Temperature Rise Characteristic of Engineering Vehicle

Refurbished Tire

Qian

g

Wan

g

, Xiao

j

ie Qi, Yunlon

g

Wan

g

andGuotianWan

g

School of Automobile and Traffic Engineering, Heilongjiang Institute of Technology, Hongqi Street, HarBin, China

63070266

6

@

qq

.com

Keywords: Engineering vehicle refurbished tire, Stead-state temperature field, Finite element analysis, Temperature rise

Characteristics.

Abstract: In order to further clarify the temperature rise characteristic of engineering vehicle refurbished tire, computer

geometry models and the finite element analysis modals of the 26.5 R25 engineering vehicle refurbishment tire

were built using Pro/E Wildfire and ANSYS Workbench software, the boundary conditions of finite element

analysis of steady state temperature field was determined, then the steady-state temperature field test system for

the rolling working condition of engineering vehicle refurbished tire was constructed, and last the temperature

field distribution characteristics and heat flux distribution characteristics of the tire layer, buffer layer, belt layer,

tread body layer, tire side layer and toe mouth rubber layer along the width direction and radial direction of the tire

were obtained. The simulation and test results are shown: the two sides of the tread body layer shoulder had the

highest temperature, with the lowest temperature on the belt layer, buffer layer, and both sides along the width

direction of tread body layer. The interior temperature of the refurbished tire increased with the speed of the

running tire, among them, the temperature of the buffer layer and the tire layer increased greatly, and the tread

body layer was the second, and the temperature of the belt layer was the smallest. The maximum heat flux was

near the shoulder position of the tread body layer.

1 INTRODUCTION

In recent years, with the rapid development of

construction, mining and other industries, the usage

of tires for engineering machinery vehicles is

increasing, but due to its poor working conditions

and frequency of usage, the production of

engineering vehicle waste tires is increasing sharply.

The amount of rubber used for an engineering

vehicle tire is about 15% of the total tire

consumption, therefore, improving the

refurbishment rate of the waste tires of engineering

vehicle, which can effectively improve the

utilization rate of the waste tires of engineering

vehicles, save rubber resources and promote green

environment, thus "black pollution" will be

effectively changed into "black energy"(Liu

Chundao., 2016; Sun Hongyan, 2015). At present,

the research on engineering vehicles refurbished

tires done by developed countries such as America,

Japan, and South Korea and China mainly

concentrated in the refurbishment industry

conditions and related policy analysis, refurbishment

process equipment development, refurbishment

process technology, refurbished tire product quality

evaluation, etc. There are not many studies on

macroscopic and microscopic mechanical properties

in the use of engineering refurbished tire, except

some results gotten by the author of this paper and

the research group in recent years, no results have

been published. Due to the lack of basic technology

of engineering tires refurbishment, engineering

refurbished tires often appear not wear-resisting,

easy to collapse cost block, even tread separation,

and other damage forms caused by blasting and the

blasting in the process of usage, seriously affecting

popularization and application (Ma Xiao., 2015;

Wang Qiying, 2015). For this purpose, this paper

built a computer geometry model, finite element

analysis model and temperature rise characteristic

test system, qualitatively and quantitatively

described and evaluated the temperature rise

characteristics of engineering vehicle refurbished

tire, thus It provides important theoretical guidance

for the researches on the performance evaluation,

optimization of the refurbishment process and the

using promotion.

Wang, Q., Qi, X., Wang, Y. and Wang, G.

Temperature Rise Characteristic of Engineering Vehicle Refurbished Tire.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 409-413

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

409

2 THE GEOMETRIC MODEL

CONSTRUCTION OF STEADY

TEMPERATURE FIELD OF

ENGINEERING REFURBISHED

TIRE

In this paper, tread layer, buffer layer, belt layer, tire

body layer, tire side layer and steel wire ring were

respectively established based on the 26.5R25

refurbished radial tire, combining with its material

distribution model and using Pro/E Wildfire

software, then as shown in fig.1. Virtual assembly

was completed by using Pro/E Wildfire software

assembly module, and saved as IGES format, and

the steady-state temperature field of engineering

refurbished tires was analyzed by using ANSYS

Workbench finite element software, and imported

into ANSYS Workbench software, and the three-

dimensional geometry model is shown in fig.2

(Wang Jun, 2016; Wang Guolin, 2016; Qin Tao,

2016) .

1-Tread layer 2- Buffer layer 3-Belt-layer 4-Tire body

layer 5-Tire

side layer 6-Toe-mouth rubber layer 7- Steel wirering

Figure 1 3D geometry model and explosion model based

on Pro/E Wildfire software

Figure 2 3D geometry model based on ANSYS

Workbench software

3 THE FINITE ELEMENT MODEL

CONSTRUCTION OF

ENGINEERING REFURBISHED

TIRE STEADY-STATE

TEMPERATURE FIELD

The finite element model was created as shown in

fig.3, with 26,762 nodes and 14,333 units. Tread

layer, buffer layer, tire side layer and toe-mouth

rubber layer were simulated by Mooney Rivlin

model, and belt layer and tire body layer were

simulated by composite material layer unit, and steel

wire ring was simulated by physical unit. The heat

conductivity coefficient of each layer is shown in

tab.1, and the heat transfer coefficient of each layer

at different speeds is shown in tab.2. Initial

temperature was set as 20°C, and the measured tire

pressure and calculated temperature under different

speeds are as shown in tab.3. The speed of free

rotation working condition was 40 km/h, and

temperature loading model of 95 ° C tire inner cavity

temperature is as shown in fig.4 (Wang Ruoyun,

2016; Yan Shan, 2016).

Figure 3 Finite element model

Table 1 Heat conductivity coefficient of each layer

Tire

body

layer

Belt

layer

Buf

fer

laye

r

Tre

ad

laye

r

Tire

side

layer

Toe

mouth

rubber

layer

Tire

bead

Heat

conduc

tivity

coeffici

ent

W/m·°C

18.64 34.38 0.24 0.20 0.36 0.28 52.12

Table 2 Heat transfer coefficient of each layer surface at

different speeds

Speed

km/h

w

h

W/(m

2

·°C)

n

h

W/(m

2

·°C)

c

h

W/(m

2

·°C)

q

h

W/(m

2

·°C)

10 15.22 10.65 10.65 6.09

20 27.25 19.08 19.08 10.90

30 38.30 26.81 26.81 15.32

40 48.77 34.14 34.14 19.51

50 58.82 41.17 41.17 23.53

60 68.56 47.99 47.99 27.42

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

410

Table 3 The measured tire pressure and calculated

temperature at different turning speeds

Speed km/h

Measured tire pressure

kPa

Calculated inner

cavity air

temperature°C

10 465 30

20 498 51

30 534 75

40 565 95

50 572 99

60 584 107

Figure 4 Temperature loading model

4 SOLUTION AND ANALYSIS

Fig.5 shows the distribution cloud graph of the tire

temperature field and the temperature distribution of

each layer along the radial direction of engineering

refurbished tires. The fig. 5 shows that the

temperature peak appeared inside tire body layer

near the shoulder (95.2°C), the lowest temperature at

tire shoulder of tread surface (45.6°C). The

simulation results show that the heat transferred

from the interior of the engineering refurbished tire

to the exterior, the tire body layer was composed of

a layer of steel wire curtain, whose heat conductivity

was relatively higher than that of rubber and whose

shoulder was the thinnest, so the temperature was

the highest. The shoulder rubber of tread layer was

much thicker and was not conducive to the diffusion

of heat, so the temperature was the lowest. In

addition, because of the tire side was a layer of steel

wire curtain fabric and a thin layer of rubber, thus its

temperature was also high.

Figure 5 Temperature distribution cloud graph of

temperature field and temperature distribution of each

layer along radial direction

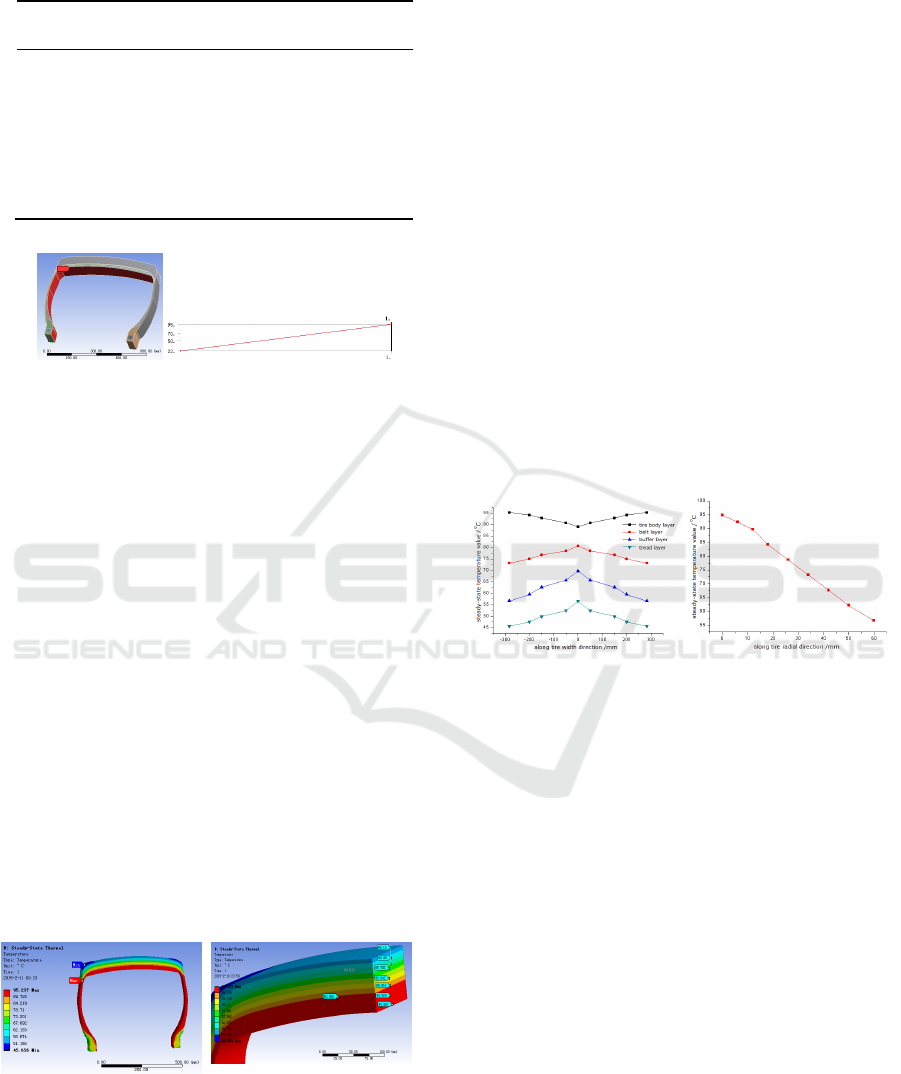

Fig.6 shows the temperature distribution curve of

each layer along the width direction and radial

direction. It can be seen from fig.6 and fig.7 that the

temperature at the two sides of shoulder of the tread

body layer was the highest, and the temperature

gradually decreased to the cross section center; the

temperature at both sides of the belt layer, buffer

layer and tread layer along width direction was the

lowest, and the temperature gradually increased to

the cross section center, and among them the change

degree of the belt layer was not large, and the

temperature variation degree of buffer layer and

tread layer was larger. Along the radial direction, the

temperature gradually decreased from interior of the

tire body layer to exterior of the tread layer and

change trend was approximately linear. The

temperature peak of the tire side layer was at the

junction of the tire side layer and the toe mouth

rubber layer, and the temperature highest point of

the toe mouth rubber layer was at the junction of the

toe mouth rubber layer and the steel wire ring, then

the highest temperature of the steel wire ring was

located at the junction of the steel wire ring and the

toe mouth rubber.

(a) (b)

Figure 6 Each layer along width direction(a)and radial

direction(b)temperature distribution

Fig.7 shows the temperature variation curve of

the center line of the tire cross section along the

radial direction at different speeds. It can be seen

from fig. 8 that, with the increase of driving speed,

the temperature of any point of the refurbished tire

increased, and the temperature of the belt layer

increased by a minimum, the tire body layer was

secondary, and the temperature of the buffer layer

and the tread layer increased greatly. The results

show that, with the increase of the driving speed of

the tire, the heat was quickly introduced to the buffer

layer and the tread layer from the tire body layer

through the belt layer. Because the heat conductivity

of the rubber material in the buffer layer and the

tread layer was low, the temperature of this part had

risen sharply. If the heat could not be introduced into

the atmosphere in time, the adhesive force between

the tread layer and the buffer layer, and the buffer

layer and the belt layer would be reduced, even due

Temperature Rise Characteristic of Engineering Vehicle Refurbished Tire

411

to the high temperature effect, the failure of the tread

layer produced.

Figure 7 Temperature variation curves of tire radial

direction at different speeds

The test system composition is shown in fig.8,

and its mainly consists of air compressor 1, bench 2,

motor 3, reducer 4, coupling 5, bracket 6, rotation

axis 7, tires under test 8, tire pressure gauge 9,

platform 10, thermocouple 11, wires 12, plugs 13,

and a thermometer 14.

1- Air compressor 2- Bench 3- Motor 4- Reducer 5-

Coupling 6- Bracket7- Rotation axis 8- Tire under test 9-

Tire pressure gauge 10- Platform 11- Thermocouple 12-

Wires 13- Plugs 14- Thermometer

Figure 8 Composition of testing system

The tire pressure of 26.5R25 engineering

refurbished tire was 600kPa, the inner cavity stable

tire pressure testing results under different rotating

speed working conditions are shown in tab.4, the

steady-state temperature value of each layer is

shown in tab.5, the comparison curve of steady-state

temperature measured results and simulation results

is shown in fig.9, The measured value was close to

the simulation value, which verified the correctness

of the simulation model.

Table 4 The inner cavity stable tire pressure of

engineering refurbished tires under different rotation

speeds

Speed

km/h

Running time

h

Initial tire

p

ressure

k

Pa

Stable tire

p

ressure kPa

10 2 600 615

20 2 600 648

30 2 600 684

40 2 600 715

50 2 600 748

60 2 600 783

Table 5 The steady-state temperature value of engineering

refurbished tires under different rotation speeds

Speed

km/h

Temperature

of measured

point a °C

Temperature

of measured

point b °C

Temperature

of measured

point c °C

Temperature

of measured

point d °C

10

89.2 81.3 69.3 56.9

20

90.5 81.1 70.7 58.5

30 91.3 82.9 72.1 60.5

40 92.3 83.9 72.9 60.1

50 92.5 85.4 73.9 63.8

60 92.6 86.6 76.0 64.7

Stating: Measured points a,b,c and d respectively

represent the central section of tire body layer, the

central section of belt layer, the central section of

buffer layer, and the central section of tread layer.

Figure 9 Comparison curve of measured value and

simulation value of steady-state temperature distribution at

different rotation speeds

5 CONCLUSION

(1)Temperature was higher on both sides of the tire

shoulder of tire body layer, which gradually

decreased to the center of the cross section, and the

lowest temperature was at the both sides of the width

direction of belt layer, buffer layer and tread layer,

which gradually increased to the center of the cross

section, moreover, the changing degree of the belt

layer was not large, and the temperature variation

degree of buffer layer and tire layer was larger.

(2)With the increase of the running speed, the

temperature of any point of interior tire was all

increased, among them the temperature increasing

degree of the belt layer was the smallest, and the

layer of the tire body layer was the second, and the

temperature increasing degree of the buffer layer and

the tread layer was much larger.

(3)The maximum heat flux of the tire body layer

was near the shoulder part, the maximum heat flux

was on both sides of the width direction of the belt

layer and of the tread layer, the maximum heat flux

was on both sides of the width direction of the buffer

layer, the maximum heat flux was at the junction of

the tire side layer and the tire body layer, the

maximum heat flux was at the junction of the toe-

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

412

mouth rubber layer and the tire body layer, and the

heat flux in the middle part of the steel wire ring was

the largest.

(4)The heat from engineering refurbished tires

would gather at the junction of the shoulder position

and the various layers, therefore, it is necessary to

pay more attention to the close adhesion between the

shoulder position and the buffer layer and the tread

rubber. At the same time, the transition of the rubber

joint in each layer should be smooth, which reduces

the probability of the failure of the shoulder position

and each layer.

ACKNOWLEDGEMENTS

Project originating from: Heilongjiang Province

Natural Science Fund in 2015(E2015025)

REFERENCES

Liu Chundao. The Tire Refurbishment Industry Leads the

Future of Low-Carbon Energy Saving [J]. Modern

Rubber Technology,2016,42(02):9-14.

Sun Hongyan, Zhang Qianchuan. The Quality Control

and Inspection of Automobile Refurbished Tire [J].

Shandong Industrial Technology,2015,(22):30.

Ma Xiao.Tire Refurbishment Method[J].Tire Industry,

2015,35(01):23.

Wang Qiying, Li Zongjian, Zhou Yingmei, Hao

Lingzhong. A New Way Analysis to Giant

Engineering Machinery Tire Refurbishment[J].Rubber

Plastic Technology and Equipment, 2015,41(01):15-

20.

Wang Jun,Li Liang,Sun Lin and so on. Finite Element

Analysis of 245/70R16Tire [J]. The Tire Industry,

2016,36(09):520-528.

Wang Guolin, Tong Xin, Dong Zilong, Xu Haiqing. Study

on the Relationship between the Grounding

Characteristics of Radial Tire and Tire Crown

Temperature Field [J].Rubber

Industry,2016,63(05):276-280.

Qin Tao. Automatic Partitioning Program Research on

Tire Finite Element Grid [D]. Donghua University,

2016.

Wang Ruoyun. Study on Dynamic Mechanical Properties

of Tire Rubber Material Based on Finite Element

Analysis Technology [D]. Beijing University of

Chemical Technology, 2016.

Yan Shan,Wang Wei. Finite Element Analysis and

Experimental Study on Complex Tread Pattern Tire

[J]. Rubber Industry,2016,63(02):102-106.

Temperature Rise Characteristic of Engineering Vehicle Refurbished Tire

413