Root Cause Analysis of Deep Drawing Processes with Superimposed

Low-Frequency Vibrations on Servo-Screw Presses

A Practical Research on Predictability in Simulation

André Sewohl

1

, Sebastian Kriechenbauer

2

, Peter Müller

2

, Holger Schlegel

1

and Dirk Landgrebe

2

1

Institute of Machine Tools and Production Processes, Chemnitz University of Technology,

Reichenhainer Straße 70, 09126 Chemnitz, Germany

2

Fraunhofer-Institute for Machine Tools and Forming Technologies,

Reichenhainer Straße 88, 09126 Chemnitz, Germany

Keywords: Process Simulation, Process Design, Deep Drawing, Superimposed Vibration, Servo-Screw Press.

Abstract: In the area of sheet metal forming, modelling and simulation of deep drawing processes with finite-element

analysis are an essential method for an accurate process design and the production engineering of complex

parts. The continuous evaluation and qualification of simulation strategies improve the predictability and

help to understand complex forming processes. In order to fulfil the constantly growing requirements on

product quality and part variety, dimensional accuracy as well as energy and cost efficiency, it is necessary

to achieve reasonable forecasting results and optimal parameters. However, the development of enhanced

deep drawing techniques supported by vibrations is in general just beginning. Currently, prediction of

process parameters as well as the knowledge about effects and coherences of highly dynamic processes with

flexible kinematics are insufficient. In this paper, an approach for improvements in simulation of a new

technology for deep drawing on servo-screw presses called cushion-ram pulsation is presented. Numerical

and experimental model tests in special constructed set-ups have to be performed to determine particular

forces. Sensitivity based methods help to identify significant process parameters of complex forming

processes with superimposed vibrations. The evaluation of these parameters allows the development of

specific meta-models which approximate the behavior in the simulation.

1 INTRODUCTION

In recent years, finite-element analysis (FEA) in

simulation has become established as a powerful

tool for process design. Also in the field of sheet

metal forming, it is an integral part for the

development of deep drawing processes and tools.

Even in the early design phase, the feasibility of

deep-drawing processes can be assessed quite well.

In the simulation of forming processes, workpiece

properties like stress, deformation and hardening

state, wall thickness, dimensional and shape

accuracy, indication of failure cases or areas are of

particular interest concerning the product

requirements, which must be satisfied (Großmann

and Neugebauer, 2010). In addition to energy and

resource efficiency of forming processes, good

component quality is an important competitive

factor in sheet metal forming. Therefore, ever higher

demands are placed on the dimensional accuracy of

formed sheet metal parts, whereby the efficiency of

the processes must not be affected. Due to the

performance leaps in FEA-tools, the simulation of

deep drawing processes with finite-elements has also

proved to be an efficient tool for large models with

many thousands of degrees of freedom starting from

feasibility studies up to the compensation of

springback.

Nevertheless, the forecast capability is limited

due to the complex, mostly non-linear relationships

in deep drawing. The deviations are often caused by

the tool development, since not all influences can be

considered in the simulation. Especially interactions

between the process, tool and machine are only

poorly replicable (Denkena and Hollmann, 2013).

As a result the final quality of the part can deviate

considerably from the simulation result for deep

Sewohl, A., Kriechenbauer, S., Müller, P., Schlegel, H. and Landgrebe, D.

Root Cause Analysis of Deep Drawing Processes with Superimposed Low-Frequency Vibrations on Servo-Screw Presses - A Practical Research on Predictability in Simulation.

DOI: 10.5220/0006906706210627

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 621-627

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

621

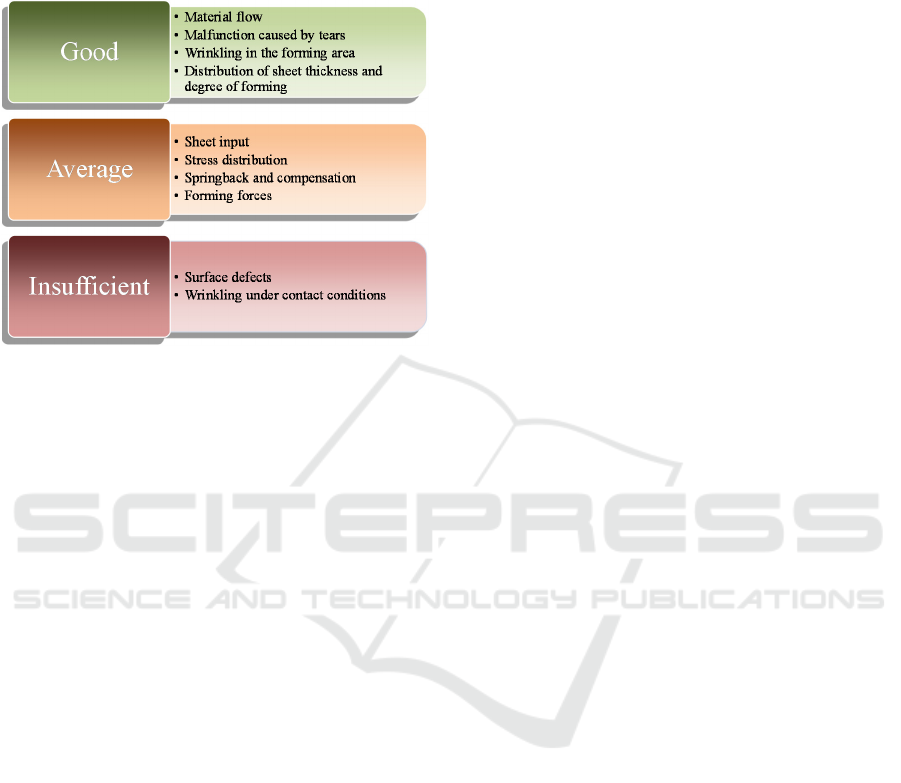

drawing processes. An overview of the forecast

capability in forming simulation is shown in

figure 1, with three groups being distinguished (Roll,

2012).

Figure 1: Forecast capability in forming simulation (Roll,

2012).

From figure 1 it becomes clear that surface

defects and wrinkles can only be detected poorly due

to the complex conditions. This is a particular

challenge for innovative technologies with extended

process kinematics. In order to fulfil the rising

demands and increase the profitability and

productivity of forming machines, at a consistent or

improved quality of drawn parts, the conventional

deep drawing process must be continuously

enhanced. An overview of deep drawing techniques

with variable motion paths is presented in

(Kriechenbauer et al., 2014). There is shown, how

superimposed low-frequency vibrations up to 50 Hz

can be a new approach to extend forming limits in

deep drawing.

One well-known example is the technology of

cushion pulsation described in (Fiat, 1994). Positive

effects of pulsating blankholder forces, like the

reduction of friction forces or the enlargement of the

gap between the wrinkling- and the fracture-border,

are described in (Doege, 2000). However, optimal

process variables of cushion pulsation could neither

temporally nor spatially be quantified in a systematic

manner yet. An approach for a cylindrical cup

through numerical simulation coupled with an

optimization technique is presented in (Kitayama et

al., 2016). The influence of process parameters from

pulsating blankholder forces on drawing depth for a

square cup is investigated in (Nezami et al. 2017).

Another example of a highly dynamic deep

drawing process is the cushion-ram pulsation on

servo-screw presses (Kriechenbauer et al., 2014).

The development of electromechanical servo-screw

presses constitutes a significant progress for deep

drawing with superimposed low-frequency

vibrations and opens new potential in sheet metal

forming. The direct driven system is characterized

by outstanding dynamical axis features, high

stiffness and the transferability of high forces. Due

to flexible controlling options, it is possible to

realize variable motion paths with ram and cushion

even in workpiece contact during forming process.

The cushion-ram pulsation extends forming limits

(Kriechenbauer et al., 2014). However, this new

approach has been investigated in an almost

exclusively phenomenological way and the design of

the process is only supported by empirical methods.

In (Neugebauer et al., 2012), progress has been

made in the simulation of low frequency vibrations

during deep-drawing processes on servo-screw

presses. New methods have been developed to

improve the predictability of process simulation by

considering the quasi-static interaction between

process and machine in (Drossel et al., 2013).

Despite the improvements, it has not yet been

possible to reproduce the component quality with

sufficient accuracy due to extensive wrinkling

phenomena.

In particular, for the simulation of the cushion-

ram pulsation, new methods have to be developed in

order to be able to predict the formation of wrinkles

more accurately and to take into account quality-

determining influences during the process

adjustment with superimposed low-frequency

vibrations. Furthermore the prognosis of optimal

process parameters is insufficient. So far there are no

corresponding assessment bases. In addition to basic

questions about process design, the root causes of

the technological effects are largely unexplained.

Fundamental research is needed in order to ensure

the prognosis accuracy of deep drawing techniques

with superimposed low-frequency vibrations on

servo-screw presses.

Consequently, the main goal of the following

paper is to give a contribution for improvements in

simulation and design of deep drawing processes

supported by vibrations, with cushion-ram pulsation

as an example. This technology is described in the

next section. Subsequently, a novel method for the

determination and assessment of single force

components is presented. This approach will be used

to enable a comparison between conventional deep

drawing, cushion pulsation as well as cushion-ram

pulsation and to understand effects and coherences

of complex forming processes. Afterwards, special

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

622

developed test setups for experimental model tests

and preliminary results are presented. Finally a

summary and outlook of future work is provided.

2 DEEP DRAWING WITH

SUPERIMPOSED

LOW-FREQUENCY

VIBRATIONS

In the area of sheet metal forming low- as well as

high-frequency excitation mechanisms can be used

to generate different kind of vibrations. Typical

vibration amplitudes are in the millimeter range at

frequencies lower than 50 Hz (Klose and Bräunlich,

2000) and in the micrometer range at high

frequencies above 1 kHz (Siegert and Ulmer, 2001).

Usually superposition of vibrations in the tool takes

place with a magnetostrictive, piezoelectric, electro-

mechanic, or hydraulic excitation. The vibrations

favor tribological conditions between tool and sheet.

As a result the friction force is reduced. Further

positive effects of forming techniques supported by

vibrations are extended process limits, saving of

lubricant, higher drawing ratios as well as the

reduction of drawing steps and cracks (Mauermann,

2010).

Deep drawing techniques with superimposed

vibrations are highly dependent on the properties of

the forming machines used. In the past, mainly

hydraulic systems were used for this purpose.

However, modern servo-screw presses enable

vibrations in the sub millimeter range at frequencies

up to 50 Hz without additional actuators

(Kriechenbauer et al., 2014). Advantages of these

systems are high drive stiffness and dynamics as a

result of the axial powertrain arrangement. In

addition rapid changes of direction and quick load

cycles are feasible in ram as well as in cushion due

to high jerk values and great accelerations

(Neugebauer et al., 2012).

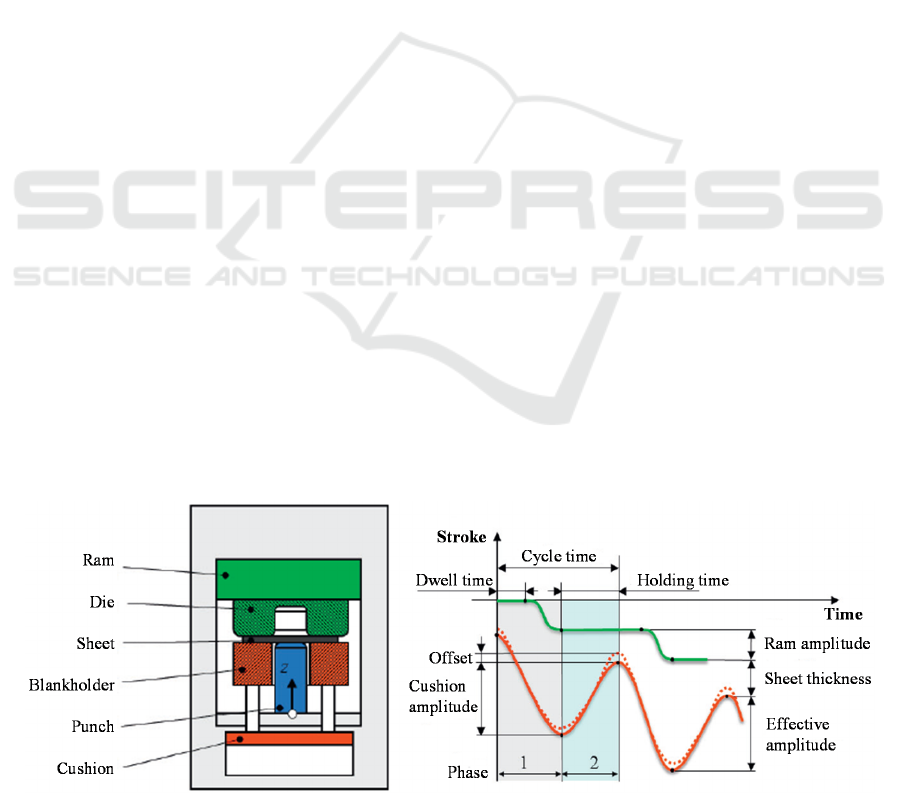

The special drawing technique on servo-screw

presses with synchronized motion paths of ram and

cushion, called cushion ram pulsation is in focus of

the investigations. This technique is a position-

controlled process with additional holding times for

the ram. The synchronized motion paths of cushion

and ram consists of sinusoidal cycles. The sequence

and corresponding parameters for an individual

cycle are illustrated in figure 2. One single cycle is

divided into two process steps. The cushion moves

away from the stationary ram during dwell time in

the first step. As a result the distance between the

sheet and the blankholder grows and the flange gap

opens. After dwell time the ram moves down to

draw the part in a small step. Due to the open flange

gap only low friction and compression forces occur

in the drawing radius and in the flange. However the

opened flange gap enables a disadvantageous

formation of wrinkles too. Subsequently in step two

the ram is stopped during the holding time and the

cushion moves against the stationary ram. That

results in an increase of surface pressure and

wrinkles in the flange will be reduced. Thereby the

cycle is completed and can be repeated as required

with possible different parameters.

During deep drawing operations, high tensile

stresses in the part frame usually lead to fractures,

which frequently occur in the punch radius. For

cushion-ram pulsation, drawing progress with

opened flange gap in the first step represents a

process similar to deep drawing without

blankholder, whereby local tensile stresses in the

frame are reduced and critical loads are shifted to

higher drawing ratios. In conventional deep drawing,

formation of wrinkles is prevented with the

blankholder and high friction forces must also be

Figure 2: Process parameters for cushion-ram pulsation (Neugebauer et al., 2012).

Root Cause Analysis of Deep Drawing Processes with Superimposed Low-Frequency Vibrations on Servo-Screw Presses - A Practical

Research on Predictability in Simulation

623

considered. As a result the total force introduced via

the punch during drawing progress is always lower

in cushion-ram pulsation than in conventional deep

drawing (Neugebauer et al., 2012). In the second

step there is no progress in drawing. Consequently

no tensile stress relevant for breakdown affects the

edge. Due to the technological separation of drawing

progress and reduction of wrinkles, larger drawing

depths can be achieved, which is a technical benefit

of the cushion-ram pulsation.

Elastic deformations of press machine and tool

systems have to be compensated by specific

parameter settings. A negative offset or die closing

force is proposed in (Neugebauer et al., 2012). The

formation of wrinkles depends on the limited ram

and cushion amplitudes. In order to achieve high

productivity it is necessary to decrease amplitudes

and to increase frequency. Usual amplitudes are

settled in the sub millimeter range.

3 NOVEL METHOD FOR THE

SEPARATION OF FORMING

FORCE

In this section, a novel method for identifying the

root causes of extended forming limits is described.

First of all, the total force required for forming is

divided into the individual terms for buckling,

bending and friction, similar to (Siebel and

Beisswänger, 1955) and (Pankin, 1961). The

necessary spatial resolution distinguishes between

flange and die radius. In both areas buckling,

bending and friction processes take place. The last

step is a time distinction for the discontinuous

processes like cushion pulsation or cushion-ram-

pulsation. A phase with low surface pressure and a

phase with high surface pressure exist there.

With the three force components for buckling,

bending and friction in the two areas of die radius

and flange for the three methods and an additional

phase I and II for cushion pulsation and cushion-ram

pulsation respectively, there are 30 individual force

components, which are summarized in table 1.

In order to determine the individual force

components, experimental and numerical tests are

planned. In this way, a better calibration of the

finite-element calculations and a fundamental evalu-

ation possibility of deep drawing with superimposed

low-frequency vibrations should be realized.

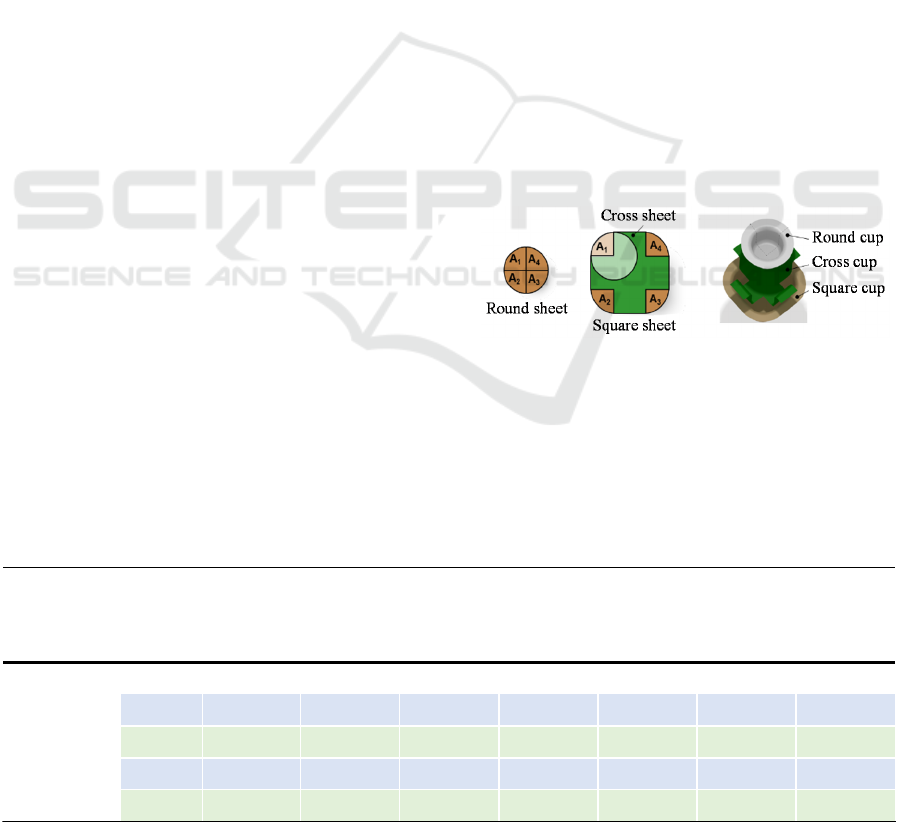

For the investigation a modular part series

illustrated in figure 3 is used. The round sheet is

virtually divided into four parts A1 to A4.

Subsequently, straight stripes are inserted, resulting

in a square sheet with round corners of a defined

radius. The inserted stripes form a cross sheet. Due

to the decomposition of the square cup, the influence

of buckling in the corner regions of the square sheet

is eliminated, thus only bending and friction forces

act. When the round cup is drawn, all three force

components take place. Together with the cross cup,

the total forming force for the square cup is

obtained. In this configuration it is possible to

examine individual force components in isolation

from each other.

Figure 3: Composition of modular part series.

To ensure that the part geometries complement

each other in a completely modular way, the

remaining geometry elements are not changed. In

addition it is necessary to observe preferably

constant and comparable boundary conditions. This

Table 1: Individual force components for deep drawing (DD), cushion pulsation (CP) and cushion-ram pulsation (CRP).

Technology Total force Kind of force

Buckling Bending Friction

Die radius Flange Die radius Flange Die radius Flange

DD F F

Bu-D

F

Bu-F

F

Be-D

F

Be-F

F

F-D

F

F-F

CP phase I F

CPI

F

CPI-Bu-D

F

CPI-Bu-F

F

CPI-Be-D

F

CPI-Be-F

F

CPI-F-D

F

CPI-F-F

phase II

F

CPII

F

CPII-Bu-D

F

CPII-Bu-F

F

CPII-Be-D

F

CPII-Be-F

F

CPII-F-D

F

CPII-F-F

CRP phase I F

CRPI

F

CRPI-Bu-D

F

CRPI-Bu-F

F

CRPI-Be-D

F

CRPI-Be-F

F

CRPI-F-D

F

CRPI-F-F

phase II F

CRPII

F

CRPII-Bu-D

F

CRPII-Bu-F

F

CRPII-Be-D

F

CRPII-Be-F

F

CRPII-F-D

F

CRPII-F-F

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

624

means that for cushion pulsation and cushion-ram-

pulsation, suitable averages must be used as

reference values for the vibration-superimposed

process variables. Furthermore the demountability of

the square cup must be demonstrated for deep-

drawing processes with extended process kinematics

on basis of the experimentally measured force

components.

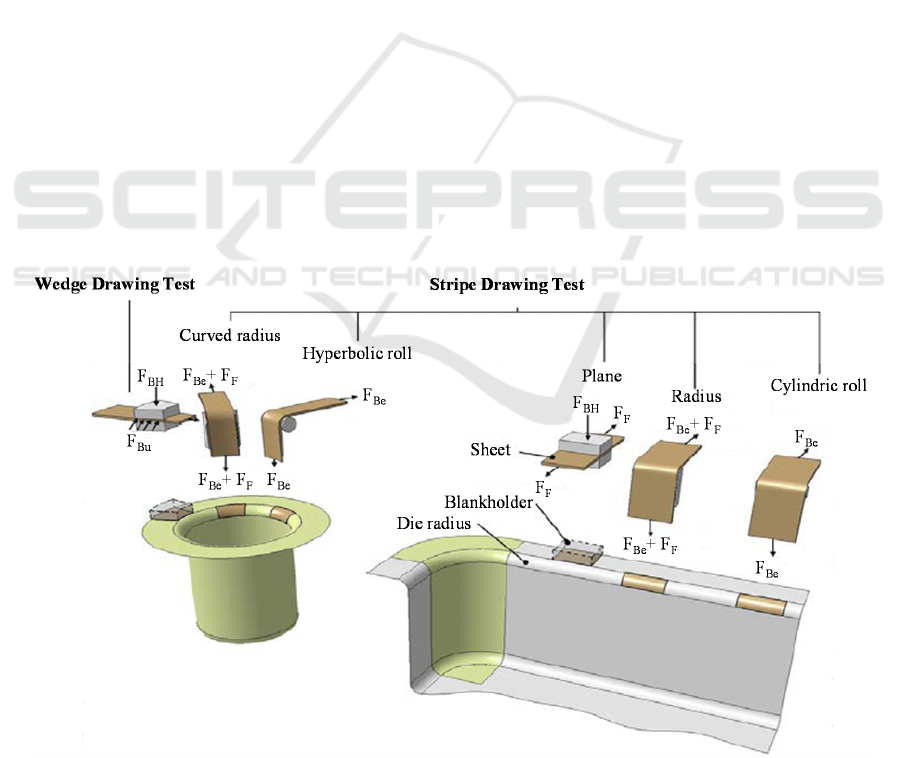

A more detailed differentiation requires addition-

al model tests, which emulate forming conditions.

Further individual force components are determined

in stripe drawing tests corresponding to (Netsch,

1994) and wedge drawing tests, which are also used

for the measurement of friction coefficients. These

model tests are illustrated in figure 4.

The friction force in the die radius is different

from those in the flange, due to different surface

pressures. Therefore the influence of friction for the

two areas is examined separately. Friction forces in

the flange are measured with the stripe drawing test

in the plane. The friction coefficient is used in the

forming simulation with finite-elements for a

corresponding material combination and normal

force. The bending forces occurring in the die radius

are determined in tests with a moveable cylindric

deflection roll. Subsequently the friction forces in

the die radius can be calculated from tests with a

fixed radius. Buckling forces can only be isolated

experimentally in the flange area, since bending also

takes place in the die radius and a metrological

resolution of the force components is not possible.

The force component in the flange may be

investigated using the wedge tensile test. In order to

recreate the conditions of the cylindrical cup the

stripe drawing tests are built with appropriately

shaped deflection roller and die radius.

However, influences from the surrounding

material areas cannot be taken into account in these

experimental model tests. Frictional losses on the

wedge surfaces also influence the result. In order to

quantify these effects, simulation models for the

stripe drawing tests with idealized boundary condi-

tions are created and validated. Force components,

which cannot be measured in experiments, must be

numerically calculated and evaluated.

4 EXPERIMENT AND

SIMULATION

In this section, first experimental and simulative

results from the conducted stripe drawing test are

presented. The experimental determination of single

force components requires the design of special test

setups. The experimental assembly for stripe and

wedge drawing tests as well as the constructed

fixture with the plane tool are illustrated in figure 5.

Figure 4: Stripe and wedge drawing tests for the determination of individual force components: left modified model tests for

the round cup, right stripe drawing tests for the square cup (Netsch, 1994).

Root Cause Analysis of Deep Drawing Processes with Superimposed Low-Frequency Vibrations on Servo-Screw Presses - A Practical

Research on Predictability in Simulation

625

Figure 5: Experimental assembly for stripe and wedge drawing tests.

Figure 6: Simulation results from stripe drawing tests with movable and fixed deflection roller.

This setup consists of two servo-hydraulic axes.

The system enables the simultaneous and highly

dynamic control of several axes. The horizontally

arranged axis is used for the position controlled feed

while the vertically arranged axis creates the normal

forces. Force and distance measurement takes place

directly on the axes. The tool sets for different

model tests are flexible interchangeable and all tests

can be carried out in the experimental assembly. In

addition, the developed system can be used to

superimpose vibrations like in cushion pulsation and

cushion-ram-pulsation. An interrupted feed with

variable motion paths is possible, besides constant

and pulsating force transmission. Furthermore a

transition from low to high surface pressure as well

as a change between sliding and static friction when

stopping can be generated. During wedge drawing

tests the friction losses are kept as low as possible by

appropriate design and technological measures on

the wedge surfaces. This is realized by freely

rotating wheels. Here, buckling forces at the wedge

surfaces and the friction force at the blankholder are

measured.

Simulation models for the method of single force

components are set up in the first step additionally to

the experimental investigations. The models

describe the stripe drawing tests and the wedge

drawing test with finite elements. The main goal of

the simulation is to achieve a good replication of the

real experiments. Simulation results from stripe

drawing tests with movable and fixed deflection

roller for the determination of the friction and

bending forces in the radius are illustrated in

figure 6. Due to the influence of friction, the

drawing force with fixed deflection roller is higher.

A comparison between averaged values of measured

and simulated force components in preliminary

investigations of stripe drawing tests with fixed and

moveable deflection roller show good agreement

(table 2). From this it can be concluded, that the

used simulation models are suitable for recreating

experimental model tests.

Table 2: Comparison between averaged values of

measured and simulated force components for stripe

drawing tests with fixed and moveable deflection roller.

Simulation

results

Measurement

results

Deviation Δ [%]

F

Be

= 334 N F

Be

= 370 N Δ

Be

= 9.73

F

Be

+F

F

= 724 N F

Be

+F

F

= 753 N Δ

Be+F

= 3.85

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

626

5 CONCLUSIONS

In this paper, current research results in evaluation

of simulation strategies for deep drawing processes

with superimposed low-frequency vibrations on

servo-screw presses are presented. A method for the

determination and assessment of single force

components was developed to enable a comparison

between conventional deep drawing, cushion

pulsation and cushion-ram pulsation. In addition

special test setups required for experimental

investigations as well as corresponding simulation

models were designed. A good agreement of the

results has been achieved in preliminary

investigations. The simulation models can be used to

determine further components of total deep drawing

force.

The core idea of the research project is the

evaluation and improvement of simulation strategies

for deep drawing technologies with variable motion

paths on servo-screw presses. For this reason, in the

next step, the single force components of cushion

pulsation and cushion ram pulsation have to be

investigated in experimental and numerical tests.

Subsequently experimentally determined parameters

are numerically evaluated. Then they can be used as

a boundary condition in the process simulation.

Furthermore, process parameters with low impact

have to be identified and eliminated in a sensitivity

analysis. The individual sensitivities are determined

using a DoE (Design of Experiments) method

known from statistical experimental design. The

sensitivity analysis yields a meta-model that

characterizes the relationship between the input and

output variables. This will result in an efficient

simulation model, which is quantitatively secured. In

future investigations, the individual force

components, which were not accessible in a direct

force measurement experiment or falsified by

experimental constraints, will be determined from

the validated models.

ACKNOWLEDGEMENTS

The presented results of this paper are part of a

public research project. The project (SCHL 2048/3-1

LA 3752/1-1) is financed by the research association

“Deutsche Forschungsgemeinschaft” (DFG). The

financial support is gratefully acknowledged by the

authors.

REFERENCES

Denkena, B., Hollmann, F. (2013). Process Machine

Interactions. Springer Verlag, Berlin, pp. 383-401.

Doege, E. (2000). Schwingende Niederhalterkraft

verbessert die Tiefziehergebnisse. MM -

Maschinenmarkt, 106(37), pp. 28-30

Drossel, W.-G., Müller, P., Großmann, K., Schenke, C.

(2013). Modellierung von Prozessen auf Servo-

Pressen. EFB-Report 367, Hannover.

Fiat AUTO S.p.a. Pr. (1994). Process and hydraulic press

for the pressing of sheets. EP0613740B1.

Großmann, K., Neugebauer, R. (2010).

Simulationsunterstützung für das Tiefziehen auf

Servospindelpressen. In: 30. EFB-Kolloquium:

Blechverarbeitung, Bad Boll.

Kitayama, S., Natsume, S., Yamazaki, K., Han, J., Uchida,

H. (2016). Numerical investigation and optimization

of pulsating and variable blank holder force for

identification of formability window for deep drawing

of cylindrical cup. International Journal of Advanced

Manufacturing Technology, 82(1-4), pp. 583–593

Klose, L., Bräunlich, H. (2000). Erweiterung

umformtechnischer Grenzen durch vibrations-

überlagerten Tiefziehprozess. Forschung für die

Praxis, 383, pp. 1-64.

Kriechenbauer, S., Mauermann, R., Müller, P. (2014).

Deep drawing with superimposed low-frequency

vibrations on servo-screw presses. In: Procedia

Engineering, 81, pp. 905-913.

Mauermann, R. (2010). Synchroziehen eine

Tiefziehvariante. UTFscience, 2, pp. 1-5.

Netsch, T. (1994). Methoden zur Ermittlung von

Reibmodellen für die Blechumformung. PhD thesis,

Technische Universität Darmstadt.

Neugebauer, R., Drossel, W.-G., Kriechenbauer, S.

(2012). Erweiterung der Umformgrenzen mit Direkt-

Servo-Spindelpressen. EFB-Report 354, Hannover.

Nezami, S., Akbari, A., Ahangar, S. (2017). Parametric

investigation of pulsating blank holder’s effect in deep

drawing process of rectangular Al 1050 Cup. Journal

of the Brazilian Society of Mechanical Sciences and

Engineering, 39(10), pp. 4081-4090

Pankin, W. (1961). Die Grundlagen des Tiefziehens im

Anschlag unter besonderer Berücksichtigung der

Tiefziehprüfung. Bänder Blech Rohre, 4, pp. 133-143.

Roll, K. (2012). Sheet metal forming simulation for

automotive applications. In: Deutsch-französische

Sommerschule: Verfestigung und Schädigung von

Metallwerkstoffen unter großen Dehnungen –

Konstitutive Modellierung und numerische

Implementierung, Dortmund.

Siebel, E., Beisswänger, H. (1955). Tiefziehen. Hanser

Verlag, München.

Siegert, K., Ulmer, J. (2001). Influencing the Friction in

Metal Forming Processes by Superimposing

Ultrasonic Waves. In: CIRP Annals - Manufacturing

Technology, 50(1), pp. 195-200.

Root Cause Analysis of Deep Drawing Processes with Superimposed Low-Frequency Vibrations on Servo-Screw Presses - A Practical

Research on Predictability in Simulation

627