A New Device for Hydrogen Production on Demand with Application

to Electric Assist Bike: Description, Production Characteristics and

Basic Control

Jocelyn Sabatier

1

, Fabrice Mauvy

2

, Jean-Louis Bobet

2

, Damien Mohedano

3

,

Matthieu Faessel

3

and Frédéric Bos

3

1

Bordeaux University, IMS Lab., UMR 5218 CNRS, 351 Cours de la Libération, 33405 Talence, France

2

CNRS, ICMCB Lab, UPR 5026, 87 Avenue du Dr Albert Schweitzer, 33600 Pessac, France

3

Bordeaux University, TechnoShop Coh@bit platform, Bordeaux Institute of Technology,

15 Rue Naudet, 33750 Gradignan, France

Keywords: Hydrogen, PEM Fuel Cell, Production on Demand, Water Hydrolysis, Magnesium.

Abstract: Using a magnesium-based hydrolysis reaction that spontaneously produces hydrogen with a high kinetic and

a high efficiency, this paper proposes a solution to supply a PEM fuel cell that permits production on

demand. This solution is an instrumented reactor that uses capsules with magnesium powder and that

controls the hydrolysis reaction in order to maintain a constant pressure. The hydrogen produced by the

reactor is used to feed a PEM fuel cell in which variable electric loads are applied. By solving both the

hydrogen supply and storage problems, such a system is particularly suitable for light mobility applications.

1 INTRODUCTION

Urban travel covers a significant economic reality.

The last mile represents almost 20% of the total cost

of the freight value chain. In France, it accounts for

about 20% of the traffic, occupies 30% of the road

network and is responsible for 25% of greenhouse

gas emissions (Roullé and Lorrillard, 2012). The last

mile problem of goods and persons thus raises many

essential issues - economic, environmental, societal

and urbanistic - that the authorities are trying to

solve with electric vehicle such as bicycle or

tricycle. As the recharging of these means of

transport is a lengthy process, dihydrogen (H

2

)

coupled with a fuel cell as a source of fuel is thus

often considered.

Hydrogen mobility is seen by many as a solution

for the future. Indeed, the modularity of hydrogen

(used directly or indirectly via a fuel cell), its high

combustion energy (3 times that of hydrocarbons)

and its non-polluting nature make it a very

promising fuel. However, three major problems

hinder the large-scale development of this

technology.

Environment: 95% of the hydrogen currently

produced comes from steam reforming of natural gas

which does not solve environmental problems. The

production of hydrogen without an environmental

impact therefore remains an important issue

Refueling: In a country such as France, there are

only very few points where hydrogen refueling is

possible.

Storage: Hydrogen can be stored under pressure

or in liquid form, which in both cases causes storage

safety and/or cost problems, or in solid form in

hydrides, which solves the safety question but

induces a large tank mass constraint. In any case, the

volume of the tank will be larger than a tank of

hydrocarbons.

The work described in this paper provides an

answer in the area of electric assistance for bikes or

tricycles or more generally for light mobility. In

such applications, the hydrogen must be produced

on demand, as the PEM fuel cell needs to consume it

to produce electrical energy, to avoid any storage

constraints. To reach this goal, the hydrogen is

produced by the help of water hydrolysis. In order to

control the reaction, a dedicated reactor was

designed. This reactor has been implemented in a

Sabatier, J., Mauvy, F., Bobet, J-L., Mohedano, D., Faessel, M. and Bos, F.

A New Device for Hydrogen Production on Demand with Application to Electric Assist Bike: Description, Production Characteristics and Basic Control.

DOI: 10.5220/0006846304110419

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 1, pages 411-419

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

411

test bench to feed a PEM fuel cell associated to an

electric load.

2 CHEMICAL REACTIONS FOR

HYDROGEN PRODUCTION

In the present study, hydrogen gas is produced by

hydrolysis reaction. One of the main advantage is

that no additional energy is required (low

temperature operation) and delocalized and rather

pure hydrogen can be produced. Various materials

have been used to perform hydrolysis: complex

hydrides (Kojima et al, 2004), (Muir and Yao,

2011), metal (Huang et al, 2013), metal hydride

(Uesugi et al, 2011), and intermetallics (Li et al,

2013) (Huang et al., 2014).

Magnesium metal was selected in this study for

hydrogen production via hydrolysis due to its high

electrochemical activity, low density, low cost,

abundance and nontoxicity.

Magnesium reacts with water according to the

following equation:

2

2

2

HOHMgO2HMg

. (1)

However, the magnesium hydrolysis reaction is

always blocked by the formation of a passive

hydroxide layer Mg(OH)

2

at the surface of the solid

grains and cannot be carried out completely

(maximum yield of 10 to 15% only). In order to

improve the hydrolysis efficiency of Mg, different

additives and grinding processes have been

investigated. The technical solution used here is

described in details in (Awad et al, 2016) (Mauvy et

al, 2017). The resulting powder exhibits fast kinetics

and 100% yield. Considering reaction (1), 1 g of

magnesium powder (with above-mentioned

additives) with 1.5 g (or ml) of water produces

0.877 l (or 0.0789 g) of dihydrogen, leading to a

chemical energy of 9.03 kJ. In the laboratory, the

efficiency of this reaction is within 90 and 100%

(depending on the additives used) (Awad et al,

2016).

3 REACTOR

3.1 Description of the Setup

The reaction described by relation (1), is

spontaneous (if prepared as explained in (Awad et

al, 2016)) and only terminates when one of the two

reagents (magnesium or water) is lacking.

For bike electric assistance fed with a PEM fuel

cell, in order to avoid a constraining storage tank,

hydrogen must be produced on demand, as the PEM

fuel cell needs to consume it to produce electricity.

Water circulation

Hydrogen circulation

Heat exchange

Figure 1: Reactor used to control the water hydrolysis that

produces hydrogen: sectional view (up), general view

(down).

To control the kinetic parameters, an

instrumented reactor was designed and is shown

schematically in figure 1. A peristaltic pump

immersed in the water tank is used to supply a water

flow proportional to the control voltage applied to

the motor driver. This linearity between control

voltage and water flow will facilitate the synthesis of

the control law presented in section 4. The water is

stored in the compartmented tank and the

magnesium powder is contained in the separate

capsule. According to (1), a stoichiometry ratio of

1.5 between mass of water and mass of magnesium

is required. Through the nozzle , the water

sprinkles the magnesium powder and hydrogen is

produced. The hydrogen is evacuated via a non-

return valve into the water tank. The tank thus

acts as a buffer volume and allows the produced

1

2

3

4

5

6

7

8

9

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

412

hydrogen to cool, inducing a partial condensation of

the water vapor it contains. As reaction (1) is

exothermic, the reactor was equipped with a heat-

pipe cooling system . Two sensors measure the

pressure variations inside the tank and inside the

reaction chamber. A PT1000 probe was also

implemented to measure the temperature of the

reaction chamber. Two safety valves were also

mounted on the reactor.

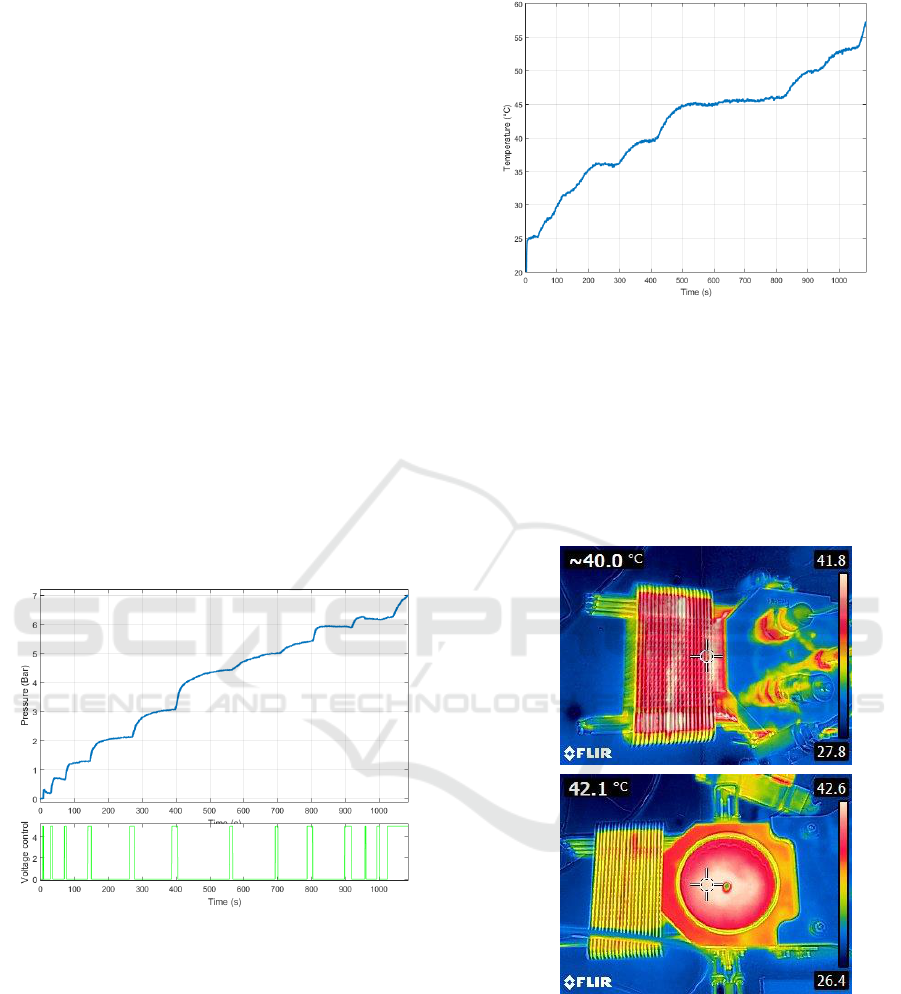

3.2 Tests without Control

The first tests of the H

2

production system were

done with a direct voltage control of the peristaltic

pump and with a capsule containing 10g of

magnesium powder. The variations in the voltage

applied to the pump and the hydrogen pressure

inside the reactor are shown in figure 2. This figure

shows that the reactor is able to control the hydrogen

production since the water injected when the pump

is controlled is completely consumed, and the

pressure no longer rises, meaning that the hydrolysis

reaction has stopped. If water is injected again, the

reaction is resumed and the pressure increases step

by step.

Figure 2: Pressure variation (top) resulting in voltage

control of the pump (bottom).

Due to :

- the proportionality between the injected water flow

and the control voltage applied to the pump

driver,

- the stoichiometry conditions imposed by reaction

(1),

it is possible to define when all the magnesium of

the capsule has been consumed and to create a fuel

gauge.

Figure 3: Temperature variation during the test.

Reactor chamber temperature variations are

shown in figure 3. This temperature analysis was

completed by thermal imaging as illustrated by

figure 4. These figures highlight the efficiency of the

heat-pipe cooling system that reaches a high

temperature during the test in comparison with the

other parts of the reactor (strong heat dissipation of

the cooling system).

(a)

(b)

Figure 4: Thermal imaging of the reactor during the test

and after the test, reaction chamber being open.

A New Device for Hydrogen Production on Demand with Application to Electric Assist Bike: Description, Production Characteristics and

Basic Control

413

(a) (b)

(c) (d)

Figure 5: Powder spray system (a), and capsule with

magnesium powder (b), capsule containing the reaction

products (c) and (d).

Figure 5 shows:

(a) the reaction chamber and the nozzle , without a

capsule;

(b) the reaction chamber with a capsule filled with

magnesium powder

(c) the capsule inside the reaction chamber at the end

of the reaction

(d) the capsule outside the reaction chamber after the

reaction.

After the reaction, the capsule content is magnesium

hydroxide which is a non-polluting and non-harmful

substance (black color due to the additives).

4 TEST BENCH

4.1 Description

The reactor was integrated into the test bench

described in figure 6, equipped with a 100W PEM

type fuel cell. On this bench, the fuel cell is

connected to a resistor (load) controlled in PWM

mode. At the output of the reactor, the hydrogen

pressure is reduced to 0.6 bar to be compatible with

the fuel cell operating specifications. The hydrogen

flow that supplies the fuel cell is also measured by a

flowmeter. The bench supervisor measures the

pressures and temperature inside the reactor, the

hydrogen flow and also several electrical quantities

at the fuel cell and the load terminals. The

supervisor generates the PWM signal applied to the

load, warns the operator when all the magnesium

inside the reactor has been consumed, and manages

Figure 6: Test bench with the reactor and the 100W PEM

fuel cell.

several safety devices. Another goal of this

supervision is to control the kinetics of the

hydrolysis reaction, by regulating the water flow

injected by the pump, through the control of the

voltage V(t) applied to the pump driver, in order to

maintain the hydrogen pressure P(t) inside the

reactor at a reference value P

ref

(t), where t is time.

This is carried out by a control loop shown in figure

7.

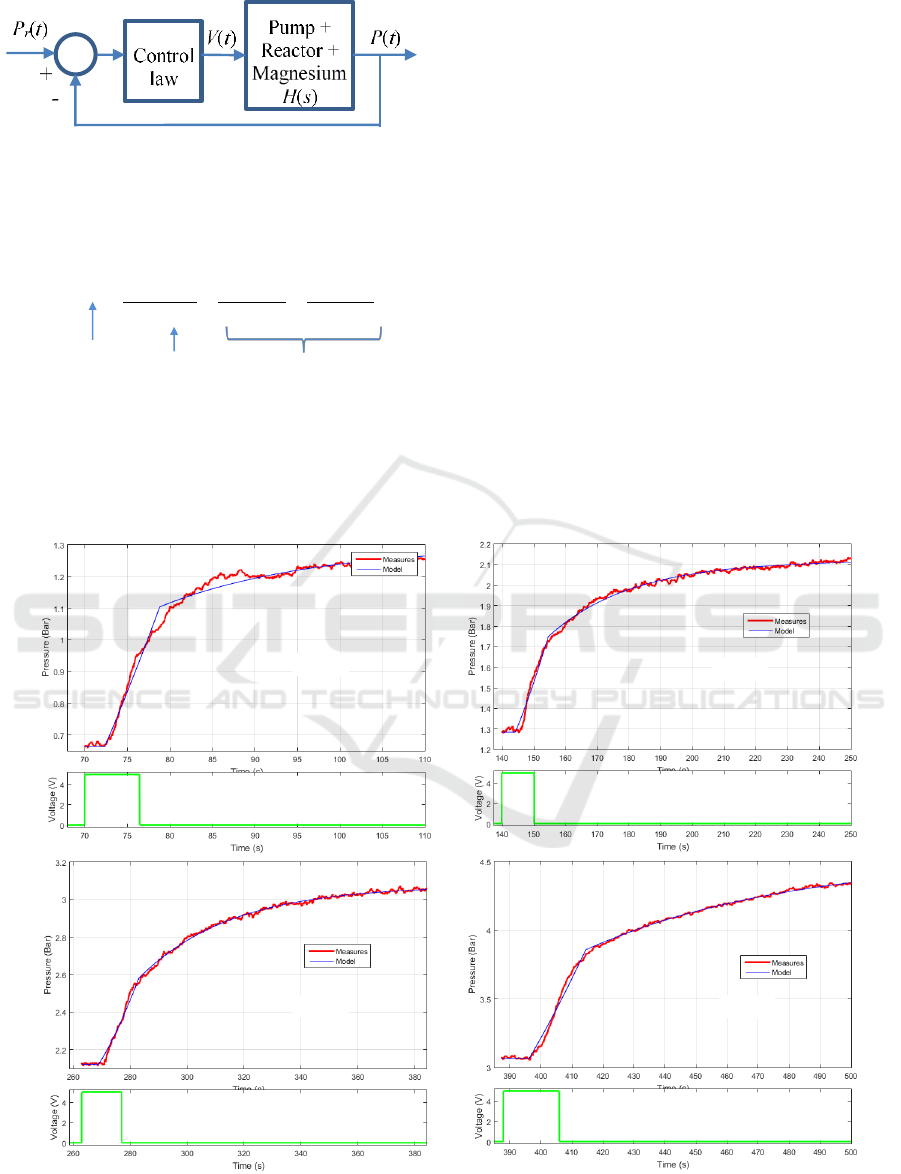

4.2 Dynamical Behaviour Analysis

Prior to the design of the control law in figure 7, the

dynamical system linking the pressure P(t) inside the

reactor and the control voltage V(t) applied to the

pump driver must be modeled. Figure 2 shows the

pressure variations when limited duration step input

voltages are applied to the pump driver. This figure

reveals that such a system is weakly non-linear:

similar pressure behaviors are obtained in spite of

variable step duration and whatever the operating

pressure and temperature. A linear modeling

approach was therefore adopted using a transfer

function H(s), where s denotes the Laplace variable.

Measures plotted in figure 8, extracted from the

curves in figure 3, highlight that the pressure

responses begin with a transport delay with respect

to the pump control voltage (part 1). It is followed

by a quasi-linear rise of the pressure (part 2) and

finally there is a long memory relaxation after

stopping the pump (part 3).

Pressure

reducer

Flow

meter

Reactor

Fuel

cell

Load

Fuel cell

controller

Bench

supervisor

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

414

Figure 7: Solution for the pressure control inside the

reactor.

A possible transfer function H(s) is thus:

111

3

3

2

2

1

1

s

K

s

K

ss

K

esH

sT

(2)

where T (sec), is the model time delay, and where K

i

(bars/V) and

I

(sec), i[1..3] are respectively gains

and time constants.

Numerical values of the parameters in relation (2)

can be evaluated for the various operating pressures

considered as shown by figure 8. They are obtained

using a nonlinear optimization algorithm that

minimizes the difference between the recorded data

and the model output. The following inequalities

were obtained:

-2

1

-3

1.9609x103.8929x10 K

. (3)

2

2

-1

1.0061x101.1188x10 K

(4)

2

3

1

1.4938x101.1142x10 K

(5)

1

1

7.4150x104.4598

(6)

4

2

1

2.2138x101.7927x10

(7)

4

3

1

7.3709x101.7927x10

(8)

sTs 91

. (9)

Comparisons between the system and the model

responses obtained are shown in figure 8 and reveal

that the models capture the dynamical behavior of

the system well.

Figure 8: Evolution of the pressure inside the reactor versus time and model response for different working conditions: (a)

from 0.7 bar to 1.2 bar, (b) from 1.3 bar to 2.1 bar, (c) from 2.1 bar to 3 bar, (d) from 3 bar to 4.5 bar.

Part 1

Part 2

Part 3

(a)

(b)

(c)

(d)

A New Device for Hydrogen Production on Demand with Application to Electric Assist Bike: Description, Production Characteristics and

Basic Control

415

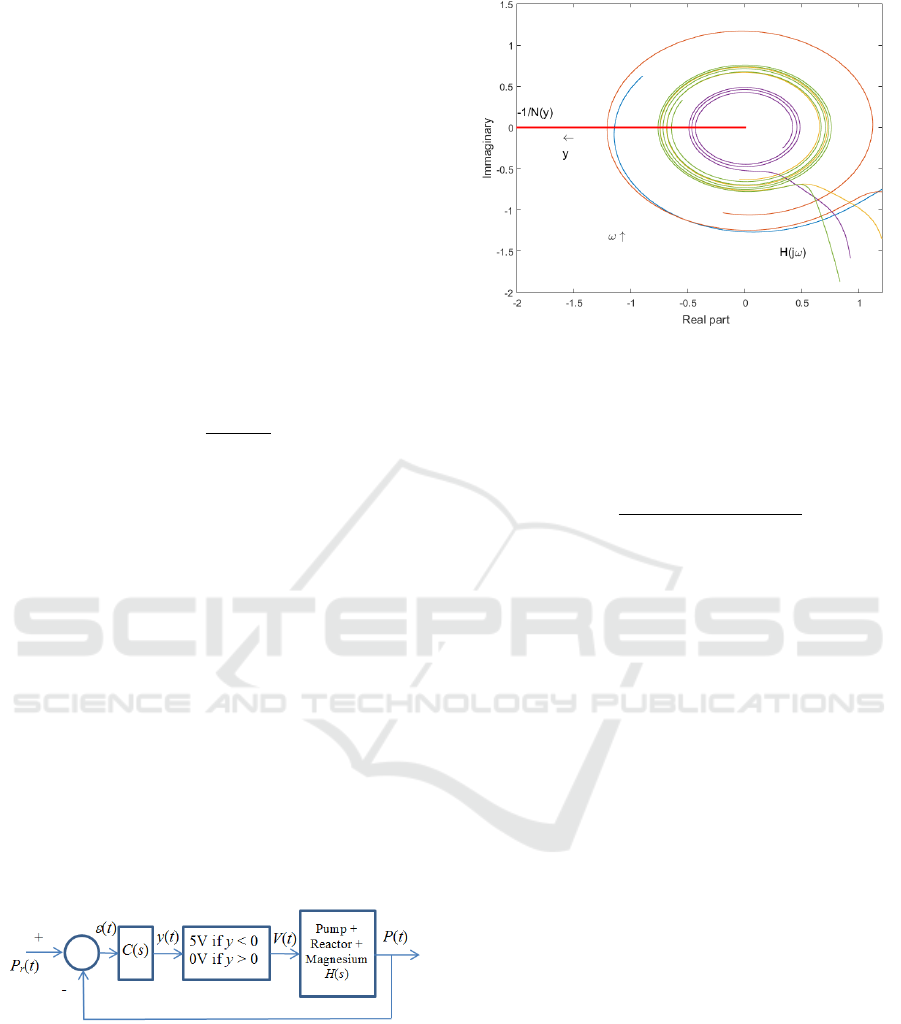

4.3 Pressure Controller

Due to the tradeoff imposed by time delays on a

control law (Middleton, 1991) a linear robust control

cannot lead to a large bandwidth feedback system

for the pressure control. Thus, to take into account

parametric variations (Utkin, 1993) highlighted in

the previous section and to ensure a fast dynamical

behavior, a switching controller was used for the

reactor pressure control, the presence of a chattering

phenomenon being the price to pay. This control law

is shown in figure 9.

The controller C(s) is designed to ensure closed loop

stability and to control the period and the magnitude

of the chattering phenomenon. This controller is

defined by the transfer function C(s) reported in

relation (10)

15/

1100

s

s

sC

. (10)

As shown in figure 10, in which the Nyquist

diagram of the transfer function C(s)H(s) and of the

describing function and of the relay nonlinearity are

plotted, such a controller ensures closed loop

stability and a limit cycle whose frequency is within

the interval [0.07- 1.2] rd/s, depending on the

parameters considered for H(s). In this frequency

band, the gain of H(j) is less than -20 dB, thus

leading to a limit cycle magnitude close to 0.2 bar.

The controller C(s), but also several other

supervision functions (temperature, magnesium

gauge, end of reaction detection, fuel cell on/off,

load control, …) are implemented with a National

Instruments MyRio board. The sampling period T

e

of the supervision main loop and thus of the pressure

control loop is chosen equal to 10 ms. The sampling

frequency is thus 628 rd/s. This is more than 1000

times the controlled system bandwidth.

Figure 9: Solution for the control of the pressure inside the

reactor.

Figure 10: Nyquist plot of the transfer function C(s)H(s)

and of the describing function of the relay nonlinearity.

The controller discretization can thus be done using

the Euler approximation s = (1-z

-1

)/T

e

. It thus defined

by

9.950248-z

-9.9502489.955223z

zC

. (11)

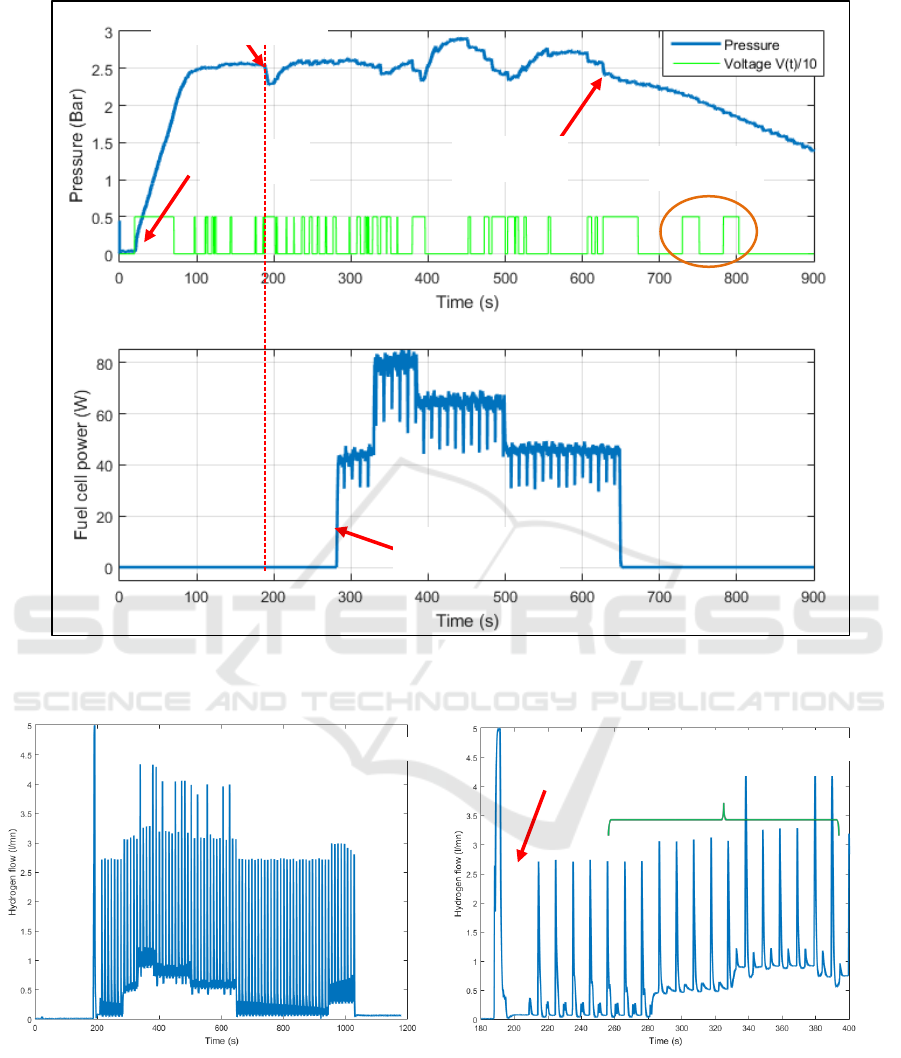

4.4 Results

To evaluate the efficiency of the pressure control

loop, a test with 15 g of magnesium powder was

carried out. During the test, the pressure reference is

set to 2.5 bars. The evolution of the pressure versus

time is shown in figure 11. On this figure, the pump

control voltage and the electrical power produced by

the fuel cell are also depicted. Figure 12 shows the

hydrogen flow produced by the reactor and figure 13

plots the reactor temperature variations.

These figures highlight that the pressure control loop

was started about 25 seconds after the beginning of

the test. The maximum voltage was then applied to

the pump leading to a fast increase of the pressure

inside the reactor (around 50 mbar/s). At time t =

100s, the reference pressure was reached and the

control voltage went back to 0. Without hydrogen

consumption, the pressure remained stable.

The fuel cell is started at time t = 190s. A strong

purge is created by the fuel cell management system

(see figure 11) leading to a pressure decrease inside

the reactor that is countered by the pressure closed

loop. For proper fuel cell operation, the system

generates purges and periodic short circuits (every 5

seconds alternately) that do not affect the pressure

control (on the time interval [200s – 280s]. On the

time interval [280s – 650s], a varying load is applied

to the fuel cell. When the load increases, hydrogen

consumption also increases (see figure 12).

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

416

Figure 11: Pressure variation inside the reactor and control voltage applied to the pump (up), electrical power produced by

the fuel cell.

Figure 12: Hydrogen flow produced by the reactor during the test (a) and zoom on the beginning of the test (b).

However, the pressure remains stable, thus

demonstrating the efficiency of the pressure control

loop. When the load decreases (at time 380s and

500s), a kind of overshoot appears. This

phenomenon was assigned to an excess of water in

the reactor when the hydrogen demand falls sharply,

since the system and the control law do not allow

this water to be withdrawn.

At time 630s, the reactor temperature decreases

in spite of the pump control voltage being high. This

Control loop

start-up

End of the

reaction

Fuel cell start-up and

corresponding purge

Fuel cell

start-up

Periodic purges and

short circuits

Control

forcing

Load applied to the

fuel cell

(a)

(b)

A New Device for Hydrogen Production on Demand with Application to Electric Assist Bike: Description, Production Characteristics and

Basic Control

417

means that all the powder has been consumed. To

check it, the pump control voltage is forced at time

730s and 780s. As no pressure increase appears, this

confirms the end of the reaction. It should be pointed

out that the noisy power signal in figure 11 is the

result of purges and short circuits imposed on the

fuel cell. The reactor temperature evolution versus

time is shown by figure 13. The temperature remains

below 75°C and decreases when all the powder has

been consumed (this signal thus informs about the

end of the reaction).

5 REACTOR BEHAVIOUR IN

REAL OPERATION

Given the satisfactory behavior of the prototype, the

authors are currently mounting the prototype on the

electric bike shown in figure 14. This electric bike

was designed at the Bordeaux Institute of

Technology and presented at the 2015 Intelligent

Transport System ITS World Congress. It provides

an electric assistance proportional to the power

produced by the cyclist using pedals that capture the

pedaling effort. As shown by figure 15, the electric

power is provided by a kit mounted on the bike

which incorporates a 100 W fuel cell.

6 CONCLUSIONS

In this research work, a solution to produce

hydrogen on demand based on water hydrolysis

using magnesium was presented. It involves a

reactor whose internal pressure is adjusted by

controlling the hydrolysis reaction. Tests on a bench

fitted with a 100 W PEM fuel cell have

demonstrated the technological potential of this

solution for electric assistance applications in the

field of light mobility.

In this first phase of tests, the reactor was designed

to withstand a pressure of 25 bars, which makes it

rather cumbersome. The authors are thus working on

an improved, more ergonomic version, with more

sophisticated control solutions for a better pressure

control (overshoot suppression).

ACKNOWLEGMENTS

The authors acknowledge the AST society, the

Aquitaine SATT, for the funding of the prototype

presented in this paper in the form of the HELP

maturation project.

The authors also acknowledge the Bordeaux

Institute of Technology team who designed the

electric bike on which the reactor is currently

installed (Leyney and Sabatier, 2016) during a

project that was funded by Bordeaux city.

Figure 13: Temperature inside the reactor during the test.

Figure 14: Electrified Bordeaux city bike shown during

the 2015 Intelligent Transport System (ITS) World

Congress.

Figure 15: Fuel cell and control kit installed on the bike.

Fuel cell

start-up

Control

loop start-

up

End of the

reaction

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

418

REFERENCES

Awad A. S., El-Asmar E, Tayeh T., Mauvy F., Nakhl M.,

Zakhour M., Bobet J. L. (2016), Effect of carbons (G

and CFs), TM (Ni, Fe and Al) and oxides (Nb2O5 and

V2O5) on hydrogen generation from ball milled Mg-

based hydrolysis reaction for fuel cell, Energy Vol 95,

pp 175-186.

Huang X, Gao T, Pan X, Wei D, Lv C, Qin L, et al., 2013,

A review: feasibility of hydrogen generation from the

reaction between aluminum and water for fuel cell

applications. J Power Sources, Vol 229, pp 133-40.

Huang JM, Ouyang LZ, Wen YJ, Wang H, Liu JW, Chen

ZL, et al. (2014), Improved hydrolysis properties of

Mg

3

RE hydrides alloyed with Ni. Int J Hydrogen

Energy Vol. 39, pp 6813-8.

Kojima Y, Kawai Y, Kimbara M, Nakanishi H,

Matsumoto S., 2004, Hydrogen generation by

hydrolysis reaction of lithium borohydride. Int J

Hydrogen Energy, Vol. 29, pp 1213-7.

Leyney M, Sabatier J., Conception d’un kit d’assistance

électrique pour la flotte des vélos de la ville de

Bordeaux en versions purement électrique et

hybridation à base de Pile à Hydrogène - GeSi Revue

des départements de Génie Electrique & Informatique

Industrielle n°88 (2016), p. 41-51.

http://www.gesi.asso.fr/images/revue/complet/GESI88

.pdf

Li F, Sun L, Zhao J, Xu F, Zhou H-Y, Zhang Q-M, et al.

(2013), Mechanisms of H2 generation for metal doped

Al16M (M¼Mg and Bi) clusters in water. Int J

Hydrogen Energy, Vol. 38, pp 6930-7.

Mauvy F., Bobet J. L., Sabatier J., Bos F. (2017), Matériau

à base de magnésium destiné à la production de

dihydrogène ou d'électricité, INPI Patent application

on October 6th, 2015 under the reference 1559,

published on April, 13th, 2017 ref WO2017060368 A1

Middleton R.H., Trade-offs in linear control system

design, Automatica, Vol. 27, pp 281-292, n° 2, 1991.

Muir SS, Yao X., 2011, Progress in sodium borohydride

as a hydrogen storage material: development of

hydrolysis catalysts and reaction systems. Int J

Hydrogen Energy Vol. 36, pp 5983-97.

Roullé J. M., Lorrillard J., 2012, Pour un renouveau de la

logistique urbaine, Note d'analyse 274,

http://archives.strategie.gouv.fr/cas/content/note-

danalyse-274-pour-un-renouveau-de-la-logistique-

urbaine.html.

Uesugi H, Sugiyama T, Nii H, Ito T, Nakatsugawa I.,

2011, Industrial production of MgH2 and its

application. J Alloy Compd, Vol. 509S, pp. 650-3.

Utkin V. I., 1993, Sliding Mode Control Design Principles

and Applications to Electric Drives, IEEE

Transactions on Industrial Electronics, Vol. 40, n°1,

pp 23–36.

A New Device for Hydrogen Production on Demand with Application to Electric Assist Bike: Description, Production Characteristics and

Basic Control

419