists the probability of OSD based on

a SPOF whereas FTA lists all events that lead to a

SPOF. This means that FMEA calculates the risk

top-down whereas FTA calculates the corresponding

risk bottom-up. Another difference is, that FTA deter-

mines the percentage probability that the correspond-

ing SPOF applies whereas FMEA determines the re-

sulting RPN. As stated in 2 there are two methods for

calculating the tradeoff: RCM and PCM. If the RCM

method is applied with FMEA the tradeoff is calcu-

lated based on the ratio between the current RPN and

the maximal possible RPN whereas for FTA this is

done based on the ratio between the current proba-

bility and the maximal possible probability that the

SPOF occurs. Even though the PCM algorithm is ap-

plied the tradeoff can be calculated using FTA risk

assessment. In contrast to FMEA, FTA does not need

any priorities for calculating the tradeoff, i.e., a classic

AHP can be performed for calculation. It is therefore

possible to apply any other risk assessment method if

probabilities are assigned to the SPOFs.

The second scenario proves stability if some

changes on the system model are made, i.e., im-

pact analyses must be performed [Langermeier et al.,

2015]. Due to the rapid development in the auto-

motive industry, new assistance systems occur from

time to time and hence, new hardware and software

must be installed in the car. This involves changes

ton the system model and thus also the safety risk

which makes it necessary to update the SGH. Assum-

ing there is an additional LA system, a new subtree

LA is acceptably safe with all its subgoals and SPOFs

must be created. In the same way as the ACC the LA

considers goals and SPOFs with respect to sensors,

actuators, software as well as the communication be-

tween them. Pairwise comparisons as well as the risk

assessments must be performed in accordance with 2.

Finally, a new top goal ACC and LA are acceptably

safe must be created that combines the two subtrees,

including a pairwise comparison between the ACC-

and the LA subtree.

In practice, there are some regulations regarding

software and hardware that are given by certification

authority, impacting the SGH or alternative solutions

[Langermeier et al., 2015]. Scenario 2 already cov-

ered scalability of the SGH indirectly, hence, objec-

tive of this scenario is to change alternative solutions

and to evaluate it. Assuming there is an SGH cov-

ering an LA system, the certification authority stipu-

lates the minimal resolution of the installed cameras.

Thus, alternative solutions have to be adapted with

the new resolution and risk assessments between all

SPOFs and the updated alternative solutions must be

set again before calculating the updated tradeoffs.

4 RELATED WORK

In this section, related publications and projects will

be presented and compared with the approach of a

tradeoff analysis on SCS.

MODELSWARD 2018 - 6th International Conference on Model-Driven Engineering and Software Development

508

4.1 Safety Assessment with the AHP

and the FMEA

The AHP by Thomas L. Saaty [Saaty, 1990] is used

for making decisions regarding safety in various do-

mains, e.g., in [Jianbin et al., 2009], [Wang et al.,

2011] and [Cheng et al., 2011]. However, the AHP

is also used for making decisions based on security

concerns, e.g., in [Ji et al., 2010] and [Taha et al.,

2014]. A tradeoff analysis on behalf of safety, con-

sidering security and timing concerns as well as func-

tional demands does not seem to have been evaluated

scientifically before and is therefore unique in liter-

ature. Although the AHP is also used for making

decisions on security concerns, e.g., [Jianbin et al.,

2009] and [Taha et al., 2014] a tradeoff analysis on

behalf of safety, taking security and timing issues

as well as functional demands into account doesn’t

seem to have been evaluated scientifically before and

is therefore unique in literature. A fairly similar ap-

proach, performing a tradeoff analysis on behalf of

safety that combines the FMEA with the AHP, is the

work of [Zhao et al., 2013]. They focus on analyzing

the reliability of manufactoring processes by means of

the Process Failure Mode Effect and Critically Anal-

ysis (PFMECA), enhanced by the AHP. This method

has solely been designed for analyzing safety in man-

ufacturing processes. The method proposed in this

paper can be applied to any SCS, product or process.

4.2 Related Projects on Safety and

Security

There is a project which is important to be consid-

ered: SESAMO (Security and Safety Modelling).

Although it pursues quite similar objectives, it fo-

cuses on safety and security requirements, aiming

”to develop a component-oriented design methodol-

ogy based upon model-driven technology, jointly ad-

dressing safety and security aspects and their inter-

relation for networked embedded systems in multi-

ple domains.” [SESAMO, 2015]. One major objec-

tive has been developing procedures for integrated

analysis of safety and security demands, focusing on

identifying hazards to facilitate an informed tradeoff

between contradicting safety and security demands.

One goal is to provide convincing evidence, justifying

”that the risks associated with the system are as low

as reasonably practicable” [Paulitsch et al., 2012].

Stating that a system cannot be safe without being se-

cure, the SESAMO project supports the position of

considering safety as the top-level goal, that can be

affected by security issues. [Paulitsch et al., 2012] In

contrast to this paper, the SESAMO project does not

provide a competitive tradeoff analysis by a system-

atic method like the modified AHP combined with the

FMEA. Moreover, the results of the tradeoff analy-

sis as proposed by SESAMO are not fully compatible

with the FMEA. However, the FMEA is a compulsory

part of the certification requirements in the automo-

tive industry [Paulitsch et al., 2012]. Moreover, there

is another project called SafeCer (Safety Certification

of Software-Intensive Systems with Reusable Com-

ponents). It aims to increase ”[...] efficiency and re-

duce(d) time-to-market by composable safety certifi-

cation of safety-relevant embedded systems.” [Safe-

Cer, 2015] The project focused on providing methods

and tools composing safety arguments for a system

by reusing already established arguments and proven

properties of the subsystems. This project share the

goal of providing means (architectures, tools, pro-

cesses or standardization) to enhance efficient safety

assurance and certification. However, this project

doesn’t explicitly aim to support a MCDA taking

safety, security and timing issues into account, as it

has been proposed in this paper. [SafeCer, 2015]

5 CONCLUSION AND OUTLOOK

In this paper an approach has been presented how to

combine SST concerns for the development of safety-

critical systems. Thereby, safety issues with a max-

imum degree of safety are of primary importance.

For that purpose, an SGH has been introduced which

is based on GSN. This SGH contains all safety-,

security- or timing goals and SPOFs within a hierar-

chical structure. Furthermore, it contains alternative

solutions, in order to calculate a tradeoff. Addition-

ally, it has been demonstrated how to perform risk as-

sessments of the SPOFs using the FMEA technique.

The tradeoff in itself is calculated by means of two

possible methods: The RCM and the PCM. The ba-

sis for the calculation is either the FMEA technique

or the AHP algorithm. Furthermore, the approach has

been evaluated based on an application example com-

paring two different ACC systems by means of three

selected scenarios with respect to stability and adapt-

ability of applied techniques. For further work, it

would be useful to cluster some goals and to perform

the tradeoff analysis in an abstract manner. Thus, it

would be possible without any effort to check if a sys-

tem component is profitable or not. Another aspect

that has not been considered in this paper concerns

product line engineering. In those days there are nu-

merous configuration options of an automotive vehi-

cle. Hence, a product line approach will be developed

contemporary.

Multi-Concerns Engineering for Safety-Critical Systems

509

REFERENCES

Bowles, J. (2003). An assessment of RPN prioritization

in a failure modes effects and criticality analysis. In

Annual Reliability and Maintainability Symposium,

2003, Columbia, USA.

Bundesministerium des Inneren (2017). Fehler-

moeglichkeits - und einflussanalyse (FMEA). In

Organisationshandbuch, Berlin, Germany.

Cheng, C. et al. (2011). An AHP method for road traf-

fic safety. In Fourth International Joint Conference

on Computational Sciences and Optimization (CSO),

Dalian, China.

Harker, P. (1987). Derivatives of the perron root of a posi-

tive reciprocal matrix: With application to the analytic

hierarchy process. In Applied Mathematics and Com-

putation, volume 22, Philadelphia, USA.

Ji, X. et al. (2010). AHP implemented security assessment

and security weight verification. In Second Interna-

tional Conference on Social Computing (SocialCom),

Leeds, UK.

Jianbin, G. et al. (2009). The safety detection research of

wind power units based on ahp method. In Interna-

tional Conference on Sustainable Power Generation

and Supply, Nanjing, China.

Kelly, T. et al. (2004). The goal structuring notation - a

safety argument notation. In Proceedings of the De-

pendable Systems and Networks 2004 Workshop on

Assurance Cases, New York, USA.

Langermeier, M. et al. (2015). Adaptive approach for im-

pact analysis in enterprise architectures. In Business

Modeling and Software Design. BMSD 2014, Cham,

Switzerland.

Liu, H. et al. (2016). Risk evaluation in failure mode and

effects analysis using fuzzy digraph and matrix ap-

proach. In Journal of Intelligent Manufacturing, vol-

ume 27, New York, USA.

Nilsson, D. et al. (2008). A roadmap for securing ve-

hicles against cyber attacks. In National Workshop

on High-Confidence Automotive Cyber-Physical Sys-

tems, Michigan, USA.

Paulitsch, M. et al. (2012). Evidence-based security in

aerospace. In ISSRE Workshops 2012.

Saaty, T. (1990). How to make a decision: The analytic hi-

erarchy process. In European Journal of Operational

Research, volume 48.

SafeCer (2015). SafeCer project homepage.

http://safecer.eu. accessed November, 13th.

SESAMO (2015). SESAMO project homepage. http://

sesamo-project.eu/. accessed November, 13th.

Taha, A. et al. (2014). Ahp-based quantitative approach for

assessing and comparing cloud security. In 13th In-

ternational Conference on Trust, Security and Privacy

in Computing and Communications, Darmstadt, Ger-

many.

Wang, H. et al. (2011). Safety assessment on railway cross-

ings based on extension ahp and set pairs analysis. In

International Conference on Management and Service

Science (MASS), Dalian, China.

Zhao, Y. et al. (2013). An improved risk priority number

method based on ahp, reliability and maintainability

symposium (rams). In 2013 Proceedings - Annual,

Beijing, China.

MODELSWARD 2018 - 6th International Conference on Model-Driven Engineering and Software Development

510