A Cyclical Model for Waste Products Inventory-Routing

at Power Stations

Yiqing Zhong, Guopeng Yao, Yangyang Sun, Yang Li and Xian Zhou

State Key Laboratory of Coal-Based Clean Energy, Huaneng Clean Energy Research Institute, Beijing, China

{Zhongyiqing, Yaoguopeng, Sunyangyang, Liyang, Zhouxian}@hnceri.com

Keywords: Inventory-routing, Mixed-integer program, Optimization, Waste Product.

Abstract: The inventory routing problem (IRP) is one of the challenging optimization problems in supply chain

management (SCM). Inventory Routing Problems currently get a lot of attention, in which a typical property

is that inventory control and vehicle routing tasks are taken into account simultaneously. The objective of the

IRP is to jointly determine optimal quantities of the product to be delivered to the customers, delivery times

and optimal vehicle routes for the shipment of these quantities. At power enterprises, SCM strategies are

more and more interesting for the resource optimization. In this paper, a cyclical inventory routing problem is

modeled and accounted for one distribution system of waste products at the power stations. This proposed

problem is formulated as a linear mixed-integer program, in which the demand rates of customers are

assumed to be constant. As to the resource optimization, a practical instance is presented and thoroughly

discussed, to illustrate the behavior of the proposed model.

1 INTRODUCTION

Waste Products at power stations, e.g. coal fly ash,

plaster etc., are comprehensively utilized in building

industry. However a challenging problem when ones

intend to deliver and store such waste products, e.g.

coal fly ash, due to the fact that it is dispersive

mixed-solid and is scattered very easily,. As a result,

special vehicles (i.e. tank trucks) have to be

employed for its delivery, and high costs arise.

In this paper, a cyclical multi-period inventory

routing problem (IRP) is discussed, in which the

delivery and storage of coal fly ash can be

represented. Inventory routing problems involve the

integration of inventory management and vehicle

routing optimization. The typical main objective in

such problems is to determine an optimal

distribution policy, consisting of a set of vehicle

routes and delivery quantities that minimize the total

inventory holding and transportation costs. The IRP

arises in distribution systems implementing a

'Vendor Managed Inventory' (VMI) policy.

Compared with the traditional non-integrated

inventory replenishment and vehicle scheduling, in

which customers manage their inventories

themselves and call in their orders, overall inventory

and routing performances throughout the supply

chain are by far superior when VMI is implemented.

Nowdays, the IRP has been one of the most

challenging and interesting optimization problems in

supply chain and logistics management.

2 A BRIEF LITERATURE

REVIEW

Since Bell et al. (1983) first investigated the

integrated inventory management and vehicle

scheduling, various versions of the inventory routing

problems have been extensively studied. A large

variety of solution approaches have also been

proposed for the solution of these problems.

Inventory routing problems can be modeled and

approached in different ways depending on the

characteristics of its parameters. Different models

can be obtained for example, when customers

consume the product at a stable or at a variable rate;

when the planning horizon is finite or infinite, and

so on. Dror and Ball (1987) decompose a multi-

period IRP into series of single period problem.

They study the problem with constant demands and

then propose and compare two solution approaches

for the resulting single period problem. Campbell et

al. (2002) and Campbell and Savelsbergh (2004)

also worked on the multi-period IRPs where the

decisions are executed over a finite horizon. For

recent research devoted to the multi-period IRPs, we

refer to e.g. Yu et al. (2008), Taarit et al. (2010), etc.

46

Zhong, Y., Yao, G., Sun, Y., Li, Y. and Zhou, X.

A Cyclical Model for Waste Products Inventory-Routing at Power Stations.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 46-50

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Other fundamental contributions in the class of

infinite inventory routing problems are for example

Anily and Federgruen (1990) and Hall (1992).

Aghezzaf et al. (2006) address a special case of

infinite inventory routing problems, namely, the

cyclic inventory routing problem (CIRP), in which a

single distribution center, supplying a single

product, serves a set of customers, each being visited

by an assigned vehicle in a cyclical manner and in

such a way that at no moment a stock-out should

occur at any of the customers. Later this cyclic

problem and its variants are further discussed in e.g.

Raa and Aghezzaf (2009) and Zhong and Aghezzaf

(2011).

The strategy presented in inventory routing

problems allows to reduce costs if a supplier or a

third-party logistics server regards the delivery and

storage of coal fly ash as a model of the IRP, due to

the fact that the supplier or the logistics provider

may coordinate both inventory control and

transportation policy. More specially, a multi-period

inventory routing problem (MP-IRP) is concerned

with a distribution system using a fleet of

homogeneous vehicles to distribute the product from

a single depot to a set of customers having stable

demands. The considered distribution policies are

executed over a given finite horizon, for example on

a set T of consecutive periods (or days). The

objective is to determine the quantities to be

delivered to the customers, the delivery time, and to

design the vehicle delivery routes, so that the total

distribution and inventory costs are minimized. The

resulting distribution plan must prevent stockouts

from occurring at all customers during the planning

horizon. A mixed-integer model is built up for this

MP-IRP, in which the distribution pattern of 'multi-

tour' is employed, i.e. a vehicle can make a set of

different tours when it is used (see e.g. Aghezzaf et

al. 2006, Zhong and Aghezzaf (2011). In addition,

the presented model considers the vehicle fleet size

as part of the optimization problem and has to be

determined. Also, the initial inventory levels at the

customers have to be determined in this model,

instead of predefined amounts as done in other

similar works (see for example Taarit et al. 2010 and

references therein).

The remainder of this paper is organized as

follows. In Section 3, a linear mixed-integer

formulation for the MP-IRP is presented. In Section

4, a practical case is studied to illustrate the behavior

of the presented model. Finally, some concluding

remarks are provided in Section 5.

3 PROBLEM FORMULATION

To be more precise, the discussed multi-period IRP

consists of a single distribution center r using a fleet

of homogeneous trucks to distribute a single product

to a set of geographically dispersed customers S over

a given planning horizon. It is assumed that

customer-demand rates and travel times are stable

over time. Thus, the objective of this MP-IRP is to

determine the quantities to be delivered to the

customers, the delivery time, and to design the

vehicle delivery routes, so that the total distribution

and inventory costs is minimized while preventing

stockouts from occurring at all customers during the

whole planning horizon.

To build up this mixed-integer model for the

MP-IRP, some main assumptions are made below:

1) The time necessary for loading and unloading

a truck is neglected in the model;

2) Inventory capacities at the depot are assumed

to be large enough so that the corresponding

capacity constraints can be omitted in the model;

3) Transportation costs are assumed to be

proportional to travel times;

4) Split delivery is not allowed, such that a

customer is always replenished by one vehicle, in

the same tour in each period of the planning horizon.

A more formal description and a proposed linear

mixed-integer formulation of the MP-IRP are given

in the following paragraphs:

Let H={1,2,...,T} be the planning horizon set of

consecutive periods indexed by t. Let

be the size

in time unit of one period,, for example 8 working

hours. Let S be the set of customers indexed by i and

j and S

+

= S U {0} where 0 represents the depot. A

homogeneous fleet of trucks V is used to serve these

customers. The other necessary parameters of the

model are given below:

v

: the fixed operating cost of truck

Vv

(in

RMB per truck);

v

: the capacity of truck

Vv

(in ton);

jt

: the holding cost of per unit per period of

product at customer

Sj

(in RMB per ton per

period);

0j

: the initial holding cost of per unit of

product at customer

Sj

(in RMB per ton);

jt

D

: the demand at customer

Sj

in period

Ht

(in ton), i.e.

jtjt

dD

for

Ht

, where

A Cyclical Model for Waste Products Inventory-Routing at Power Stations

47

jt

d

represents the demand rate at customer j (in ton

per hour);

: travel cost of truck (in RMB per km per

hour);

: truck speed (in km per hour);

ij

tr

: duration of a trip from customer

Si

to

customer

Sj

(in hour);

j

C

: the inventory capacity at customer j (in ton).

The variables of the model are defined as

follows:

jt

I

: the inventory level of customer

Sj

at

the end of period

Ht

(in ton);

0j

I

: the initial inventory level of customer

Sj

(in ton);

v

ijt

Q

: the quantity of product remaining in truck

Vv

when it travels directly to the customer

Sj

from customer

Si

in period

Ht

.

This quantity equals zero when the trip (i, j) is not

on any tour made by truck

Vv

in period t (in

ton);

jt

q

: the quantity that is delivered to customer

Sj

in period

Ht

, and 0 otherwise (in ton);

v

ijt

x

: a binary variable sets to 1 if customer

Sj

is visited immediately after customer

Si

by truck

Vv

in period

Ht

, and 0

otherwise;

v

y : a binary variable sets to 1 if truck

Vv

is

being used, and 0 otherwise;

Thus, the linear mixed-integer formulation for

the multi-period IRP is presented as follows:

)1(

00

TtSjSj

jjjtjt

VvVvTt

SiSj

v

ijtijvv

II

xtryCV

Subject to:

)2(,1 TtSjx

Vv

Si

v

ijt

)3(,,0 VvTtSjxx

SiSk

v

jkt

v

ijt

)4(

1101

SjDqII

jjjj

)5(2,,

1,

tTtSjDqII

jtjttjjt

)6(, TtSjqQQ

Vv

Si

Vv

Sk

jt

v

jkt

v

ijt

)7(,,, VvTtSjixQ

v

ijt

vv

ijt

)8(, VvTtxtr

v

ijt

SiSj

ij

)9(,,

0

SjTtTtII

jtj

)10(,, VvTtSjyx

Si

vv

ijt

)11(,,,

0,0,,0},1,0{,

0

VvTtSji

qQCIIyx

jt

v

ijtjjtj

vv

ijt

Three cost components are taken into account in

the model: the total fixed operating cost of using the

truck(s); the total transportation cost; the total

inventory holding cost, including the initial

inventory holding cost and the inventory holding

cost at every end of period

Ht

. For the

restrictions, constraints (2) guarantee that each

customer is visited by each truck at most once in

period t. Constraints (3) are the usual flow

conservation constraints assuring that if a truck

arrives at a customer, it must leave after it served

this customer to a next customer or to the depot.

Constraints (4), (5) are the inventory balance

constraints of each customer. Constraints (6) are the

delivered load balance constraints. These constraints

eliminate possible formation of sub-tours.

Constraints (7) ensure that the quantity carried by a

vehicle should not exceed the truck's maximum

capacity. Constraints (8) indicate that the total travel

time of a vehicle should not exceed the considered

horizon length in each period. Constraints (9)

indicate that the initial inventory level at customer j

at the end of period T shall cover its initial inventory.

Constraints (10) indicate that at every period, a

vehicle cannot be used to serve any customer unless

this vehicle is already selected. Constraints (11) are

the integrality and sign constraints to be imposed on

the variables, in which the capacity constraints at all

customers are taken into account.

4 CASE STUDY

To gain a better understanding of the MP-IRP's

model, this section provides a small practice

example to illustrate different behaviors of the MP-

IRP's model, in which variable initial inventories are

taken into account. This example corresponds to a

third-party logistics company delivers the coal fly

ash from one power station to a set of 7 customers,

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

48

including 5 cement plants and 2 brickyards. To be

more precise, let us consider this small instance for

the MP-IRP, consisting of 7 customers indexed by

{1, 2

,

..., 7}, and a single depot (i.e. the power plant)

indexed by 0. These 7 clients are distributed

uniformly over a square of 100 by 100 km. A fleet

of homogeneous trucks with capacity 35 ton is

available for the distribution of the product. The

fixed using cost of the truck

is 800RMB per day.

The truck's average speed

is 50 km per hour, and

the travel cost

is 8RMB per km. In this case the

planning horizon set contains 3 consecutive periods

(i.e. 3 days), and the size of one period

is assumed

to be 8 hours. Demands of these clients and the

inventory holding costs for each client are shown in

Table 1 below.

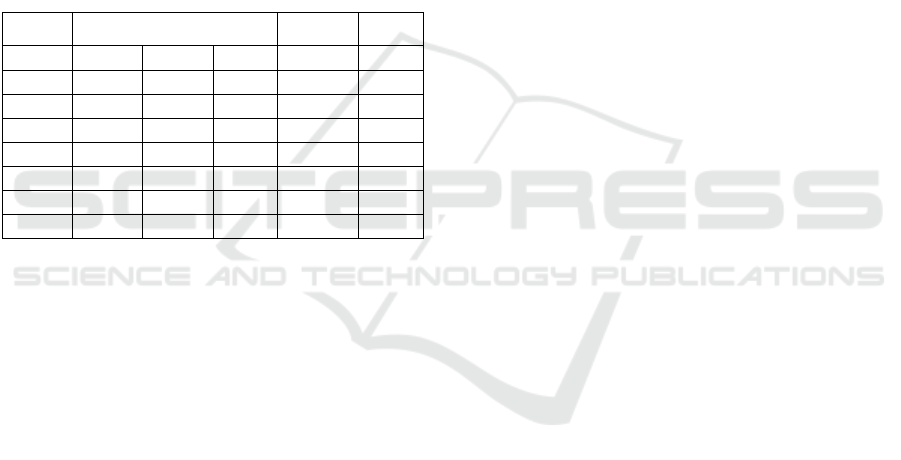

Table 1 Parameters for a case of 7-clients

D

jt

(t)

j

(R/t)

d

j

(t/h)

Client t=1 t=2 t=3

1 8.07 9.27 9.57 0.32 2.99

2 3.93 4.53 3.33 1.28 1.31

3 7.05 7.65 8.70 1.18 2.60

4 6.54 5.28 5.91 1.17 1.97

5 5.61 5.85 6.09 0.41 1.95

6 6.27 5.97 6.57 0.70 2.09

7 9.42 8.28 9.06 0.86 2.94

By solving the instance, the optimal solution

shows that a fleet of 2 trucks is required to replenish

the customers. The delivery routes in each period are

shown below, with the total cost around 9195RMB

(for 3 days).

A. t=1: Vehicle 1 :={(3), (7)}; Vehicle 2:={(2, 4,

5)}.

B. t=2: Vehicle 1 :={(4, 6)};Vehicle 2:={(1)}.

C. t=3: no delivery occurs.

Due to the fact that variable initial inventory

arises in the model, it is allowed the solver to find a

best three-way tradeoff for each customer, among

the initial inventory, the inventory at the end of

every period and the quantity to be delivered to

each, such that the total distribution and inventory

costs can be reduced as much as possible. According

to the financial statistics of the company, without the

logistics optimization presented above, the average

running cost is around $5000$RMB per day in this

case, where the operation manner corresponds to

that the company receives the orders given by the

customers, the trucks are sent and the deliveries

occur then. As a result, one can observe that the MP-

IRP model for this coal fly ash distribution system

might achieve a cost saving around 38.7% when this

optimization model is used.

5 CONCLUSION

This paper provides a specific multi-period

inventory routing problem (MP-IRP) that might be

addressed for the distribution of coal fly ash. In

general, it consists in a single depot distributing a

single product to a set of customers having

stationary demands, using a fleet of homogeneous

vehicles over a given finite horizon. The objective is

to determine the quantities to be delivered to the

customers, the delivery time, and to design the

vehicle delivery routes, so that the total distribution

and inventory costs are minimized. The presented

MP-IRP is formulated as a linear mixed-integer

program with some side constraints. A practical case

is studied to illustrate the behaviors of the MP-IRP

and the merits of such a model. The extensions to

this problem, if for example, the variants by taking

stochastic inventory into account or some efficient

meta-heuristics for the model, are worthy being

investigated further.

ACKNOWLEDGEMENTS

This paper is supported by the Foundation for

Science and Technology of China Huaneng Group

(HNKJ16-H02).

REFERENCES

Bell, W. J., Dalberto, L.M., et al., 1983.Improving the

distribution of industrial gases with an on-line

computerized routing and scheduling optimizer.

Interfaces, Vol.13, No.6, pp. 4-23.

Dror M. and Ball M., 1987. Inventory-routing: Reduction

from an Annual toa Short Period Problem. Naval

Research Logistics Quarterly, 34, pp.891-905.

Campbell, A.M., et al., 2002. Inventory Routing in

Practice. Society for Industrial and Applied

Mathematics, Philadelphia, pp. 309-330.

Campbell A.M. and Savelsbergh M., 2004. A

decomposition approach for the inventory routing

problem. Transportation Science, Vol.38, No.4,

pp.488-502.

Yu Y., Chen H.X et al., 2008. A new model and hybrid

approach for large scale inventory routing problem.

European Journal of Operational Research, 189, pp.

1022-1040.

A Cyclical Model for Waste Products Inventory-Routing at Power Stations

49

Taarit N.B, et al., 2010. A lagangian heuristic method and

an iterative approach for the inventory routing

problem. MOSIM’10, Hammamet, Tunisia.

Anily S. and Federgruen A., 1990. One-warehouse

Multiple Retailer Systems with Vehicle Routing Costs.

Management Science, 36, pp. 92-114.

Hall R.W., 1992. A Note on Bounds for Direct Shipping

Costs. Management Science, 38, pp. 1212-1214.

Aghezzaf E.H., et al., 2006. Modeling Inventory Routing

Problem in Supply Chain of High Consumption

Products. European Journal of Operation Research,

169, pp. 1048-1063.

Raa B. and Aghezzaf E.H., 2009. A Practical Solution

Approach for the Cyclic Inventory Routing Problem.

European Journal of Operational Research, Vol. 192,

No.2, pp.429-441.

Zhong Y.Q. and Aghezzaf E.H., 2011. Combining DC-

programming and Steepest-Descent to Solve the

Single-Vehicle Inventory Routing Problem. Computer

& Industrial Engineering, Vol.61, No.2, pp. 313-321.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

50