Data Management System for Drive-based Smart Data Services

A Pratical Approach for Machine-Internal Monitoring Applications

Chris Schoeberlein, André Sewohl, Holger Schlegel and Matthias Putz

Institute of Machine Tools and Production Processes, Chemnitz University of Technology,

Reichenhainer Straße 70, 09126 Chemnitz, Germany

Keywords: Industry 4.0, Machine Tool, Computerized Numerical Control, Drive Data, Monitoring.

Abstract: In the field of machine tools, a continuous trend towards automated and networked production systems is

recognizable in order to cope with the autonomous and self-organized systems promoted within Industry

4.0. For this purpose, large quantities of partially unstructured data exist within the machine-internal control

system. The informational value of this data can be enhanced by suitable algorithms and utilized for

multivalent applications. In addition to the information of the computerized numerical control such as feed

rate or axis positions the drive systems of machine tools can be consulted. The major advantage of the drive

internal information is due to the high temporal resolution of the available data, which is significantly above

the interpolation cycle of modern CNC (e.g. Siemens 840D sl). However, a major obstacle is the access to

this information, since most of the parameters are processed directly in the drive internal control loops and

therefore not transmitted to the superordinate control. Within the paper, a practical solution for the

automatic acquisition and processing of drive data is presented. Based on a machine internal data

management system in combination with an industrial embedded system the extraction and aggregation of

control loop data in the sense of so-called Smart Data Services is realized.

1 INTRODUCTION

In the course of Industry 4.0, an increasing demand

for self-monitoring systems can be derived in the

field of production systems. To meet these

requirements, a variety of approaches with the goal

of a holistic monitoring of machine tool exist. (Teti

et al., 2010) provides a detailed overview of the

historical development of sensor-based systems as

well as their application in research and industry.

(Matsabura and Ibaraki, 2009) and (Bindu and

Vinod, 2015) focus more on the monitoring of

production processes by measuring the prevailing

cutting forces. The authors discuss not only the

sensory acquisition of the measured quantities but

also the utilization of signals from the feed drives.

In addition to these methods, innovative research

approaches using the drive-internal control circuits

to evaluate their fundamental functionality were

developed in recent years. For example,

(Schoenherr, 2012) examined a method for the

assessment of the speed control loop based on the

Prony analysis. In contrast, (Quellmalz et al., 2014)

pursues an approach to access the quality of the

speed control loop by easily evaluable index values

based on a parallel comparison model. On the other

hand, (Hellmich, 2014) uses highly sampled control

loop signals for a process-parallel estimation of

control plant parameters like total moment of inertia

or effective friction torque.

All these methods have in common that they

require specific control loop-internal signals with

high temporal sampling (sample rate ≥ 1 kHz). For

this purpose, modern production systems already

have a large number of integrated information

sources. However, these sources have mostly been

insufficiently included in the performance

monitoring of the machine tools. This is due to the

fact that the underlying data is difficult to access and

therefore its utilization is limited to machine-internal

purposes, for example the control of the feed axes.

On the other hand, the use of network

technologies in the production environment

increased in recent years. As a result, the volume of

communication partners and interfaces has increased

significantly, which led to an accelerating

networking of production systems with their

environment. Apart of real-time capable interfaces to

Schoeberlein, C., Sewohl, A., Schlegel, H. and Putz, M.

Data Management System for Dr ive-based Smart Data Services - A Pratical Approach for Machine-Internal Monitoring Applications.

DOI: 10.5220/0006882703890395

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 389-395

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

389

Figure 1: Structure of a typical computerized numerical control (Hellmich et al., 2016).

field devices (e.g. sensors, actuators), the interfaces

to the corporate network, which have lower or no

real-time requirements, should be mentioned in

particular (Weck and Brecher, 2006).

Consequently, the main goal of the paper is the

utilization of these interfaces to establish a

consistent information chain from the feed drives via

the CNC to the cloud. This forms the basis for

control loop-based monitoring methods. At the

beginning, an analysis of modern control systems

including the underlying communication channels

will be carried out (section 2). Subsequently, a novel

systematic approach for an automatic drive data

acquisition is presented (section 3). Section 4 is

focused on the machine-level integration of the

proposed method using an industrial embedded

system available on the market. By implementing an

exemplary identification algorithm, the functionality

of the system is validated and an outlook for future

developments is provided.

2 CONTROL OF MACHINE

TOOLS

In the field of machine tools, a higher-level machine

control is needed to realize an automated production

process. This superordinate control can usually be

assigned to the class of computerized numerical

controls. As shown in figure 1, the structure of such

a CNC can be subdivided into three essential

functional components. The COM part, also referred

to as the Human Machine Interface, allocates the

interface between the operator and the controller and

contains all operating, display and communication

functions. The PLC part is used to adapt the CNC to

the respective machine type. Structurally, it

corresponds to a programmable logic controller and

is utilized for signal processing of binary inputs and

outputs as well as for coupling various peripheral

components. In addition, the user has the

opportunity to integrate own specific functions. The

numerical control kernel realizes the main

functionality of the machine tool control like path

control, interpolation and the associated generation

of the motion setpoints. Typically, the position

control of the subordinated axes is also implemented

in the NC-Kernel.

Figure 2: Separation of the cascaded servo control in

electromechanical axes.

Whereas the data exchange of the controller

internal components usually is realized via shared

memory areas (dual-port RAM) (Siemens, 2010),

industrial established fieldbus systems are common

for the communication with the drive-internal

control units. These systems are usually based on a

specific communication protocol, which is divided

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

390

into a cyclical and a user-specific, acyclical part

(Profibus, 2006). Within the cyclical part, all

parameter values relevant for the axis control (e.g.

speed set point value, actual position value) are

exchanged equidistantly in form of telegrams. Due

to the classification of the control loops in the

presented topology, not all control variables are

transmitted from the drives to the control system by

default. This can be partially avoided by expanding

the predefined telegrams with the desired values

(Siemens, 2011a). A second, acyclical data channel

can be used for diagnostic purposes or the

parametrization of the drives. By using proprietary

read/ write services, a user-specific data exchange

between the CNC and the drives can be

implemented. This forms the basis for the proposed

data management system in the following section.

3 SMART DATA MANAGEMENT

BASED ON DRIVE DATA

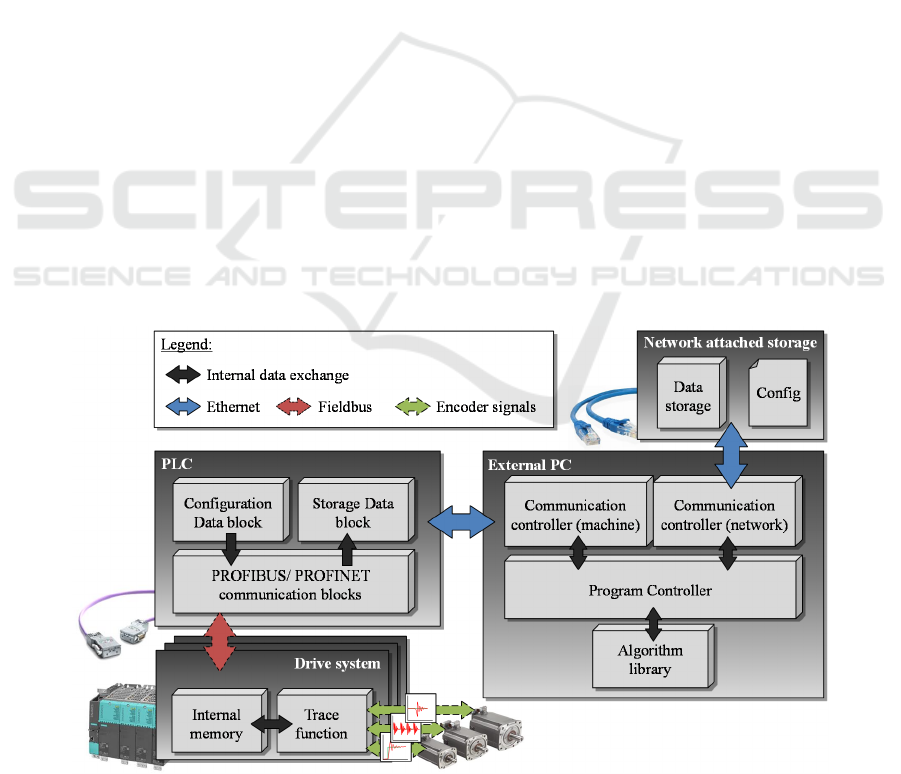

In this section, the novel data management system

with special focus on the provision of high-

frequency drive signals will be presented. The

overall procedure (figure 3) is divided into two main

subsystems:

• A control-internal part, based on the fieldbus

communication between the drives and the

CNC and

• A control-external part, which includes the

necessary communication functions as well as

algorithms for data storage and aggregation

3.1 Drive Data Acquisition based on

Controller-Internal Functions

Due to the high system clock, only the drive-side

control modules are capable to record equidistant

sampled drive data with the required high

frequencies. For this purpose, the manufacturers of

modern drive systems (e.g. Siemens Sinamics S120)

already offer pre-installed measuring functions

(trace-function), which are located directly in the

control unit. This control unit works with a base

clock of 8 kHz and thus meets the requirements of

control loop-based monitoring methods (Siemens,

2011b). The trace function is primarily controlled

during the machine commissioning phase via a

corresponding engineering system. However, it is

also possible to implement a remote control of this

trace tool through dedicated list parameters.

The access to these parameters can be

implemented with the already mentioned read/ write

services of the PROFIBUS or PROFINET

connection. Targeted utilization in form of a state

machine allows an automated recording from the

PLC part of the control. The basic functional process

is illustrated in figure 4. First, the essential recording

parameters (signals, recording cycle, duration, etc.)

are parameterized in a configuration data block in

Figure 3: Structure of the drive based data management system.

Data Management System for Drive-based Smart Data Services - A Pratical Approach for Machine-Internal Monitoring Applications

391

Figure 4: Sequential scheduling of control internal drive

data acquisition.

the PLC part of the CNC. The transfer of the

configured data to the drive control unit is

implemented via the function block FB2, which is

part of the default PLC-configuration. Subsequently,

the recording in the drive system is started

immediately or after a specific trigger condition

occurs (e.g. motor torque exceeds a configured

value). After completing the measurement, the

signals are stored in dedicated data blocks in the

PLC. The recorded signals are transferred via

cyclical calls of the function block FB 3. Due to

manufacturer-side limitations the signals are

transmitted in packages of eight values each. Further

details on the procedure and the underlying

functions are described in detail in (Hellmich et al.,

2016).

In comparison, the procedure described there

was restructured for an utilization in the intended

overall scenario. All parameters have been

integrated into a multi-instance function block,

which serves as the basis for the external access and

offers benefits in terms of memory utilization and

computing power.

3.2 Automatic Data Extraction and

Processing

After transferring the measured values to the PLC, a

central storage and enhancement of the

informational value in the sense of so-called Smart

Data Services is intended. Due to the limited

memory capacity and the cycle time dependent on

the program scope, this part of the CNC is not

suitable for permanent storage or further signal

processing.

As mentioned in section 2, however, modern

control systems have the standard possibility of the

integration into the company-internal Ethernet

network and thus to realize the coupling of a

personal computer with sufficient computing power.

There are various software interfaces already

available on the control side, for example to transmit

centrally generated part programs or for remote

maintenance. As part of the overall concept shown

in figure 3, an Ethernet-based software tool called

Snap7 has been determined, which provides the

essential functions for a bidirectional data exchange

between the PLC and external computing

technology in a corresponding library (Nardella,

2015). In addition to preinstalled communication

functions, various options for implementing

personalized read and write requests are included.

The novel created software application works

according to the client-server principle and thus

allows a data exchange between the machine control

and the connected computing technology. The

particularly developed program was designed to be

scalable in order to prospectively enable the support

of other control manufacturers without extensive

adjustments.

Functionally, a distinction can be made between

three essential components. An algorithm library

(module “calculations”) accommodates all functions

for the further processing of the logged drive data to

the mentioned control loop-based Smart Data

Services. This also includes the algorithm-specific

parametrization of the trace function. All required

communication functions were implemented in so-

called communication controllers. Their task is the

control-side access and thus the transmission of the

trace parameters and the recorded data. On the other

hand, additional communication partners such as the

central server for data storage are included. The

coordination of communication and calculation is

handled by a central process control whose basic

structure is illustrated in figure 5.

At the beginning, a machine-specific configuration

file located on the central server is loaded which

contains all required parameters. Subsequently, the

parametrization of the control-internal data

recording is initialized. After the extraction of the

data stored in the controller, the calculation of the

respective Smart Data Service and a cloud-based

backup of the results for further analysis (e.g. trend

analysis, data mining) as well as their visualization

take place.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

392

Figure 5: Sequential scheduling of control external data

processing.

4 HARDWARE-

IMPLEMENTATION AND

FUNCTIONAL VALIDATION

In this section, the previously presented method is

integrated in an exemplary machine control using

an industry-standard embedded system and is

validated by utilization of an exemplary

identification algorithm.

For control external implementation, a scalable,

Linux-based computing system called Revolution

Pi developed by Kunbus was defined. Its main

component is a multi-core processor which is

architecturally based on a conventional Raspberry

Pi. The core module is already installed in a rugged

profile rail housing by the manufacturer and meets

all standardized requirements for the industrial

utilization of programmable logic controllers. In

addition to simple control cabinet integration, it is

also possible to connect various gateways, for

example for the communication via customary bus

systems or in form of digital and analog input and

output modules. The data exchange with the CNC

is realized via an Ethernet connection as explained

in the previous section. Due to the limited memory

capacity of the embedded system (4 GB), the

configuration of the procedure and storage of the

results is located on the central server. In addition,

the controller-internal data acquisition was

integrated in the PLC part of the control.

For the experimental verification, a method for

a noninvasive identification of control plant

parameters developed by (Hellmich, 2014) was

selected and adapted for industrial purposes. This

modular method estimates actual values for total

moment of inertia and friction torque of the

considered axis based on high sampled drive

signals, in particular actual motor speed and torque.

First of all, a conceptual classification of the

underlying modules of the procedure into the

extended control architecture was carried out.

Thus, a part of the modules (data acquisition, signal

pre-processing, excitation detection) was

implemented within the control, whereas the

majority of the calculations are performed on the

Revolution Pi. The division of the modules into the

individual components is illustrated in figure 6. For

more detailed information of the underlying method

see (Hellmich, 2014) or (Schoeberlein, 2016).

Figure 6: Integration of the non-invasive identification

algorithm into the novel data management system.

All subcomponents were integrated on a three-

axis test rig with a commercially available

Siemens-CNC (Sinumerik 840D sl). In order to

validate the method, an exemplary selected feed

axis was excited with a sinusoidal velocity profile.

The actual values of the recorded signals for motor

speed and torque in x-direction are shown in figure

7. As it can be seen in the enlarged view, the

recording was performed with a sampling clock of

500 µs. A measurement of these values with such a

high resolution is only feasible in the drive-internal

control modules. In addition to the high-frequency

signal recording, an exemplary parameter

identification was performed based on the

measured signal profiles. A comparison of the

calculated moment of inertia and friction torque

based on construction data as well as experimental

preliminary investigations shows a good agreement

(table 1). From this it can be concluded that the

combination of Smart Data Management System

and drive-based Smart Data Services located in a

fully-integrated embedded system is suitable for

machine-internal monitoring functions.

Data Management System for Drive-based Smart Data Services - A Pratical Approach for Machine-Internal Monitoring Applications

393

Figure 7: Recorded values for actual motor speed and torque.

Table 1: Comparison of the identification results with

theoretical calculations.

Calculation

results

Identification

results

Δ [%]

J

x

= 34.46 kgm² J

x

= 34.67 kgm² J

x,Δ

= 0.6

T

R,x

= 0.051 T

R,x

= 0.057 T

R,x, Δ

= 10.5

5 CONCLUSIONS

In this paper, current research results in the field of

drive-based Smart Data Services for production

systems were presented. In addition to the

establishment of a control-internal data management

system for the acquisition of control loop data, the

machine infrastructure was selectively expanded by

integrating an embedded system available on the

market. This allows the machine-level processing of

cyclical logged drive data and their informational

enhancement to significant characteristic values.

Furthermore, a global data store has been set up,

which ensures the availability of all measured

signals as well as calculation results and can serve as

a basis for further applications.

The core idea of the research project is the

manufacturer-independent networking of production

systems as well as a central data provision and

further processing in the sense of Smart Data

Services. For this reason, in the next step,

possibilities for connecting further control

manufacturers (e.g. Heidenhain) and an associated

drive data acquisition has to be realized. Due to the

architectural differences in the control systems, new

approaches are needed here. Subsequently, further

control loop-based monitoring algorithms should be

implemented and investigated for their suitability by

long-term tests. At this point, the earlier mentioned

control-loop based algorithms as performance index

(Quellmalz et al., 2014) or Prony-Analysis

(Schoenherr, 2012) are eligible to improve the

understanding of the control behavior parallel to the

process. Furthermore, it would be conceivable to use

the results directly to adapt the drive control

parameters online and thus react to changing

circumstances. Due to the conceptual design of the

data management system, in addition to the

extraction of the drive data their targeted adaption is

feasible.

The conclusion is the expansion of the data

infrastructure, for example considering the global

availability within the network storage or the parallel

recording of machine and additional sensor data.

Subsequent correlation and pattern analysis will

provide new insights into the state of production

systems and contribute to autonomous, cyber-

physical systems in the sense of Industry 4.0.

ACKNOWLEDGEMENTS

Funded by the European Union (European Social

Fund) and the Free State of Saxony.

time (ms)

torque (Nm)

speed (1/min)

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

394

REFERENCES

Bindu, B., Vinod, B., (2015). Measurement of Cutting

Forces in CNC Turning Centers: A Review.

International Journal of Mechanical Engineering,

3(5), pp. 77-87.

Hellmich, A., (2014). Nichtinvasive Identifikation von

Regelstreckenparametern für elektromechanische

Achsen. PhD Thesis, Chemnitz University of

Technology.

Hellmich, A., Quellmalz, J., Schoeberlein, C., Schlegel,

H., Putz, M., (2016). Drive Data Aquisition for

Controller Internal Monitoring Applications, Journal

of Machine Engineering, 13(2), pp. 82-94.

Matsabura, A., Ibaraki, S., (2009). Monitoring and Control

of Cutting Forces in Machining Processes: A Review.

International Journal of Automation Technologies,

3(4), pp. 445-456.

Nardella, D., (2015). SNAP7 1.4.0: Reference manual.

Viewed 27 April 2018, http://snap7.sourceforge.net.

Neugebauer, R. (eds.), (2012). Werkzeugmaschinen –

Aufbau, Funktion und Anwendung von spanenden und

abtragenden Werkzeugmaschinen. Springer Verlag,

Berlin.

PROFIBUS Nutzerorganisation e.V., (2006). Profile

Device Technology PROFIDRIVE: Technical

Specification for PROFIBUS and PROFINET Version

4.1. PROFIBUS Nutzerorganisation e.V., Karlsruhe.

Quellmalz, J., Schlegel, H., Rehm, M., Neugebauer, R.,

(2014). Influence analysis on the model comparison

performance index for servo drive control.

Proceedings of the 16th International Conference on

Mechatronics – Mechatronika 2014. (eds. Brezina, T.,

Maga, D., Stefek, A.), Brno, Brno University of

Technology, pp. 242-247.

Schoeberlein C., (2016). Konzept und beispielhafte

Implementierung einer nichtinvasiven Identifikations-

routine an Werkzeugmaschinen. Master Thesis,

Chemnitz University of Technology.

Schoenherr, R., (2012). Regelkreisüberwachung mecha-

tronischer Antriebssysteme. PhD Thesis, Chemnitz

University of Technology.

Siemens AG, (2010): SINUMERIK 840D sl / 828D Basic

Functions Function manual. Siemens AG, Nürnberg.

Siemens AG, (2011). Simatic S7-300 – Connection of the

SINAMICS S120 to the Technology CPU. Siemens

AG, Nürnberg.

Siemens AG, (2011). SINAMICS – S120 Commissioning

manual. Siemens AG, Nürnberg.

Teti, R., Jemielniak, K., O’Donnell, G., Dornfeld, D.,

(2010). Advanced monitoring of machining opera-

tions. In: CIRP Annals – Manufacturing Technology,

59(2), pp. 717-739.

Weck, M. (eds.), Brecher, C., (2006). Werkzeugmaschinen

3 – Mechatronische Systeme, Vorschubantriebe,

Prozessdiagnose. Springer Verlag, Berlin.

Data Management System for Drive-based Smart Data Services - A Pratical Approach for Machine-Internal Monitoring Applications

395