Embedded Agent based on Cyber Physical Systems: Architecture,

Hardware Definition and Application in Industry 4.0 Context

Mario Ricardo Nascimento Marques Junior, Braian Konzgen Maciel,

Gabriel M. Balota, Renan T. Fonseca, Manuel Simosa, Henrique S. Conceic¸

˜

ao,

Eder Mateus Nunes Gonc¸alves and Silvia Silva da Costa Botelho

Center of Computational Sciences, Federal University of Rio Grande, Rio Grande, Brazil

Keywords:

Industry 4.0, Intelligent Agent, Cyber Physical Systems, Single Board Computer.

Abstract:

Industry 4.0 is promoting a new Industrial Revolution through the application of computer and communication

technologies for the construction of Cyber Physical Systems (CPS), which can be considered a key component

for the development of this new revolution. In this context, this article proposes to implement an architecture

for embedded intelligent agents based on CPS. For this, it is proposed a classification of hardware suitable

for boarding this agent. Through this classification a device and initial testing of the agent is selected using

the MTConnect standard, which currently presents itself as a potentially efficient standard for this application

given the guarantees of some communication requirements. The initial tests presented satisfactory results in

the system against the requirements of communication, processing and storage. In addition, the benefits of

the proposed architecture over traditional automation systems are presented. Finally, the possible scenario for

validation of this architecture is presented.

1 INTRODUCTION

The evolution of the industrial environment is fun-

damental for the supply of human demands. And

as new needs and challenges arise, technological in-

novations need to emerge to meet those demands.

Throughout history, the industrial scenario underwent

three major transformations: the 1st Industrial Re-

volution was characterized by the mechanization of

production, with the invention of the steam engine.

The introduction of electricity and creation of assem-

bly lines, characterized the 2nd Industrial Revolution.

The 3rd Industrial Revolution emerged in the 1970s,

when the electronics and information technology in-

dustries were still developing the automation of pro-

duction processes (Drath and Horch, 2014).

According to (Kagermann et al., 2013), the intro-

duction of the German program called Industrie 4.0

has given rise to the challenge that is presented as the

4th Industrial Revolution, in which intelligent machi-

nes and components can communicate autonomously.

Thus, decisions on the shop floor can be made by the

machines themselves, from information provided in

real time. Another important feature, which can be

highlighted from Industry 4.0, is the integration of

various technologies related to the system, focusing

on its cybernetic representation. Cybernetic represen-

tation can be seen as a digital representation of the

real entity, so it is also called Digital Twin (Lee et al.,

2015).

Within this new world that is being idealized,

some concepts gain great prominence and direct in-

fluence for the development of the 4th Industrial Re-

volution. Cyber Physical Systems(CPS) (Jazdi, 2014)

and Internet of Things (IoT) (Shrouf et al., 2014) are

some of the concepts that have contributed to the alre-

ady known and emerging technologies applied to in-

dustrial manufacturing.

For (Zhou et al., 2015), Industry 4.0 is a vision for

the future, as it currently faces many difficulties and

challenges, including scientific challenges, techno-

logical challenges, economic challenges, social pro-

blems and political issues. Examples of scientific and

technological challenges include the development of

intelligent devices, building the network environment,

large data analysis and processing, and digital manu-

facturing.

The ability to communicate and transfer data bet-

ween different devices (sensors and actuators) within

an industrial environment emerges as one of the pro-

584

Junior, M., Maciel, B., Balota, G., Fonseca, R., Simosa, M., Conceição, H., Gonçalves, E. and Botelho, S.

Embedded Agent based on Cyber Physical Systems: Architecture, Hardware Definition and Application in Industry 4.0 Context.

DOI: 10.5220/0006863505840591

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 584-591

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

blems to be solved for the new industry infrastructure.

Several standards have emerged to ensure that equip-

ment from different sources can collect and transmit

data in a safe and efficient way.

Another point that has a great prominence in this

scenario is the decentralization of control and incre-

ment of complexity for the accomplishment of all the

operations. Thus the need to develop the autonomous

behavior of the system through approaches such as

multi-agent systems.

In this context, the present article proposes a clas-

sification of Single Board Computers (SBC) for in-

dustrial applications based on an intelligent agent ba-

sed CPS architecture. Once the CPS architecture,

based on 5C (Lee et al., 2015), was developed, it

was necessary to define constraints for supported har-

dware to deploy it. The CPS architecture aims to meet

most of the principles of Industry 4.0 using establis-

hed technologies. The SBC classification indicates

which levels of the CPS architecture on each device

type are able to run on it.

2 OVERVIEW OF CONCEPTS

AND TECHNOLOGIES FOR

INDUSTRY 4.0

This section presents some concepts of techniques as

well as technologies that are gaining prominence with

the development of the next industrial revolution.

2.1 Industry 4.0 Principles

Industry 4.0 is based on six basic principles (Hermann

et al., 2016):

• Real-time operation capability: consists of in-

stant acquisition and processing of data, allowing

decision-making within the constraints time of the

environment;

• Virtualization: proposes the existence of a virtual

copy of the intelligent factories, allowing the re-

mote traceability and monitoring of all the proces-

ses through the numerous sensors spread throug-

hout the plant;

• Decentralization: decision-making can be done

by the cyberphysical system according to the

needs of real-time production. In addition, ma-

chines will not only receive commands, but will

be able to provide information about their work

cycle;

• Service Orientation: Use of service-oriented soft-

ware architectures coupled with the Internet of

Services concept.

• Modularity: Production according to the demand,

coupling and uncoupling of modules in the pro-

duction, offering flexibility to change the tasks of

the machines easily.

• Interoperability: The ability of machines, devices,

sensors and humans to connect and communicate

through the Internet of Things and the Internet.

2.2 Cyber Physical Systems

According to (Lee et al., 2015) the CPS is a system

composed of the union of physical subsystems in net-

work with the computation. The CPS is responsible

for connecting the virtual world with physical rea-

lity, which integrates computing, communication and

storage capacities, and can operate in real time in a

reliable, secure, stable and efficient way.

According to (Barbosa et al., 2016) CPS is an es-

sential aspect for the consummation of the 4th Indus-

trial Revolution, ie, is the key point for the current

industry transformation in Industry 4.0. Cyber Phy-

sical Systems aim to monitor and control industrial

processes through a network of intelligent devices and

sensors, using virtual models of processes that corre-

spond to real processes models, through the combi-

nation of computational, communication and control

elements (Kim and Kumar, 2012). With this it is pos-

sible to decentralize the decision making, that is, an

intelligent device has the power to self-contro

The constitution of CPS may involve the use of

various technologies, such as Multi Agent Systems

(MAS), Service-Oriented Architecture (SoA), Cloud

Computing, Big Data, Machine-to-Machine (M2M)

and Visual Computing.

The integration between different technologies

aims to contribute to the CPS facing challenges iden-

tified in the principles of Industry 4.0. Multi Agent

Systems, for example, can contribute on flexibility,

robustness, adaptation, configuration and distributed

control of these systems.

In the context of Industry 4.0, intelligent agents

and Multi Agent Systems share common ground with

CPS. They can enable CPS with a myriad of capa-

bilities to achieve complexity management, decentra-

lization, intelligence, modularity, flexibility, robust-

ness, and real-time responsiveness capabilities (Lei-

tao et al., 2016).

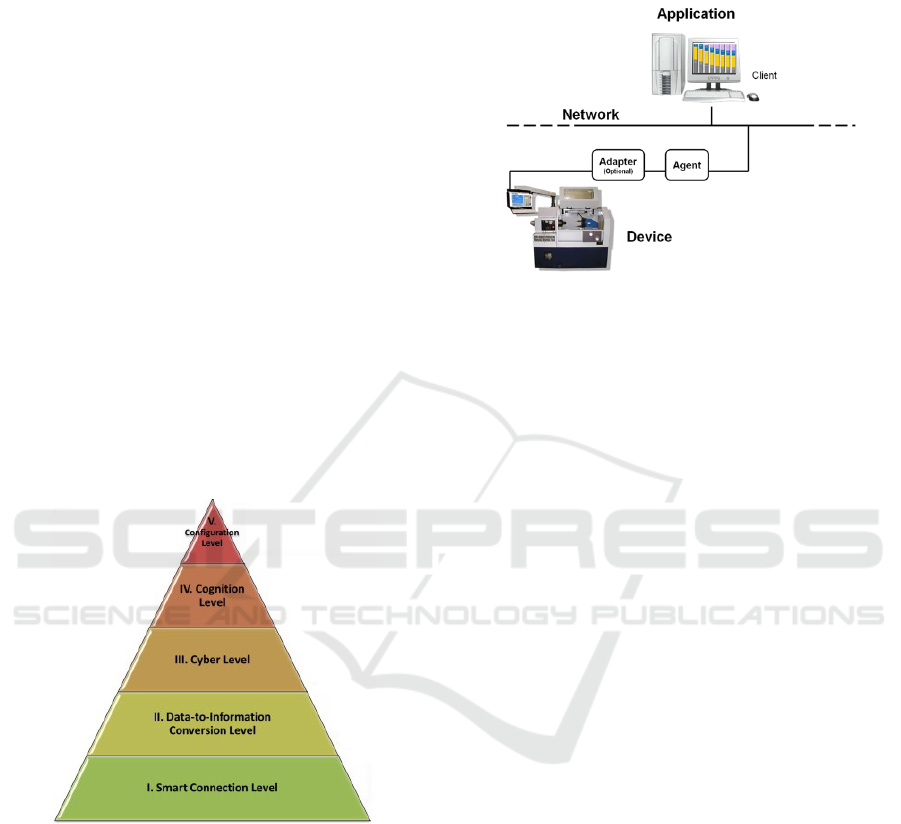

2.3 5C Architecture for CPS

Among the CPS architectures, the architecture deno-

minated 5C proposed by (Lee et al., 2015) has great

prominence in the literature. It serves as a guide for

Embedded Agent based on Cyber Physical Systems: Architecture, Hardware Definition and Application in Industry 4.0 Context

585

developing and implementing CPS for industrial ap-

plications. This architecture is divided into five levels

as seen in Figure 1:

(i) Smart Connection: this level is responsible to

acquire accurate and reliable data from sensors,

controllers and even ERP systems, with seamless

and tether-free guaranties;

(ii) Data-to-information Conversion: this level is

responsible for generating meaningful informa-

tion from different data sources, which can be

achieved using algorithms for prognostics and he-

alth management.

(iii) Cyber: Considering that this level must to gather

massive information, it must use specific analytics

to extract additional information about the status

of individual components and machines;

(iv) Cognitive: This level must generate e provide

knowledge of the monitored systems for other

components and operators;

(v) Configuration: This level acts as a supervisory

control since it can attribute self-capabilities for

the system generating corrective and preventive

decisions.

Figure 1: 5C Architecture for Developing a CPS for Indu-

stry 4.0 (Lee et al., 2015).

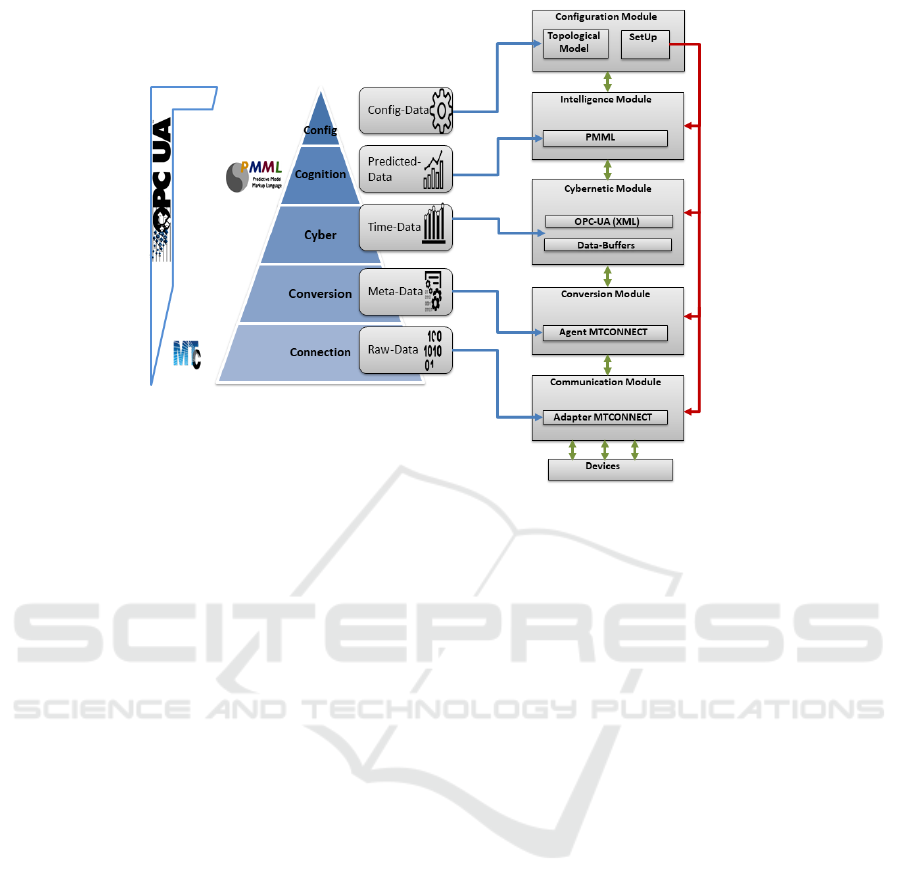

2.4 MTConnect

The ability to connect between different devices ap-

pears as one of the main challenges of Industry 4.0.

Several standards and protocols have been developed

in recent years, and the MTConnect Institute has de-

veloped a solution to this problem.

The MTConnect standard is based on standard In-

ternet technologies such as HTTP (Hyper Text Trans-

fer Protocol) and XML (Extensible Markup Lan-

guage). A system that implements the MTConnect

protocol has five fundamental components: Device,

Adapter, Agent, Network and Application/Client, ar-

ranged according to Figure 2. The most important

components are Agent and Adapter.

Figure 2: Basic architecture of device connected using MT-

Connect standard (MTConnect, 2008).

In the context of Industry 4.0 MTConnect emerges

as a solver for connection between physical devices of

a CPS, acting at the lowest level ensuring the acquisi-

tion of data independent of the format or protocol of

communication.

3 PROPOSED ARCHITECTURE

This section aims to propose an architecture for the

development of intelligent embedded agents based on

Cyber Physical Systems. The CPS 5C architecture

proposed by (Lee et al., 2015) is taken by reference.

The intelligent agent design is based on the charac-

teristics of this architecture and the theory of Multi

Agent Systems, in order to enable the construction of

intelligent environments compatible with CPS.

The embedded intelligent agent must be able

to perceive and interact with the physical medium

through sensors and actuators, as well as interact with

virtual agents through the network. It can also pre-

sent control elements, through algorithms such as PID

(Proportional-Integral-Derivative Controller) and Ar-

tificial Intelligence, promoting distributed control and

decentralization.

3.1 Agent Software Architecture

The proposed software architecture for agent develop-

ment is organized into five modules: configuration,

intelligence, cybernetic, conversion and communica-

tion.

Figure 3 presents the layout as well as the techno-

logies and functionalities of the agent software archi-

tecture modules.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

586

Figure 3: Software architecture in 5 modules.

• Configuration Module: responsible for the confi-

guration interfaces of all the modules. In it are de-

fined interfaces to access and define the properties

of the topological model, properties of communi-

cation, control, intelligence and storage. The to-

pological model is a hierarchical structure replete

with information of the devices, components and

systems that make up the agent-managed physi-

cal structure, when this is the case. This module

requires a complete modeling of all components

connected or managed by the agent.

• Intelligence Module: responsible for the mapping

and tracking of patterns, behaviors and data qua-

lity control. It uses advanced algorithms to point

out faults and promotes the predictive and cog-

nitive behavior of the system. From this module

emerge basic functions of manufacturing systems,

such as control, monitoring, planning and schedu-

ling.

• Cybernetic Module: responsible for the manage-

ment of system information in order to represent

them on a temporal scale through inferences and

predictions. It consists of a buffer, which regis-

ters the agent data and a data adapter for external

databases that enables data acquisition.

• Conversion Module: responsible for the conver-

sion of data collected in the communication mo-

dule into information for the system, assigning se-

mantics and some type of treatment to guarantee

the continuous provision of this information.

• Communication Module: responsible for adap-

ting the different protocols of industrial networks

to the standard adopted in the system and to ena-

ble interoperability through this standard. The

module also provides the model with the topolo-

gical description of the equipment for the other

agents through the network.

The architecture described above imposes greater

restrictions on communication and information ma-

nipulation for the first three layers, communication,

conversion and cybernetics, and greater processing re-

strictions for the upper layers, intelligence and confi-

guration. From these requirements it was necessary to

establish a classification for SBC able to board this ar-

chitecture. This classification is presented in the next

section.

4 HARDWARE CLASSIFICATION

With the technological advancement of the advance-

ment in the past few years, the Single Board Compu-

ters (SBC) had an increase of the capacity of proces-

sing and memory, reduction of cost and consequently

its popularization. Faced with this, several projects

have emerged that use this type of hardware for in-

dustrial applications.

An SBC is a computer shipped in a reduced form

and ready for use. It can be considered as a generic

solution in hardware and software that can be used

in the development of embedded systems. It provi-

Embedded Agent based on Cyber Physical Systems: Architecture, Hardware Definition and Application in Industry 4.0 Context

587

des a complete platform for the development of end

products for various applications such as medical, in-

dustrial automation, aerospace and robotics.

Thus, this section will be presented recent projects

that use the Raspberry Pi platform in industrial appli-

cations. A classification of hardware devices will also

be performed for the development and implementa-

tion of the CPS Agent modules.

4.1 Industrial Solutions using

Raspberry Pi

An industrial computer based on Raspberry Pi meet-

ing the IEC 61131-2 standard is shown in (Revoluti-

onPi, 2017). This standard establishes hardware stan-

dards for any product in which the primary purpose

is the function of industrial control equipment, inclu-

ding PLC (Programmable Logic Controller) or its as-

sociated peripherals for the purpose of control and

command of machines. Depending on customer re-

quirements, this device may be supplemented by di-

gital or analog I/O modules as well as by appropriate

fieldbus gateways to connect it to an industrial net-

work. The base modules and expansion modules are

shipped with 24 Volts which is the standard used in

the industry.

The Strato Pi (SferaLabs, 2017) base empowers

the Raspberry Pi Model B version 2 and 3 models

with various hardware features to make it suitable for

use in professional applications where reliability and

continuity of service are essential requirements.

Modberry (ModBerry, 2017) is a universal con-

troller built with the needs of the automated, teleme-

tric and integrated systems markets in mind. It has

several communication interfaces such as digital or

analog I/O modules, GPS, Modbus and Wi-Fi.

NetPI (netIOT, 2017) is a Raspberry Pi 3

architecture-based platform for implementing custom

industrial automation projects with Cloud, Internet of

Things and Industry 4.0 features.

4.2 Hardware Classification for CPS

Agent

According to (Newark, 2014), SBC today are ba-

sically divided into two categories: proprietary and

open source. Proprietary is one who is usually de-

signed for use in final application or as a reference

for evaluation. They are industrial projects that go

through the same tests that a final product requires.

Open source SBCs give users access to the design and

layout of hardware and the source code used on the

board. This is ideal for all users because they can ea-

sily understand how software and hardware operate

and adopt design to meet project requirements.

Considering the most popular open source SBC,

a classification was created, analyzing characteristics

such as: Processing capacity, available memory, I/O

devices and connectivity. The classes in turn were de-

fined using only the processing capacity and available

memory information of each hardware, as seen in the

Table 1.

The characteristics adopted to define the classes of

hardware, processing capacity and available memory

will serve as the basis for implementations of diffe-

rent types of applications. According to the establis-

hed classes a set of characteristics such as levels of

intelligence, cognition and control, compatible with

the structure of the CPS agent module, will be added

to each component of the class, or even how many

layers of the 5C architecture will be contemplated in

each device.

A survey of SBC corresponding to the Odroid,

Raspberry Pi, Banana Pi and Orange Pi families was

carried out and the following classes were defined:

• Class A - Devices with Quad Core Processors

from 1GHz:

Within this class are the devices with a large pro-

cessing capacity, having processors with 4 cores

that can reach up to 2GHz, and with different

capacities of memories, ranging from 512MB to

2GB. Class A SBC are divided into the following

subclasses:

– Subclass A1 - Quad Core from 1.2 GHz up to

2GHz and 2GB memory;

– Subclass A2 - Quad Core from 1.2 Ghz up to

1.5 GHz and 1GB memory

– Subclass A3 - Quad Core up to 1 Ghz and 1

GB memory;

– Subclass A4 - Quad Core from 1 Ghz up to

1.5GHz and 512 MB memory.

• Class B - Dual Core processors of 1 GHz and me-

mory up to 1 GB:

Class B is characterized by devices that have a

considerable processing rate with 1GHz two-core

processors, and a memory capacity of up to 1GB.

• Class C - Single Core processor with a maximum

of 1 GHz and up to 512 MB of memory:

The class C of SBC is characterized by devices

that have a processing rate, can reach up to 1GHz,

but only 1 core. Another characteristic point of

this class is the low capacity of memory can reach

up to 512 MB.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

588

Table 1: Classification of SCB according to their processing and memory capacities.

Device Processing I/O RAM Connectivity Class

Banana Pi R2

ARM Cortex-A7

(ARMv7) 1.2GHz

Quad Core ARMv7

2x USB 2.0

40pin header

2GB DDR3

RAM

Wi-Fi 802.11n

Bluetooth 4.1

Ethernet port

A1

Odroid XU4

Samsung Exynos5422

ARM Cortex-A15

Quad 2.0GHz

2x USB 3.0

1x USB 2.0

30Pin: GPIO/IRQ

/SPI/ADC

12Pin: GPIO /I2S/I2C

2GB LPDDR3

RAM PoP stacked

Ethernet port

WLAN Antenna

A1

Odroid C2

Amlogic ARM

Cortex-A53(ARMv8)

64 bits 1.5Ghz

Quad Core

4x USB 2.0

1x USB OTG

40pin GPIOs

7pin I2S GPIO

]/I2C/ UART/ADC

2GB 32bit DDR3

912MHz RAM

(512MByte x4pcs

Wi-Fi adapter

Ethernet RJ-45

A1

Odroid C0

Amlogic S805 SoC

ARM Cortex-A5

(ARMv7) 1.5GHz

Quad Core ARMv7

2x USB 2.0

40pin (GPIO/UART/

SPI/I2C/ADC)

7pin port (I2S)

1GByte DDR3

32bit RAM

(512MByte x 2pcs)

792Mhz

WLAN

with Antenna

A2

Raspberry Pi 3

Broadcom BCM2837

4 x ARM Cortex-A53

1.2Ghz 64bit ARMv7

4x USB 2.0,

40 pin port

GPIO / UART

/ SPI / I2S

1GB 32bit

LPDDR2

450MHz

Wi-Fi 802.11n

Bluetooth 4.1

Ethernet port

A2

Raspberry Pi 2

Broadcom BCM2836

4x ARM Cortex-A7

900MHz ARMv7

4x USB 2.0,

40pin port

(GPIO/UART/

SPI/I2C/I2S)

1GB 32bit

LP-DDR2

400MHz

Ethernet port A3

Odroid C1+

Amlogic S805 SoC

4x ARM

Cortex-A5 1.5GHz

ARMv7 Architecture

4x USB 2.0

1x USB OTG

40pin GPIO/UART/

SPI/I2C/ADC)

7pin port (I2S)

1GB 32bit

DDR3

792MHz

Gigabit Ethernet

WLAN with

Antenna

A3

Banana Pi Zero

Cortex-A7

(ARMv7) 1.0 GHz

Quad Core ARMv7

Micro USB

40pin GPIO

512 MB DDR3

RAM

Wi-Fi 802.11n

Bluetooth 4.0

A4

Banana Pi M1+

A20 ARM Cortex-A7

(ARMv7) 1.0GHz

Dual Core

2x USB 2.0

40pin (GPIO/UART/

SPI/I2C/ADC)

1GB DDR3

Wi-Fi 802.11n

Ethernet port

B

Raspberry Pi 1

Broadcom BCM2835

ARM11 de 700Mhz

Single Core

2x USB 2.0

40pin GPIO

512 GB 32bit

LP-DDR2

400MHz

Ethernet port C

Raspberry Pi 0 W

Broadcom BCM2835

ARM11 de 1GHz

Single Core

Micro USB

40pin GPIO

512MB

LPDDR2

SDRAM

Wi-Fi: 802.11n

Bluetooth

C

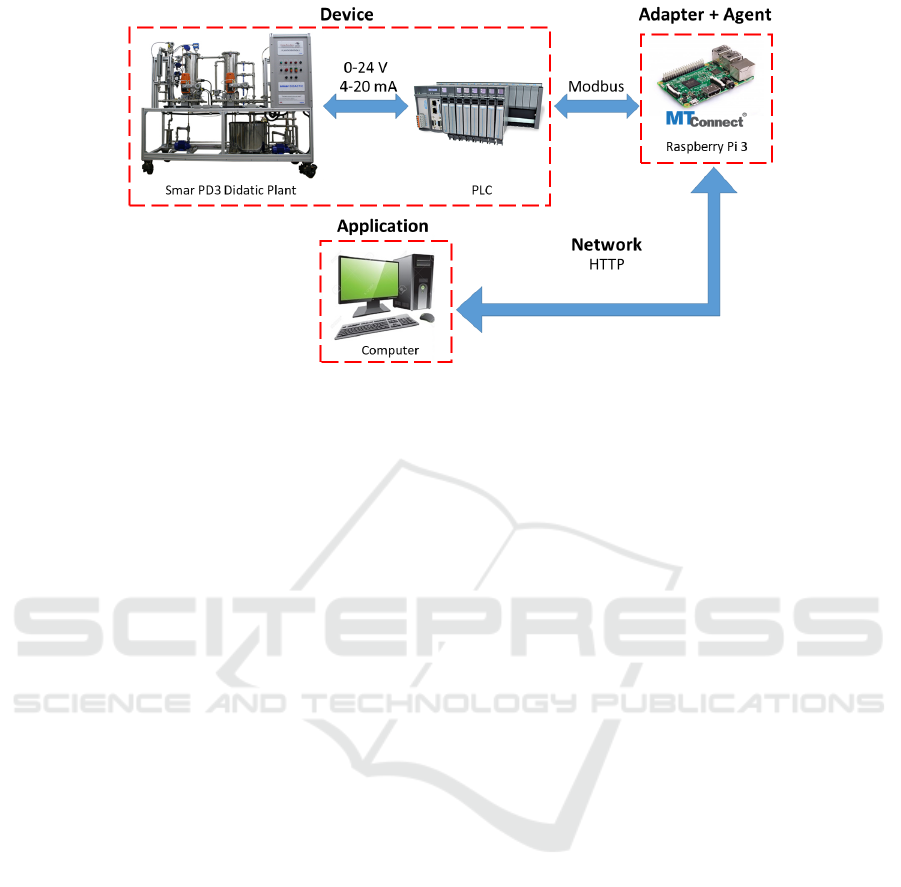

5 INITIAL TESTS

This section will present the scenario in which the ini-

tial tests were carried out. After this the results obtai-

ned with these tests will be presented.

5.1 Methodology

For the initial tests, a Smar PD3 Industrial Didactic

Plant, a Raspberry Pi 3 and a computer (Figure 4)

were used. The industrial plant has several equipment

and instruments such as temperature, flow and level

transmitters. These devices in turn are connected to

the Nexto3030 PLC from the Altus manufacturer.The

algorithm to control the PLC was replaced by one that

has a function that acquires and makes available the

data from the equipment connected to it via Modbus

TCP/IP communication.

With the PLC transmitting plant data via Mod-

bus TCP/IP, a Modbus TCP/IP adapter was imple-

mented in MTConnect. This adapter was implemen-

ted using C++ programming language. The adap-

ter has the function of transforming the data obtai-

ned from the plant to the MTConnect standard. The

Embedded Agent based on Cyber Physical Systems: Architecture, Hardware Definition and Application in Industry 4.0 Context

589

Figure 4: Arrangement and connection of the equipment used in the tests.

topological modeling of the plant was also done in

the MTConnect XML standard. The default agent

was used, which is also implemented in C++. This

agent publishes the adapter data to a standard HTTP

page. The adapter and agent run on a Raspberry Pi

3 connected to the Ethernet network of the PLC. An

internet-connected computer was also used to access

the page that provides the XML generated by MT-

Connect.

5.2 Results

From the implementation of the agent and adapter it

is possible to access through a web browser the HTTP

page that displays an XML generated by MTConnect.

This XML comprises time series of all events, sam-

ples and conditions of the equipment running on the

plant. A cut-off the agent response to the sample com-

mand can be seen in Figure 5. It is noted that the

agent made available all the plant data according to

the XML modeling previously done. A comparison

with data read directly in the PLC proved the accuracy

of the data. It has also been proven that MTConnect

fully implements the communication and conversion

modules, in addition to implementing part of the cy-

bernetic module through buffer, thus justifying its use.

6 CONCLUSIONS AND FUTURE

WORK

This article proposes an architecture of an intelligent

embedded system to compose a Cyber Physical Sy-

stem. The embedded agent was based on the intelli-

gent agent theories and based on the CPS architecture

named 5C.

It has also been demonstrated the application of

this architecture in industrial environments and par-

tial results obtained in the laboratory. Advantages of

this architecture include standardization of communi-

cation, promotion of distributed control, autoconfigu-

ration, visibility and transparency of data as well as

interoperability between agents and applications.

The proposed experiment was able to transform

the Modbus TCP/IP data to the MTConnect standard.

The MTConnect agent has full capability of executing

the communication, conversion, and partial modules

of the cybernetic module. These capabilities justify

their choice for application of this architecture. The

ability of Raspberry Pi 3 to run these modules has also

been proven.

As seen in Section 4, SBC devices are increa-

singly common for applications in industrial solutions

today. And the Raspberry Pi platform has been gai-

ning ground due to its high performance, and a consi-

derable cost compared to other platforms. Raspberry

Pi devices present the desirable requirementes for the

development of this work, as seen in Table 1.

As future work, we can mention the develop-

ment of a connection interface for the industrial plant

equipment to Raspberry, thus dispensing with the use

of PLC. The implementation of the other modules,

fundamental to the architecture presented in this ar-

ticle, must also be performed. Existing technologies

such as OPC UA (Open Platform Communications

Unified Architecture) and PPML (Predictive Model

Markup Language) present themselves as possible so-

lutions for the implementation of these modules be-

cause they have functions provided in them, besides

being standards, thus allowing different tools to speak

the same language.

In addition, it will be necessary to develop or

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

590

Figure 5: Agent response to the Sample command.

adapt essential software for industrial automation

such as SCADA (Supervisory Control Systems and

Acquisition of Data), Distributed Control System

(DCS), and AR-DCS (Augmented Reality Distributed

Control System) (Rodrigues, 2016) for communica-

tion from the MTConnect standard. Finally, perform

performance tests, functionalities and robustness of

this system compared to traditional automation sys-

tems.

ACKNOWLEDGMENT

The authors would like to thank to the funders of this

project FINEP, CAPES, CNPq and the company Altus

for the trust placed in the team for the conclusion of

this project. They also thank the Federal University

of Rio Grande for the space provided in which this

project is developed.

REFERENCES

Barbosa, J., Leit

˜

ao, P., Trentesaux, D., Colombo, A. W., and

Karnouskos, S. (2016). Cross benefits from cyber-

physical systems and intelligent products for future

smart industries. In Industrial Informatics (INDIN),

2016 IEEE 14th International Conference on, pages

504–509. IEEE.

Drath, R. and Horch, A. (2014). Industrie 4.0: Hit or

hype?[industry forum]. IEEE industrial electronics

magazine, 8(2):56–58.

Hermann, M., Pentek, T., and Otto, B. (2016). Design prin-

ciples for industrie 4.0 scenarios. In System Sciences

(HICSS), 2016 49th Hawaii International Conference

on, pages 3928–3937. IEEE.

Jazdi, N. (2014). Cyber physical systems in the context of

industry 4.0. In Automation, Quality and Testing, Ro-

botics, 2014 IEEE International Conference on, pages

1–4. IEEE.

Kagermann, H., Helbig, J., Hellinger, A., and Wahlster, W.

(2013). Recommendations for Implementing the stra-

tegic initiative INDUSTRIE 4.0: securing the future

of German manufacturing industry; final report of the

Industrie 4.0 working group. Forschungsunion.

Kim, K.-D. and Kumar, P. R. (2012). Cyber–physical sys-

tems: A perspective at the centennial. Proceedings of

the IEEE, 100(Special Centennial Issue):1287–1308.

Lee, J., Bagheri, B., and Kao, H.-A. (2015). A cyber-

physical systems architecture for industry 4.0-based

manufacturing systems. Manufacturing Letters, 3:18–

23.

Leitao, P., Karnouskos, S., Ribeiro, L., Lee, J., Strasser,

T., and Colombo, A. W. (2016). Smart agents in in-

dustrial cyber–physical systems. Proceedings of the

IEEE, 104(5):1086–1101.

ModBerry (2017). ModBerry. https://www.iot-store.com.

au/products/modberry-500-m3-max-industrial-embed

ded-raspberry-pi-based-computer. Acessed: 2017-

09-20.

MTConnect (2008). MTConnect Institute. http://www.mt

connect.org. Acessed: 2017-08-13.

netIOT (2017). netPI. https://www.netiot.com/de/netpi/

industrial-raspberry-pi-3/. Acessed: 2017-09-20.

Newark (2014). A brief history of single board computers.

http://www.newark.com/wcsstore/ExtendedSitesCata

logAssetStore/cms/asset/pdf/americas/common/NE1

4-ElectronicDesignUncovered-Dec14.pdf. Acessed:

2017-10-18.

RevolutionPi (2017). Revolution Today. https://revolution.

kunbus.com. Acessed: 2017-09-20.

Rodrigues, N. G. (2016). Augmented reality applied to

data supervision and acquisition systems using mobile

devices. In Brazilian Congress of Automation(CBA)

2016. CBA.

SferaLabs (2017). StratoPi. https://www.sferalabs.cc/ stra

to-pi/ #documentation. Acessed: 2017-09-20.

Shrouf, F., Ordieres, J., and Miragliotta, G. (2014). Smart

factories in industry 4.0: A review of the concept and

of energy management approached in production ba-

sed on the internet of things paradigm. In Industrial

Engineering and Engineering Management (IEEM),

2014 IEEE International Conference on, pages 697–

701. IEEE.

Zhou, K., Liu, T., and Zhou, L. (2015). Industry 4.0: To-

wards future industrial opportunities and challenges.

In Fuzzy Systems and Knowledge Discovery (FSKD),

2015 12th International Conference on, pages 2147–

2152. IEEE.

Embedded Agent based on Cyber Physical Systems: Architecture, Hardware Definition and Application in Industry 4.0 Context

591