Develo

p

ment of an Automatic Testin

g

S

y

stem for Corn

Peng Song, Han Zhang, Cheng Wang, Xiaodong Wang and Bin Luo

*

Beijing Research Center of Intelligent Equipment for Agriculture, Beijing, China

Beijing Research Center for Information Technology in Agriculture,Beijing,China

{songp, zhangha, wangc, wangxd, luob}@nercita.org.cn

Keywords: Testing system; Corn ear test; Parameters measure; Image process; Automatic control.

Abstract: Currently, the mainly used methods for corn parameters are traditional artificial method and semi-automatic

method based on machine vision technology, which restrict the efficiency of multiple date acquisition during

corn breeding. To solve this problem, an automatic testing system for corn was developed. This system is

consist of corn ear testing unit, automatic threshing unit, corn kernels testing unit, post-processing unit and

system control unit. Corn ear testing unit contains four cameras as well as a weighting sensor, which can

measure corn ear parameters such as ear weight, ear length, ear width, ear row number, grains per row, bare

tip size, et al. automatically. Corn kernels testing unit measures corn kernels parameters including kernel

color, kernel width, kernel length, kernel shape, kernel number, et al. based on computer vision technology

after kernels were spreading out by a vibrating mechanism. Post-processing unit can lift kernels to a fixed

height, packaging the kernels and print a label contains corn ear and corn kernel parameters. An industrial

control tablet combined with I/O module were chosen for the system control unit, receiving sensing

information and feedback to control the device. Results of experiment showed that the prototype can realize

the whole testing process for corn, includes ear parameters measuring, ear threshing, kernel parameters

measuring, kernel lifting, kernel packaging and label printing automatically. The average efficiency of the

prototype was up to 4 ear/minute, the average measurement accuracy for ear length and ear width is up to

98.93% and 97.71%, the average accuracy of kernel number is up to 99.11%, which can improve the

efficiency of corn breeding obviously.

1 INTRODUCTION

Corn breeding affects the quality and yield of corn.

Therefore, measurements of corn parameters

determine directly the quality evaluation and

selection of breeding materials (LIU Guanyi, 2013).

These parameters include ear weight, length, and

thickness; ear row number; row kernel grain number;

and corn kernel number, length, width, type, color,

moisture, and volume weight (Cao Jinghua, 2011).

Parameters that measure efficiency and accuracy are

key factors restricting breeding efficiency.

With the development of information technology,

machine vision and digital image processing

technologies have been used in the detection and

classification of agricultural products on a large scale

(WANG Qiao, 2017; Nayak R K, 2015;

C.Igathinathane, 2009; Cao Weishi, 2012). An

increasing number of scholars have studied the

parameter extraction method of corn ears or corn

kernels (Liu Changqing, 2014; Ma Qin, 2012; Wang

Chuanyu, 2013; Zhang Fan, 2015; Zhou Jinhui, 2015;

Wang Huihui, 2010; Lü Yongchun,2010), but only a

few have studied the design and realization of the

automatic testing system. Wang et al.(2015)

developed a maize kernel trait extraction system to

realize the measurement of total kernel number, long

and short axes, and length-width ratio through a line-

scan camera. The average measured efficiency of the

system is 12 s per ear. Xiao et al. (2015) designed an

automatic assembly line organization to measure corn

parameters and performed virtual modeling and

simulation to discuss the feasibility of the assembly

line processing for corn ear measuring. Wu et al.

(2016) designed an automatic corn ear testing system

to realize the automatic corn ear feeding, sorting,

image collection and analysis and automatic

weighing.

Existing corn testing devices and methods

measure corn ears and kernels separately rather than

simultaneously, thereby slowing down the process of

testing a large amount of breeding materials. The

high-throughput automatic corn measuring device

designed in the study realizes the rapid,

460

Song, P., Zhang, H., Wang, C., Wang, X. and Luo, B.

Development of an Automatic Testing System for Corn.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 460-466

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

comprehensive, and automatic acquisition of testing

parameters from corn ears to kernels, greatly reducing

the human cost for testing and improving breeding

efficiency. Thus, this system is of great significance

in enhancement of breeding efficiency.

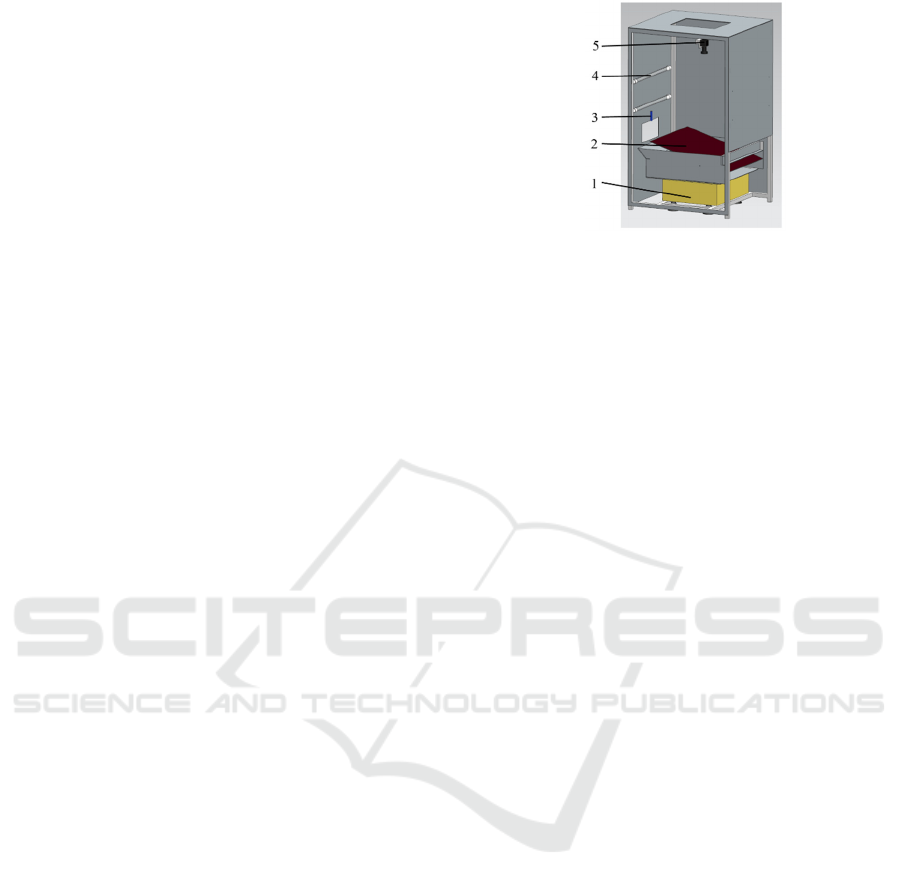

2 OVERALL SCHEME DESIGN

OF THE SYSTEM

An automatic corn testing system was designed to

realize the composite measurement of the parameters

of corn ears and kernels. The modular design is

adopted to divide the automatic measuring device into

five parts according to their function, namely, corn

ear testing unit, ear threshing unit, corn kernel testing

unit, kernel post-processing unit, and system control

unit. The ear testing unit uses weighing sensor to

measure ear weight, uses multiple cameras to take

corn ear images for analysis and acquire the main

parameters of corn ear, including ear weight, ear

length, ear width, ear row number, row kernel

number, bare tip size. The ear threshing unit enables

automatic ear threshing and impurity removal after

ear testing. The kernel testing unit vibrates the

threshed kernels to avoid large-area adhesion and

accumulation. It also analyzes kernel images and

acquires kernel number, length, width, type, and

color. The kernel post-processing unit includes

pneumatic hoisting mechanism, automatic packaging

mechanism, and 2D code label printing system. This

unit prints 2D code labels first before ascending corn

kernels to a certain height and encapsulating them.

The 2D code labels contain all measured information

of the corresponding ear. The system control unit

ensures that the entire system is running orderly,

stably, and automatically. The Principle of the

automatic testing system for corn is shown in Fig. 1.

Fig.1 Principle of automatic testing system for corn

3 KEY UNIT DESIGN

The automatic testing system is mainly composed of

corn ear testing unit, automatic threshing unit, corn

kernel testing unit, post-processing unit and system

control unit. A thresher for single ear from Canada is

chosen for the core of automatic threshing unit,

threshing efficiency can up to 3~5 s/ear, with low

breakage. For post-processing unit, a vacuum suction

machine was used to lifting kernels, which can ensure

the lifting process without mixture between

neighboring corn. Thus, the key elements of the

system include core ear testing unit, corn kernel

testing unit and system control unit.

3.1 Corn Ear Testing Unit

Corn ear parameters include ear weight, ear length,

ear width, ear row number, row kernel number, bare

tip size, average kernel thickness, and ear color. To

ensure that the ear testing unit can adapt to the

detection requirements of various forms of corn ears

and provide consideration to the precision and speed

of ear testing in the automatic testing process, the ear

testing unit structure is designed, as shown in Fig. 2.

Fig.2 Structure of corn ear testing unit

Development of an Automatic Testing System for Corn

461

1.Weighing sensor 2.Ear loading sensor 3.Ear unloading

motor 4.Cameras for ear images 5.Ear unloading sensor 6.

Load bearing steel wire 7. Corn ear carrying device

8.bearing bracket 9.Sample under test

Ear testing unit mainly includes weighing sensor,

cameras, and ear bearing mechanism, the ear bearing

mechanism consists of a bearing bracket and an ear

bearing device. The whole ear bearing mechanism is

placed above the weighing senor with a range of 0~10

kg and a precision of 0.1 g. The ear bearing device

adopts two Tungsten wires with high hardness and a

diameter of 1.5 mm. Those two wires are installed in

parallel with adjustable space. During work, the

sample ear is placed above two wires. Four high-

resolution color cameras are evenly distributed

around the ear with an interval of 90° to acquire corn

ear images in four directions. In this study, ear images

are taken using a high-resolution color CMOS

industrial digital camera and the lens with a focal

length of 5 mm. In addition, four 12 V bar LED white

light sources are distributed in the middle of the

adjacent cameras to guarantee uniform illumination.

Ear loading sensor detects ear feeding, which triggers

four cameras to acquire ear images and record ear

weights simultaneously. Then, ear unloading motor

drives the ear carrying device to revolve round the

axis. The ears slide down to the threshing unit under

the effect of gravity, which resets both the unloading

motor and the bearing device, waiting for the feeding

of the next ear. The ear unloading sensor is installed

at the discharge outlet to detect whether the corn ear

is successfully discharged to the kernel threshing unit.

3.2 Kernel Testing Unit

When the testing system works, corn kernels after

being threshed and cleaned are randomly scattered in

the kernel testing unit under the effect of gravity. At

this time, the industrial camera is used to acquire

kernel images and then obtain the kernel parameters,

including kernel number, kernel shape, length, width,

and color. Corn kernels, which are scattered in the

kernel testing unit after being threshed and cleaned,

are easily adhered and accumulated. Thus,

guaranteeing the accuracy of the kernel parameters is

difficult if the images to process are directly acquired.

To solve the problem, the kernel testing unit consists

of three parts: (1) image acquisition device for

collecting kernel images; (2) automatic spreading

mechanism for reducing kernel adhesion and

accumulation and obtaining high-quality kernel

images; and (3) kernel discharging mechanism for

ensuring the smooth implementation of high-

throughput assembly line operation and allowing the

discharge of kernels whose test parameters have been

measured into the next link. The structure of the

kernel testing unit is shown in Fig. 3.

Fig.3 Structure of corn kernels testing unit

1. Vibration platform 2. Kernel layer board 3. Threshing

unload sensor 4. Strip source 5. Camera for kernels image

The camera of the kernel image acquisition device

adopts a high-resolution color CMOS industrial

digital camera. The CMOS size of the camera is 1/2.5

inch with an imaging resolution of 2592 × 1944

pixels. After the test, the corn kernel distribution area

is designed to 50 cm × 40 cm to improve the pixel

utilization rate of the camera and meet the testing

demands of single-corn ear kernels of different

specifications.

The automatic spreading mechanism vibrates the

plate containing corn kernels under the drive of the

vibrating platform before the acquisition of corn

kernel images to avoid corn kernel accumulation.

After spreading, it triggers the camera to acquire

kernel images. The kernel discharging mechanism

uses the linear motor to drive the kernel plate to form

a certain angle and make the kernels slide down under

the effect of gravity.

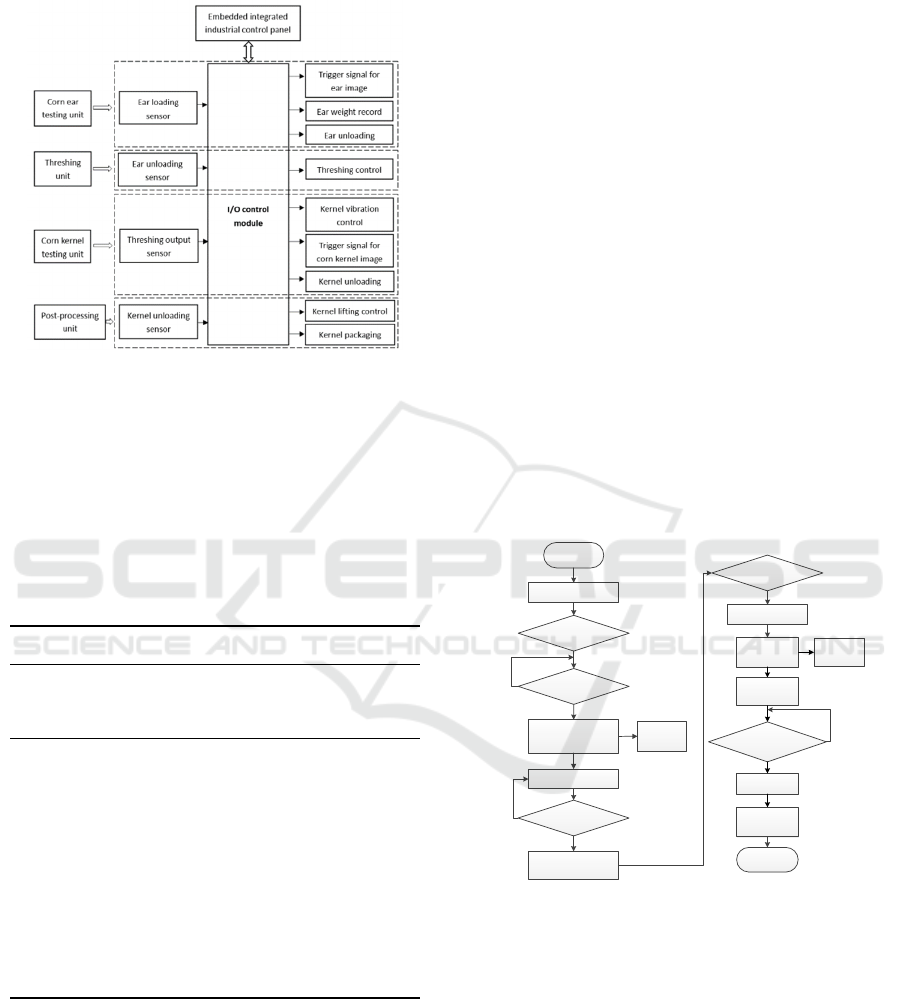

3.3 System Control Unit

The Kunluntongtai TPC7062K industrial control

tablet and the Modbus input–output module comprise

the control system. The Modbus module uses the

RS485/RS232-based Modbus RTU standard

communication protocol with 16 photoelectric

isolating switch input channels and 16 photoelectric

isolating relay output channels.

After corn ear feeding, the ear loading and

unloading sensors are installed at the ear processing

unit, the kernel threshing detection senor at the outlet

of the threshing unit, and the kernel discharging

sensor at the outlet of the kernel testing unit. This

procedure realizes the automation of ear image

acquisition and analysis, discharging, kernel

threshing and spreading, kernel image acquisition and

analysis, as well as lifting, packaging and label

printing. The output signals of the sensors are all

switch quantities, which are taken as the input signals

to control the testing system according to the

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

462

designed logic and time sequence. The overall design

of the control system is shown in Fig. 4.

Fig.4 Overall design of control system

The system uses four input signal terminals and

12 output signal terminals. In addition, it is comprised

of three sets of mechanical switches, namely, system

power-on, control system start/stop, and power

system emergency shutdown. The input-output signal

terminal configuration of the control module is shown

in Table 1.

Table 1 I/O ports configuration of control module

Name

Port

channel

Signal connected

Input port

10001 Ear loading senso

r

10002 Ear unloading senso

r

10003 Threshing output senso

r

10004 Kernel unloading senso

r

Output

port

00001 Motor for ear unloading(extending)

00002 Motor for ear unloading(restoration)

00003 Signal for ear image acquisition

00004 Start stop signal of threshing

00005 Signal of kernel vibration platfor

m

00006

Motor for kernel

unloading(extending)

00007

Motor for kernel unloading

(restoration)

00008 Signal for kernel image acquisition

00009 Start stop signal of lifting device

00010 Kernel unloading signal after lifting

00011 Packaging signal

00012 Barcode printing signal

When the power is turned on, the control system

starts and the device completes initialization to wait

for ear feeding. Ear loading sensor detects the ear

information and then judges the kernel discharging

state of the last ear. If the last ear’s kernel is

discharging or already discharged successfully, the

ear weight is read from the weighing sensor. At the

same time, four cameras are triggered to collect the

ear images from four angles. If the last ear’s kernel

has not discharged kernels yet, the mechanism waits.

The kernel process of the last ear must be completed

when the current ear threshes kernels to avoid the

mixture of kernels on adjacent ears during measuring.

The acquired ear images are processed to extract ear

parameters. On the contrary, the ears are discharged

to reset the weighing sensor. When the ear

discharging sensor detects the entry of ears into the

thresher, the thresher starts to thresh corn kernels. At

this time, the threshed kernels are scattered in the

kernel testing unit. When detecting the scattering of

kernels at the outlet of the thresher, the vibration

spreading mechanism vibrates until the threshing is

completed to avoid large-area kernel adhesion and

accumulation. The camera of the kernel testing unit is

triggered to collect kernel images, which are then

processed. At the same time, the kernels are

discharged and the fan of the pneumatic lifting device

starts to lift the kernels to the specified height and

package them. After processing the kernel images and

obtaining the kernel test information, the ear test 2D

code is automatically printed and the test parameters

of the corresponding ears and kernels are written into

the 2D code. The system control process is shown in

the figure below.

Start

System Initialization

Ear load succeed?

Ear weighting & ear

images acquisition

Ear loading, reset

weight sensor

Ear unloading

succeed?

Ear threshing,vibrate

to spread kernels

Threshing over?

Stop vibrating

N

Y

N

Y

Y

Ear testing

Kernel image

acquisition

Kernel

discharging

Kernel

testing

Kernel discharged?

Kernel lifting

End

The last ear unloaded?

Y

Y

N

Packaging, label

printing

Fig.5 The flow chart of system control

4 EXPERIMENT AND ANALYSIS

The automatic testing system for corn was built

according to the design shown in Fig. 6. Then, the

corn testing experiment was carried out. Test samples

were composed of the corns harvested in Hainan

breeding base of Liaoning Dongya Seed Industry Co.,

Ltd.

Development of an Automatic Testing System for Corn

463

Fig.6 The prototype

4.1 System Operation Test

During the test, the total time consumed for a single

corn ear from artificial feeding to kernel packaging

was recorded. Twenty ears were randomly selected.

Statistical results showed that the average time was

27.2 s per ear.

On this basis, 50, 100, and 150 corn ears were

randomly selected for the experiments. Three runs of

experiments were conducted to verify the stability

and operation speed of the system. In each group of

test, the ears were fed continuously. In other words,

when the last corn ear was discharged automatically

and the ear bearing mechanism was reset, the next one

was fed rapidly. The total time from feeding the first

ear to packaging the last one in each group of samples

was recorded.

Then, the average time consumed for single corn

ear test during the continuous operation of the system

was

()/(1)tTt N=−Δ −

, where T is the total time

consumed for the test of each group of samples;

tΔ

is the whole process time consumed by a single ear,

having a constant of 27.2;

and N is the total number of samples.

Table 2 Processing efficiency at continuous mode

No.

Sample

number

Total time

consuming/s

Processing

effiency/(Ear·min

-1

)

1 50 759.5 4

2 100 1490.4 4

3 150 2231.3 4

The results show that the average efficiency of the

prototype was up to 4 ear/minute, which can improve

the efficiency of corn breeding obviously.

4.2 Ear Testing Experiment

Among ear testing parameters, except the ear weight

that was acquired by the weighing sensor, other

parameters such as ear length, ear diameter, bare tip

size, ear row number, row kernel number, kernel

thickness, and ear color were obtained by four

cameras from four angles. The ears were placed

between two high-strength steel wires. Thus, four

original ear images were obtained by four cameras of

the system, which are shown below.

(a) (b) (c) (d)

(e) (f) (g) (h)

(a)Original image of Cam. 1 (b)Original image of Cam. 2

(c)Original image of Cam. 3 (d)Original image of Cam. 4

(e)Background removal for Fig.8(a) (f)bare tip extract for

Fig.7(a) (g)kernel extract for Fig.7(a) (h)kernel track for

Fig.7(a)

Fig.7 Images of corn ear and the processing results

Table 3 Results for corn ear testing

Sample

No.

Ear length Ear width

Ear rows

Measu-

red

manual-

ly/mm

Measu-

red by

system/

mm

Accu-

racy/

%

Measu-

red

manual

ly/mm

Measu-

red by

system/

mm

Accu-

racy/

%

Measu-

red

manually

/mm

Measu-

red by

system/

mm

1

131.68 133.76

98.44

40.36 40.48

99.70

14 14

2 121.02 122.97 98.41 38.52 39.49 97.54 14 12

3 95.74 96.85 98.85 35.42 36.88 96.04 16 16

4 108.32 109.26 99.14 41.86 43.07 97.19 16 16

5 117.36 119.39 98.30 45.26 46.52 97.29 16 16

6 145.62 147.08 99.01 40.78 41.52 98.22 16 16

7 168.34 169.97 99.04 49.70 51.34 96.81 18 18

8 108.94 109.56 99.43 42.68 43.53 98.05 14 14

9 73.48 73.92 99.40 31.26 31.48 99.30 12 12

10 97.88 98.24 99.63 41.28 42.36 97.45 14 14

Averag

e

1168.38 1181 98.93 407.12 416.67 97.71 150 148

4.3 Kernel Testing Experiment

After background removal and separation of adhered

kernels, the original images obtained in the corn

kernel testing unit were analyzed. Single kernels were

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

464

studied to measure kernel number, kernel type, kernel

length, kernel width, and other testing parameters.

The original kernel images obtained by the automatic

testing device and the kernel separation results are

shown in Fig. 8.

(a)Original kernel image (b) Segment result

Fig. 8 Image of corn kernels and the processing result

Table 4 Results of maize kernel number measuring

No.

Measured

manually

Measured by

system

Accuracy/%

1 351 344

98.01

2 424 419

98.82

3 505 499

98.81

4 318 316

99.37

5 492 487

98.98

6 276 276

100.00

7 532 530

99.62

8 582 577

99.14

9 429 428

99.77

10 367 362

98.64

Average 4276 4238 99.11

5 CONCLUSIONS

An automatic testing system for corn was designed in

this study to realize corn ear testing, automatic

threshing, kernel testing, automatic packaging, 2D

code generation and printing. On this basis, a

prototype machine was developed to test the stability

and efficiency of the system. Experimental results

showed that the automatic testing system could

automatically acquire various parameters involved in

the corn ear and kernel testing process. The average

efficiency of the prototype was up to 4 ear/minute.

The average measurement accuracy for ear length and

ear width is up to 98.93% and 97.71%. The average

accuracy of kernel number is up to 99.11%.These

results indicate that the system can greatly improve

the corn breeding efficiency.

ACKNOWLEDGEMENTS

This work was financial supported by the National

Key Research and Development Project

(2017YFD0701205)

REFERENCES

LIU Guanyi,YANG Xiaohong,Bai Ming,et al. Detecting

techniques of maize ear characters based on line scan

image[J]. Transactions of the Chinese Society for

Agricultural Machinery, 2013, 44(11): 276-280.(in

Chinese with English abstract)

Cao Jinghua,Ran Yanzhong, Guo Jincheng. The design and

realization of corn test system[J]. Journal of Changchun

Normal University: Natural Science, 2011, 30(4): 38-

41.

WANG Qiao,CHEN Bingqi,ZHU Deli,et al. Machine

Vision-based Selection Machine of Corn Seed Used for

Directional Seeding[J]. Transactions of the Chinese

Society for Agricultural Machinery. 2017,48(2): 27-37.

(in Chinese with English abstract)

Nayak R K,Mishra D,Rath A K. Anaive SVM-KNN based

stock market trend reversal analysis for Indian

benchmark indices[J]. Applied Soft

Computing,2015,35: 670-680.

C.Igathinathane, L. O. Pordesimo, W. D. Batchelor. Major

orthogonal dimensions measurement of food grains by

machine vision using ImageJ. Food Research

International, 2009, 42:76~84.

Cao Weishi, Zhang Chunqing, Wang Jinxing, et al. Purity

identification of maize seed based on discrete wavelet

transform and BP neural network. Transactions of the

Chinese Society of Agricultural Engineering, 2012,

28(2):253-258.

Liu Changqing,Chen Bingqi. Method of image detection

for ear of corn based on computer vision[J].

Transactions of the Chinese Society of Agricultural

Engineering (Transactions of the CSAE), 2014, 30(6):

131-138. (in Chinese with English abstract)

Ma Qin, Jiang jingtao, Zhu Dehai et al. Rapid measurement

for 3D geometric features of maize ear based on image

processing[J]. Transactions of the Chinese Society of

Agricultural Engineering. 2012, Vol.28 Supp.2, 208-

212.

Wang Chuanyu,Guo Xinyu,Wu Sheng,et al. Investigate

maize ear traits using machine vision with panoramic

photograyphy[J]. Transactions of the

CSAE,2013,29(24):155-162. (in Chinese with English

abstract)

Zhang Fan, Li Shaoming, Liu Zhe, et al. Screening Method

of Abnormal Corn Ears Based on Machine Vision[J].

Transactions of the Chinese Society for Agricultural

Machinery, 2015,46(Supp.):45-49. (in Chinese with

English abstract)

Zhou Jinhui,Ma Qin,Zhu Dehai,et al. Measurement

method for yield component traits of maize based on

Development of an Automatic Testing System for Corn

465

machine vision [J] . Transactions of the Chinese

Society for Agricultural Machinery,2015,46(3) :221-

227. (in Chinese with English abstract)

Wang Huihui,Sun Yonghai,Zhang Tingting,et

al.Appearance quality grading for fresh corn ear using

computer vision[J].Transactions of the Chinese Society

for Agricultural Machinery,2010,41(8):156-159, 165.

Lü Yongchun, Ma Qin, Li Shaoming, et al. Image features

measurement of maize ear based on background plate

scale[J].Transactions of the Chinese Society of

Agricultural Engineering, 2010, 26(14): 43-47. (in

Chinese with English abstract)

WANG Ke,LIANG Xiuying,ZONG Li, et al. Design

and Realization of a High-throughput Maize Kernel

Trait Extraction System[J]. Journal of Agricultural

Science and Technology, 2015,17(2): 94-99. (in

Chinese with English abstract)

XIAO Boxiang,WANG Chuanyu,GUO Xinyu,et al.

Automatic pipelining mechanism design for maize ear

analysis[J]. Journal of System Simulation, 2015,

27(4):913-919. (in Chinese with English abstract)

Wu Gang, Chen Xiaolin, Xie Jiayu, et al. Design and

Experiment of Automatic Variety Test System for Corn

Ear[J]. Transactions of the Chinese Society for

Agricultural Machinery, 2016, 47(Supp.): 433-441. (in

Chinese with English abstract)

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

466