Dynamics of Lateral Liquid Sloshing in Flat Cylinder Tanks

Zehong Wei

1

and Xuelian Zheng

2

1

School of automobile, Guangdong mechanical and electrical polytechnic, Guangzhou, China

2

School of Transportation, Jilin University, Changchun, China

weizehong@hust.edu.cn, zhengxuelian@jlu.edu.cn

Keywords: Liquid sloshing, cylinder tank, simulation, dynamics.

Abstract: As a complicated fluid-solid coupling multi-body system, the modelling of tankers are quite difficult. Many

efforts had been made to establish equivalent mechanical model to describe liquid sloshing in tanker to

simplify the modelling of tankers. The investigation on dynamics of liquid sloshing in tanks will be of great

significance and a necessary support. FLUENT software was used to simulate liquid sloshing in flat

cylinder tank under the situation of different lateral acceleration and liquid fill level, the center of mass

(CM) of liquid bulk was utilized to analyze the dynamics of liquid sloshing. It turned out that the trajectory

of liquid bulk’s CM could be described by a curve, not the whole liquid bulk participates in sloshing, and

there is a strong nonlinear characteristics in sloshing damping.

1 INTRODUCTION

Road tank vehicles are commonly used in carrying a

wide range of liquid cargoes, mainly of a dangerous

nature. At the same time, tankers also create severe

traffic safety problems, which would result in huge

people injury and property damage. Therefore, great

attention must be paid to tanker driving safety.

It was universally accepted that liquid sloshing in

partially-filled tanks is the most important factor

result in tanker traffic accidents (Hasheminejad et al,

2009). As a complicated fluid-solid coupling multi-

body system, it is quite hard to model tank vehicles,

not even to investigate tankers’ dynamic

characteristics (Rumold, 2001). On the assumption

of an equivalent mechanical model was established

to describe liquid sloshing in tanks, the modelling of

tanker and its dynamic analysis will be an easy work

(Salem, 2000; Zheng et al, 2012; Qing et al, 2011;

Utsumi, 2004). Hence, the purpose of this paper is to

investigate dynamics of liquid sloshing in flat

cylinder tank which are widely used in tankers. The

research result will be a support for the

establishment of equivalent mechanical model.

2 FLUENT SIMULATION FOR

LATERAL LIQUID SLOSHING IN

FLAT CYLINDER TANKS

The software of FLUENT was used to simulate

lateral liquid sloshing in flat cylinder tanks. By

FLUENT simulation, lateral sloshing force acting on

tank walls, liquid bulk’s transient CM, and sloshing

moment on specific point were recorded. Also,

sloshing animation was generated to judge

subjectively whether software simulation could

reproduce lateral liquid sloshing correctly or not.

2.1 Tank model

A flat cylinder tank model with a length of 1 m and

a radius of 0.86 m was used in this study. The radius

of this tank model was decided according to market

survey on cross-sectional area of tanks on tank

vehicles. It was showed that the value was about 2.5

m

2

. The length of this tank model was set given the

consideration of calculation simplicity of the mass of

liquid bulk.

Only lateral liquid sloshing was taken into

account in the flat cylinder tank, and liquid sloshing

in different cross sections were supposed to be the

same. Therefore, the three dimensional liquid

sloshing in cylinder tank could be substituted for

two dimensional sloshing in tank cross sections.

308

Wei, Z. and Zheng, X.

Dynamics of Lateral Liquid Sloshing in Flat Cylinder Tanks.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 308-313

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

A pressure inlet was set on the top of tank cross

section. The circular cross section model was

meshed with elements of quadrangle, and pave was

selected as the meshing type.

2.2 Sloshing condition

Liquid fill percentage was used to describe the

volume or the mass of liquid bulk in the tank. It was

defined as the ratio of the height of liquid free

surface to the diameter of the tank. Lateral liquid

sloshing under the condition of different liquid fill

levels was considered, and the liquid fill level was

set to be 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9,

respectively.

In practical situation, lateral acceleration of tank

vehicles is hardly to exceed 1.0 g. therefore, lateral

acceleration acts on tank was set to be 0.1 g, 0.2 g,

0.3 g, 0.4 g, 0.5 g, 0.6 g, 0.7 g, 0.8 g, 0.9 g and 1.0 g,

respectively.

The purpose of this study was to investigate

inherent dynamics of liquid sloshing and to establish

equivalent mechanical model. There hence, free

oscillation of liquid bulk should be simulated to

acquire sloshing parameters. To simulate free

oscillation of liquid bulk, liquid bulk’s CM should

be away from equilibrium position. Two different

methods to obtain the initial condition of free

oscillation were proposed. For the first one, forced

oscillation under the action of lateral acceleration

was carried out first. While the center of mass of

liquid bulk arrives at the highest point, the

simulation of forced oscillation was stopped. Then,

the ended moment in this forced oscillation case was

taken as the initial condition of free liquid sloshing.

For the second one, liquid free surface was set to be

tilted at the very beginning of free oscillation

simulation. Gradient of tilted liquid free surface was

obtained by

()

0

=atan

y

ag

θ

(1)

where a

y

is lateral acceleration acting on tanks.

While the second method to simulate liquid free

oscillation was much easier than the first one, it was

used to simulate liquid sloshing in this study.

2.3 Simulation settings

A 2D planer, transient simulation was used to

simulate liquid sloshing in flat cylinder tank.

Pressure-based was selected as the solver. Air and

water were multiphase flows in tank model, and air

was set to be the primary phase. The volume of

water, and intersection line between air and water

were defined by user defined function. Laminar was

used as the viscous model. Pressure inlet was set on

the top of circular cross section, and the pressure

inlet was also set to be reference pressure location.

Gravity was acted on the liquid bulk, who directs to

the negative y-axis. The scheme of PISO was used

as pressure-velocity coupling method. For other

parameters, they were accepted as software default

setting.

Sloshing force and moment were monitored

during simulation. Liquid bulk’s CM was calculated

and recorded by user defined function.

3 DATA FILTERING BY

WAVELET

Liquid bulk’s CM was used to investigate sloshing

dynamics in this study. Before dynamic analysis,

data filtering was carried out. Many filtering

methods were tried, it turned out that wavelet

filtering has the best performance. Therefore, liquid

bulk’s CM, including x-coordinate and y-coordinate,

was filtered by wavelet. Sym8 was chosen as the

wavelet function, and 8 layer decomposition was

done. Comparison of liquid bulk’s CM before and

after wavelet filtering was presented in Figure 1.

Also, oscillation angle of liquid bulk’s CM, which

was a function of x-coordinate and y-coordinate, was

also presented to illustrate data filtering result.

In Figure 1, oscillation angle was obtained by

()

=atan

x

y

θ

−

(2)

where x is the x-coordinate of liquid bulk’s CM, y is

the y-coordinate of liquid bulk’s CM.

Noise in raw data was with small amplitude and

did have regular frequencies. Reason that bring

irregular noise should be calculation accuracy error.

For this situation, wavelet filtering was a pleasure

select.

Compared with x-coordinate, y-coordinate has

noise with rather large amplitude. That is to say that

y-coordinate of liquid bulk’s CM has much violent

changes in sloshing, and the change trend along y-

axis has much lower possibility than that along x-

axis.

Oscillation angle obtained by filtered liquid

bulk’s CM is much smoother that that obtained by

raw data, which reveals the correctness of data

filtering.

Dynamics of Lateral Liquid Sloshing in Flat Cylinder Tanks

309

0 0.5 1 1.5 2 2.5 3 3.5 4

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

time,s

x-coordinate of CG,m

unfiltered

filtered

1.5 1.6 1.7 1.8 1.9 2

0.045

0.05

0.055

0.06

0.065

time,s

x-coordinate of CG,m

unfilte red

filtered

0 1 2 3 4

-0.658

-0.657

-0.656

-0.655

-0.654

-0.653

-0.652

-0.651

-0.65

-0.649

time,s

y-coordinate of CG,m

unfiltered

filtered

1.4 1.6 1.8 2 2.2

-0.657

-0.6565

-0.656

-0.6555

-0.655

-0.6545

time, s

y-coordinate of CG,m

unfilt ered

filtered

0 0.5 1 1.5 2 2.5 3 3.5

4

-0.1

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

time,s

oscillation angle,rad

unfiltered

filtered

1.5 1.6 1.7 1.8 1.9 2

0.065

0.07

0.075

0.08

0.085

0.09

0.095

time, s

oscillation angle,rad

unfiltered

filtered

Figure 1: Comparison of liquid bulk’s CM before and after

wavelet filtering.

4 DYNAMICS OF LATERAL

LIQUID SLOSHING

Dynamics of lateral liquid sloshing was investigated

by filtered liquid bulk’s CM. Its moving trajectory,

oscillation frequency and damping were researched

in this study.

4.1 Trajectory of the center of mass of

liquid bulk

Trajectory of the center of mass of liquid bulk under

different lateral accelerations, i.e. different tilted

liquid free surface, were presented in Figure 2 as

blue lines. Also, circle which has the radius that is

equal to the mean value of distances from liquid

bulk’s transient CM to the center of tank cross

section was also presented as pink line. The tank

was expressed by red line. The maximum oscillation

angle of liquid bulk’s CM, which was defined by the

tilt angle of liquid free surface at the very beginning,

was expressed by dotted red line.

For each tilted liquid free surface, liquid fill

percentage changes from 0.1 to 0.9. FP is short for

liquid fill percentage, and LA is short for lateral

acceleration in Figure 2.

-0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8

-0.8

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

x-coordinate,m

y-coordinate,m

FP0.1-LA0.7

FP0.2-LA0.7

FP0.3-LA0.7

FP0.4-LA0.7

FP0.5-LA0.7

FP0.6-LA0.7

FP0.7-LA0.7

FP0.8-LA0.7

FP0.9-LA0.7

(1) lateral acceleration is 0.7 g

-0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8

-0.8

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

x-coordinate

,

m

y-coordinate,m

FP0.1-LA1.0

FP0.2-LA1.0

FP0.3-LA1.0

FP0.4-LA1.0

FP0.5-LA1.0

FP0.6-LA1.0

FP0.7-LA1.0

FP0.8-LA1.0

FP0.9-LA1.0

(2) lateral acceleration is 1.0 g

Figure 2: Trajectory of liuqid bulk’s CM under different

lateral acceleration and fill percentage

It was quite clear that the trajectory of liquid

bulk’s CM coincides well with the specific circle. A

much more detailed investigation showed that R-

square between the two lines is 1.00 for most cases,

only case of FP=0.1, LA=1.0 g and FP=0.2, LA=1.0

g is 0.99. This result revealed that the trajectory of

liquid bulk’s CM could be described by a circle, and

radius of this circle is the mean value of distances

from liquid bulk’s transient CM to the center of tank

cross section.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

310

4.2 The part of liquid bulk participates

in sloshing

An interesting phenomenon was discovered from

curves of oscillation angle of liquid bulk’s CM

which can be obtained by equation (2), as shown in

Figure 3. It was quite clear that liquid sloshing is a

damped oscillation, whose amplitude decreases as

time goes on. Differences in amplitude between

peaks were smooth and small, however, the

difference between original oscillation angle and

amplitude of the first peak are quite large, and the

difference does not keep constant under different

simulation conditions. It seems like that after liquid

bulk sloshes under the action of gravity, its CM

drops greatly and it could not arrive at its original

position.

0 5 10 15 20

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

Time,s

Theta,rad

Figure 3: Curves for oscillation angle of liquid bulk’s CM

when LA=0.6,FP=0.9

A ratio was defined to describe the difference

between the original oscillation angle of liquid

bulk’s CM and amplitude of the first peak, which is

expressed by

10P

ra

θθ

=

(3)

where

1

P

θ

is amplitude of the first peak.

For all simulation conditions, ra was calculated

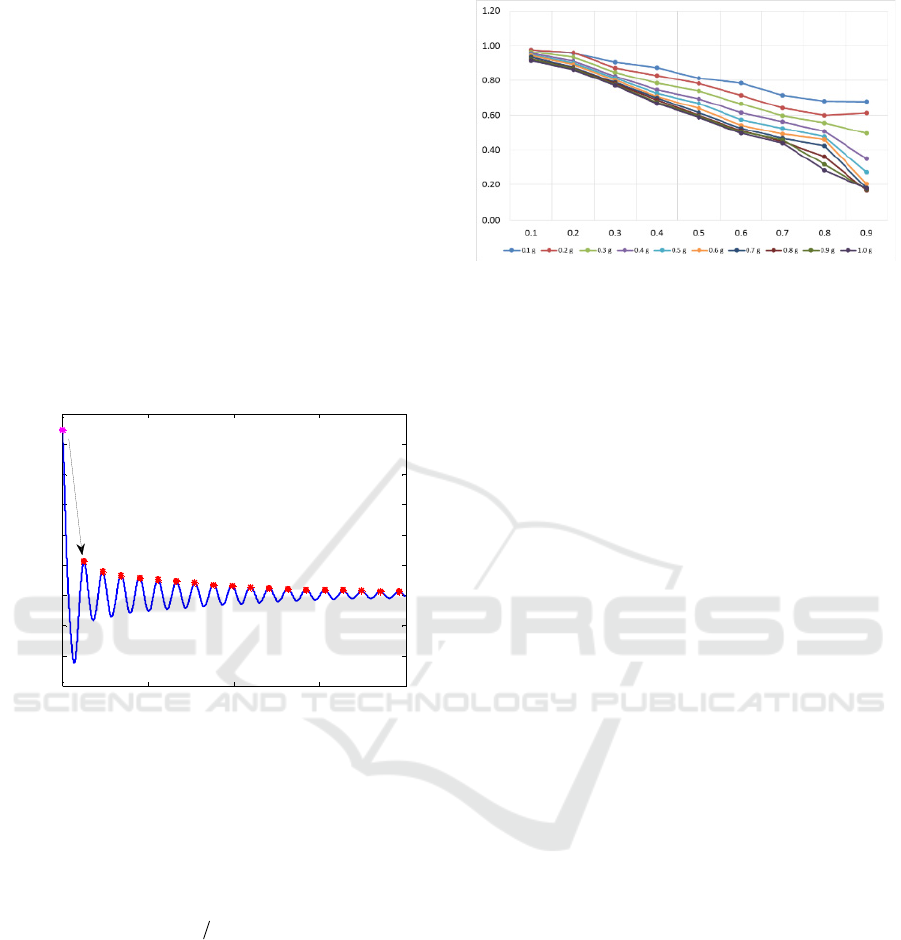

and presented in Figure 4. While lateral acceleration

keeps constant, ra decreases with the increasement

of liquid fill level. Besides, while liquid fill

percentage keeps constant, ra decreases with the

increasement of lateral acceleration. The ratio

changes from 0.98-0.17.

Figure 4: ra in different simulation conditions

The great drop from original oscillation angle

was supposed not be caused by damping, due to the

fact that damping coefficient obtained by the ratio is

too large. A possibility reason lead to this

phenomenon is the fact that not the whole liquid

bulk participates in sloshing. For simulation initial

condition, liquid bulk’s CM was set to away from

equilibrium position. Its coordinate was determined

by gradient of liquid free surface, tank shape, and

liquid fill level. As the simulation starts, liquid

bulk’s CM moves towards the equilibrium position,

and it will arrives at a highest position under the

action of inertial force. However, due to the fact that

not the whole liquid bulk participates in sloshing,

liquid bulk’s CM cannot arrives at its original

position, or even arrives at a position that is close to

its original position. After the first peak, liquid bulk

oscillates under the action of inertial force, and its

amplitude decreases gradually because of damping.

It was also drawn from Figure 4 that the part of

liquid that participates in sloshing decreases with the

increasement of lateral acceleration and liquid fill

level.

4.3 Liquid sloshing frequency and

damping

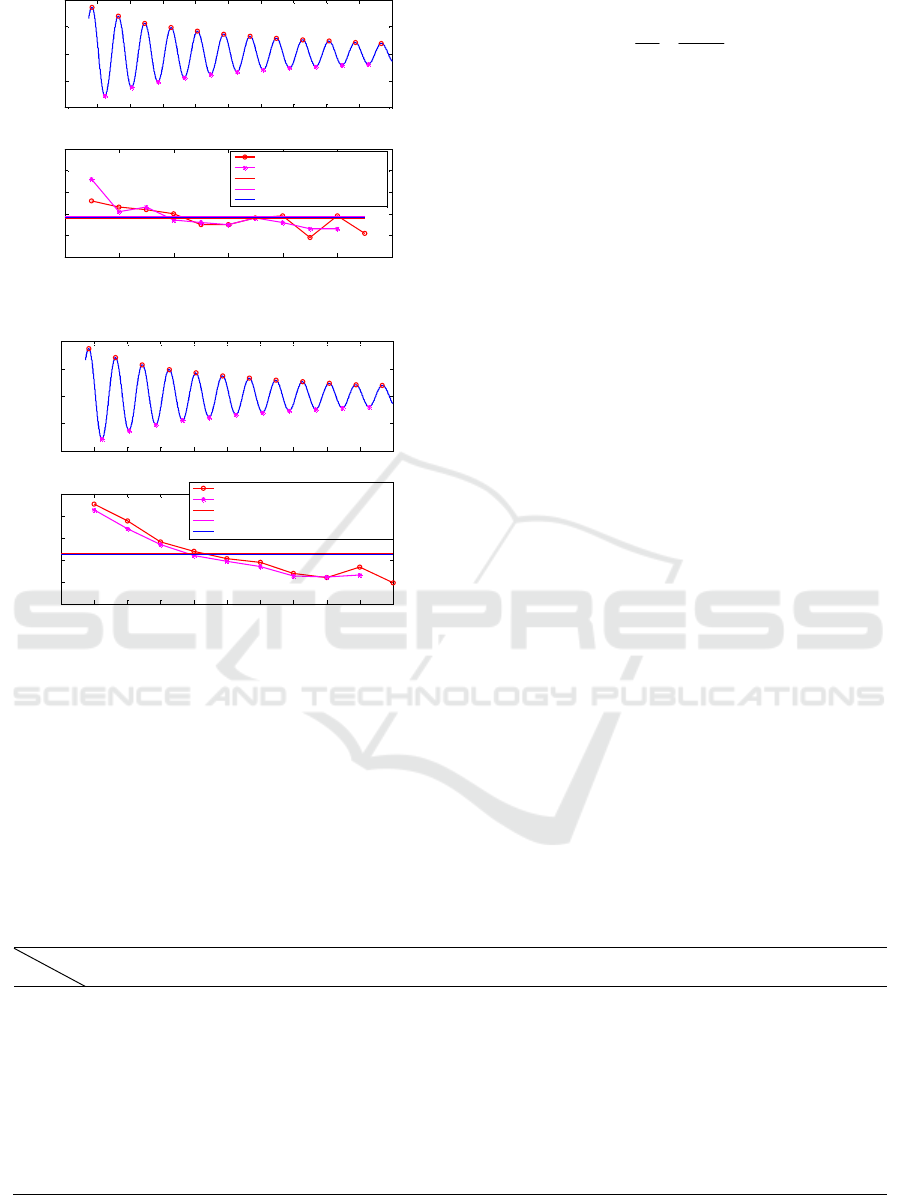

Sloshing frequency and damping were studied

according to curves of oscillation angle. As shown in

Figure 5 and Figure 6. Peaks and valleys of

oscillation angle were picked out, and oscillation

period can be obtained by time interval between

adjacent peaks or valleys. Periods obtained by peaks

and those obtained by valleys have little difference,

their mean values are almost the same.

Dynamics of Lateral Liquid Sloshing in Flat Cylinder Tanks

311

0 2 4 6 8 10 12 14 16 18 20

-0.4

-0.2

0

0.2

0.4

Time,s

Theta

0 2 4 6 8 10 12

1.59

1.6

1.61

1.62

1.63

1.64

Number

Time,s

period obtained by peaks

period obtained by valleys

average period obtained by peaks

average period obtained by valleys

average period

Figure 5: Sloshing frequency when FP=0.5, LA=0.6 g

0 2 4 6 8 10 12 14 16 18 20

-0.4

-0.2

0

0.2

0.4

Time,s

Theta

0 1 2 3 4 5 6 7 8 9 10

0.04

0.06

0.08

0.1

0.12

0.14

Number

Damping Coefficient

damping coefficient obtained by peaks

damping coefficient obtained by valleys

average damping coefficient obtained by peaks

average damping coefficient obtained by peaks

average damping coefficient

Figure 6: Sloshing damping when FP=0.5, LA=0.6 g

Besides, there is not an apparent changing trend

in period with time grows. Therefore, the mean

value of periods obtained by peaks and those

obtained by valleys is supposed to be sloshing

period. Based on that, sloshing frequency in

different simulation conditions were acquired, which

were listed in Table 1.

Damping coefficient can also be obtained by

adjacent peaks or valleys, which is expressed by

()

1

=ln

p

i

p

in

nT

θ

β

θ

+

(4)

where T is oscillation period,

p

i

θ

is amplitude of the

ith peak or valley,

()

p

in

θ

+

is amplitude of the (i+n)th

peak or valley. Damping coefficients obtained by

peaks or valleys have quite little difference.

However, damping coefficient drops with time flies,

which means that damping characteristics of lateral

liquid sloshing is nonlinear. Furthermore, the

changing trend of damping coefficient is quite

apparent, which cannot be ignored.

The mean value of damping coefficients obtained

by peaks and valleys were also calculated, which

were listed in Table 2.

5 CONCLUSIONS

Lateral liquid sloshing in flat cylinder tanks under

the situation of different lateral acceleration and

cargo fill percentage were simulated by FLUENT.

The center of mass of liquid bulk were used to

investigate dynamics of lateral liquid sloshing, it

was discovered that:

(1) The trajectory of liquid bulk’s CM could be

described by a curve.

(2) Not the whole liquid bulk participates in

sloshing.

(3) Sloshing frequency almost keeps constant,

but its damping coefficient drops gradually with

time goes on.

Based on the dynamics of liquid sloshing,

equivalent mechanical model can be established.

This will be the future work. Furthermore, dynamics

of lateral sloshing for other kinds of liquid should be

investigated to get much more universe conclusions.

Table 1: Frequency of lateral liquid sloshing

LA

FP

0.1g 0.2g 0.3g 0.4g 0.5g 0.6g 0.7g 0.8g 0.9g 1.0 g

0.1 1.8232 1.8247 1.8292 1.8341 1.8397 1.8459 1.8522 1.8581 1.8646 1.8685

0.2 1.7777 1.7825 1.7853 1.7885 1.7918 1.7962 1.8013 1.8087 1.8141 1.8192

0.3 1.7274 1.7322 1.7335 1.7364 1.7391 1.7418 1.7444 1.7471 1.7503 1.7530

0.4 1.6702 1.6725 1.6747 1.6758 1.6774 1.6789 1.6808 1.6823 1.6838 1.6856

0.5 1.5999 1.6038 1.6052 1.6051 1.6095 1.6083 1.6089 1.6095 1.6100 1.6114

0.6 1.5193 1.5200 1.5208 1.5223 1.5234 1.5256 1.5259 1.5255 1.5264 1.5270

0.7 1.4174 1.4190 1.4200 1.4238 1.4207 1.4212 1.4221 1.4227 1.4224 1.4205

0.8 1.2800 1.2823 1.2840 1.2824 1.2831 1.2840 1.2833 1.2836 1.2850 1.2836

0.9 1.0730 1.0768 1.0750 1.0781 1.0783 1.0802 1.0825 1.0821 1.0826 1.0830

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

312

Table 2: Damping of lateral liquid sloshing (10

-2

)

LA

FP

0.1g 0.2g 0.3g 0.4g 0.5g 0.6g 0.7g 0.8g 0.9g 1.0 g

0.1 0.69 0.80 0.95 1.14 1.35 1.54 1.71 1.85 1.99 2.10

0.2 0.56 1.62 2.03 2.34 2.83 3.06 3.33 3.43 3.55 3.65

0.3 1.79 3.51 3.65 4.55 5.01 5.31 5.54 5.80 6.21 5.98

0.4 2.25 4.30 5.63 6.01 6.79 7.02 7.47 7.52 7.94 8.29

0.5 2.73 5.26 7.12 7.17 9.53 8.45 8.82 8.98 8.63 9.05

0.6 4.28 8.02 9.35 10.70 11.31 11.57 11.82 11.30 11.24 11.34

0.7 5.39 9.81 11.43 12.10 11.95 11.93 12.69 13.24 13.05 12.47

0.8 5.74 10.26 11.70 11.92 11.79 13.01 12.81 13.11 13.58 12.75

0.9 4.81 9.73 10.69 11.32 12.16 12.04 12.46 13.06 12.96 11.58

REFERENCES

Hasheminejad, SM&Aghabeigi, M2009. Liquid

sloshing in half-full horizontal elliptical tanks.

Journal of Sound and Vibration, 324(1-2): 332-

349.

Qing, L& Xingrui, M 2011. Equivalent mechanical

model for liquid sloshing during draining. Acta

Astronautica, 68: 91-100.

Rumold, W2001. Modeling and simulation of

vehicle carrying liquid cargo. Multi-body System

Dynamics, 5(04): 351-374.

Salem MI 2000. Rollover stability of partially filled

heavy-duty elliptical tankers using trammel

pendulums to simulate fluid sloshing. PhD

thesis, West Virginia University, Department of

Mechanical and Aerospace Engineering.

Utsumi, M, 2004. A mechanical model for low-

gravity sloshing in an axisymmetric tank.

Transactions of the ASME, 71: 724-730.

Zheng XL & Li XS 2012. Equivalent mechanical

model for lateral liquid sloshing in partially-

filled tank vehicles. Mathematical Problems in

Engineering, ID: 162825.

Dynamics of Lateral Liquid Sloshing in Flat Cylinder Tanks

313