Optimal Coordination of Robot Motions with Positioner and Linear

Track in a Fiber Placement Workcell

Jiuchun Gao

1

, Anatol Pashkevich

1

, Marco Cicellini

1

and Stéphane Caro

2

1

Laboratoire des Sciences du Numérique de Nantes (LS2N), Institut Mines-Télécom Atlantique, Nantes, France

2

Laboratoire des Sciences du Numérique de Nantes (LS2N), Centre National de la Recherche Scientifique, Nantes, France

Keywords: Redundant Robotic System, Composite Fiber Placement, Optimal Motion Coordination.

Abstract: The paper proposes a methodology for optimal coordination of motions in robotic systems with multiple

redundant actuators. In contrast to our previous results dealing with a single redundant axis, the extended

technique is proposed allowing the robot, positioner and linear track to be actuated simultaneously in order

to reduce the total processing time. The developed technique transforms the original continuous problem

into a discrete one where the desired time-optimal motions are presented as a shortest path on the task graph

satisfying the problem-specific acceleration and velocity constraints imposed on the joint coordinates. The

desired time optimal motions are generated using enhanced dynamic programming algorithm that considers

both of these constraints. Two case studies are presented to demonstrate efficiency of the approach and

evaluate benefits of simultaneous actuation of all robotic system axes.

1 INTRODUCTION

Currently, composite materials have been

increasingly used in aerospace and automotive

industries because of their good strength-to-weight

ratio and durability (Pham et al., 2016, Garoushi,

2018). For fabricating complex composite parts,

automated fiber placement technique is widely used

(Gay, 2014, Frketic et al., 2017). The relevant

technological process can be implemented by using

either specifically designed CNC machines or

robotic systems. Such machines have no limitations

on the component size, but they are expensive and

usually require large work-floor areas (Gallet-

Hamlyn, 2011). In contrast, the robotic systems are

relatively cheap and flexible, allowing changing the

product type easily. However, they are usually

kinematically redundant because of excessive

number of actuated axes that are provided by a 6-dof

robot, a 1-dof positioner and a 1-dof linear track. For

this reason, in robotic fiber placement the optimal

coordination of the manipulator motions with the

positioner/track movements is an important issue.

In literature, there are a number of works that deal

with the redundancy resolution in robotic systems.

Relevant techniques are usually based on the pseudo

inverse of the kinematic Jacobian (Flacco and De

Luca, 2015). However, they can be hardly applied to

the considered problem because they do not allow

generating optimal trajectories satisfying real-life

industrial requirements (Kazerounian and

Nedungadi, 1988). Alternatively, there are also

several techniques based on conversion of the

original continuous problem to a discrete one. The

simplest one is able to generate time-optimal

trajectories for point-to-point motions and was

applied to the spot-welding (Gueta et al., 2008,

Gueta et al., 2017). A slightly different method was

proposed in (Pashkevich et al., 2004) for the laser

cutting and arc-welding applications where the

motion amplitude for the actuated axes was

minimized but the tool speed was assumed to be

constant.

For the considered process, where the tool speed

variations are allowed in certain degree, a discrete

optimization based methodology was proposed in

our previous work (Gao et al., 2017). It allows the

user to convert the original problem to the

combinatorial one taking into account particularities

of the fiber placement technology and to generate

time-optimal coordinated motions for the robot and

positioner. However, the technique was applied to a

planar benchmark example only, with a single

redundant variable. In this work, an extension of the

previous results is proposed allowing dealing with

Gao, J., Pashkevich, A., Cicellini, M. and Caro, S.

Optimal Coordination of Robot Motions with Positioner and Linear Track in a Fiber Placement Workcell.

DOI: 10.5220/0006848105670575

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 567-575

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

567

the optimal motion coordination for robotic systems

with higher degree of redundancy, which arises

when the robotic manipulator, the positioner and

linear track actuated simultaneously.

2 ROBOTIC FIBER PLACEMENT

PROBLEM

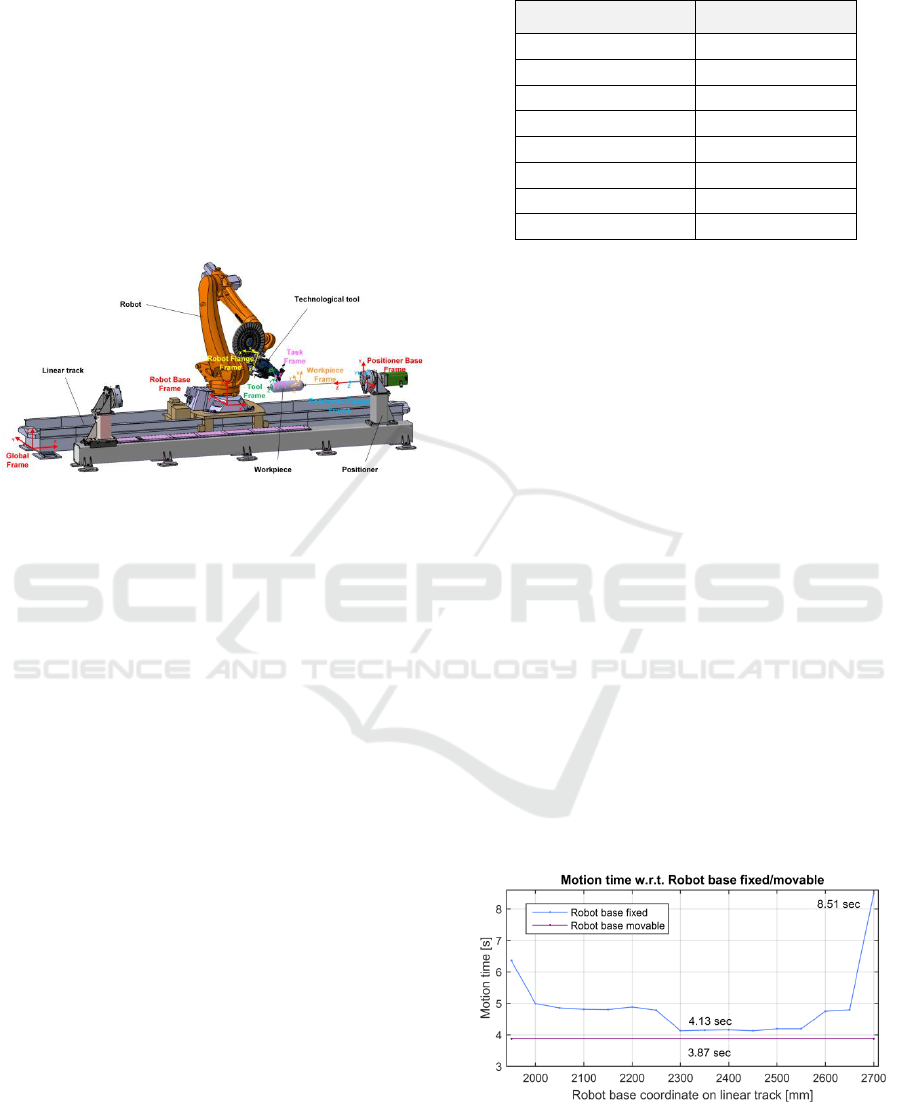

A typical robotic fiber placement workcell is

presented in Figure 1. Here, the workpiece to be

covered by the composite fiber reinforcement is

manipulated by the positioner, which is able to

change its orientation in order to improve

accessibility of certain zones by the technological

tool. This tool is attached to the robot flange and

ensures placement of the fiber reinforcement in

desired locations. The robot is installed on a

translational linear track allowing adjusting its base

location while processing relative large products.

Figure 1: Robotic fiber placement workcell.

In robot-based composite manufacturing,

preparation of the manufacturing process includes a

number of stages presented in Figure 2, where the

motion coordination of all robotic system

components is one of the most difficult procedures.

Within this process, the desired fiber placement path

is generated using a dedicated CAM system and it is

presented in a discrete form. Further, the obtained

set of task points is transformed into the task graph

that describes all possible combinations of the robot,

positioner and linear track coordinates. Then, the

motion generator produces the optimal trajectories

that correspond to the “shortest” path on the task

graph. Finally, the obtained motions are converted

into the program for the robot control system.

Figure 2: Manufacturing process preparation for robotic

fiber placement processes.

3 SYSTEM KINEMATIC MODEL

To describe the fiber placement task, let us present it

as a sequence of the frames

()

{ , 1,2,... }

i

task

F i n

, in such

a way that the X-axis is directed along the path

direction and Z-axis is normal to the workpiece

surface pointing outside of it. Using these notations,

the task locations can be described by a set of 4×4

homogenous transformation matrices and the

considered task is formalized as follows:

(1) ( ) ( )

; 1,2,...

w w i w n

task task task

inTTT

(1)

where all vectors of positions and orientations are

expressed with respect to the workpiece frame (see

superscript “w”). To execute the given fiber

placement task, the technological tool must visit the

frames defined by (1) as fast as possible.

In any task location, the spatial configurations of the

robot, positioner and linear track can be described by

the joint coordinates

R

q

,

P

q

and

L

q

. So, the task

locations can be expressed using the direct kinematic

functions of these components, which are further

denoted as

()

RR

g q

,

()

PP

gq

and

()

LL

gq

. This allows

us to write the kinematic equations describing the

given fiber placement task in the following form

( ) ( )

( ) ( )

( ) ( )

( ) 1,2,...;

World i i Tool

Lbase L L R R task

World i w i

Pbase P P task

g q g

g q i n

T q T

TT

(2)

where all notations are defined in Figure 1. It is clear

that the above equations cannot be solved for

R

q

,

P

q

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

568

and

L

q

in unique way because the robotic system is

kinematically redundant. On the other side, it gives

some freedom for optimizing the coordinated

motions of the robotic manipulator with the

positioner and linear track movements.

4 GENERATION OF OPTIMAL

COORDINATED MOTIONS

To present the problem in a formal way, let us define

the function

()

R

tq

,

()

P

qt

and

()

L

qt

describing

profiles of the robot, positioner and linear track joint

coordinates as a function of time

[0, ]tT

.

Additionally, let us introduce a sequence of time

instants

12

{ , ,... }

n

t t t

corresponding to the cases when

the technological tool visits the task locations (1).

So, the considered motion coordination problem can

be presented as

( ), ( ), ( )

()

min max

, , , , , ,

min

, , , ,

{ ( ), ( ), ( ) 1, 2, ... }

min

..

( ( )) ( ( ))

( ( ))

()

()

R L P

R i P i L i

t q t q t

World Tool

Lbase L L i R R i task

World w i

Pbase P P i task

R P L R P L i R P L

R P L R P L i

find

t q t q t i n

such that

T

st

g q t g t

g q t

t

t

q

q

T q T

TT

q q q

qq

max

,,

min max

, , , , , ,

max

1

()

( ( ))

( ), ( ), ( ) 0

0, ; 1, 2, ...

R P L

R P L R P L i R P L

Ri

R i P i L i

n

t

cond t C

colls t q t q t

where

t t T i n

q

q q q

Jq

q

(3)

where the main objective is to minimize the total

motion time using full capacities of the redundant

robotic system, which are limited by the maximum

velocity/acceleration values for the actuated joints.

Besides, the collision constraints

()colls

as well as

the distance to singularities

()cond

are also taken

into account.

Because of specific constraints, the above presented

continuous optimization problem cannot be solved

in a straightforward way. For this reason, the

considered problem is converted into a discrete form

by sampling the redundant variables corresponding

to the positioner and the linear track. Then, using

ideas proposed in our previous work (Gao et al.,

2017) and applying sequentially the direct

kinematics of the positioner and linear track as well

as the inverse kinematics of the robot, one can get a

configuration state for the robotic system in joint

space (see Figure 3). This allows generating an

extended task graph where all task locations are

ordered in time. This graph contains all possible

configuration states of the considered robotic system

for executing the given fiber placement path, and the

desired time-optimal solution of the relevant

optimization problem is presented as the shortest

path connecting the initial and the final layers. An

outline of the task graph generation algorithm is

presented in Appendix A.

Figure 3: Transformation of the original continuous

problem into discrete form.

The structure of this 3D graph is presented in

Figure 4 where the nodes

12

( , , )

12

{ , };

k k i

task

kkL

correspond to the i

th

task location

()wi

task

T

and the

indices

12

( , )kk

are related to the sampled

coordinates of the positioner and linear track

respectively.

Using such presentation, the original continuous problem

(1) is converted into a specific shortest-path problem on

the graph, where all three successive nodes satisfy the

acceleration constraints and the distances between two

nodes

12

( , , )k k i

task

L

and

12

( , , 1)k k i

task

L

are equal to the technological

tool displacement time from the i

th

to the (i+1)

th

task point,

which is restricted by the maximum velocities and

accelerations of the robot, the positioner and the linear

track. It should be also noted that some of the nodes are

excluded from the graph because of violation of the

collision or singularity constraints as well as the joint

limits. These nodes are marked as “inadmissible” ones in

Figure 4, and they are not connected to any neighbour. So,

the objective function to be minimized (robot motion time)

Optimal Coordination of Robot Motions with Positioner and Linear Track in a Fiber Placement Workcell

569

Figure 4: Task graph corresponding to the motion

generation problem with two redundant variables.

can be presented as the sum of the edge weights

11

1 2 1 2

( , , ) ( , , 1)

1

1

( , ) min

i i i i

k k i k k i

task task

n

i

T dist LL

(4)

that is computed as

11

1 2 1 2

11

1 2 1 2

( , , ) ( , , 1)

( , , ) ( , , 1)

max

1,2,...8

( , ) max

i i i i

i i i i

k k i k k i

jj

k k i k k i

task task

j

j

qq

dist

q

LL

i.e. taking into account the maximum allowable

velocities

max

{ 1,2,...8};

j

qj

of the actuators.

Corresponding optimal solution is represented by the

sequence

1 1 2 2

1 2 1 2 1 2

( , , 1) ( , , 2) ( , , )

{ } { } { }

nn

k k k k k k n

task task task

L L L

that

contains the actuated coordinates of the robot,

positioner and linear track. It worth mentioning that

the above expression straightforwardly takes into

account the velocity constraints, while the

acceleration constraints are verified by means of the

second order approximation applied to the

corresponding functions

()

R

tq

,

()

P

qt

and

()

L

qt

on

the time interval

11

[ , ]

ii

t t t

. It allows us to present

the acceleration constraints on the desired trajectory

of the considered robotic system in the following

form:

( 1) ( )

1

max

11

2

ii

i j i j

j

i i i i

t q t q

q

t t t t

(5)

where

11

1 2 1 2

( , , ) ( , , 1)

()

i i i i

k k i k k i

i

j j j

q q q

and the time

intervals

i

t

are computed as the distance between

the nodes

12

( , , )

ii

k k i

task

L

and

11

12

( , , 1)

ii

k k i

task

L

.

To find the desired optimal path, conventional

optimization techniques can be hardly applied

because of extremely high computing time (Gao et

al., 2017). Besides, these techniques are not able to

take into account the acceleration constraints that are

very essential here. For these reasons, a dedicated

problem-oriented algorithm has been developed for

this problem.

This algorithm is based on the dynamic

programming principle, aiming at sequentially

finding the shortest paths for the problems of lower

dimensions, i.e. from

11

12

( , 1)

12

{ , , }

k , k

task

kkL

to the

current nodes

12

( , )

12

{ , , }

ii

k , k i

task

kkL

. If the length of the

corresponding shortest path is denoted as

12

,,k k i

d

,

then the shortest path for the next locations

12

( , , 1)

12

{ , , }

k k i

task

kkL

can be obtained by combining the

optimal solutions for the previous column

12

( , )

12

{ , , }

k k , i

task

kkL

and the distances between the task

locations with the indices i and i+1,

1 2 1 2

1 2 1 2

,

12

( , , 1) ( , )

, , 1 , ,

min ,

kk

k k i k k , i

k k i k k i task task

d d dist LL

(6)

This expression is applied recursively, starting from

the second layer of the task graph (

2i

) and

finishing by the last one (

in

). So, the desired

optimal path can be obtained after selection of the

minimum length

12

, , 1k k i

d

corresponding to the last

layer. An outline of this path planning algorithm is

presented in Appendix B. In fact, this algorithm is

generalization of our previous technique that was

developed for motion coordination of the robotic

manipulator and positioner (without linear track). As

follows from relevant study, this algorithm is rather

time efficient in this more complicated case; which

deals with two redundant axes.

5 COMPARISON OF MOTION

COORDINATION STRATEGIES

To demonstrate advantages of the proposed

technique, let us apply it to an industrial problem

that deals with fabrication of a high-pressure

composite vessel. Relevant robotic fiber placement

workcell (see Figure 5) is composed of 6-axis serial

robot KUKA KR210 R3100, 1-axis translational

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

570

linear track KUKA KL2000 and 1-axis rotational

positioner AFPT 550.

For comparison purposes, two cases will be

considered where the robot base is assumed either

fixed or movable by means of the linear track. These

two cases correspond to different degrees of

redundancy provided by the positioner only or by

the positioner together with the linear track. For the

first case, the technique described in our previous

work (Gao et al., 2017) will be applied while the

second case is based on the technique proposed in

this paper.

Figure 5: Robot-based fiber placement workcell and

arrangement of coordinate frames.

5.1 Optimal Motion Coordination for

Fixed Robot Base

A composite vessel considered in this case study is

relatively small compared to the robot workspace. It

is composed of a cylindrical part and two elliptical

domes at both ends of the cylinder. The cylinder is

168 mm in diameter and 1200 mm in length. The

laying task includes a single circuit placement of

helical lamina. This allows executing the

manufacturing task with fixed robot base, which

simplifies the motion coordination but obviously

leads to some increase of the total motion time.

Nevertheless, here also arises another optimization

problem that deals with optimal robot placement

relative to the workpiece mounted on the positioner.

To find the optimal location of the robot base, the

space of linear track coordinate (defining the robot

placement) was sampled and the proposed motion

planning technique was applied several times,

assuming that the robot and the positioner

coordination is required only. This yields the 2D

task graph corresponding to a single redundant

variable (positioner rotation angle), which was used

to generate the time-optimal motions for each robot

base location. Relevant results are presented in

Table 1.

Table 1: Total motion time for different robot locations.

Robot location [mm]

Motion time [sec]

2000

4.99

2100

4.80

2200

4.88

2300

4.13

2400

4.16

2500

4.19

2600

4.75

2700

8.51

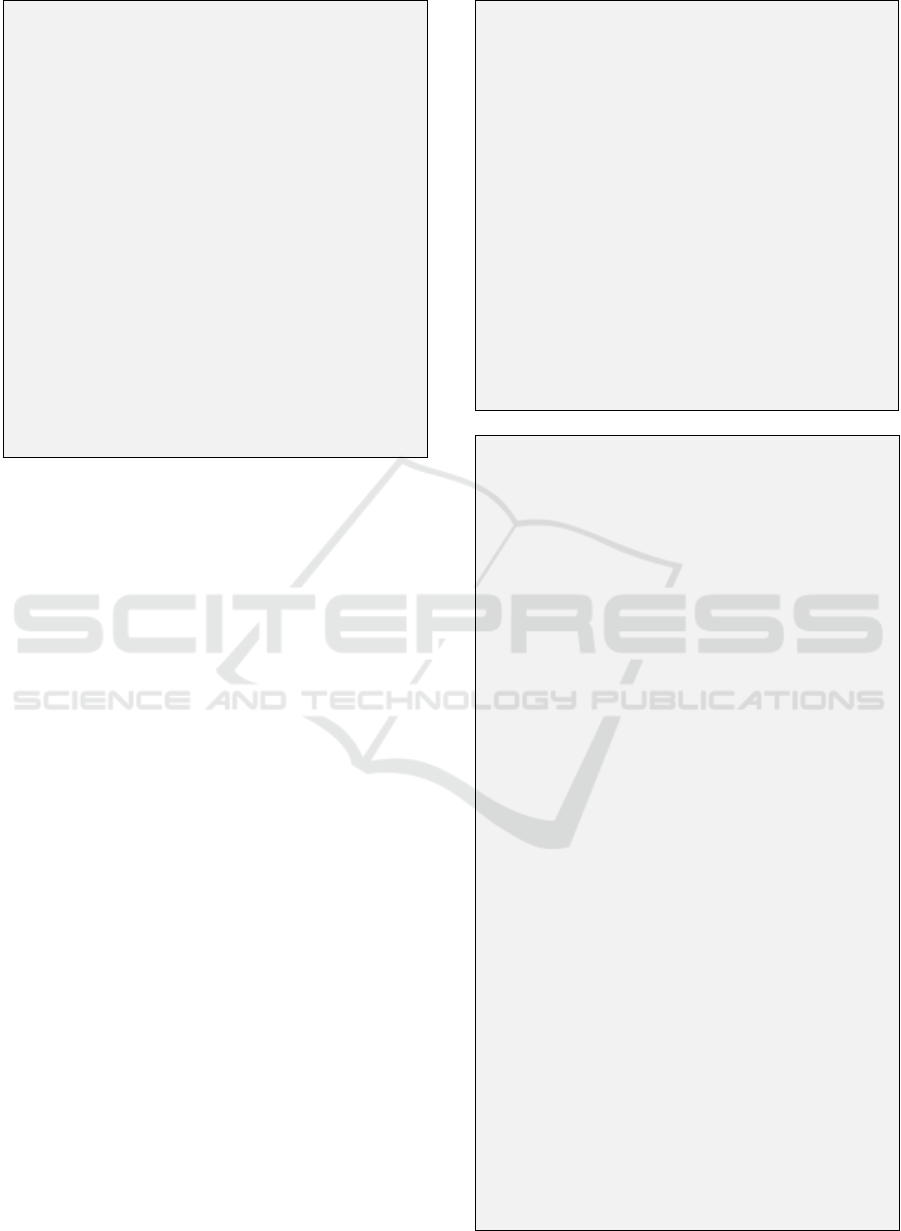

As follows from the obtained results, the optimal

robot location corresponds to the linear track

coordinate 2300 mm, which ensures the smallest

motion time of 4.13 sec to execute the desired

technological task using capacities of the robot and

the positioner only. It worth mentioning that this

value is about 50% less compared to the non-optimal

robot positioning when the desired path is located

very close to the border of the robot workspace. In

the following section, the obtained motion time will

be compared with the similar value obtained for the

case of movable robot base (when the actuation

capacities of the linear track are also used).

5.2 Optimal Motion Coordination for

Movable Robot Base

Another alternative for manufacturing the

considered composite vessel is to actuate both

positioner and linear track simultaneously, which

corresponds to movable robot base. To coordinate

motions of all mechanical components in this case,

the joint coordinate spaces of both the positioner and

the linear track were sampled with the step of 5° and

15 mm respectively. Then, the proposed extension of

the time-optimal motion generation technique that

deals with two redundant variables was applied.

Figure 6: Total motion time for the cases of non-actuated

and actuated linear track.

Optimal Coordination of Robot Motions with Positioner and Linear Track in a Fiber Placement Workcell

571

Relevant computational results are presented in

Figure 6. As follows from them, using movable

robot base allows reducing the total motion time

down to 3.87 sec, which is about 6% less compared

to the case of the fixed robot base. The obtained

trajectories are shown in Figures 7 and 8, which

show the displacement and velocity profiles for all

eight actuators of the 6-axis robot, 1-axis positioner

and 1-axis linear track. It should be mentioned that

after discrete optimization, a dedicated smoothing

technique may be also used to locally improve the

velocity and acceleration profiles and ameliorate the

actuator working conditions.

Figure 7: Displacement profiles of the coordinated time-

optimal motions of the robot, positioner and linear track.

6 CONCLUSIONS

This paper presents an extended technique dealing with

the optimal motion coordination in redundant robotic fiber

placement systems. In contrast to previous results dealing

with a single redundant axis only, this technique allows

the robot, positioner and linear track to be actuated

simultaneously in order to reduce the total motion time.

First, the original continuous optimization problem is

converted into a combinatorial one where the desired time-

optimal motions are presented as a specific shortest path

Figure 8: Velocity profiles of coordinated time-optimal

motions of the robot, positioner and linear track.

on the task graph. Then, the desired time-optimal

motions are generated using enhanced dynamic

programming algorithm that takes into account the

actuator capabilities (coordinate limits, velocities

and accelerations) as well as the kinematic and

geometric constraints allowing avoiding collisions

and singular configurations of the manipulator. The

proposed technique is illustrated by two case studies

confirming simultaneous actuation of all robotic

system axes. In future, the proposed technique will

be generalized for the robotic systems with higher

degrees of redundancy.

ACKNOWLEDGEMENTS

This work is supported by the China Scholarship

Council (Grant N°210404490018). The author also

acknowledged CETIM for the motivation of this

research work.

REFERENCES

Flacco, F. & De Luca, A. 2015. Discrete-time redundancy

resolution at the velocity level with acceleration/torque

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

572

optimization properties. Robotics and Autonomous

Systems, 70, 191-201.

Frketic, J., Dickens, T. & Ramakrishnan, S. 2017.

Automated manufacturing and processing of fiber-

reinforced polymer (FRP) composites: An additive

review of contemporary and modern techniques for

advanced materials manufacturing. Additive

Manufacturing.

Gallet-Hamlyn, C. 2011. Multiple-use robots for

composite part manufacturing. JEC composites, 28-30.

Gao, J., Pashkevich, A. & Caro, S. 2017. Optimization of

the robot and positioner motion in a redundant fiber

placement workcell. Mechanism and Machine Theory,

114, 170-189.

Garoushi, S. 2018. Fiber-Reinforced Composites. In:

MILETIC, V. (ed.) Dental Composite Materials for

Direct Restorations. Cham: Springer International

Publishing.

Gay, D. 2014. Composite materials: design and

applications, CRC press.

Gueta, L. B., Chiba, R., Arai, T., Ueyama, T., Rubrico, J.

I. U. & Ota, J. 2017. Compact design of a redundant

manipulator system and application to multiple-goal

tasks with temporal constraint. Journal of Advanced

Mechanical Design, Systems, and Manufacturing, 11,

JAMDSM0012-JAMDSM0012.

Gueta, L. B., Chiba, R., Ota, J., Ueyama, T. & Arai, T.

Coordinated motion control of a robot arm and a

positioning table with arrangement of multiple goals.

Robotics and Automation, 2008. ICRA 2008. IEEE

International Conference on, 2008. IEEE, 2252-2258.

Kazerounian, K. & Nedungadi, A. 1988. Redundancy

resolution of serial manipulators based on robot

dynamics. Mechanism and machine theory, 23, 295-

303.

Pashkevich, A. P., Dolgui, A. B. & Chumakov, O. A.

2004. Multiobjective optimization of robot motion for

laser cutting applications. International Journal of

Computer Integrated Manufacturing, 17, 171-183.

Pham, D.-C., Sridhar, N., Qian, X., Sobey, A. J., Achintha,

M. & Shenoi, A. 2016. A review on design,

manufacture and mechanics of composite risers.

Ocean Engineering, 112, 82-96.

APPENDIX A

TASK GRAPH GENERATION

As mentioned in Section 4, here the pseudo-codes of

the 3D task graph generation are presented. Its input

includes is a sequence of 4×4 location matrices

{ ( ) | 1,2,... }Task i i n

, the discretization densities m

1

and m

2

, and the upper/lower limits of the redundant

variables denoted as

max

P

q

,

min

P

q

and

max

L

q

,

min

L

q

respectively. The algorithm transforms the task

locations

()Task i

into the joint space.

This procedure contains two steps. Firstly, the

redundant variables are uniformly discretized in the

ranges of

],[

maxmin

PP

qq

and

],[

maxmin

LL

qq

, and

m

1

×m

2

×n matrix

1 2 1 2

{ ( , , ), ( , , )}

PL

q k k i q k k i

is

obtained, where

1 1 2 2

1,2,... ; 1,2,...k m k m

and

1,2,...in

. Then, at the second step,

(.)

P

g

,

(.)

L

g

and

(.)

1

R

g

are sequentially applied, and the robot

configuration states for

1 2 1 2 1 2

{ ( , , ), ( , , ) | , , }

PL

q k k i q k k i k k i

are

computed. After checking with the joint limits,

collision and the distance to singularities, the task

graph is finally generated with nodes:

1 2 1 2 1 2 1 2

( , , ) { ( , , ), ( , , ), ( , , )}

P L R

k k i q k k i q k k i k k iLq

where

1 1 2 2

1,2,... ; 1,2,...k m k m

and

1,2,...in

.

Input:

{Task(i)|i=1…n} – matrices of task locations.

{q

P

max

(i), q

P

min

(i)|i=1…n}

– upper/lower limits of positioner coordinate.

{q

L

max

(i), q

L

min

(i)|i=1…n}

– upper/lower limits of linear track coordinate.

m1 – discretization density for positioner.

m2 – discretization density for linear track.

u – robot configuration index.

Output:

{L(k1,k2,i)|k1=1…m1;k2=1…m2;i=1…n}

– 3D matrices of task locations:

Notations:

q

L

, q

P

, q

R

– Linear track, positioner and robot joint

coordinates;

P

T

task

– Transformation from positioner base to task

locations;

R

T

task

– Transformation from robot base to task

locations;

Invoked functions:

g

P

(.) – Positioner direct kinematic function;

g

L

(.) – Linear track direct kinematic function;

g

R

-1

(.) – Robot inverse kinematic function;

coll(.)– Collision test function;

cond(.)– Condition number calculation;

Tran(.)– Transformation from robot base to

positioner base.

Optimal Coordination of Robot Motions with Positioner and Linear Track in a Fiber Placement Workcell

573

APPENDIX B

SHORTEST PATH SEARCH

Here, the pseudo-codes of the shortest path search

are presented. The input is the 3D matrix of the

locations

12

{ ( , , )}k k iL

, which contains information

on the configuration states satisfying the equality

constraint, the collision constraint and the singularity

constraint. The algorithm operates with two tables

( , )D k i

and

( , )P k i

that include the minimum

distances for the sub-problem of lower size (for the

path

1 i

) and the pointers to the previous

locations respectively.

The procedure is composed of four basic steps. The

step (1) reshapes the 3D graph to the one with

m

1

×m

2

lines and n columns for simplifying the

programming. In step (2), the recursive formula (6)

is implemented. For the admissible configuration

nodes, the acceleration constraints are examined

using the expression (5) for each candidate path

connecting the nodes with the indices i, i−1 and i−2.

It is worth mentioning that the function

()accl

requires three inputs corresponding to i, i−1 and i−2,

but the location for i−2 is determined using the

pointer

( , 1)P j i

to the previous location in the

current path. Then, it finds the minimum path from

the current node to the first column and records the

reference into the pointer matrix. In steps (3) and

(4), the optimal solution is finally obtained and

corresponding path is extracted by means of the

backtracking.

1) Graph conversion:

m:= m1*m2;

C(k,i):=0; k=1,2,…m; i=1,2,…n;

for i=1 to n

Tem(k1,k2):=0;

for k1=1 to m1

for k2=1 to m2

Tem(k1,k2) = L(k1,k2,i);

end

end

C(:,i):=reshape(Tem);

end

2) Path searching:

set D(k,i):=0;P(k,1):=null;k=1,2,…m;

for i=2 to n

for k=1 to m

for j=1 to m

if(C(k,i)≠null)&(C(k,i-1)≠null)

if(i=2)|(acc(C(k,i),C(j,i-1))=0)

r(j):=D(j,i-1)

+dist(C(k,i),C(j,i-1));

else

r(j):=inf;

end

end

end

set D(k,i):=min({r(j)|j=1,2…m});

P(k,i):=argmin({r(j)|j=1,2…m});

end

end

3) Shortest path selection:

set D

MIN

:=min({D(k,n)|k=1,2,…m});

k

0

(n):=argmin({r(j)|j=1,2…m});

4) Backtracking:

for i=n to 2

k

0

(i-1):=P(k

0

(i),i);

end

Input:

{L(k1,k2,i)|k1=1…m1;k2=1…m2;i=1…n}

– 3D matrix of task locations

Output:

D

MIN

– minimum path length;

{k

0

(i)|i=1…n} – optimal path indices;

Notations:

{D(k,i)|k=1…m1·m2;i=1…n}

– distance matrix;

{P(k,i)|k=1…m1·m2;i=1…n}

– pointer matrix;

{C(k,i)|k=1…m1*m2;i=1…n}

– 2D matrix of task locations;

Invoked functions:

reshape(.)-transform m1×m2 matrix to one

column array;

dist(.) – distance between nodes;

accl(.) - Acceleration test on nodes.

Positioner and linear track discretization:

for i=1 to n

dq

P

(i):=(q

P

max

(i)-q

P

min

(i))/(n-1);

dq

L

(i):=(q

L

max

(i)-q

L

min

(i))/(n-1);

for k1=1 to m1

for k2=1 to m2

q

P

(k1,k2,i):=q

P

min

(i)+(k1-1)·dq

P

(i);

q

L

(k1,k2,i):=q

L

min

(i)+(k2-1)·dq

L

(i);

end

end

end

Location matrix creation:

for i=1 to n

for k1=1 to m1

for k2=1 to m2

P

T

task

:=g

P

(q

P

(k1,k2,i))·Task(i);

R

T

task

:=Tran(q

L

(k1,k2,i))·

P

T

task

;

q

R

(k1,k2,i):= g

R

-1

(

R

T

task

,u);

end

end

end

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

574

The above presented algorithm has been tested using

Matlab 2016b environment (running at Intel

®

i5 CPU

@2.67GHz 2.67GHz). In the case of the fixed robot

base, it took about one minute to generate the time-

optimal motions for each sampled robot location. In

the case of the movable robot base, the computation

required about one hour. It is clear that in other

programming environment, the computing time

would be essentially smaller.

Optimal Coordination of Robot Motions with Positioner and Linear Track in a Fiber Placement Workcell

575