A Variable Neighborhood Search Algorithm for the

Long-term Preventive Maintenance Scheduling Problem

Roberto D. Aquino, Jonatas B. C. Chagas and Marcone J. F. Souza

Instituto de Ci

ˆ

encias Exatas e Biol

´

ogicas, Departamento de Computac¸

˜

ao,

Universidade Federal de Ouro Preto, Ouro Preto, Brazil

Keywords:

Long-term Maintenance Programming, Scheduling, Variable Neighborhood Search, Combinatorial Optimiza-

tion, Meta-heuristic.

Abstract:

In this work we propose a Variable Neighborhood Search (VNS) approach for the long-term maintenance

programming of an iron ore processing plant of a company in Brazil. The problem is a complex maintenance

programming where we have to assign the machine preventive programming orders to the available work teams

over a 52-week planning. In order to evaluate our solution we developed a general mixed integer programming

model and used the numerical results as the benchmark. The proposed VNS approach improved most of the

instances leading to new benchmarks.

1 INTRODUCTION

Preventive maintenance of industrial machines and

equipment is an effective way to keep the production

system in good condition. In fact, this type of mainte-

nance seeks to correct failures even before they occur,

thus avoiding losses and risks of interruption of pro-

duction. This practice consists in periodically perfor-

med maintenance on the basis of technician’s expe-

rience or according to specifications in the manufac-

turer’s manual.

Problems related to maintenance optimization

have become very attractive, arousing the interest

of several researchers. (Sim

˜

oes et al., 2011) made

an review on maintenance performance measurement

published in 67 journals between 1969 and 2009.

(Sharma et al., 2011) also made an extensive review

on this area, which were reviewed 104 articles starting

from early 1960s. According to these last authors,

maintenance optimization could have several optimi-

zation criteria such as maintenance cost rate, profi-

tability, plant utilization, performance efficiency and

work safety. Although there are some articles on op-

timization of maintenance cost, they are all focused

on the maintenance strategy such as Reliability Cen-

tered Maintenance (RCM), Total Productive Mainte-

nance (TPM) and Plant Asset Management (PAM).

All these techniques have several trade-offs that have

to be balanced to give an optimal solution.

(Yamayee et al., 1983) proposed a mathematical

formulation for optimal preventive maintenance sche-

duling problem and used dynamic programming as a

framework to solve it. The problem was to schedule

21 maintenance orders with different capacities and

different costs.

(Yao et al., 2004) proposed a mixed integer pro-

gramming model for the short-term preventive main-

tenance scheduling for 29 maintenance orders dis-

tributed on 11 different tools associated with a time

window. The objective is to maximize the overall

tool availability and minimize unavailability during

the periods when a significant amount of work is ex-

pected.

(Adhikary et al., 2016) present a multi-objective

genetic algorithm for a preventive maintenance sche-

duling problem that involves the maximization of

availability and minimization of maintenance cost for

a continuous operating series system. The results rea-

ched by the authors shows that the genetic algorithm

can improve the availability along with profound re-

duction of the maintenance cost.

This work has its focus on the problem of assig-

ning the machine preventive maintenance orders to

the work teams over a specific time period. The goal

is to maximize the number of orders performed and

minimize the number of work teams necessary to exe-

cute them.

In real scenarios we have to take into account spe-

cific constraints related to the maintenance order pro-

gramming. Most of these constraints are directly re-

Aquino, R., Chagas, J. and Souza, M.

A Variable Neighborhood Search Algorithm for the Long-term Preventive Maintenance Scheduling Problem.

DOI: 10.5220/0006689703030310

In Proceedings of the 20th International Conference on Enterprise Information Systems (ICEIS 2018), pages 303-310

ISBN: 978-989-758-298-1

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

303

lated to the scheduling problems, widely studied in

the literature (see (Brucker, 2007)). The work team

(group of workers that have to work together) can-

not perform more than one maintenance order at the

same time. Moreover, each machine cannot have

more than one preventive maintenance being execu-

ted at the same time. Each preventive maintenance

also have a time window limit that must be obeyed.

Besides above mentioned constraints, each preventive

maintenance has to be performed by a team that has

the ability to perform it. Furthermore, there exists

usually more than one team that is able to execute the

same preventive maintenance.

At the studied company, the long-term mainte-

nance programming is made by the engineering team

using a specific maintenance software. It is a gene-

ral maintenance software that manages all preventive

and corrective maintenance activities such as work

order, inventory, and material management. It also

has the data of all maintenance procedures performed

and all the maintenance plans. The maintenance plan

for each machine includes all the preventive mainte-

nance that have to be performed, the frequency that

each preventive maintenance has to be performed,

the expected time to complete the preventive mainte-

nance, the team which is able to perform the preven-

tive maintenance and the materials and tools that are

necessary. From this database it is built a 52-weeks

preventive maintenance plan, which consists of assig-

ning the preventive maintenance to the teams. The

problem is that the maintenance plan is unfeasible and

it has to be rescheduled. To do it, the maintenance

team works in extra hours, but even so, some preven-

tive maintenance are not allocated.

For solving this problem, we developed a general

mixed integer programming model and also a heuris-

tic approach, based on the Variable Neighborhood Se-

arch meta-heuristic (Mladenovi

´

c and Hansen, 1997).

The main difference of our problem from the

ones that we found on the literature is the objective

function. Here we want to maximize the number of

orders executed and try to minimize the number of

teams necessary to execute them. The greatest chal-

lenge is the huge size of it. In our problem we have

more than 30,000 maintenance orders to be executed.

The remaining of this paper is organized as fol-

lows. Section 2 shows the mathematical formulation,

which formally describes the problem. Section 3 pre-

sents a heuristic approach, based on VNS, for solving

the problem. The results are discussed in Section 4

and the conclusions are presented in Section 5.

2 PROBLEM DEFINITION AND

MATHEMATICAL MODEL

The Long-term Preventive Maintenance Scheduling

Problem (LTPMSP) can be formally described as fol-

lows. Let E = {1, 2, ··· , Q} be the set of Q indus-

trial machines which must be submitted to preventive

maintenance. Let also T = {1, 2, · ·· , N} be the set of

N preventive maintenance, and let W = {1, 2, · ·· , M}

be the set of M available work teams and responsible

to realize them. The processing time of the preven-

tive maintenance i is denoted by P

i

. Each preventive

maintenance i ∈ T must be realized in a single ma-

chine E

i

and just one work team is sufficiently capable

to perform it, but two or more different maintenance

may be associated with the same machine. However,

only one preventive maintenance can be performed at

a time on a specific machine.

In addition, each preventive maintenance has a

time window, i.e, an interval [ e

i

, l

i

], where e

i

and l

i

correspond, respectively, to the earliest and the latest

time available to perform the preventive maintenance

i. Each preventive maintenance i ∈ T requires a work

team with a specific ability, being that W

i

⊆ W indi-

cates the set of work teams with ability to perform

it. If the preventive maintenance i is not performed,

there is a penalty cost C

i

that must be paid. Each work

team k ∈ W can process at most one preventive main-

tenance at a time, and has availability to work by h

k

continuous hours. The set T

k

⊆ T indicates the pre-

ventive maintenance that can be executed by the work

team k.

The aim of the LTPMSP is to determine a schedu-

ling plan to perform as many preventive maintenance

as possible in order to minimize the number of work

teams. In order to formulate the problem, we define

five sets of decision variables, which are described as

follows:

• x

k

i j

: binary variable that gets 1 if maintenance i is

performed immediately before maintenance j by

the work team k; 0, otherwise;

• y

ik

: binary variable that gets 1 if maintenance i is

performed by the work team k; 0, otherwise;

• z

k

: binary variable that gets 1 if work team k is

used; 0, otherwise;

• c

ik

: completion time of the maintenance i when it

is performed by the work team k;

• r

i j

: binary variable that gets 1 if maintenance i is

performed before maintenance j and 0, otherwise.

With these variables we can describe the LTPMSP

by the Mixed-Integer Linear Programming (MILP)

formulation expressed by Equations (1)-(17):

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

304

min

∑

k∈W

z

k

+

∑

i∈T

C

i

1 −

∑

k∈W

i

y

ik

!

(1)

∑

k∈W

i

y

ik

≤ 1 i ∈ T (2)

∑

i∈T

k

∪{0}\{ j}

x

k

i j

= y

jk

j ∈ T , k ∈ W

j

(3)

∑

j∈T

k

x

k

0 j

= z

k

k ∈ W (4)

∑

i∈T

k

∪{0}\{l}

x

k

il

=

∑

j∈T

k

∪{0}\{l}

x

k

l j

k ∈ W , l ∈ T

k

(5)

c

0k

= 0 k ∈ W (6)

c

jk

≥ c

ik

+ P

j

− M

0

i j

(1 − x

k

i j

)

k ∈ W , i ∈ T

k

∪ {0}, j ∈ T

k

(7)

c

ik

≥ (e

i

+ P

i

)y

ik

k ∈ W , i ∈ T

k

(8)

c

ik

≤ l

i

k ∈ W , i ∈ T

k

(9)

c

jk

0

≥ c

ik

+ P

j

− M

0

i j

(1 − r

i j

)

k ∈ W , k

0

∈ W , i ∈ T

k

, j ∈ T

k

0

,

|k 6= k

0

, i < j, E

i

= E

j

(10)

c

jk

0

≤ c

ik

− P

i

+ M

00

i j

r

i j

k ∈ W , k

0

∈ W , i ∈ T

k

, j ∈ T

k

0

,

|k 6= k

0

, i < j, E

i

= E

j

(11)

c

ik

≤ h

k

k ∈ W , i ∈ T

k

(12)

x

k

i j

∈ {0, 1}

k ∈ W , i ∈ T

k

∪ {0}, j ∈ T

k

∪ {0}

(13)

y

ik

∈ {0, 1} k ∈ W , i ∈ T

k

∪ {0} (14)

z

k

∈ {0, 1} k ∈ W (15)

c

ik

≥ 0 k ∈ W , i ∈ T

k

(16)

r

i j

∈ {0, 1}

i ∈ T , j ∈ T |i < j, E

i

= E

j

(17)

aa

We define a fictitious maintenance 0 that precedes

immediately the first maintenance and follows imme-

diately the last maintenance performed by each work

team. The completion time of this maintenance is 0

for all work teams, as imposed by the constraint (6).

The objective function (1) minimizes the total

number of work teams, while maximizes the num-

ber of maintenance performed through the minimiza-

tion of the penalties. Constraint (2) ensures that each

maintenance is performed by at most one work team.

Constraint (3) guarantees if a work team k performs

a maintenance j, that maintenance must be contained

in the maintenance schedule of work team k. By con-

straint (4), if at least one maintenance is assigned to

the work team k, this work team is used. Constraint

(5) ensures the continuity of the maintenance sche-

dule of each work team. Constraint (7) calculates the

completion time of all preventive maintenance. The

constraints (8) and (9) force that all maintenance is

performed in their respective time windows. The con-

straints (10) and (11) ensure that two or more mainte-

nance are not performed at the same time on the same

machine. Note that these last two constraints can be

applied only between different work crews because

there will be no overlap of execution of maintenance

by the same work team, it being ensured by the pre-

decessor constraints. The constraint (12) ensures that

the number of working hours of work teams are not

exceeded. And, finally, the constraints (13) to (17)

define the scope and domain of the decision variables.

The constants M

0

i j

and M

00

i j

in Equations (7), (10)

and (11) can be any sufficiently large number that is

greater or equal to l

i

+ P

j

and l

j

+ P

i

, respectively.

3 HEURISTIC APPROACH

As showed in results section (Section 4), the MILP

formulation for the LTPMSP presents a high com-

plexity and solving it by this method requires exces-

sive computational time. Therefore, in this section

A Variable Neighborhood Search Algorithm for the Long-term Preventive Maintenance Scheduling Problem

305

we describe a heuristic approach based on the meta-

heuristic Variable Neighborhood Search (VNS) in or-

der to obtain high quality solutions with short compu-

tational time. The proposed heuristic and its compo-

nents are detailed below.

3.1 Solution Representation and

Evaluation Function

A solution to the problem is represented by a permuta-

tion π = hπ

1

, π

2

, ..., π

N

i of the N maintenance orders.

The evaluation of the quality of a solution π is done

as follows. Consider a procedure where the preven-

tive maintenance orders are sequentially allocated to

the first available time slot that have a duration greater

or equal of the preventive maintenance duration. For

each preventive maintenance, the available time slot is

built checking its time window and the non-allocated

time of the teams. When all the allocation conditi-

ons are met, the preventive maintenance is allocated

at the beginning of the available time slot; otherwise,

a penalty is incurred.

In order to clarify the characteristics of this allo-

cate procedure, consider an instance with 6 mainte-

nance orders involving 3 machines, which should be

executed by 3 teams. The maintenance orders 1, 2,

3 and 6 can be executed by the work teams 1 and 2,

and the maintenance orders 4 and 5 by work team 2.

The maintenance orders 1, 3 and 5 must be executed

at machine 1, while the maintenance orders 2 and 6

at machine 2 and maintenance order 3 at machine 3.

The time windows of the maintenance orders start in

the following time: 0, 2, 3, 2, 3, 4; and end in the

following time: 4, 7, 9, 6, 8, 7. The processing times

of the preventive maintenance are the following: 1,

2, 3, 1, 2, 1. The penalty for not performing a main-

tenance order is the following: 20, 30, 40, 20, 30,

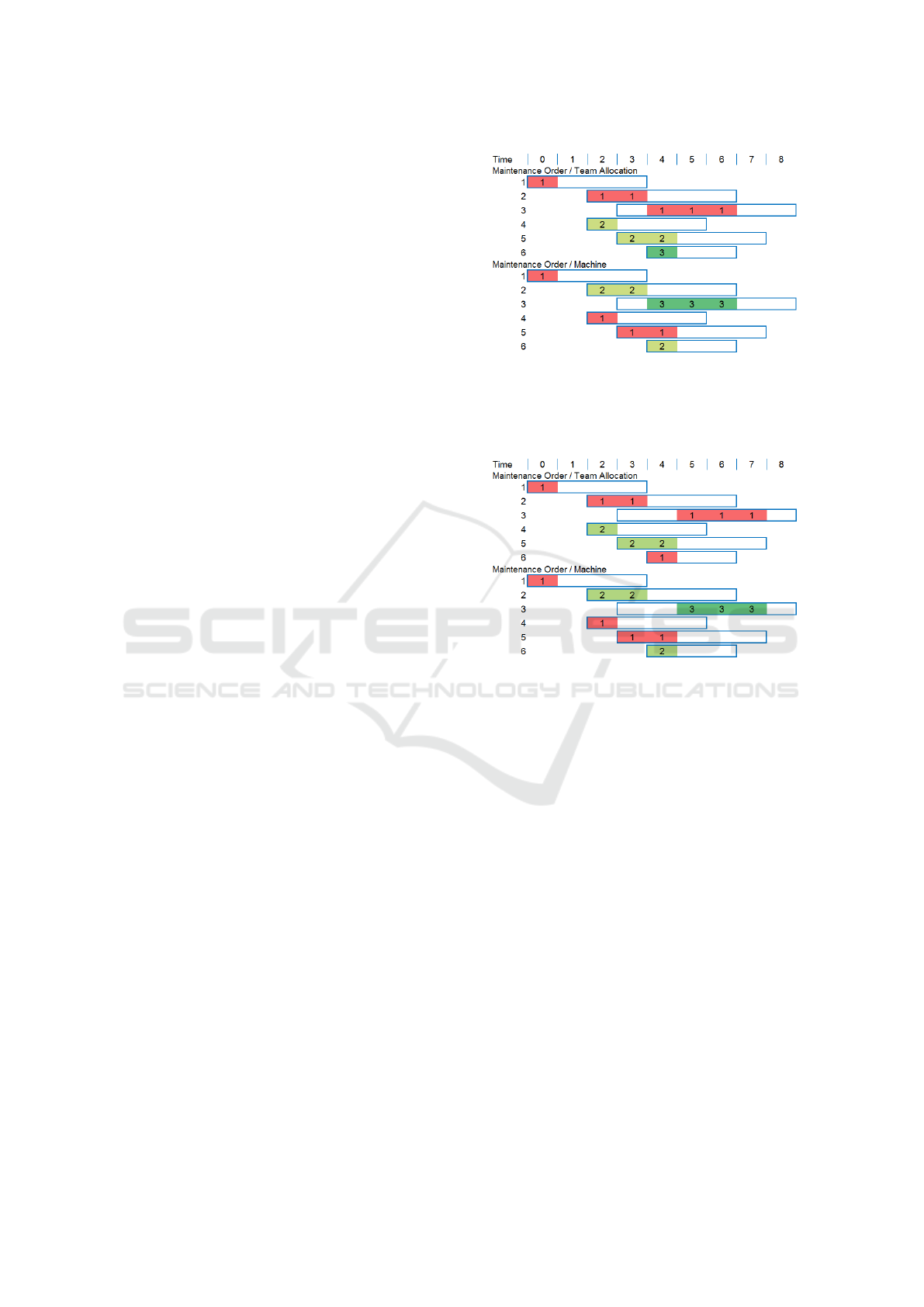

40. Figure 1 shows an allocation to the permutation

π = h1, 2, 3, 4, 5, 6i. The time window of each mainte-

nance order is represented by a horizontal bar, and the

time and duration are represented by the filled part.

This allocation has a cost of 3.

3.2 Initial Solution and Neighborhood

Structure

The initial solution is obtained choosing any random

permutation π of N maintenance orders.

In order to explore the solution space, we define

a simple neighborhood structure that consists of ex-

changing two positions of the permutation π. Figure

2 shows a solution s and one of its neighbors s

0

for

instance with 6 maintenance orders, while Figure 3

Figure 1: Initial allocation example.

s =

1, 2, 3, 4, 5, 6

s

0

=

1, 2, 6, 4, 5, 3

Figure 2: A solution s and a neighbor s

0

.

Figure 3: Allocation after swap of preventive maintenance

orders 3 and 6.

shows the allocation from s

0

. This allocation is the

optimal solution with cost 2.

We represent all neighbors of a solution s are re-

presented by N (s).

3.3 Variable Neighborhood Search

Variable Neighborhood Search (VNS), proposed by

Mladenovi

´

c & Hansen (Mladenovi

´

c and Hansen,

1997) (see e.g. (Hansen and Mladenovi

´

c, 2014) for

a recent description), is a method that explores the so-

lutions through systematic changes on the neighbor-

hood structures. For each neighborhood, it searches

for a local optimum.

Algorithm 1 describes the pseudo-code of VNS

for solving the LTMPSP. The algorithm’s initial so-

lution (line 1 of Algorithm 1) is generated randomly

according to Section 3.2 and it is considered as the

best solution so far. While maximum neighborhood

structure are not achieved (line 12), the algorithm pro-

gressively shakes (see SHAKE procedure, shown in

Figure 4) the current best solution s (line 4) and ap-

plies a local search (line 5). This local search (see

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

306

LOCAL-SEARCH procedure, shown in Figure 5) con-

sists of applying a descent method using a best impro-

vement strategy. If a better solution is achieved (line

6), it is accepted and the neighborhood structure is

returned to 1 (lines 7 and 8, respectively). Otherwise,

the neighborhood structure is incremented by 1 in line

10. When the loop is interrupted either by time limit

or the maximum number of neighborhood structure,

the best solution is returned (line 13).

Algorithm 1: VNS.

1 s ← initial solution

2 k ← 1

3 repeat

4 s

0

← SHAKE(s, k)

5 s

00

← LOCAL-SEARCH(s

0

)

6 if f (s

00

) − f (s) < 0 then

7 s ← s

0

8 k ← 1

9 else

10 k ← k + 1

11 end

12 until k > k

max

;

13 return s

procedure SHAKE (s, k)

s

0

← s

i ← 1

while i ≤ k do

select a random neighbor solution s

00

∈ N (s

0

)

s

0

← s

00

i ← i + 1

end

return s

0

end procedure

Figure 4: SHAKE procedure.

procedure LOCAL-SEARCH (s)

s

0

← s

repeat

get the best neighbor solution s

00

∈ N (s

0

)

if f (s

00

) < f (s

0

) then

s

0

← s

00

end

until f (s

00

) ≥ f (s

0

);

return s

0

end procedure

Figure 5: LOCAL-SEARCH procedure.

4 COMPUTATIONAL

EXPERIMENTS

Our proposed MILP formulation was coded in C++

language using the Concert Technology Library of

CPLEX 12.5 Academic Version, with default settings,

except for the runtime that was limited to 1 hour. The

VNS algorithm was coded in C++ language and exe-

cuted sequentially. All the experiments were perfor-

med on an Intel Core i5-4440 CPU @ 3.10GHz x 4

computer, 8GB RAM, Ubuntu 14.04 LTS 64 bits.

Our VNS algorithm (Algorithm 1) has only one

parameter (k

max

) that was empirically determined and

set to N, i.e, the number of preventive maintenance

orders.

The real instance of the studied iron ore proces-

sing plant consists of 33,484 preventive maintenance

orders involving 1,032 industrial machines to be allo-

cated to 145 work teams. As the MILP formulation

is not able to solve real-size instances, we have cre-

ated 100 different instances in order to compare the

VNS algorithm to the MILP. As reported in Table 1,

these instances, which are sub-instances of the real

instance, differ from each other by the number of pre-

ventive maintenance orders, number of industrial ma-

chines and number of work teams.

We now present the results obtained by our appro-

aches for the LTPMSP. Notice that since there is no

literature regarding this problem, we are only going

to compare the results of our approaches.

In Table 1, the four first columns describe the in-

stances, where the columns ID, Q, N and M inform,

respectively, the identifier number of each instance,

the number of industrial machines, the number of pre-

ventive maintenance orders and the number of avai-

lable work teams. The results obtained by the MILP

formulation are described in the columns Obj, #T, #P,

Opt, Gap and Time(s). The column Obj shows the so-

lution value obtained at the end of the computation,

#T informs the number of work teams used to per-

form the #P preventive maintenance orders, the co-

lumn Opt shows if each instance was solved to op-

timality (indicated by an asterisk), the column Gap

shows the relative gap between upper bound (Ob j)

and LB computed as (Ob j - LB)/Ob j, where LB is the

lower bound value at the end of the computation and

the column Time(s) informs the processing time in se-

conds spent by the MILP formulation. In the last five

columns, we present the VNS results. The column

Obj shows the best solution value found after 10 exe-

cutions of the VNS algorithm, while the column σ

informs the standard deviation of the all 10 solution’s

values. The columns #T, #P have the same meaning

of the columns for the MILP formulation, which refer

to the best solution found by the VNS algorithm. Fi-

nally, the column Time(s) shows the processing time

in seconds required by the VNS.

Notice that in order to highlight the solution qua-

lity of each proposed method, best results reached in

each instances are boldfaced.

The results show that, within a 1 hour time limit,

A Variable Neighborhood Search Algorithm for the Long-term Preventive Maintenance Scheduling Problem

307

Table 1: Comparative analysis of the MILP formulation and the VNS algorithm.

Instances MILP VNS

ID Q N M Obj #T #P Opt Gap Time(s) Obj #T #P σ Time(s)

001 2 20 2 434 2 18 * 0.00 0.3 434 2 18 0.0 0.2

002 3 219 3 19 * 0.00 7.2 219 3 19 0.0 0.2

003 4 219 3 19 * 0.00 82.0 219 3 19 0.0 0.2

004 5 219 3 19 * 0.00 85.5 219 3 19 0.0 0.2

005 10 219 3 19 * 0.00 28.8 219 3 19 0.0 0.3

006 30 2 434 2 28 * 0.00 2.0 434 2 28 0.0 1.4

007 3 219 3 29 * 0.00 10.7 219 3 29 0.0 1.2

008 4 219 3 29 * 0.00 333.4 219 3 29 0.0 1.2

009 5 220 4 29 0.01 1h 219 3 29 0.0 1.5

010 10 219 3 29 0.01 1h 219 3 29 0.0 1.3

011 40 2 434 2 38 * 0.00 57.2 650 2 37 68.3 4.8

012 3 219 3 39 * 0.00 186.3 219 3 39 0.0 4.6

013 4 220 4 39 0.01 1h 219 3 39 0.0 4.7

014 5 220 4 39 0.99 1h 219 3 39 0.0 4.8

015 10 221 5 39 0.02 1h 219 3 39 0.0 5.2

016 60 2 434 2 58 * 0.00 67.7 650 2 57 0.0 26.7

017 3 219 3 59 * 0.00 1358.2 219 3 59 0.0 28.9

018 4 220 4 59 1.00 1h 219 3 59 0.0 29.9

019 5 221 5 59 0.99 1h 219 3 59 0.0 29.6

020 10 652 4 57 1.00 1h 219 3 59 0.0 30.8

021 80 2 866 2 76 0.50 1h 1082 2 75 113.8 102.7

022 3 219 3 79 0.99 1h 219 3 79 111.5 109.5

023 4 436 4 78 1.00 1h 219 3 79 113.8 112.7

024 5 653 5 77 1.00 1h 219 3 79 111.5 119.9

025 10 653 5 77 1.00 1h 219 3 79 113.8 120.7

026 3 20 3 579 3 17 * 0.00 2.1 579 3 17 0.0 0.2

027 4 220 4 19 * 0.00 14.7 220 4 19 0.0 0.2

028 5 220 4 19 * 0.00 129.9 220 4 19 0.0 0.2

029 6 220 4 19 * 0.00 3076.4 220 4 19 0.0 0.2

030 12 220 4 19 0.01 1h 220 4 19 0.0 0.2

031 30 3 579 3 27 * 0.00 6.3 579 3 27 0.0 1.2

032 4 220 4 29 * 0.00 38.3 220 4 29 0.0 1.0

033 5 220 4 29 * 0.00 316.8 220 4 29 0.0 1.0

034 6 220 4 29 0.01 1h 220 4 29 0.0 1.1

035 12 223 7 29 0.99 1h 220 4 29 0.0 1.2

036 40 3 579 3 37 * 0.00 807.3 723 3 36 74.4 4.5

037 4 220 4 39 * 0.00 238.5 220 4 39 0.0 4.3

038 5 221 5 39 0.01 1h 220 4 39 0.0 4.3

039 6 221 5 39 0.01 1h 220 4 39 0.0 4.3

040 12 225 9 39 0.99 1h 220 4 39 0.0 4.9

041 60 3 1515 3 51 0.76 1h 1659 3 50 63.0 24.6

042 4 220 4 59 * 0.00 1619.3 220 4 59 0.0 29.8

043 5 221 5 59 0.01 1h 220 4 59 0.0 29.2

044 6 222 6 59 0.99 1h 220 4 59 0.0 30.3

045 12 225 9 59 1.00 1h 220 4 59 0.0 31.3

046 80 3 3891 3 59 0.32 1h 1947 3 69 84.9 92.8

047 4 2524 4 68 0.13 1h 220 4 79 0.0 104.3

048 5 2525 5 68 0.26 1h 220 4 79 0.0 105.8

049 6 2886 6 66 0.42 1h 220 4 79 0.0 116.5

050 12 12895 7 16 0.90 1h 220 4 79 0.0 121.1

our MILP formulation found the optimal solution (co-

lumn Opt with *) for 26 instances (26% of the total).

It is also observed that for 92 instances (92% of the

total), the VNS algorithm found solutions whose va-

lues are equal or better to those obtained by the MILP

formulation.

Notice that, for a given Q and N, the MILP for-

mulation behaves better for the smaller values of M,

since the smaller this value the lower the combina-

torial complexity of the problem. As seen from Ta-

ble 1, the MILP formulation obtained better solutions

than the VNS algorithm only for the instances with

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

308

Table 1 (continuation): Comparative analysis of the MILP formulation and the VNS algorithm.

Instances MILP VNS

ID Q N M Obj #T #P Opt Gap Time(s) Obj #T #P σ Time(s)

051 4 20 3 723 3 16 * 0.00 530.6 723 3 16 90.1 0.3

052 4 220 4 19 * 0.00 1862.6 220 4 19 0.0 0.2

053 5 220 4 19 0.01 1h 220 4 19 0.0 0.2

054 6 220 4 19 0.01 1h 220 4 19 0.0 0.2

055 12 220 4 19 0.01 1h 220 4 19 0.0 0.2

056 30 3 723 3 26 0.40 1h 723 3 26 97.2 1.2

057 4 220 4 29 0.01 1h 220 4 29 0.0 1.1

058 5 221 5 29 0.02 1h 220 4 29 0.0 1.1

059 6 220 4 29 0.01 1h 220 4 29 0.0 1.2

060 12 222 6 29 0.99 1h 220 4 29 0.0 1.4

061 40 3 867 3 35 1.00 1h 1011 3 34 37.2 4.2

062 4 220 4 39 0.01 1h 220 4 39 0.0 4.0

063 5 221 5 39 0.02 1h 220 4 39 0.0 4.0

064 6 222 6 39 0.21 1h 220 4 39 0.0 3.7

065 12 223 7 39 1.00 1h 220 4 39 0.0 4.5

066 60 3 2163 3 47 1.00 1h 2091 3 47 88.5 23.1

067 4 652 4 57 0.73 1h 220 4 59 0.0 28.5

068 5 221 5 59 0.61 1h 220 4 59 0.0 30.0

069 6 222 6 59 0.99 1h 220 4 59 0.0 29.2

070 12 1086 6 55 1.00 1h 220 4 59 0.0 35.3

071 80 3 3171 3 62 1.00 1h 3459 3 60 104.3 72.6

072 4 220 4 79 0.01 1h 220 4 79 0.0 95.4

073 5 221 5 79 0.99 1h 220 4 79 0.0 103.7

074 6 222 6 79 0.99 1h 220 4 79 0.0 117.9

075 12 8215 7 42 1.00 1h 220 4 79 0.0 102.0

076 5 20 4 724 4 16 * 0.00 62.9 724 4 16 68.3 0.3

077 5 221 5 19 * 0.00 277.8 221 5 19 0.0 0.2

078 6 221 5 19 0.01 1h 221 5 19 0.0 0.2

079 7 221 5 19 0.01 1h 221 5 19 0.0 0.2

080 14 221 5 19 0.01 1h 221 5 19 0.0 0.3

081 30 4 724 4 26 0.20 1h 724 4 26 70.0 1.1

082 5 221 5 29 0.01 1h 221 5 29 0.0 1.1

083 6 221 5 29 0.01 1h 221 5 29 0.0 1.1

084 7 221 5 29 0.01 1h 221 5 29 0.0 1.1

085 14 225 9 29 0.98 1h 221 5 29 0.0 1.2

086 40 4 868 4 35 1.00 1h 868 4 35 107.6 3.5

087 5 221 5 39 0.01 1h 221 5 39 0.0 3.4

088 6 222 6 39 0.02 1h 221 5 39 0.0 3.7

089 7 222 6 39 0.02 1h 221 5 39 0.0 3.5

090 14 223 7 39 1.00 1h 221 5 39 0.0 3.9

091 60 4 1588 4 50 1.00 1h 1732 4 49 86.2 21.5

092 5 221 5 59 0.02 1h 221 5 59 0.0 23.0

093 6 222 6 59 0.02 1h 221 5 59 0.0 24.9

094 7 223 7 59 0.99 1h 221 5 59 0.0 27.4

095 14 225 9 59 1.00 1h 221 5 59 0.0 28.9

096 80 4 3388 4 61 0.92 1h 3316 4 61 108.7 67.9

097 5 509 5 78 0.43 1h 221 5 79 0.0 82.7

098 6 510 6 78 0.43 1h 221 5 79 0.0 86.2

099 7 511 7 78 0.43 1h 221 5 79 0.0 98.6

100 14 3102 6 67 0.91 1h 221 5 79 0.0 101.2

the smallest number of workers, considering the in-

stances with the same number preventive maintenance

orders and the same number of industrial machines.

According to the column σ, we can note that the

VNS algorithm presented good convergence, as the

standard deviation of the 10 solutions obtained is

equal to zero or close to zero for most of the instances.

Regarding the computational time and the solu-

tion’s quality, we can see that the VNS algorithm is

more efficient while compared to the MILP formula-

tion. For all instances the VNS algorithm was faster

than the MILP formulation, and analyzing the 8 in-

stances (instances with ID 011, 016, 021, 036, 041,

061, 071 and 091) in which the VNS algorithm obtai-

A Variable Neighborhood Search Algorithm for the Long-term Preventive Maintenance Scheduling Problem

309

ned worse solutions than the MILP formulation, we

can see that the difference between the solutions is

only an unperformed preventive maintenance, except

for the instance with ID 071, which has that difference

of 2 preventive maintenance orders.

Note that for none of the 100 instances, reported

in Table 1, the MILP formulation and the VNS algo-

rithm were able to allocate all preventive maintenance

orders for the set of available work teams (see the co-

lumns N and #P). This occurs even when the number

of available work teams is greater than the number of

used work teams (see the columns M and #T), and

even when the optima solution was found (see e.g.

the instances with ID 003, 004, 005, 008, 028, 029).

This fact arises because the time windows defined for

maintenance orders prevent them from being perfor-

med due to the constraint that only one maintenance

can be performed at the same time on a specific ma-

chine (see constraints (10) and (11) in the MILP for-

mulation described in Section 2).

For the complete instance it was not possible to

make a comparison with the MILP formulation be-

cause the CPLEX optimizer could not handle the in-

stance. To get a result with the VNS approach within

a reasonable time, we limited the application of the

algorithm to one hour. Even with this time limit, the

VNS could assign 30,975 maintenance orders from a

total of 33,484 (92,5% of the orders).

5 CONCLUSIONS

In this paper, we examined the optimization approach

proposed in the literature and built our own MILP mo-

del based on the real objective function and restricti-

ons of a preventive maintenance of an existing iron

ore processing plant. This MILP model is very straig-

htforward and helps us understand the problem mat-

hematically. Although its easiness to understand, it

can not solve large instances. In order to get a reaso-

nable solution, we proposed a VNS approach that was

able to handle the real instance with good results.

Although the proposed algorithm gave good re-

sults, it was not able to compare the results of the

real instance with a baseline. In the future, we would

like to implement more meta-heuristic approaches

and evaluate the results using the VNS as the baseline.

Other enhancement is a improvement on the local se-

arch and shaking algorithm to consider only exploring

promising solutions.

ACKNOWLEDGEMENTS

The authors thank Fundac¸

˜

ao de Amparo

`

a Pesquisa do

Estado de Minas Gerais (FAPEMIG), Conselho Na-

cional de Desenvolvimento Cient

´

ıfico e Tecnol

´

ogico

(CNPq) and Universidade Federal de Ouro Preto

(UFOP) for supporting this research.

REFERENCES

Adhikary, D. D., Bose, G. K., Jana, D. K., Bose, D., and

Mitra, S. (2016). Availability and cost-centered pre-

ventive maintenance scheduling of continuous opera-

ting series systems using multi-objective genetic algo-

rithm: A case study. Quality Engineering, 28(3):352–

357.

Brucker, P. (2007). Scheduling algorithms, volume 3. Sprin-

ger.

Hansen, P. and Mladenovi

´

c, N. (2014). Variable neighbor-

hood search. In Search methodologies, pages 313–

337. Springer.

Mladenovi

´

c, N. and Hansen, P. (1997). Variable neig-

hborhood search. Computers & Operations Research,

24(11):1097–1100.

Sharma, A., Yadava, G., and Deshmukh, S. (2011). A lite-

rature review and future perspectives on maintenance

optimization. Journal of Quality in Maintenance En-

gineering, 17(1):5–25.

Sim

˜

oes, J. M., Gomes, C. F., and Yasin, M. M. (2011). A

literature review of maintenance performance measu-

rement: A conceptual framework and directions for

future research. Journal of Quality in Maintenance

Engineering, 17(2):116–137.

Yamayee, Z., Sidenblad, K., and Yoshimura, M. (1983). A

computationally efficient optimal maintenance sche-

duling method. IEEE Transactions on Power Appara-

tus and Systems, 102(2):330–338.

Yao, X., Fern

´

andez-Gaucherand, E., Fu, M. C., and

Marcus, S. I. (2004). Optimal preventive mainte-

nance scheduling in semiconductor manufacturing.

IEEE Transactions on Semiconductor Manufacturing,

17(3):345–356.

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

310