A Numerical Simulation of Smoke Extraction in the Tunnel Sidewall

Yu Li and Shijie Cai

School of Civil and Safety Engineering, Dalian Jiaotong University, Dalian, Liaoning, China, 116028

467797823@qq.com

Keywords: Fire, sidewall smoke-extraction, smoke-extraction rate, efficiency.

Abstract: The rectangular tunnel (450 m × 10 m × 5 m) and smoke vent (4.5 m × 4.5 m) located on the sidewall, with

its bottom flush with the ground, were simulated to analyze the law of smoke extraction in the tunnel sidewall.

Numerical simulations were conducted to analyze the law of smoke extraction in the tunnel sidewall at

different rates of smoke extraction. Based on the results, the output of the smoke extraction system decreases

with the increase in extraction rate. By contrast, the efficiency of the smoke extraction system increases with

the increase in smoke extraction rate.

1 INTRODUCTION

Timely and efficient extraction of smoke from the

tunnel is one of the crucial technologies in

emergency rescue during a fire (Jiang Xuepeng,

2014; Hu Longhua, 2005; Jiang Yaqiang,2010; Han

Jianyun, 2013; Jiang Yaqiang, 2009). Therefore,

analyzing the law of smoke extraction in tunnels is

significant.

In this regard, Li et al. (2013), Hu et al. (2008),

and Oka et al. (1995) investigated the relationship

between the distance of backlayering and the

longitudinal velocity of the wind, which is the

critical velocity of the wind for restraining the

countercurrent flow of smoke. Wu and Bakar (2000),

Vauquelin and Telle (2005), and Tanaka et al. (2015)

conducted macroscopic studies on the efficiency of

horizontal extraction, including the rate of extraction

at the smoke vent, the shape and location of the

smoke vent, the power of the fire source, and the

influence of the relative position of the smoke vent

and air inlet on the efficiency of smoke extraction.

During the construction of an extra-long tunnel, a

level gallery would be dug for every 400-500m in

the tunnel sidewall in order to facilitate

transportation, which leads to the outside of the

tunnel. When the tunnel is built, the gallerys’

openings are naturally used as smoke vents. So in

this study, we assume one smoke vent should be set

for every 450m in the tunnel sidewall.

2 NUMBERICAL SIMULATION

2.1 Design of The Model of The Tunnel

In this study, FDS 5.5.3 is employed (version,

published in 2012). A model of the fire can be

established, and movement of smoke, temperature,

and toxic concentration during the fire can be

predicted (Liang Ping, 2010).

In this study, the size of tunnel in the numerical

simulation is set as 450 m × 10 m × 5 m. Propane is

used as the fuel. The size of the fire source is 10 m

× 2.6 m × 1 m and located at the center 220 m from

the left side of the tunnel. The tunnel for mechanical

smoke extraction is 130 m from the right side of the

fire source, and is set at the internal sidewall of the

tunnel. After the fire started, the smoke vent was

closed and mechanical smoke extraction began after

60 s. A specific model is shown in Figure. 1.

Figure. 1 Simulation model of the tunnel (unit:m)

Li, Y. and Cai, S.

A Numerical Simulation of Smoke Extraction in the Tunnel Sidewall.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 329-333

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

329

2.2 Monitoring Equipment

Four thermocouples and two sites for thickness

monitoring are set at the left and right sides of the

fire source, with the distance of 50 m.

Thermocouples are set at locations 50 m from the

left and right sides of the fire source, with y equal to

6 m, and are equidistantly distributed along the

vertical direction, with the interval of 0.9 m. The

highest point is 1.4 m from the ceiling. Thickness

monitoring sites are set at locations where the values

of y are equal to 6 and 8 m, respectively. At the

smoke vent, a total of 60 thickness monitoring sites

are set, with the interval along the horizontal

direction being 1 m and the interval along the

vertical direction being 0.9 m. Forty thermocouples

and 40 monitoring equipment of gas flow rate are set

with equal distances in the vertical direction. The

interval is set as 0.9 m and the distance of the highest

point is 1.4 m from the ceiling to ensure that the

temperature and velocity of the upper smoke layer

and lower air layer can be perfectly detected. A

device for monitoring mass flow rate is placed at the

right side of the fire source to cover the entire smoke

vent. The cross-section at the leftmost side of the

tunnel is set to be fully open as the air inlet during

smoke extraction.The specific layout is shown in the

following figures.

Figure. 2 Schematic diagram of the layout of the

monitoring sites for the thickness of the smoke layer

Figure. 3 Schematic diagram of the layout of the

monitoring sites for air velocity

2.3 Conditions for Numerical Simulation

The conditions for numerical simulation are listed as

follows:The numbers of each condition are 1-10;the

power of each fire source is 15MW;each ambient

temperature is 20°C;each size of smoke vent is 4.5

m × 4.5 m;each computation time is set as 600s;

and the rates of smoke extraction are 0m3/s

(NO.1)、20m3/s(NO.2)、40m3/s(NO.3)、

60m3/s(NO.4)、80m3/s(NO.5)、100m3/s(NO.6)、

120m3/s(NO.7)、140m3/s(NO.8)、160m3/s

( NO.9 ) and 180m3/s( NO.10 ) .The smoke

extraction rate in the tunnel is regarded as a variable.

Under different rates of mechanical smoke

extraction, the variations of the shape, temperature,

and thickness of the smoke layer and the Froude

number (Fr) are investigated.

3 RESULTS AND DISCUSSION

3.1 Calculation of The Output and

Efficiency of The Smoke

Extraction System

Vauquelin (2002, 2008) defined two global

parameters used to describe the performance of the

horizontal smoke extraction system quantitatively.

One parameter is the ventilation system efficiency

(VSE). The other parameter is the ventilation system

output (VSO). The expressions of these two

parameters are as follows:

VSO=q

se

/q

e

(1)

VSE=q

se

/qs (2)

where q

se

denotes the mass flow rate of

discharged smoke, q

s

denotes the mass flow rate of

generated smoke, and q

e

denotes the mass flow rate

of rated smoke extraction. As reported in the

literature (Jiang Yaqiang, 2009), under the condition

of no plugholing of the smoke layer, the content of

discharged gas at the smoke vent is all smoke. As

such, q

se

is equal to q

e

. Under this condition, VSO is

100% and the system exhibits the best performance.

When plugholing of the smoke layer occurs, q

se

becomes less than q

e

. Under this condition, VSO

represents the proportion of smoke in discharged

gas. The remaining proportion (1 − VSO) is air.

Evidently, the higher the VSO, the better the

performance of the smoke extraction system.

In this study, the smoke extraction rate is

expressed as

V

e

and the corresponding mass flow

rate is expressed as q

e

, i.e., the mass flow rate of gas

discharged through the smoke vent. The velocity of

smoke (U) passing through the monitoring section is

assumed to be distributed evenly in the horizontal

direction of the tunnel. The thickness of the smoke

layer is S

h

. Given the distance of 0.5 m from the top

of the smoke vent on the sidewall to the ceiling, the

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

330

true S

h

’=S

h

-0.5 is obtained. The density of the upper

smoke layer is . The width of the tunnel is denoted as

d. Then, the mass flow rate of discharged smoke is

calculated as follows:

q

se

=ρ

s

×U×S

h

’×d

(3)

Eq. (3) is substituted in Eqs. (1) and (2) to obtain

the calculation formulas of VSE and VSO, as

follows:

e

hs

q

d'SUρ

VSO

e

se

q

q

(4)

s

hs

q

d'SUρ

VSE

s

se

q

q

(5)

Figure. 4 shows that VSO decreases with the

increase in smoke extraction rate by using Eqs. (3),

(4), and (5). When the extraction rate is low, the total

amount of gas discharged is small, with smoke

accounting for a large proportion, i.e., VSO is large.

With the continuous increase in the smoke extraction

rate, turbulence occurs. Although the total amount of

extracted smoke also increases, VSO gradually

reduces and finally stabilizes at 11%. In contrast to

VSO, VSE increases with the increase in the smoke

extraction rate. Based on the “Code for Metro

Design”(GB, 2003), the amount of discharged smoke

in the platform and hall of the station should be

calculated as 1 m

3

/min/m

2

of the construction area.

Based on this criterion, the designed volume of

smoke extraction for the model is calculated to be 75

m

3

/s. Considering Figures.4, the optimum smoke

extraction rate for this model is 60 m

3

/s. Under this

condition, VSO is 21.14% and VSE is 41.59%.

Figure. 4 Change of performance of the smoke extraction

system with the variation of the smoke extraction rate

3.2 Analysis of The Fr for The Layering

of Smoke

In fluid mechanics, the Fr is usually employed to

describe the proportion of inertial and buoyant forces.

A larger value of the Fr indicates a stronger

dominance of inertial force (GB, 2003; Vandeleur P

H E, 1989). In this study, inertial force, being the

horizontal shear force between smoke and air, is the

dominant factor of the occurrence of mixing,

whereas buoyant force is the dominant factor in

maintaining the layering of smoke. The Fr is

expressed as follows:

2/1

int

2

s

]

ρHg

Vρ

[

Fr

(6)

where g is the acceleration of gravity;∆V is the

shear velocity ; and Hint is the height of the

interface of the smoke layer. Smoke is regarded as

ideal gas. As such, the average density can be

obtained through the conversion of the average

temperature in the equation of the state of ideal gas,

expressed as follows: PV = nRT (n = m/M). The

average temperature is obtained based on the

function T(z), which reflects the vertical distribution

of temperature. The average temperature of the

upper smoke layer is calculated as follows:

H

H

u

dzzT

HH

T

int

)(

1

int

(7)

The average temperature of the lower air layer is

calculated as follows:

int

0

int

)(

1

H

l

dzzT

H

T

(8)

The function reflecting the vertical distribution

of temperature obtained by fitting is substituted in

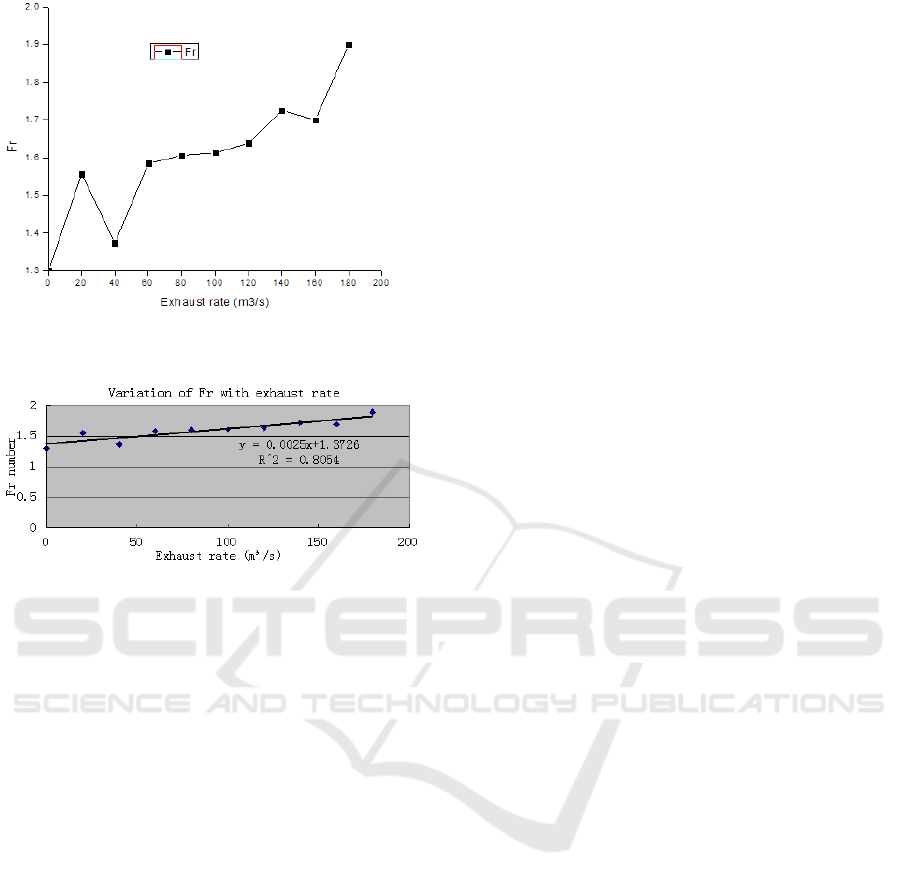

Eqs. (6), (7), and (8). Figures. 5 and 6 are obtained

by calculating the aforementioned equations,that

show the variation of the Fr of the smoke vent with

the change of the smoke extraction rate when the

power of the fire source is 15 MW and the linear

function fitted by using Excel. Figures. 5 and 6

show that the Fr at the smoke vent increases with

the increase in smoke extraction rate, i.e., the

shearing motion of the smoke and air layers in the

tunnel strengthens in general. As a result, mixing of

the smoke and air layers at the smoke vent is

intensified and the volume of discharged smoke

decreases because of turbulence.

A Numerical Simulation of Smoke Extraction in the Tunnel Sidewall

331

Figure. 5 Variation of the Fr with the change of the smoke

extraction rate (15 MW)

Figure. 6 Fitting of the Fr with the change of the extraction

rate (15 MW)

4 CONCLUSIONS

In this study, numerical analyses are conducted

under different smoke extraction rates to analyze the

law of smoke extraction. We obtained the following

conclusions:

(1) VSO decreases with the increase in the smoke

extraction rate, whereas VSE increases with the

increase in the smoke extraction rate.

(2) The Fr at the smoke vent increases with the

increase in the smoke extraction rate.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the support

received for this project from the Scientific Research

Foundation of Liaoning Education Department (No.

L2015096) and the Doctoral Scientific Research

Foundation of Liaoning Province (No. 201601249)

REFERENCES

Jiang Xuepeng, Yuan Yueming, et al Effect of smoke

extraction rate on the plugholing of smoke layer below

the smoke vent in tunnels[J] Journal of Safety and

Environment, 14(02): 36-40, 2014

Hu Longhua, et al Effect of the position of air inlet on the

efficiency of mechanical smoke extraction in an

underground long tunnel[J] Engineering Science, 7(5):

90-92, 2005

Jiang Yaqiang, et al Influence of transverse smoke

extraction on the characteristics of the layering of

smoke in tunnel fires[J] Engineering mechanics, 27(7):

245-250, 2010

Han Jianyun, et al Experimental investigation on the

influence of cross-section area of the shaft on natural

smoke extraction[J]. Fire Safety Science, 22(1): 32-36,

2013

Linjie Li,et al.Research on the phenomenon of

plug-holing under mechanical smoke exhaust in tunnel

fire [J]. Procedia Engineering, 2013, 62, 1112-1120

Hu L H, et al. Studies on buoyancy-driven back-layering

flow in tunnel fires[J]. Experimental Thermal and

Fluid Science,2008,32(8):1468―1483

Yasushi Oka, et al. Control of smoke flow in tunnel

fires[J]. Fire Safety Journal,1995,25:305―322

Wu Y, Bakar M Z A. Control of smoke flow in tunnel fires

using longitudinal ventilation systems-A study of the

critical velocity[J]. Fire Safety

Journal,2000,35:363―390

Vauquelin O, Telle D. Definition and experimental

evaluation of the smoke ‘confinement velocity ’in

tunnel fires[J]. Fire Safety Journal,2005,40:320―330

Futoshi Tanaka, et al. Performance validation of a hybrid

ventilation strategy comprising longitudinal and point

ventilation by a fire experiment using a model-scale

tunnel[J]. Fire Safety Journal,2015,71:287-298

Jiang Yaqiang, et al. A numerical study on the effects of

mechanical extraction rate on the plugholing of smoke

layer in a long tunnel[J] Journal of university of

science and technology of China, 39(4): 420-424,

2009

Liang Ping, Numerical simulation of the effect of smoke

channel in tunnel fires based on FDS[J] Journal of

transport science and engineering, 26(1): 50-53, 2010

Vauquelin O, Mégret O. Smoke exhaust experiments in

case of fire in a tunnel [J]. Fire Safety

Journal,2002,37(5):525-533

Olivier Vauquelin. Experimental simulations of

fire-induced smoke control in tunnels using an

“air–helium reduced scale

model”:Principle,limitations,results and future[J].

Tunneling and Underground Space Technology, 2008,

23: 171—178

Jiang Yaqiang Characteristics of smoke transport in

channels under different conditions of smoke

extraction University of science and technology of

china, 2009

GB 50157-2003. Code for metro design[S] Beijing:

Standard Press of China

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

332

Vandeleur P H E,et al. Numerical study of the stratifie

smoke flow in a corridor:Full-scale calculations[J].

Fire Safety Journal, 1989,14:287―302

A Numerical Simulation of Smoke Extraction in the Tunnel Sidewall

333