Automatic Planning of Manufacturing Processes using Spatial

Construction Plan Analysis and Extensible Heuristic Search

Ludwig N

¨

agele, Andreas Schierl, Alwin Hoffmann and Wolfgang Reif

Institute for Software & Systems Engineering, University of Augsburg, 86159 Augsburg, Germany

Keywords:

Manufacturing Planning, Construction Plan Analysis, Heuristic Planning.

Abstract:

When automating small-batch manufacturing processes, the time spent for process planning and robot pro-

gramming becomes more important. This paper proposes an automated process including construction plan

analysis, process planning and execution to reduce the amount of manual work required. The process starts

by analyzing the structure of the desired product and deriving required process step results, then uses heuristic

search to find possible production steps and task assignments, and concludes by simulating or executing the

resulting production plan. The approach is evaluated on a case study with a simulated robot automatically

building different LEGO

R

DUPLO

R

structures starting from a 3D model defining the desired product.

1 INTRODUCTION

When new products transfer from design to produc-

tion, not only the supply of resource materials has

to be ensured but also manufacturing processes have

to be defined that consist of many single production

steps. When automating production with robots to

reduce cost, a suitable robot cell configuration needs

to be provided, robots have to be programmed and

teached, end-effectors such as welding tongs are to be

integrated. Additionally, proper flow of production

parts through the manufacturing process is necessary.

Thus, before a product finally comes to produc-

tion, a lot of time-consuming work has to be per-

formed by engineers, technicians and programmers.

While this effort usually is profitable for high lot

sizes, the process and program definition for smaller

lot sizes or even single individual product manufac-

turing forms an enormous challenge to the producer.

In this paper, we present a modular approach for

automatic planning of manufacturing processes aim-

ing for speeding up the entire development process up

to the final robot program definition. In a first step, an

engineer’s construction plan is parsed and analyzed

to generate a structural model. From this model, pos-

sible process definitions and their order are derived

which describe manipulator independent manufactur-

ing steps. Appropriate robots are assigned to each

process step in order to form an executable action

as part of the final program. Besides, techniques are

used for optimizing both planning time and the result.

Figure 1: Simulated KUKA KR 6 robot and Schunk

WSG 50 gripper performing LEGO brick placement.

The approach is suitable for production of high lot

sizes just as for manufacturing unique products.

As a main contribution, the paper presents an ap-

proach for spatial analysis of a construction blueprint

resulting a detailed structure model of the product.

Furthermore, the work introduces a technique for de-

riving an optimized order of process steps necessary

for manufacturing a given structure model.

After an overview of other approaches to perform

automatic planning of manufacturing tasks in sec-

tion 2, an introduction to the case study with LEGO

R

DUPLO

R

is given in section 3 (see Fig. 1). Section 4

presents the elements and steps of the approach in de-

tail, followed by a description of the heuristics used

for finding proper sequences of process steps and for

planning with appropriate robots. As an evaluation

of the approach, its application to the LEGO domain

576

Nägele, L., Schierl, A., Hoffmann, A. and Reif, W.

Automatic Planning of Manufacturing Processes using Spatial Construction Plan Analysis and Extensible Heuristic Search.

DOI: 10.5220/0006861705760583

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 576-583

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

for building structures is presented in section 6. Ex-

perimental results from a survey of different heuristic

variants for the LEGO example are discussed in sec-

tion 7 before the work concludes in section 8.

2 RELATED WORK

Manufacturing and assembly with robots is still an

ongoing topic in research. Some approaches con-

centrate on discrete planning techniques to solve al-

location of resources and task assignment to spe-

cific robots. For this, the STRIPS planner developed

in Stanford (Fikes and Nilsson, 1971) and the Plan-

ning Domain Definition Language (PDDL) by Mc-

Dermott et al. (1998) which bases on STRIPS are

commonly used. In PDDL, physical entities are speci-

fied as objects and domain-specific predicates are de-

fined which hold situational properties of these ob-

jects. These predicates are used to describe an initial

state and a goal specification of the planning prob-

lem. With actions that are defined with preconditions

and are used to manipulate a situation by influencing

the value of predicates, the planning problem can be

solved. However, our planning domain is highly de-

pendent on geometric reasoning with pre- and post-

conditions calculated during planning time which is

difficult to express in PDDL.

In the european project SkillPro (Pfrommer et al.,

2015), skills are used to describe functionality of

available resources. Together with manufacturing re-

quirements of the final product, executable process

actions can be generated. While actions can be dy-

namically orchestrated and integrated into the manu-

facturing process at runtime, in our project we want to

focus on an overall optimization of the entire manu-

facturing process considering products’ as well as re-

sources’ characteristics and performances.

In the last few years a trend has evolved to con-

sider motion planning together with classical task

planning for robot based manufacturing. One ap-

proach by Kaelbling and Lozano-P

´

erez (2011) pro-

poses stepwise planning and execution of successive

actions in order to reduce complexity. Planning and

decomposition of tasks is done only in limited depth.

The intermediate results are then executed and plan-

ning on task level is subsequently continued based on

the new situation. In a further work, Levihn et al.

(2013) introduce concepts for foresight with a belief

state and reconsideration as improvements to their

first approach. For our project, we plan to integrate

the concept of interleaved execution while planning,

but use simulation techniques instead.

Many approaches exist which try to bring prede-

fined process steps to execution on a robot cell. But

researchers also pay attention to automatic definition

of process steps by raw construction models or 3D

data. In an approach where KUKA youbots are used

to assemble an IKEA furniture, Knepper et al. (2013)

present a geometric preplanning strategy to extract

a final assembly configuration (blueprint) from the

form and quantity of available parts. In a second step,

a symbolic planner is used to find a sequence of oper-

ations to assemble the blueprint. The presented sep-

aration of blueprint analysis, operation sequence ex-

amination and finally execution will be a paradigm for

our project.

In their work about an offline programming plat-

form for automatic programming of manufacturing

tasks in the domain of carbon fiber-reinforced poly-

mers (CFRP), N

¨

agele et al. (2015) present techniques

to derive executable robot programs from an initial

CAD model of the final product. The CAD model is

parsed and decomposed into a hierarchical task repre-

sentation with pre- and postconditions for each leaf.

The concept of task contribution units is introduced

in a further work by Macho et al. (2016) which al-

lows for dynamic planning of each task basing on a

set of various exchangeable modules. Such a mod-

ule can provide generic calculation functionality, ap-

ply domain-specific knowledge or involve interaction

with a human expert. While this offline programming

platform is mainly focused on the domain of CFRP

and the presented planning problem is almost sequen-

tial, the idea of parsing and analyzing some kind of

blueprint is taken as inspiration for our project.

3 CASE STUDY

Building up and programming manufacturing systems

often includes generic challenges on the one hand and

domain-specific problems on the other hand. As a

case study, an application in the domain of construc-

tion toy LEGO

R

DUPLO

R

is presented. Its inter-

changeable and often symmetric raster-sized bricks

keep domain-specific problems simple and allow for

focusing on generic challenges of automatized pro-

duction design.

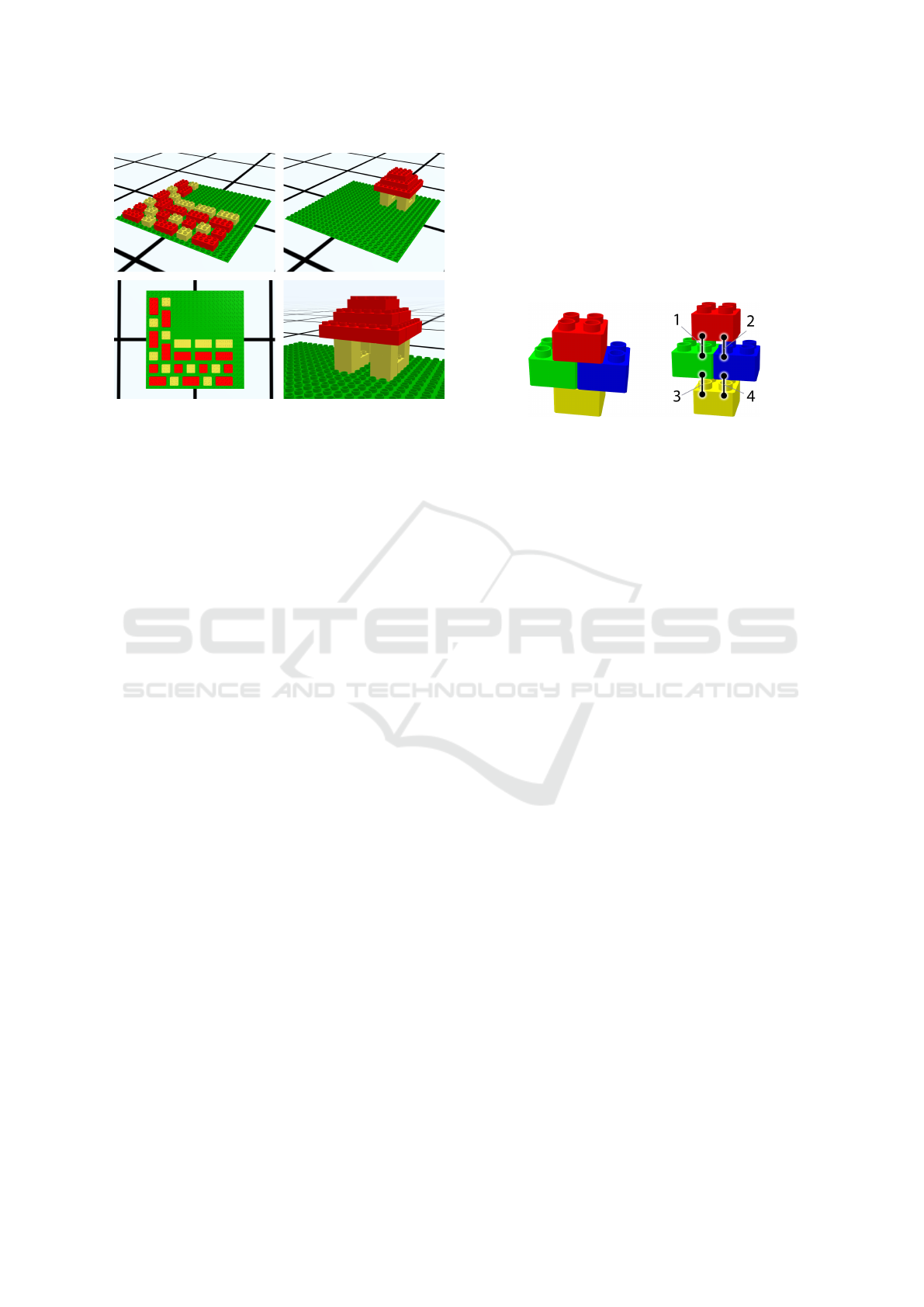

In our first scenario, we use a base plate of 24×24

studs, 13 colored bricks with dimensions of 2 × 2

studs and 13 bricks with a raster of 2× 4 studs. As an

initial setup, all bricks are randomly placed planarly

on the base plate as shown in Fig. 2 with a minimum

distance of one raster width. The goal – the manufac-

turing product – is a yellow house topped with a red

roof, having a space for an entry door and a window

area on all three other sides (see Fig. 2).

Automatic Planning of Manufacturing Processes using Spatial Construction Plan Analysis and Extensible Heuristic Search

577

Figure 2: Initial setup (left) and goal structure (right) for

building up a LEGO house.

For manipulation, a KUKA KR 6 robot with a

mounted Schunk WSG 50 gripper is used. Both ac-

tuators, as well as all LEGO parts, are integrated in

the Robotics API (Angerer et al., 2013) which allows

for object-oriented behavior programming and pro-

vides visualization by an inbuilt engine. For evalu-

ating conceptual and algorithmic results of this paper,

the inbuilt simulation feature of the Robotics API is

used to execute actuator behavior (see Fig. 1).

4 APPROACH

One main challenge in automation of manufactur-

ing is to bring a construction plan (3D model, writ-

ten script, etc.) to a stable, efficient and at best

cost-optimal manufacturing program for a robot cell.

There are several development phases and decisions

which all influence the final result with respect to

quality, resource efficiency and performance of both

product and production system. We propose an ex-

tensible module based approach which is meant to

ease this task by automatic programming of such pro-

cesses. Different modules can be contributed to pro-

vide specific knowledge and computation, ranging

from automation expertise for programming robots

and process expertise regarding manipulation and ma-

terial behavior, over to detailed knowledge about the

specific application domain. The presented approach

splits the development of manufacturing programs

into four parts: structure analysis, process planning,

task assignment and simulation and execution.

4.1 Structure Analysis

The overall goal of structure analysis is to extract as

much information out of a given initial construction

plan as possible. We assume that a construction plan

describes all parts to be assembled as well as further

information such as their relative positions to each

other or applied treatments and processes. We name

such a piece of information Attribute, which describes

one or relates multiple parts of the product. Examples

for attributes are that a product is painted or that mul-

tiple parts are plugged or glued together.

Figure 3: LEGO diamond structure with four attributes.

Fig. 3 shows a simple structure which is an expres-

sive showcase for general planning challenges. Four

2 × 2 bricks are assembled in a diamond-like shape.

The four connection lines illustrate attributes describ-

ing which bricks are in a stacked relationship to each

other and which transformation between the respec-

tive bricks is applied.

Attributes are called executionally equivalent if

they cannot be established independently. Assuming

all three lower bricks in Fig. 3 are already stacked by

attributes 3 and 4. A following placing of the top brick

would result in simultaneously establishing attribute 1

and 2. An independent establishment of only one of

these attributes is not possible. The property of execu-

tional equivalence is not valid in general on a specific

set of attributes but depends on the particular setting:

When attributes 2 and 3 are already established, the

set of attributes 1 and 4 emerges to be executionally

equivalent. However, with attributes 1 and 3 being

established, attributes 2 and 4 are not executionally

equivalent due to their contradicting stacking direc-

tion relating to their joint (blue) brick.

To automatically derive attributes from an ini-

tial construction plan, we propose Analyzer Mod-

ules which take a construction plan and return a set

of attributes. They automatically compute attributes

from existing properties or relationships, for exam-

ple through geometrical inspection. Multiple analyzer

modules can be provided for general purposes and

different domains. For instance, one analyzer mod-

ule determines parts which need to be bolted together

while another one identifies glued parts and calculates

minimal needed adhesive strength using an internal

static analysis. Once analyzer modules are available

for all properties and relationships of certain domain,

they result a complete set of attributes when applied

to a construction plan of the respective domain.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

578

A data structure describing which attributes are es-

tablished and which are not at a certain moment is

called Situation. When manufacturing a product, at

least two situations are known: a goal situation con-

taining all established attributes to form the final prod-

uct, and an initial situation which describes the setup

before assembly begins. Here, a set of attributes de-

scribes initial placements of parts, for example.

Analyzer modules as well as types of attributes are

generally contributed by application domain experts

who know about technical details, what kinds of at-

tribute types exist and how they can be identified in a

plain construction plan. The result of structure anal-

ysis is an initial situation describing start setup and a

goal situation which analyzer modules extracted out

of a construction plan.

4.2 Process Planning

To transition an initial situation to a goal situation, de-

tailed process descriptions (Process Actions), which

represent abstract robot behavior, and their order are

searched for. They furthermore indicate which at-

tributes are established or removed when executing

the behavior. For this, Skill Modules are introduced

which create particular process actions that are appli-

cable in a given situation. Depending on a concrete

skill module implementation multiple alternative pro-

cess actions are conceivable for one situation: If a

situation describes three bricks placed on the floor, a

grasping skill module provides three grasping actions

– one for each brick. At this point, alternative pro-

cess steps are introduced which later allow for overall

variability exploration and optimization.

Skill modules and their respective process actions

are contributed by process experts who have funda-

mental knowledge about process steps which can be

taken in specific situations. As a result of process

planning, skill modules provide possible process ac-

tions which can be performed in specific situations.

4.3 Task Assignment

Process actions describe behavior from the product’s

point of view. From automation view, process actions

need to be performed by concrete manipulators like

robots, grippers or tools. For defining the behavior

of process actions, skill modules use generic behav-

ior interfaces. These can later be instantiated by con-

crete manipulators whose capabilities are then used

to perform the desired action. This concept is taken

from the Robotics API where actuator and sensor in-

terfaces are used to abstract robot actions (e.g. PTP,

LIN, GRASP, MEASURE) from the underlying ma-

nipulators. With concrete manipulators assigned, a

skill module can calculate a new situation that results

when executing the process action in a given situa-

tion. When a product is being grasped, the gripper is

also part of the resulting situation.

The basic purpose of task assignment is to find

proper constellations of manipulators which can be

used to perform a process action’s task based on its

behavior descriptions. In a flexible multi-functional

robot cell like the one described by Angerer et al.

(2015), multiple robots – or even teams of robots –

might be applicable to perform the same task. This

search is done by Manipulator Modules which find

all manipulators or teams appropriate for the behavior

interfaces of the process action. In the current stage,

alternatives of manipulators are provided, but there is

no concrete strategy or criteria for selection yet.

Process actions describe their task without know-

ing the actuator effectively used. This allows to inject

concrete robots and to evaluate the appropriateness

while planning. Manipulator modules are contributed

by process and automation experts. The step of task

assignment deals with resource (manipulator) alloca-

tion and assignment as well as with finally providing

concrete execution plans.

4.4 Simulation and Execution

Once specific manipulators are assigned to a process

action, it can be executed in a given situation. The

presented approach uses Robotics API activities (An-

gerer et al., 2013) to execute process actions with

robots. The framework allows for both inbuilt simula-

tion enhanced with a graphical 3D visualization (see

Fig. 1) as well as execution with real robots on its

Robot Control Core (Vistein et al., 2014). For product

parts being correctly positioned and visualized, the

changes performed by process actions are transferred

to the world model of the Robotics API by translat-

ing attributes to geometrical or logical properties sup-

ported by the framework.

The concepts presented in this work are evaluated

in simulation only. However, the Robotics API al-

lows for a transition to real execution. For this, the

exact positions of resources, robots and parts need to

be reflected back into the world model. In general,

processes furthermore need testing and adjustments

of process parameters by automation experts.

5 HEURISTIC SEARCH

For defining an overall execution plan, several steps

have to be taken using the aspects described in the

Automatic Planning of Manufacturing Processes using Spatial Construction Plan Analysis and Extensible Heuristic Search

579

Analyzer

Module

Construction

Plan

Current Situation

Skill Action

Goal Situation

Initial Situation

Skill Action

Process

Action

Current Situation

Situation

Skill

Module

Manipulator

Module

Figure 4: Overview of steps for planning, modules and intermediate artifacts.

previous sections, each offering a variety of options

to continue with. Figure 4 gives an overview of the

steps, modules and artifacts involved when searching

for an overall process plan. In detail, following algo-

rithmic steps have to be taken:

1. Find the goal situation by applying all analyzer

modules to the construction plan. Provide initial

situation from a description of the initial setup.

Choose initial situation as current situation.

2. Apply all skill modules to current situation and

derive all possible process actions.

3. For each process action: Use manipulator mod-

ules to find all possible sets of manipulator in-

stances which satisfy the process action’s needed

behavior interfaces.

4. For each set of manipulator instances: Assign it

to the process action and derive its resulting situ-

ation. Iteratively repeat (2) through (4) with the

new situation as current situation until goal situa-

tion is reached.

5. Execute each step of the found path using the cor-

responding manipulators and respectively update

the world model after performing process actions.

As hinted by steps (2) and (3), an exponential

number of options evolves due to alternative pro-

cess actions for each situation and different manip-

ulators for each single process action. To find an

optimal process plan, we formulate an optimization

problem for the A-Star algorithm (Hart et al., 1968).

A-Star uses sets of nodes, weighted directed edges

and cost-estimations for nodes to iteratively search

for a cost-minimal path from an initial to a desired

goal node. In the presented approach, situations act

as nodes, with initial and goal situation as initial and

goal nodes. Starting with initial situation, A-Star re-

quests all edges to proceed with. For this, all possible

process actions basing on initial situation are calcu-

lated. Each process action is combined with all possi-

ble manipulator sets which are applicable for execu-

tion. Such a combination of process action and ma-

nipulators is used as edge in A-Star. Based on their

weights, edges are taken by A-Star and a subsequent

situation is computed to continue with. The weight

of an edge can be determined as the expense of the

process action and the cost of manipulators used, for

example, whereas expected remaining cost of a situa-

tion to reach goal situation needs to be estimated.

Cost estimation plays a fundamental role for A-

Star. The performance is highly dependent on the cal-

culated weights of transitions and the expected dis-

tances from nodes to the goal, which might be esti-

mated exactly in rarest cases only. If overestimated,

the result is not guaranteed to be cost-optimal. If un-

derestimated, a cost-optimal solution is guaranteed

but the search may take exhaustive time. Our ap-

proach estimates costs for situations based on their

attributes: The cost of a situation is the number of

attributes which still have to be established plus the

number of attributes which need to be removed in or-

der to reach goal situation. The actual weight of a pro-

cess action transitioning from a situation to another

is calculated as difference between the costs of both

situations, but with a minimum of 1. This prevents

weight-neutral process actions with no effect from be-

ing performed and leads to a cost-underestimation of

situations which guarantees cost-optimal solutions.

6 APPLICATION TO LEGO

The planning approach is applied to the domain of

LEGO and as a use case, a house as shown in Fig. 2 is

built automatically using the presented concepts. In

this domain, three kinds of attributes suffice to de-

scribe situations for the approach:

• A base plate is statically placed in the world by a

FixpointAttribute which describes its position.

• LegoPlacementAttributes between two bricks de-

scribe that these are plugged together with a spe-

cific relative transformation.

• A GraspAttriute denotes a brick which is grasped

by the gripper, as well as its grasping position.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

580

While the spatial positions of bricks are already

given for both initial and goal setup (see Fig. 2), ini-

tial and goal situations with attributes need to be com-

puted using analyzer modules. Being LEGO domain

experts, the authors created a LegoBrickAnalyzer-

Module which geometrically checks each pair of

bricks for being in a plugged relationship. For each

pair with an adequate spatial distance and rotation, a

LegoPlacementAttribute is generated. In the diamond

example, this analyzer module identifies the four at-

tributes depicted in Fig. 3.

To determine possible manipulation steps, skill

modules along with manipulator instances are used.

For LEGO and a robot cell consisting of a robot and

a gripper, two kinds of skill modules are relevant:

• PickupSkillModule provides process actions for

grasping and picking up each brick which is free-

standing in a given situation. After execution

of this process action, existing LegoPlacement-

Attributes of the brick are removed and a Grasp-

Attribute between brick and gripper is established

in the resulting situation.

• PlaceSkillModule provides process actions for

placing an already grasped brick on the target

position derived from the goal situation. The

resulting situation contains new LegoPlacement-

Attributes and is relieved from the GraspAttribute.

As a design-decision to this example, the gripper

can only grasp one brick at once instead of clusters of

bricks. In a first guess, a simple heuristic might build

a LEGO structure strictly processing layer by layer

from bottom to top starting at the base plate. This

straightforward approach is capable in most cases, but

due to specific intermediate structure setups, dead-

lock situations might occur: Assuming a final prod-

uct with overhanging parts, these bricks will never

be plugged from the downside. As another exam-

ple, bricks needed for the first layer can be blocked

by other bricks which will however not be removed.

To overcome such deadlock situations, a more

complex heuristic is proposed for which all possi-

ble immediate steps are reviewed and rejected where

necessary. Both PickupSkillModule and PlaceSkill-

Module precisely check geometrical and structural

suitability for picking up or placing a brick. In par-

ticular, all attributes modified in one step are checked

for required executional equivalence, and collisions

are identified and excluded, e.g. when grasping a

closely surrounded brick with hence no valid grasp-

ing point. Furthermore, a situation is rejected if it

will eventually lead to a deadlock situation. As-

suming the diamond example in Fig. 3 with first at-

tribute 3 and then attribute 1 established. The re-

sulting “C”-like construction excludes the blue brick

from ever being inserted since its two attributes 2

and 4 are not executionally equivalent. To identify

such eventual deadlocks in the situation where they

become inevitable, for example when establishing at-

tribute 1, look-aheads are performed which translate

bricks and attributes into graphs and analyze future

attributes between sub-graphs for executional equiv-

alence in a depth-first search. Such early deadlock

predictions are expensive but cut down on the state

space significantly. As a further improvement, only

established attributes that are transitively connected

to a FixpointAttribute in both, current and goal situ-

ation, contribute to the cost estimation of a situation.

This adjustment privileges bottom-up assembly (like

the simple first guess does) but does not exclude other

strategies. Thus, deadlock situations induced by the

bottom-up strategy are avoided while speeding up the

planning algorithm for building LEGO products.

7 EXPERIMENTAL RESULTS

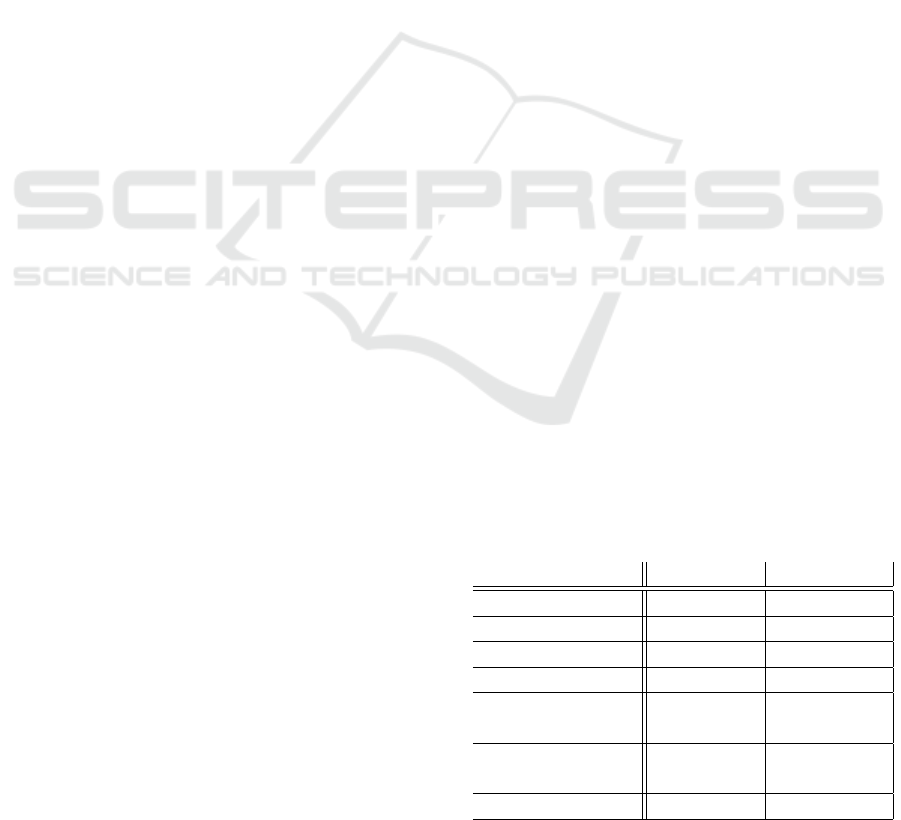

For both LEGO structures, diamond and house, pro-

cesses have been planned with the presented approach

and with modules as described in the previous sec-

tion. All experiments have been run on a Win-

dows machine with an Intel(R) Core(TM) i7-7600U

(2.80GHz) and 24 GB RAM. The heuristic search and

all modules have been executed by a Java Virtual Ma-

chine within a single-threaded context. Table 1 gives

a summary of all measured values. For the diamond

example, 10,000 experiments have been performed –

all resulting with 8 process steps. The shortest ex-

periment investigated 12 states in A-Star to find a re-

sult, on average 15.91 states are explored. To plan the

house, the calculation time of one state increases by

a factor of almost 14 compared to the diamond. The

reason is the higher amount of bricks which leads to

longer analysis time to find possible next steps and

time needed for collision checks. The house exam-

Table 1: Results of experiment runs for diamond and house.

Diamond House

Bricks 4 26

Base Plate 1 1

Test Runs 10,000 100

Result Steps 8 52

Avg. Time 0.88 ms 280.81 ms

(Std. Deviation) (± 0.79 ms) (± 74.06 ms)

Investigated States 15.91 368.21

(Min - Max) (12 - 18) (182 - 738)

Time per State 0.055 ms 0.763 ms

Automatic Planning of Manufacturing Processes using Spatial Construction Plan Analysis and Extensible Heuristic Search

581

Table 2: Tests with different enabled aspects of the heuristic: For each kind of experiment, test runs, average and standard

deviation time, average investigated states with min and max and average time per state is measured.

SingleGrasp MultiGrasp MultiRobot No-Deadl.-

w/ BottomUp w/o BottomUp w/ BottomUp w/o BottomUp Prediction

Experiment Nr. #1 #2 #3 #4 #5 #6

Test Runs 100 100 100 100 100 1

Avg. Time 0.281 s 368.477 s 0.389 s 1.005 s 9.112 s > 1,800.0 s

(Std. Deviation) (± 0.074 s) (± 214.223 s) (± 0.137 s) (± 0.432 s) (± 5.598 s) -

Investigated States 368.21 519,948.70 418.77 956.55 1,427.42 > 1.1M

(Min - Max) (182 - 738) (8.58k - 1.06M) (208 - 752) (294 - 2,598) (556 - 3,173) -

Time per State 0.763 ms 0.709 ms 0.930 ms 1.051 ms 6.384 ms *

ple has furthermore been used to evaluate different

aspects of the heuristic with 100 test runs each. Ta-

ble 2 compares six different experiments each with

different sets of activated features. All terminating

experiments returned a sequence of 52 process steps:

Picking up 26 bricks and placing 26 bricks.

Two experiments have been performed with

SingleGrasp which allows grasping of only one brick

at once. The first one uses the heuristic as described in

the previous section preferring bottom-up assembly.

After 0.281 seconds with a standard deviation time of

74 milliseconds a valid process plan was found.

With bottom-up preference being disabled, exper-

iment #2 exhibits an exploded set of states, leading

to an overall longer time to find a valid result. In

the house example, parts of the house which belong

to the upper part might already be assembled on the

base plate but can not be grasped in a later step. As an

interesting fact, the average time per state decreases

slightly. This is because there is no computation

whether a randomly picked brick fits into the bottom-

up strategy.

Two further experiments have been performed

with MultiGrasp which allows for picking up and

placing whole structures of LEGO instead of just sin-

gle bricks. Parts of the product (the roof of the house,

for example) can be assembled at another location –

even before underlying parts are finished. Also here,

both variants are tested, starting with bottom-up pref-

erence being enabled in experiment #3. All measured

values seem similar to these of experiment #1. Due

to preferred bottom-up strategy, partial assembly of

parts does not occur in practice.

As a combination of disabled bottom-up and en-

abled grasping of multiple bricks, experiment #4

clearly shows that the large state space of a free (non

bottom-up) strategy – where the order of steps is ran-

domly chosen – can be compensated by the grasping

of structures. The grasping of whole brick structures

allows for assembly of different product parts inde-

pendently and combining them afterwards.

Experiment #5 uses two robots and grippers, all

other variants left to default (#1). The introduction

of an alternative manipulator causes a significant in-

crease in time needed to find a result. This is mainly

caused by the huge number of states to be investi-

gated, owing to the fact that both robots can grasp

each LEGO brick – in parallel and in all combina-

tions. A further conspicuousness is stated by the over-

proportional standard deviation time of this experi-

ment, which can be explained by the variety of alter-

natives and the diversity of investigated states. Some

test runs seem to find a valid trace in a very early try

while others keep searching with stagnating guesses.

When early deadlock prediction is deactivated

(see section 6), many states and paths are explored

although an eventual deadlock may be certain. Exper-

iment #6 (No-Deadl.-Prediction) is aimed to show the

effects of this deactivation, but owing to the huge in-

crease of state space no test run did terminate within

the first half an hour. Instead, they finally ended up

with memory exhaustion at about 1.1 million states.

After about 20 minutes, each test run caused the Java

garbage collector to continuously occupy CPU while

significantly slowing down the overall test execution.

Owing to this influence, no valid measurement for

time per state can be made.

Besides an immense number of investigated states

in the last experiment, a low average time per state is

expected due to the deactivation of the prediction al-

gorithm. Situations are not expensively investigated

in detail to discover whether a deadlock will be un-

avoidable. As a scientific finding, even exhaustive

algorithms which essentially increase time per state

can be profitable and drastically reduce overall plan-

ning time as long as they reduce the state space sig-

nificantly. A comparison of experiment #2 (bottom-

up disabled) and experiment #1 (single-grasp and

bottom-up) confirms this observation by the increased

time per state but drastically reduced overall time.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

582

8 CONCLUSIONS AND

OUTLOOK

In this paper we introduced an approach for automatic

planning of manufacturing processes to build prod-

ucts with robots. It bases on modules which aim for

integrating expert knowledge and at the same time

separate different domain expertises such as automa-

tion, process and application into independent com-

ponents. The approach contains a heuristic search

based on cost estimations to find a suitable manu-

facturing program. Here, the modules contribute to

different steps in order to solve the overall problem:

They allow for deriving a structural model from an

engineer’s construction plan of a goal product and are

used to calculate processes to establish the structure.

Furthermore, modules can plan concrete robot actions

to perform the overall manufacturing of the final prod-

uct. We applied the presented concept to the domain

of LEGO and used it to plan the manufacturing of a

LEGO house with a robot. It has been evaluated with

different variations of heuristic properties.

As further work, we plan to improve the perfor-

mance of the heuristic search, for example by re-

ducing the state space through geometric reachability

analysis between manipulator and object. Especially

when planning with multiple manipulators, a strategy

for the selection of alternative manipulators for each

process action might be included into the approach.

As a major future research question, we will inves-

tigate strategies for parallel execution of tasks using

independent manipulators. The goal is to make plan-

ning for multiple robots in a multi-functional robot

cell feasible without the rapidly growing planning

time seen in the multi-robot evaluation results of our

work. In a further step, a second use case in a differ-

ent domain – such as CFRP – will be investigated to

demonstrate that the presented concepts can be gener-

ically applied to other domains and in real world.

ACKNOWLEDGEMENTS

This work is partly funded by the German Research

Foundation (DFG) under the TeamBotS grant.

REFERENCES

Angerer, A., Hoffmann, A., Schierl, A., Vistein, M., and

Reif, W. (2013). Robotics API: Object-oriented soft-

ware development for industrial robots. J. of Software

Engineering for Robotics, 4(1):1–22.

Angerer, A., Vistein, M., Hoffmann, A., Reif, W., Krebs, F.,

and Sch

¨

onheits, M. (2015). Towards multi-functional

robot-based automation systems. In Proc. 12th Intl.

Conf. on Inform. in Control, Autom. & Robot., pages

438–443.

Fikes, R. and Nilsson, N. J. (1971). STRIPS: A new ap-

proach to the application of theorem proving to prob-

lem solving. Artif. Intell., 2(3/4):189–208.

Hart, P. E., Nilsson, N. J., and Raphael, B. (1968). A for-

mal basis for the heuristic determination of minimum

cost paths. IEEE Transactions on Systems Science and

Cybernetics, 4(2):100–107.

Kaelbling, L. P. and Lozano-P

´

erez, T. (2011). Hierarchical

task and motion planning in the now. In Proc. IEEE

Intl. Conf. on Robot. & Autom., pages 1470–1477.

Knepper, R. A., Layton, T., Romanishin, J., and Rus, D.

(2013). Ikeabot: An autonomous multi-robot coordi-

nated furniture assembly system. In Proc. IEEE Intl.

Conf. on Robot. & Autom., pages 855–862.

Levihn, M., Kaelbling, L. P., Lozano-P

´

erez, T., and Stilman,

M. (2013). Foresight and reconsideration in hierarchi-

cal planning and execution. In Proc. IEEE/RSJ Intl.

Conf. on Intell. Robots and Systems, pages 224–231.

Macho, M., N

¨

agele, L., Hoffmann, A., Angerer, A., and

Reif, W. (2016). A flexible architecture for automat-

ically generating robot applications based on expert

knowledge. In Proc. 47

th

Intl. Symp. on Robotics.

VDE Verlag.

McDermott, D., Ghallab, M., Howe, A., Knoblock, C.,

Ram, A., Veloso, M., Weld, D., and Wilkins, D.

(1998). PDDL — the planning domain definition lan-

guage. Technical Report TR 98 003/DCS TR 1165,

Yale Center for Computational Vision and Control.

N

¨

agele, L., Macho, M., Angerer, A., Hoffmann, A., Vis-

tein, M., Sch

¨

onheits, M., and Reif, W. (2015). A

backward-oriented approach for offline programming

of complex manufacturing tasks. In Proc. 6

th

Intl.

Conf. on Autom., Robotics & Applications, pages 124–

130. IEEE.

Pfrommer, J., Stogl, D., Aleksandrov, K., Navarro, S. E.,

Hein, B., and Beyerer, J. (2015). Plug & produce

by modelling skills and service-oriented orchestration

of reconfigurable manufacturing systems. Automa-

tisierungstechnik, 63(10):790–800.

Vistein, M., Angerer, A., Hoffmann, A., Schierl, A., and

Reif, W. (2014). Flexible and continuous execution of

real-time critical robotic tasks. Intl. J. of Mechatronics

and Automation, 4(1):27–38.

Automatic Planning of Manufacturing Processes using Spatial Construction Plan Analysis and Extensible Heuristic Search

583