Automatic Detection of Subassemblies for Disassembly Sequence

Planning

Yongjing Wang

1

, Feiying Lan

1

, Duc Truong Pham

1

, Jiayi Liu

1,2

, Jun Huang

1

, Chunqian Ji

1

,

Shizhong Su

1

, Wenjun Xu

2,3

, Quan Liu

2,4

and Zude Zhou

4,5

1

Autonomous Remanfuatcuring Laboratory, Department of Mechanical Engineering,

The University of Birmingham, Edgbaston, Birmingham, B15 2TT, U.K.

2

School of Information Engineering, Wuhan University of Technology, Wuhan, 430070, China

3

Hubei Key Laboratory of Broadband Wireless Communication and Sensor Networks,

Wuhan University of Technology, Wuhan, 430070, China

4

Key Laboratory of Fibre Optic Sensing Technology and Information Processing (Ministry of Education),

Wuhan University of Technology, Wuhan, 430070, China

5

School of Mechanical and Electronic Engineering,

Wuhan University of Technology, Wuhan, 430070, China

Keywords: Remanufacturing, Disassembly Planning, Dismantling, Robotic Disassembly.

Abstract: Disassembly, the first process in remanufacturing, is labour-intensive due to the conditions of end-of-life

products returned for remanufacture. Robotic disassembly is an attractive alternative to manual disassembly

but robotic systems cannot plan disassembly sequences automatically and manual planning is still required.

Several planning methods have been proposed to take away removable components sequentially. However,

those methods do not work when it is required to break an assembly into subassemblies. This paper proposes

a method for automatic detection of subassemblies. The approach starts with using an assembly matrix and

simple logic gates to generate a contact matrix and a relation matrix. The paper details new algorithms used

to detect subassemblies through manipulating the two matrices.

1 INTRODUCTION

Remanufacturing is "the rebuilding of a product to

specifications of the original manufactured product

using a combination of reused, repaired and new

parts" (Johnson and McCarthy, 2014). One

important feature distinguishing remanufacturing

from conventional manufacturing is disassembly.

Due to the variability in the condition of the returned

products, disassembly tends to be manually carried

out. It is labour intensive, given the complexity of

the operations involved.

Developments in automated disassembly

systems started in the mid-1990s with the robotic

disassembly of a PC (Kopacek and Kronreif, 1996),

followed by several successful attempts at

dismantling electrical devices and automotive

components (Barwood et al., 2015; Gil et al., 2007;

Vongbunyong and Chen, 2015). The reported

experiments were mostly product-orientated and

based on pre-programmed sequences. A key

advance from ‘automated’ disassembly to

‘autonomous’ disassembly would be that machines

plan disassembly sequences using the structure of

the product rather than following a pre-programmed

sequence. A popular approach is based on graphs (Li

et al., 2002; Torres et al. , 2003). Many algorithms

and rule-based methods have been used to calculate

disassembly sequences, for example, the Fuzzy

Reasoning Petri Net proposed by Zhao and Li (Zhao

and Li, 2010). However, the generation of a graph

relies on human understanding instead of machine

interpretation.

Smith et al. presented a tool consisting of five

matrices to represent an assembly and used several

rules to generate disassembly sequences (Smith and

Chen, 2009; Smith et al., 2012). Tao et al. also

modified the matrices to enable partial/parallel

94

Wang, Y., Lan, F., Pham, D., Liu, J., Huang, J., Ji, C., Su, S., Xu, W., Liu, Q. and Zhou, Z.

Automatic Detection of Subassemblies for Disassembly Sequence Planning.

DOI: 10.5220/0006906600940100

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 1, pages 94-100

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

disassembly (Tao et al., 2017). However, this

optimisation-focused work did not reduce the

complexity of the mathematical representation of an

assembly in which distinguishing between fasteners

and general parts was needed although their

definitions were fuzzy and could cause confusion in

many cases. For example, it is not clear whether to

categorise objects in press-fit components as

fasteners or general parts. Another matrix-based

example can be found in the work of Jin et al. (Jin

et al., 2015; Jin et al., 2013), in which the

relationships between components were presented

using just a matrix. However, the matrix-based

methods tend to focus on sequential disassembly and

cannot work correctly when breaking an assembly

into subassemblies is required.

This paper presents a method that can detect

subassemblies automatically. Based on an analysis

of over 239 mechanical products by the authors’

team, breaking into subassemblies is a critical step

for some 23% of them (Ji et al. 2017), and cannot be

correctly dealt with using conventional methods.

Section 2 presents the definitions and derivations

of two matrices: contact and relation matrix, which

can represent the contact status of components. Such

information can be used to identify separable pairs,

pairs of components which can be broken to build

subassemblies (Section 3). A case study is given in

Section 4 to demonstrate the use of the approach.

2 CONTACT AND RELATION

MATRICES: FUNDAMENTAL

TOOLS

Jin et al. (Jin et al., 2015; Jin et al., 2013) demons-

trated a method to identify removable components

to generate feasible disassembly sequences using the

space interference matrix. The essence of the

approach is to find components that have freedom in

at least one direction, indicating that the components

are removable. A product can be disassembled after

multiple cycles of taking away removable

components step-by-step in a sequential way.

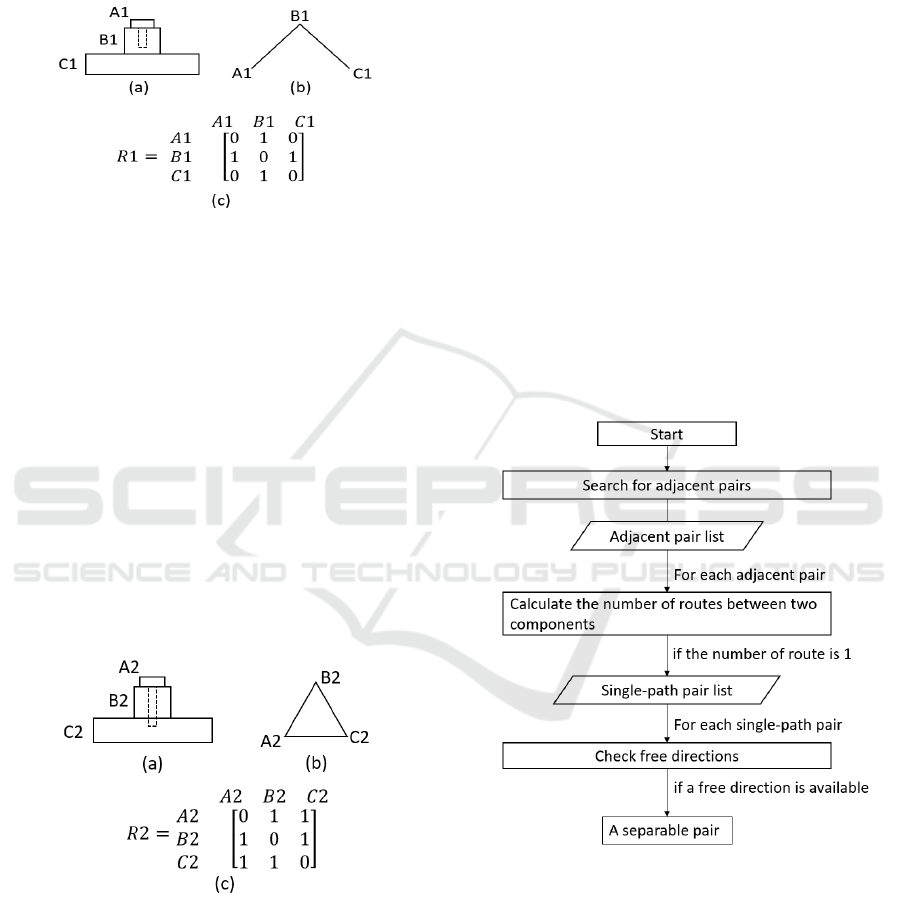

Figure 1: An example product.

If the method is adopted for the case in Figure 1

(Smith and Hung, 2015), however, after the removal

of

and

in the first step, no components can be

further disassembled, as shown in Figure 2. This is

a typical interlocking structure. An assembly cannot

be disassembled as no parts are removable until the

whole structure is broken into smaller

subassemblies.

The paper proposes the contact matrix

and relation matrix, as fundamental tools to

detect subassemblies. It can represent contact

conditions in an assembly in six directions

(X+, X-, Y+, Y-, Z+, Z-). Here, only four directions

(X+, X-, Y+, Y-) are needed for demonstrations in

two dimensions, as shown in Eq. 1.

In the matrix,

represents components in an

assembly.

.

,

.

,

.

, and

.

indicate

the contact status of the components in the

corresponding columns and rows by using two

states: 0 for no contact and 1 for contact. For

example, the assembly in Figure 1 can be

represented by the contact matrix in Eq. 2.

.

.

.

.

is 0001 because

is a

contact in Y- direction for

.

can be removed

from

in Y+ direction. Similarly,

.

.

.

.

is 0010 because

a contact

in Y+ direction for

.

can be removed from

in Y- direction. It is worth noting that symmetry may

not be observed in

.

.

.

.

and

.

.

.

.

due to requirements of

proper disassembly operations. For example,

.

.

.

.

is 1110 and

.

.

.

.

is 1111, because removing

from

is a proper operation but the reverse is not.

The relation matrix describes the general contact

status of components, derived from contact matrix

(Figure 3). The two matrices could be the keys for a

machine to understand subassemblies.

Automatic Detection of Subassemblies for Disassembly Sequence Planning

95

Figure 2: Sequential disassembly method proposed by Jin et al. (Jin et al., 2015; Jin et al., 2013).

…

=

⋮

.

.

.

.

⋯

.

.

.

.

⋮⋱⋮

.

.

.

.

⋯

.

.

.

.

(1)

C=

0000 0001 0000 0000 0001 1111 0000 0000 1111

0010 0000 0000 0000 0000 1111 0000 0000 0000

0000 0000 0000 1101 0000 0000 1111 0000 0000

0000 0000 1110 0000 0001 0000 0000 1111 0000

0010 0000 0000 0010 0000 0000 1111 1111 1111

1110 1110 0000 0000 0000 0000 0000 0000 0000

0000 0000 1101 0000 1101 0000 0000 0000 0000

0000 0000 0000 1110 1110 0000 0000 0000 0000

1110 0000 0000 0000 1110 0000 0000 0000 0000

(2)

Figure 3: Derivation of a relation matrix from a contact matrix.

3 SEPARABILITY CHECK

3.1 Definition of Separability

The separability of an assembly indicates whether it

can be broken into subassemblies. The separability of

an assembly is determined by whether it contains

‘separable pairs’, pairs of contacting components that

can be separated without affecting other contacting

components. For example, the assembly in Figure 4a

has three components: A1, B1 and C1, and two pairs

of contacting components: A1-B1 and B1-C1. If a

contact between a pair can be represented as a line,

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

96

then the physical model in Figure 4a can be simplified

to Figure 4b, which can also be represented by its

relation matrix (R1), as shown in Figure 4c. Both

pairs, A1-B1 and B1-C1, are separable, as the

separation of either pair would not affect the other.

Figure 4: An example of a product comprising separable

pairs.

However, in a similar model shown in Figure 5,

the result would be different. None of the three pairs,

A2-B2, B2-C2 and A2-C2, are separable, as the

separation of a pair could affect other pairs. For

example, the separation of A2-B2 inevitably causes

the detachment of A2 from C2. Comparing Figure 4b

to Figure 5b, it is obvious that there is only one path

between A1 and B1 (A1-B1) in Figure 4b, but there

are two paths between A2 and B2 (A2-B2, and A2-

C2-B2) in Figure 5b. When there is only one path, the

interaction between the two components is not

coupled with those with other components. A

sufficient condition for a pair to be separable is that

there is only one path between two components in a

pair, as in the pairs A1-B1 and B1-C1 in Figure 4b.

Figure 5: An example of a product comprising inseparable

pairs.

3.2 Separable Pairs Search Process

Separable pairs can be searched for using vectors,

namely node vectors, to represent components, as

shown in Eq. 3, so that the links connected to a node

can be calculated by multiplying the relation matrix

R1 with its note vector (Eq. 4 to 6).

1=

1

0

0

,1=

0

1

0

,1=

0

0

1

(3)

R1.

1=

010

101

010

∙

1

0

0

=

0

1

0

=1,

R1.1=

010

101

010

∙

0

1

0

=

1

0

1

=1+1,

R1.C1=

010

101

010

∙

0

0

1

=

0

1

0

=1

(4)

(5)

(6)

The method can be used to identify adjacent

components. Also, a path between two nodes can be

found by recursively multiplying the relation matrix

by a node vector and its adjacent node vectors until a

destination is reached. Figure 6 shows the process of

searching for separable pairs using a relation matrix.

Figure 6: Separable pairs search process.

The first step is to search for adjacent pairs, two

components in contact, which can be identified using

Eq. 3 to 6.

The second step is to identify the pair in which

there is only one route between the two components,

a sufficient condition for a pair to be separable, as

discussed earlier. We propose using a recursive

strategy using the pseudo code in Algorithm 1.

Automatic Detection of Subassemblies for Disassembly Sequence Planning

97

Algorithm 1: Generate single-path pair list from adjacent

pair list.

Main function:

Input: adjacent pair list (APL)

Output: Single-path list (SPL)

1 For every pair {X, Y} Є APL

2 counter = 0

3 searchPath(X,Y) ;

4 If counter = 1

5 add {X, Y} to SPL;

6 End if

7 End for

searchPath(X,Y)

8 Label X as discovered

9 For every component k adjacent to X

10 If k is not labelled as discovered

11 If k = Y

12 counter++;

13 If counter >=2

14 break;

15 End if

16 Else

17 Recursively call searchPath(k,Y)

18 End if

19 End if

19 Return counter

20 End for

After all single-path pairs are identified,

their corresponding elements in the contact

matrix should be checked. If the elements are

not 1111 (

.

.

.

.

≠1111 and

.

.

.

.

≠1111), it indicates that one

component has freedom on at least one direction in

relation to the other, and thus the pair is separable.

Details are explained using the discussed example in

Figure 1.

After the removal of

and

, the node-line

model of the assembly and its relation matrix are

presented in Figure 7 and Eq. 7. By using Eqs.3 and

4, eight adjacent pairs can be identified: C1-C2, C1-

C4, C2-C3, C2-f1, C3-C4, C4-C5, C5-f1 and C5-f2.

Figure 7: Model of the assembly after the removal of f3 and

f4.

R=

0101010

1010000

0101000

1010100

00010

11

1000101

0000110

(7)

Algorithm 1 is used to calculate the number of

routes between two components in a pair, starting

from the first pair C1-C2. The result indicates that the

pair is not separable, as there are two routes from C1

to C2 (C1→C2 and C1→f1→C2), as depicted in

Figure 8. For the next member on the adjacent pair

list, C1-C5, only one route is found, and thus the pair

is added to single-path list. The calculation continues

for all pairs on the adjacent pair list, and C1-C5 is the

only single-path pair. As C1 and C5 have freedom in

3 directions, the pair is a separable pair.

Figure 8: An example of searching for single-path pairs.

It indicates that the separation of C1 and C5 would

result in two subassemblies: C1-C2-f1 and C3-C4-

C5-f2. Then, f2 and f1 become removable and

disassembly iterations could carry on using sequential

disassembly planning methods.

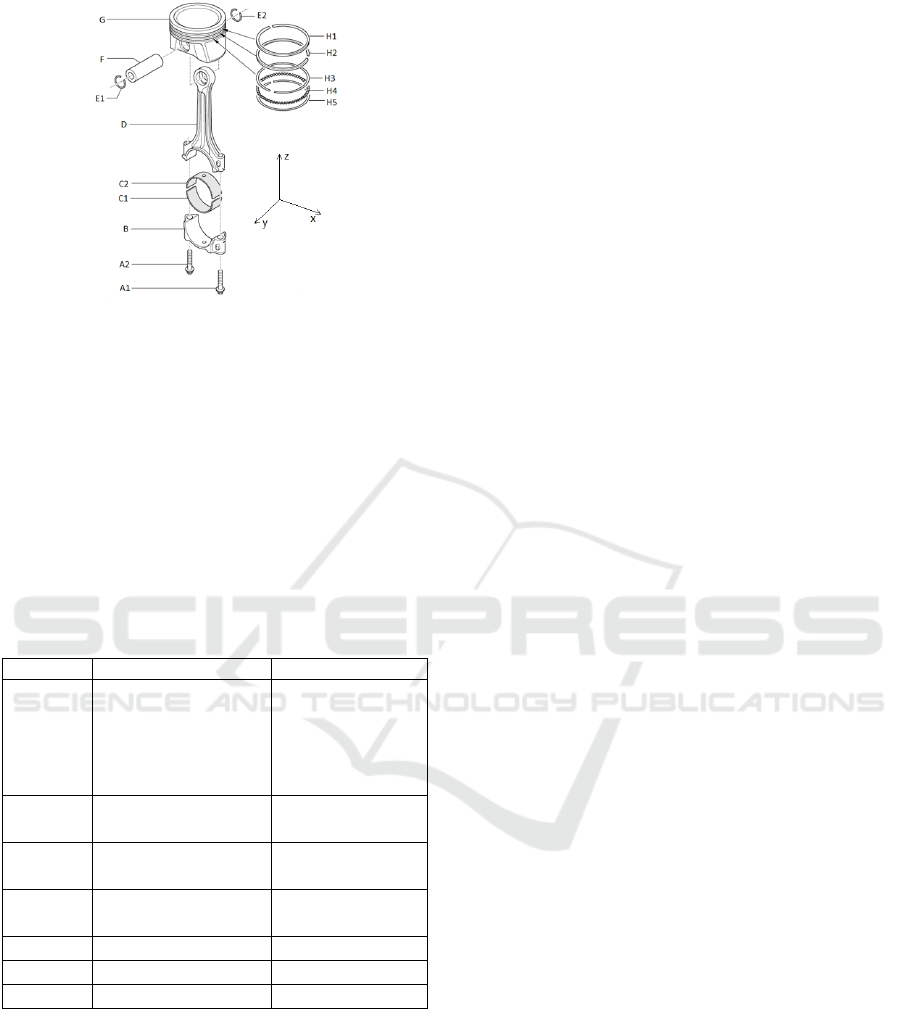

4 CASE STUDY

This section discusses a case study of the disassembly

of a piston used in a 4-stroke engine, as shown in

Figure 9.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

98

Figure 9: Parts in a piston.

If the conventional sequential disassembly

method (G. Jin et al., 2015; G. Q. Jin et al., 2013) is

adopted, the sequential disassembly plan as shown in

table 1 is obtained using the space interference matrix

(Appendix). It can be seen that no removable parts are

identified at iteration 7, and parts B, C1-2 and D form

an interlocking structure. To continue disassembly,

the methods presented in Section 3 can be employed

to identify a separable pair to break the product into

subassemblies.

Table 1: Sequential disassembly plan generated using the

method by Jin et al.

Iteration Removable parts Remaining parts

1

A1-111110

A2-111110

E1-110111

E2-111011

H1-111101

B, C1-2, D, F, G,

H2-5

2

F -110011

H2 - 111101

B, C1-2, D, G,

H3-5

3

H3 - 111101 B, C1-2, D, G,

H4-5

4

H4 - 111101 B, C1-2, D, G,

H5

5 H5 - 111101 B, C1-2, D, G

6 G - 111101 B, C1-2, D

7 None B, C1-2, D

The contact matrix and related matrix of the

structure B-C1-C2-D are given in Eqs. 8 and 9. By

using Eq. 3 to 6, three adjacent pairs can be identified:

B-C1, B-D and C2-D. Algorithm 1 is used to calculate

the number of routes between two components in a

pair. The result indicates that all three pairs are single-

path pairs. However, only B-D is a separable pair as

C

12

and C

43

are 111111, indicating that either B-C1 or

C2-D has no freedom to separate. The separation of

B and D builds two subassemblies, B-C1 and C2-D,

and thus further disassembly operations can carry on.

C=

1 2

1

2

000000 111111

111101 000000

000000 000010

000000 000000

000000 000000

000001 000000

000000 111110

111111 000000

(8)

=

12

1

2

01

10

01

00

00

10

01

10

(9)

5 CONCLUSION

Machine understanding of the structure of an assembly

in three-dimensional space is required for autonomous

disassembly planning. Conventionally, because of the

complexity of spatial information, models tended to be

complex and normally not suitable for all structures, in

particular, those containing interlocking components.

As far as the authors are aware, no previous work has

been carried out relating to this issue.

This paper presents a method to break an

assembly into subassemblies when sequential

disassembly of components is not possible. The

method is designed to work for all subassemblies

containing interlocking components and its

effectiveness was demonstrated with a case study.

Future work could investigate combining the

proposed method with conventional disassembly

planning approaches. This would undoubtedly yield a

more capable disassembly planning system suitable

for adoption in autonomous remanufacturing.

ACKNOWLEDGEMENT

This research was supported by the EPSRC (Grant

No. EP/N018524/1) and the National Science

Foundation of China (Grant No. 51775399).

REFERENCES

Barwood, M., Li, J., Pringle, T., and Rahimifard, S. (2015).

Utilisation of reconfigurable recycling systems for

improved material recovery from e-waste. In Procedia

CIRP (Vol. 29, pp. 746–751). https://doi.org/10.1016/

j.procir.2015.02.071

Gil, P., Pomares, J., Puente, S. V. T., Diaz, C., Candelas, F.,

and Torres, F. (2007). Flexible multi-sensorial system

for automatic disassembly using cooperative robots.

International Journal of Computer Integrated

Manufacturing, 20(8), 757–772. https://doi.org/ 10.10

Automatic Detection of Subassemblies for Disassembly Sequence Planning

99

80/09511920601143169

Ji, C., Pham, D. T., Su, S., Huang, J., and Wang, Y. (2017).

AUTOREMAN – D.1.1 - List of generic disassembly

task categories, Technical Report, Autonomous Rema-

nufacturing Laboratory, the University of Birmingham.

Jin, G., Li, W., Wang, S., and Gao, S. (2015). A systematic

selective disassembly approach for Waste Electrical

and Electronic Equipment with case study on liquid

crystal display televisions. Proceedings of the

Institution of Mechanical Engineers, Part B: Journal of

Engineering Manufacture. https://doi.org/10.1177/09

54405415575476

Jin, G. Q., Li, W. D., and Xia, K. (2013). Disassembly

Matrix for Liquid Crystal Displays Televisions.

Procedia CIRP, 11, 357–362. https://doi.org/10.1016/

j.procir.2013.07.015

Johnson, M. R., and McCarthy, I. P. (2014). Product

recovery decisions within the context of Extended

Producer Responsibility. Journal of Engineering and

Technology Management, 34, 9–28. https://doi.org/

10.1016/j.jengtecman.2013.11.002

Kopacek, P., and Kronreif, G. (1996). Semi-automated

robotic disassembling of personal computers. In EFTA

’96 - IEEE Conference on Emerging Technologies and

Factory Automation (Vol. 2, pp. 567–572). IEEE.

https://doi.org/10.1109/ETFA.1996.573938

Li, J. R., Khoo, L. P., and Tor, S. B. (2002). A Novel

Representation Scheme for Disassembly Sequence

Planning. The International Journal of Advanced

Manufacturing Technology, 20(8), 621–630.

https://doi.org/10.1007/s001700200199

Smith, S., and Chen, W.-H. (2009). Rule-Based Recursive

Selective Disassembly Sequence Planning for Green

Design (pp. 291–302). Springer, London. https://doi.

org/10.1007/978-1-84882-762-2_27

Smith, S., and Hung, P.-Y. (2015). A novel selective

parallel disassembly planning method for green design.

Journal of Engineering Design, 26(10–12), 283–301.

https://doi.org/10.1080/09544828.2015.1045841

Smith, S., Smith, G., and Chen, W.-H. (2012). Disassembly

sequence structure graphs: An optimal approach for

multiple-target selective disassembly sequence

planning. Advanced Engineering Informatics, 26(2),

306–316. https://doi.org/10.1016/j.aei.2011.11.003

Tao, F., Bi, L., Zuo, Y., and Nee, A. Y. C. (2017).

Partial/Parallel Disassembly Sequence Planning for

Complex Products. Journal of Manufacturing Science

and Engineering, 140(1), 011016. https://doi.org/

10.1115/1.4037608

Torres, F., Puente, S. T., and Aracil, R. (2003).

Disassembly Planning Based on Precedence Relations

among Assemblies. The International Journal of

Advanced Manufacturing Technology, 21(5), 317–327.

https://doi.org/10.1007/s001700300037

Vongbunyong, S., and Chen, W. H. (2015). Disassembly

Automation. Springer, Cham. https://doi.org/10.1007/

978-3-319-15183-0

Zhao, S., and Li, Y. (2010). Disassembly Sequence Decision

Making for Products Recycling and Remanufacturing

Systems. In 2010 International Symposium on

Computational Intelligence and Design (pp. 44–48).

IEEE. https://doi.org/10.1109/ISCID. 2010.19

APPENDIX

Space interference matrix

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

100