Lithiumniobate Die Assembled by a Low-stress Soldering Technique

Method to Fasten a Surface Acoustic Wave Sensor

Pol Ribes-Pleguezuelo

1,2

, Katherine Frei

1

, Gudrun Bruckner

3

, Erik Beckert

1

,

Ramona Eberhardt

1

and Andreas Tünnermann

1,2

1

Fraunhofer Institute for Applied Optics and Precision Engineering IOF, Albert-Einstein-Str. 7, 07745 Jena, Germany

2

Institute of Applied Physics IAP, Friedrich-Schiller University Jena, Max-Wien-Platz 1, 07743 Jena, Germany

3

Carinthian Tech Research AG, Europastraße 12, A-9524, St. Magdalen, Austria

Keywords: Surface Acoustic Wave Sensor, Optical Crystal, Packaging, Solderjet Bumping Technique, Lithiumniobate.

Abstract: Solderjet bumping technique was applied to assemble a Surface Acoustic Wave (SAW) sensor prototype

designed with a lithiumniobate crystal and a base sub-mount made of stainless steel. The assembly was

designed with this technology in order to withstand the device’s mechanical strength requirements. The initial

performed tests showed that the solderjet bumping technique can be used to assemble brittle components

without creating internal damage in the crystal. The selected solder alloy Au

80

Sn

20

used to fasten the

lithiumniobate showed proper alloy wettability and joint strength on the crystal and on the substrate material.

Finally, a lithiumniobate die device was soldered by soldering means to the stainless steel sub-mount, and

withstood the strength device requirements by passing robustness (push) tests.

1 INTRODUCTION

1.1 Motivation

The demand from industry and consumer electronics

for continuous miniaturisation and increased

integration density of components can only be

fulfilled by applying appropriate attachment and

interconnection technologies. Smart systems require

interconnection of heterogeneous materials like

crystals, ceramics, printed circuit boards, screen

printed layers, and metals. The die attachment

processes are critical for the functionality of the

devices. Depending on the application, the inter-

connection layer must act as a thermal or electrical

contact, allowing power dissipation or compensating

thermal mismatch of different materials.

Lithiumniobate (LN) is a material widely used in

optics and as High Frequency (HF) filters. This piezo

electric crystal is also used for Surface Acoustic

Wave (SAW) based physical sensors, which work

completely passively – without power supply, and

can be interrogated wirelessly and used in temperatu-

re regions well above the operation range of silicon

based devices (Reindl, 1998; Bruckner, 2017). The

high temperature operation (300 °C) poses additional

demands on the interconnection techniques.

In this work, we examine the solderjet bumping

technique for the die attachment of LN chips to

stainless steel, which promises several advantages

when compared to common adhesives based on

organic materials, as these materials are generally

limited to temperatures below 280 °C. The final goal is

to establish a bonding process that permits LN crystals

to function as combined temperature and strain or

pressure sensors in a wide temperature range (-100 °C

to 300 °C) with high reproducibility and reliability.

SAW chips are commonly fixed using silicon

based rather soft adhesives which allow low stress

bonds, but are limited to ~ 200°C. During the last

years we have tested high temperature stable epoxy-

and polyimide based glues for the attachment of SAW

dies in metallized and ceramic packages. All of these

adhesives failed in long term tests where the samples

were exposed to temperatures around 300°C for

several months. We observed outgassing that resulted

in contaminating layers on the SAW chips and

disintegration on the adhesives. In extreme cases the

glues disintegrated completely and the dies fell off.

Any outgassing from the adhesives or package can

raise chemical reaction in the microclimate of

packaged devices which damage the delicate surface

of SAW chips (Bardong 2016). Ceramic glues could

be used, but the TCE mismatch often causes breaking

Ribes-Pleguezuelo, P., Frei, K., Bruckner, G., Beckert, E., Eberhardt, R. and Tünnermann, A.

Lithiumniobate Die Assembled by a Low-stress Soldering Technique - Method to Fasten a Surface Acoustic Wave Sensor.

DOI: 10.5220/0006645400910097

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 91-97

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

91

of the chips. Metal based attachment techniques are

promising for high temperature and low stress die

attachment (Roshanghias 2017) as they allow

compensation of TCE mismatch and minimize

mechanical stress. Solderjet bumping technique is

especially suited, as no thermal stress is induced

during the bonding process.

1.2 Solderjet Bumping Technique

Solder-joining using metallic solder alloys is an

alternative to adhesive bonding. Laser-based

soldering processes are especially well suited for the

joining of optical components made of fragile and

brittle materials such as glasses, ceramics and

crystals, due to a localized and minimized input of

thermal energy (Beckert, 2009).

Solderjet bumping (Figure 1) is a technique

adapted from flip chip processing of semiconductor

devices that also allows for the flux-free and contact-

free processing of optical components and 3D-

packaging. It uses spherical solder preforms of

various soft solder alloys (e.g. tin-based lead-free

solders, low melting indium alloys or high melting

eutectic gold-tin, gold-silicon or gold-germanium

solders) in a diameter range of 40 µm to 760 µm. The

solder spheres are transferred from a reservoir to a

placement capillary with a conical tip and an inner

diameter that is slightly smaller than the diameter of

the spheres. After positioning the capillary next to the

joining geometry using an articulating robot, the

solder alloy is molten by an infrared laser pulse and

jetted out of the capillary by applying nitrogen

pressure. The jetting of liquid solder volumes

provides a very good thermal contact of the alloy with

the components, and allows for the joining within

complex 3D-integrated geometries. The bond head of

the solderjet bumper integrates solder volume

feeding, reflow, and application of liquid solder and

allowing for highly automated and flexible use.

Figure 1: Schematic drawing of the solderjet bond head able

to solder droplets with 6 degrees of freedom (DOF).

However, the formation of a metallic solder joint

using components made of non-metallic materials

with solderjet bumping requires a wettable

metallization layer applied to the components. Such

surfaces can be provided by thin film (e.g. physical

vapour deposition) or thick film (e.g. screen printing

of metal pastes) processes. Sputtered three-layer

systems (Figure 2) using a titanium adhesion layer, a

platinum diffusion barrier, and a noble gold finish

preventing oxidization and acting as a wetting

surface, provide superb conditions for wetting of

liquid solder droplets (Banse, 2005).

Figure 2: Example of three sputtered layers (Ti/Pt/Au) over

the substrate component to later be able to create a wettable

surface for the solder bump.

2 REQUIREMENTS

As stated before, the aimed operation temperature is

300 °C or higher while the processing temperature for

LN is limited to about 450 °C for a short time. Die

attachment by solderjet bumping with eutectic

materials allows high temperature operation of the

devices with minimum thermal stress induced during

the attachment process. In addition, metals are ductile

and can compensate thermal mismatch of different

materials. This property is extremely important for

LN, as the crystal is highly anisotropic. The thermal

expansion coefficient in one direction is about three

times bigger than in the other, preventing thermal

matching to metal or ceramics. Furthermore, the

metallic interface allows a good thermal contact

between chip and support, which is crucial for the

device to operate as temperature sensor.

For sensing of pressure or strain several

geometries can be used. We have considered a

cantilever setup, where the LN crystal is either

mounted on a metallic cantilever beam, or forms the

cantilever itself. In both configurations precise and

reproducible mounting of the device with sufficient

adhesion strength is essential. When solderjet

bumping is used, the die can be put in direct contact

with the metal of the pressure sensor. This is a big

advantage compared to any attachment technique

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

92

using an interface layer, as any adhesive within the

chip- metal interface would affect the device

sensitivity.

Figure 3 shows a sketch of such a sensor. The size

of the chip used for the experiments was 8 mm x 3 mm

x 0.35 mm. LN was chosen as substrate for the sensor

element because of the high coupling coefficient that

provides a high freedom in sensor design and linear

sensitivity to strain (Bruckner, 2013).

Figure 3: Schematics for a pressure sensor with thin

membrane and chip as cantilever.

3 ASSEMBLY EXPERIMENTAL

DETAILS

For this study, the solderjet bumping laser energy

parameters (represented by varying the laser

current (mA) and the laser pulse (ms)) were tuned to

provide the optimal wetting and strength of Au

80

Sn

20

100 µm diameter spherical solder-bumps on a

metalized LN substrate. Au

80

Sn

20

was selected due to

its melting temperature, low enough not to damage

the crystal during soldering alloy reflow, but high

enough to resist temperatures close to 300 °C required

for the final device application. The goal was to

successfully assemble a LN crystal to a stainless steel

baseplate. The study was done by following a design

of experiments (DoE) using input factors, the laser

current (mA) and laser pulse (ms), to study the

material responses: i) damage to the material, ii)

correct wetting provided by a correct bump melting

diameter, and iii) force needed to shear the bumps.

An important factor in this assessment was to

avoid damage to the LN substrate. A common

problem with use of LN is its high tendency to receive

photorefractive damage, which results in a change in

inhomogeneity of the refractive index of the material

(Levinstein, 1967). Another important factor is the

difference of strength and wetting of Au

80

Sn

20

solder

on both LN and stainless steel by applying bumps

using the same current and pulse energy, which is

attributed to their respective thermo-mechanical

characteristics. The relevant material characteristics

of the substrate material, the LN and the selected

alloy are listed in Table 1.

Table 1: Thermo-mechanical properties of used materials.

Lithium-

Niobate

Stainless

Steel

Au

80

Sn

20

Density (g/cm3)

4.64

8

14.7

Young's Modulus

(GPa)

170

195

68

Thermal Conductivity

(W/mK)

4.4

16.2

57,0

Melting Temp (°C)

--

--

280

3.1 Initial Tests

Preliminary tests were performed to determine the

maximum and minimum laser energy parameters.

The maximum energy was determined when the

energy was the highest possible without damaging the

substrate, while the minimum was determined when

the energy was lowest while still allowing flow of the

solder bump through the solderjet bumping jet

capillary (Figure 1). After preliminary tests were

done to find the maximum and minimum energy

parameters, a DOE was designed by using twenty-six

different laser energy points represented by their laser

current (mA) and laser pulse (ms).

The initial created damage was analyzed through

visual inspection, rating the damage on a scale of 1 to

4. (Figure 4).

Figure 4: Example of examined damage. (1) No presence of

damage; (2) material abrasion; (3) crack; (4) major crack.

Lithiumniobate Die Assembled by a Low-stress Soldering Technique - Method to Fasten a Surface Acoustic Wave Sensor

93

The diameter and shear strength results are

displayed graphically with a contour map on Figure 5.

In Figure 5, the damage on the LN substrate is shown

in red numbers at each point on the map (Upper

image).

Figure 5: Results of DoE. Upper image, bump diameter and

in red numbers damage to assess correct wettability. Image

below, bump shear strength results.

The ideal diameter of solder bump after reflow

should be approximately 175% to 200% of the

original solder sphere (Mäusezahl, 2016); for the case

of 100 µm it should be about 175 to 200 µm. As can

be seen in Figure 5, there are some results that have

an approximate diameter size of 200 µm, in particular

bumps with laser energy parameters of

3000 mA/0.5 ms, 3866 mA/0.5 ms, and

4733 mA/0.4 ms. These samples also showed no

damage and good resulting shear strength.

The tensile strength of Au

80

Sn

20

is 275 MPa

(Indium Corp., 2013) and typically shear strength

within metals is estimated to be 50% to 60% of the

ultimate tensile strength (Callister, 2013). For our

case, this results in an estimation of 137.8 to

165 MPa. In Figure 5, it can be seen that in cases with

very high laser energy, shear strength was much

below this estimation, however at lower energies

shear strength was still slightly above this estimation.

Figure 6 shows an example of a sheared solder bumps

using low energy (left) and high energy (right). A

possible reason for the weakening of Au

80

Sn

20

, is the

formation of AuSn

4

, a common occurrence when

soldering with tin and gold materiel. This compound

is known to weaken the material and the joint. Higher

energy may allow easier formation of AuSn

4

(Hare,

2010).

Figure 6: Shear test examples performed using 100 µm

AuSn bumps. Left, low energy similar to 8.9 mJ by using a

solderjet bumping settings of 3000 mA and 0.5 ms. Right,

high energy similar to 15 mJ by using a solderjet bumping

settings of 3000 mA and 0.8 ms.

These energies were also tested on stainless steel,

the base metal in which the LN is to be bonded to.

Examples of the results are shown in Figure 7. The

shear strength and wetting diameter values for these

samples are shown to be much higher than those that

were soldered on the layered LN substrate. The

reason for this may be due to the significantly

different thermal conductivity in LN and stainless

steel. Stainless steel’s higher thermal conductivity

allows for a larger spread of heat within the metal

during the period that the laser contacts the surface.

This larger heated area allows for easier wetting of

Au

80

Sn

20

solder. In LN, its low conductivity means

that heat will remain concentrated in a small area,

meaning that this area may achieve a higher

temperature than that of stainless steel, during laser

contact. As we have seen from the design of

experiments, higher laser energy, which correlates to

higher temperature, results in lower shear strength.

This may explain the reason why LN solder samples

show lower wetting diameters and lower shear

strength. The optimized laser energy was finally

obtained by using the laser values of 3000 mA and

0.5 ms (representing and approximate energy of

8.9 mJ).

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

94

Figure 7: Similar selected energy tests on stainless steel. (1)

3000 mA/0.5 ms showed a bumped diameter of 293.5 µm

and a shear force of 406 MPa. (2) 3866 mA/0.5 ms showed

a bumped diameter of 171.7 µm and a shear force of

235 MPa. (3) 4733 mA/0.4 ms showed a bumped diameter

of 172.5 µm and a shear force of 301 MPa.

The final selected laser parameters (3000 mA and

0.5 ms) were used to create a prototype LN and

stainless steel assembly which was later tested for its

strength and durability.

3.2 Assembly Procedure

Pac Tech’s Solder Ball Bumper SB2-Jet was used to

solder 100 µm AuSn bumps onto the surface of

metalized LN substrate and stainless steel base.

Using the selected optimal laser energy of 8.9 mJ

represented by using and 3000 mA and 0.5 ms, LN

samples were soldered to stainless steel with the

following methods. The LN samples were

temporarily secured to stainless steel to later be

rotated by 45°, resulting in the desired jointing edges

facing up toward the solderjet bumping capillary

(Figure 8(a)). Two methods were used to create a

joint between the LN and stainless steel. In the first

method, a rectangular pattern of four by ten bumps

was placed in four locations along each long edge of

the LN sample. These were placed in a way that half

the solder bump pattern bonded with the LN and the

other half bonded with the stainless steel (Figure

8(b)). The second method was similar to the first,

except that the bump pattern was only placed in three

locations per side. This pattern was also overlaid,

with one on top of the other (Figure 8 (c)) to secure

the bond between bumps.

Figure 8: Schematic drawing of different soldering

approaches of 100 µm solder bumps application. (a)

Schematic of the process with the laser reflow being applied

onto the bumps. (b) First described method. (c) Second

described method.

Following this method, several prototypes were

assembled as described (Figure 9).

Figure 9: Finally assembled samples.

4 ENVIRONMENTAL TESTING

4.1 Push Tests

With the selected laser energy, the LN was secured

onto stainless steel using the two methods described

in the Assembly Procedure section (Figure 8 and

Figure 9). This was then subject to a push test. The

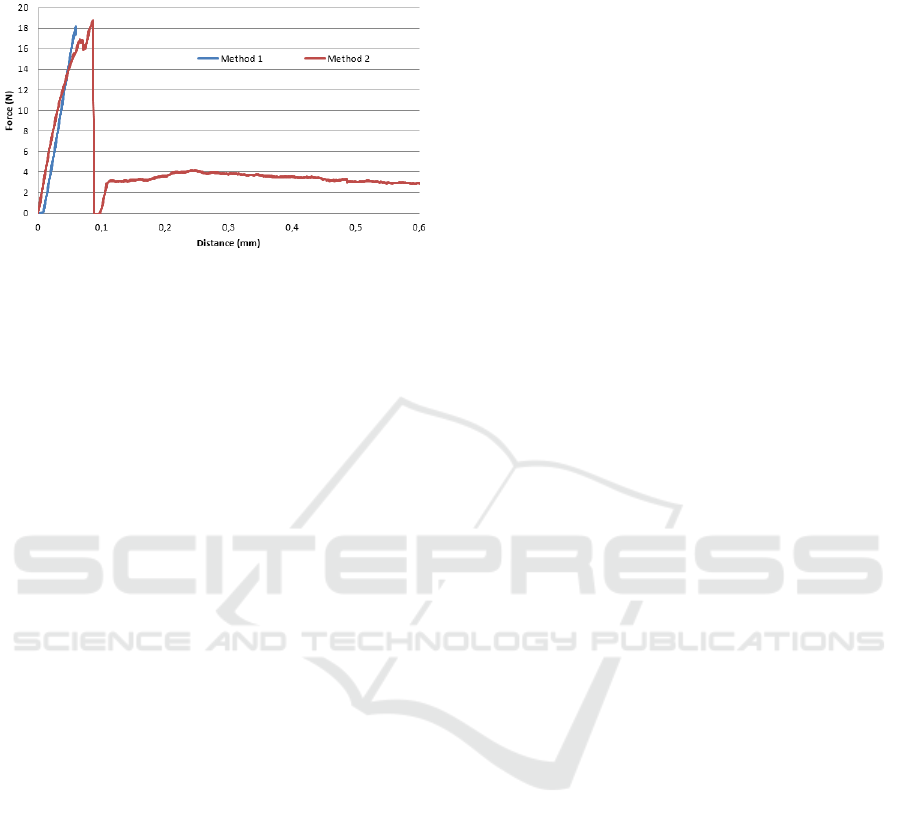

graphical results of the push test for methods 1 and 2

are shown in Figure 10. The first method showed a

maximum strength of 18.1 N. The graph of the second

method shows a spike occurring at 18.8 N, and then

suddenly dropping to zero, then rising again and

remaining steady at about 3 N. The initial spike

represents the force in which the LN broke from the

soldered joint, and the drop represents a sudden slip

after failure. The steady 3 N force indicates the LN

continued to slide between the solder joints.

Comparing the results of these two methods, it seems

that the second method is slightly better than the first

with a higher failure force. The disadvantage of this

method however is that more time and solder alloy is

required. Considering this and the small difference of

0.7 N force observed between the two methods, the

Lithiumniobate Die Assembled by a Low-stress Soldering Technique - Method to Fasten a Surface Acoustic Wave Sensor

95

first assembly method was selected as the most

optimal.

Figure 10: The graphical results of the push test for

methods 1 and 2. The graphic represents the moving

distance of the Push tests machine (Zwick Roell Z020) and

the derivate force applied onto the LN assembled crystal.

4.2 Thermal Tests

Thermal annealing tests were performed on four

samples at 300 °C to prove the devices operation

requirements. First the temperature was slowly

increased from room temperature at a rate of

100 °C/h, to finally be kept at a constant 300 °C for

12 h. Afterwards the samples were optically

inspected to check for cracks of the LN chips induced

by thermal stress. As all samples passed the test

successfully they were exposed to a strong

temperature gradient by putting the devices from

room temperature directly into a hot environment at

300 °C and out again. All devices could withstand

three cycles without cracks. Further test are planned

with larger number of samples applying different

temperatures.

5 CONCLUSIONS

Both, the optimal shear strength and wetting

parameters to assemble the lithiumniobate crystal to

a stainless steel sub-mount were shown to be at

3000 mA and 0.5 ms. The general pattern is that

lower laser energies results in higher shear strength

and smaller wetting diameters for the solder bumps.

Soldering Au

80

Sn

20

to stainless steel results in larger

wetting diameters and higher shear strength than

when soldered to lithiumniobate, likely due to the

higher thermal conductivity of stainless steel.

The two assembly methods produced remarkably

similar results in their strength, however considering

that the second method uses more material and time

to be performed, the optimal method is chosen to be

the first one. The final selected method showed to be

capable of handling the required strength demands

imposed by the final device application.

Moreover, other author’s publications focused on

the study of the birefringence effects produced by the

described soldering procedure showed how solderjet

bumping process can assemble optical components

with just a residual stress without affecting the device

optical performances (Ribes-Pleguezuelo, 2016;

Ribes-Pleguezuelo, 2017). Previous studies and

publications make us consider that the same residual

effect will not alter the device functionality for the

present assembled devices.

ACKNOWLEDGEMENTS

The authors want to acknowledge other members of

the Fraunhofer IOF for their support, especially to

Marcel Hornaff for the provided help with the DOE.

To the Deutscher Akademischer Austauschdienst

(DAAD).

This project is partly supported within the

COMET – Competence Centers for Excellent

Technologies - Program by BMVIT, BMWFJ and the

Province of Carinthia.

REFERENCES

Banse, H., Beckert, E., Eberhardt, R., Stöckl, W., Vogel, J.,

2005. Laser Beam Soldering – a New Assembly

Technology for Microoptical Systems. In Microsystems

Technologies 11, pp. 186-193.

Bardong, J., Binder, A., Toskov, S., Miskovic, G.,and

Radosavljevic, G., 2016. Investigation of low-tempera-

ture cofired ceramics packages for high-temperature

SAW sensors. In J. Sens. Sens. Syst., 5, p 85–93.

Beckert, E., Oppert, T., Azdasht, G., Zakel, E., Burkhardt,

T., Hornaff, M., Kamm, A., Scheidig, I., Eberhardt, R.,

Tünnermann, A., Buchmann, F., 2009. Solder Jetting -

A Versatile Packaging and Assembly Technology for

Hybrid Photonics and Optoelectronical Systems. In

IMAPS 42nd International Symposium on

Microelectronics, Proceedings, Vo. 42, pp. 406-412.

Bruckner, G., Schicker, J., Schlumpf, P., 2013, Stress

sensitivity of SAW Rayleigh waves on Lithiumniobate

and its application in pressure sensor design.

Proceedings IEEE International Ultrasonics

Symposium (IUS), Prague, pp. 2140-2143.

Bruckner,G., Bardong, J., Binder, A., Nicolay, P., 2017,

SAW Delay Lines as Wireless Sensors for Industrial

Applications. Proceedings of the VIII ECCOMAS

Thematic Conference on Smart Structures and

Materials, SMART 2017, Madrid, pp. 1433-1442.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

96

Callister, W. D., Rethwisch D. G., 2013. Materials Science

and Engineering: an Introduction. Wiley, New Jersey,

9

th

edition.

Hare, E., 2010. Gold Embrittlement of Solder Joints. In

SEM Lab, INC. www.semlab.com

Indium Corporation, 2013. Gold-Tin: The Unique Eutectic

Solder Alloy. In www.documents.indium.com/

qdynamo/download.php?docid=2103.

Levinstein, H. J, Ballman, A. A., Denton, R. T., Ashkin, A.,

Dziedzic, J.M., 1967. Optically Induced refractive

index inhomogeneities in LiNBo3 and LiTaO3. In

Applied Physics Letters, vol. 9, no. 1, 1966, pp. 72–74;

doi:10.1063/1.1754607.

Mäusezahl, M., Hornaff, M., Burkhardt, T., Beckert, E.,

2016. Mechanical Properties of Laser-Jetted SAC305

Solder on Coated Optical Surfaces. In Physics

Procedia, vol. 83, 2016, pp. 532–539;, doi:10.1016/

j.phpro.2016.08.055.

Reindl, L., Scholl, G., Ostertag, T., Scherr, H., Wolff, U.,

Schmidt, F., 1998, Theory and Application of Passive

SAW Radio Transponders as Sensors. IEEE Trans.

Ultrason. Ferroelectr. Freq. Control 45 (5), pp.1281-

1292.

Ribes-Pleguezuelo, P., Koechlin, C., Hornaff, M., Kamm,

A., Beckert, E., Fiault, G., Eberhardt, R., Tünnermann,

A., 2016. High-precision optomechanical lens system

for space applications assembled by a local soldering

technique. In Opt. Eng. 55(6), 065101 (2016); doi:

10.1117/1.OE.55.6.065101.

Ribes-Pleguezuelo, P., Zhang, Z., Beckert, E., Eberhardt,

R., Wyrowski, F.,Tünnermann, A., 2017. Method to

simulate and analyse induced stresses for laser crystal

packaging technologies. In Optics Express Vol. 25,

No.6; doi:10.1364/OE.25.005927

Roshanghias, A., Bruckner, G., Binder, A.,2017. High

temperature MEMS packages: die-attach solutions for

LiNbO3 under low bonding pressures. In J Mater Sci:

Mater Electron, DOI 10.1007/s10854-017-6605-3

Lithiumniobate Die Assembled by a Low-stress Soldering Technique - Method to Fasten a Surface Acoustic Wave Sensor

97