Crushing Machine and Double Roll Balancing Test in Pineapple

Stems and Leaves

Zhongqing Ou

1

, Yuan Zhang

1*

, Lijiao Wei

1

, Zhende Cui

1

, Ling Li

1

, Jin Zhang

1

and Shengli Liu

2

,

3

1

Tropical Agricultural Machinery Research Institute, Chinese Academy of Tropical Agricultural Sciences, Zhanjiang,

China

2

Agricultural Science and Technology Co., Ltd. of YIWU, Zhanjiang,China

3

The Center of CangLong Agricultural Technology Service for Zhanjiang City, Zhanjiang,China

{1224774128}@qq.com,zhang198414@126.com,weilijiao2008@163.com,441213852@qq.com,418727981@qq.com,zj671

0@21cn.com,1051568484@qq.com

Keywords: Pineapple, comminuted shredding machine, biaxial, dynamic balance, test.

Abstract: This paper describes the pineapple leaf crushing machine in detail, including two-roll structure, structural

characteristics, working principle, two-roll processing requirements and dynamic balance testing methods,

Knife sharpener and after knife edge knife straight knife with the composition. After fully considering the

radial and axial positioning and balancing, the machine can effectively increase the number of hitting,

cutting and secondary crushing of the pineapple blades after entering the crushing chamber, achieving the

goal of meeting the agronomic requirements of a crushing operation. The testing results showed that the

passing rate of pineapple leaf was 98.9% after the crushing and returning machine calibrated by dynamic

balance test. The passing rate of pineapple head was 92.4% and the working stability was 89.4%. The

unevenness of throwing and The average time to failure was 0.59 and 3.4h, the whole machine showed high

reliability, to meet the actual operational needs.

1 INTRODUCTION

Pineapple is one of the famous tropical fruit, which

is mainly distributed between the 30 degrees of the

north and the south. China's planting area is about 70

thousand hectares, mainly in Guangdong, Hainan,

Guangxi, Yunnan, Fujian and other provinces.

Pineapple leaves are rich in fructose, glucose, amino

acids, protein, organic acids, crude fiber, calcium,

iron, phosphorus, vitamins, enzymes and other

nutrients. Therefore, the comprehensive utilization

of abandoned Pineapple leaves has certain economic

benefits and important environmental benefits

(Zhang Guo, 2017). In recent years, the

comprehensive utilization of waste in the pineapple

leaf also a lot of research, such as the use of

pineapple leaf residues by anaerobic fermentation

biogas production, production of bio organic

fertilizer, silage, in the main planting area in our

country most of the pineapple, Pineapple leaves by

returning the way into the line by this way, the speed

and efficiency high promotion and easier application.

Pineapple leaf returning first adopted the way

that post-harvested pineapple stubble will be

transported to the fields through artificial or

bulldozers and other equipment, dry incineration or

compost into fertilizer, caused by a certain degree of

pollution to the environment, in order to solve this

problem, at the end of 80s, China began the study of

crushed pineapple leaf returning machinery and

technology, and experienced a multi-stage harrow

flail chopped, stems and leaves of pineapple cut and

crushing stage, the existing models mainly include:

hoe shaped flail of pineapple leaf shattering and

returning machine (Figure 1) and improved L shaped

flail pineapple leaf shattering and returning machine

(Figure 2).

Figure 1: The structure of returning hoe shaped grinding

knife.

616

Ou, Z., Zhang, Y., Wei, L., Cui, Z., Li, L., Zhang, J. and Liu, S.

Crushing Machine and Double Roll Balancing Test in Pineapple Stems and Leaves.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 616-620

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 2: Returning L shaped flail crushing structure.

Pineapple leaf shattering and returning

machinery in general operation mainly due to low

efficiency, high operation energy consumption is

due to its unique biological characteristics and

mechanical properties of the pineapple stem leaf

shattering and returning machine into the pineapple,

tend to be the 2-3 smash, in order to make the

crushing effect and meet the requirements of the

proportion (pineapple stem and leaf length is less

than 15cm is not less than 90%), but in second times,

third times in the process of grinding, pineapple

stem leaf and ground surface close to earth mixed

together, to crush it, must reduce the crushing knife

stick of pineapple leaf and soil mixture crushing

operations, so that the energy consumption increases,

at the same time. 2-3 means crushing tractor

repeated rolling land, resulting in land compaction,

is not conducive to subsequent tillage operations (Ou

Zhongqing, 2017; Zhang Yurong, 2017). Therefore,

the most direct way to reduce the problem of low

efficiency, high energy consumption and soil

compaction of pineapple stem and leaf is to reduce

the operation times of pineapple stem and leaf

crushing and returning machine under the premise of

ensuring the grinding rate.

In view of the existing pineapple stem leaf

shattering and returning machine operation

efficiency is low, operation difficulty and operation

of high energy consumption, soil compaction and

other issues, combined with reduced pineapple stem

leaf crushing returning machine number, according

to the technical thought and the overall scheme of

stable performance, simple structure, the design and

development of double roller supporting large and

medium-sized tractor pineapple stem the leaf

shattering and returning machine, also carried out a

lot of research work on dynamic balance test on twin

roll.

2 THE OVERALL STRUCTURE

AND CHARACTERISTICS OF A

DOUBLE ROLL PINEAPPLE

LEAF PULVERIZING

MACHINE

2.1 Structural characteristics

Double knife roller pineapple stem and leaf

shattering and returning machine, which comprises a

frame, a supporting rod, a transmission mechanism,

the knife roller assembly, the knife, the knife roll

assembly, fixed knife, wheel, which is characterized

in that a frame is arranged at the tail part of the front

plate, a support rod arranged inside the rack and the

gear box, the middle part. With a knife before and

after the knife roller assembly and assembly; the

knife roller assembly and the knife roller assembly is

assembled above the fixed knife before and after the

fixed knife, the knife roller assembly via a front seat

with the knife edged knife mouth and pin hinge, the

front end is provided with a a belt wheel, and is

fixed on the power output shaft of the gear box at

one end of the driving pulley is connected through

the V belt, the other end is provided with a front

pulley and fixed on the rear end of the knife roller

assembly after the belt wheel is connected through

the V belt, after the knife roller assembly through

after the knife holder and is fixed to the bolt group

straight knife (Xie Yanmin, 2017; Cui Zhende,

2013). The whole machine structure is shown in

Figure 3.

Figure 3: Structure diagram of a double knife roll

pineapple pulverizing machine.

The main features of the machine are as follows:

the structure of one big, one small and two knives

and rollers can work together to significantly

improve the crushing effect, reduce the number of

pineapple leaf crushing from 2-3 times to 1 times,

avoid multiple operations, increase productivity,

reduce energy consumption and avoid excessive

compaction of soil.

Crushing Machine and Double Roll Balancing Test in Pineapple Stems and Leaves

617

2.2 Working principle

The machine is equipped with 120-140 horsepower

tractors, the use of rear suspension as a working

power, the tractor in the forward process, the output

power through the output shaft, through the

universal transmission assembly to the bevel gear

gear shaft, through a pair of cones Gear growth and

change direction, and then through the transmission

shaft connected to the front roller pulley, drive the

front shredding roller high-speed rotation, driven by

the pulley connection after the shredding roller

rotation.Before driving the grinding knife roller

rotating speed, and grinding knife roller is connected

with a belt wheel, the knife roller to rotate in the

process through a belt pulley and a belt drive after

high speed rotary knife roller. Double roller crushing

returning machine into the stems and leaves of

pineapple pineapple, pineapple leaf machine hand to

slow down shattering and returning machine, with

the wheel, adjusting front knife roller clearance

tractor, walking forward, before driving a knife

roller rotating speed, the knife roller and the cutting,

with the fixed knife pick up, crushed pineapple leaf,

and crushed Pineapple leaves thrown after the knife

roll, after the knife roller with the fixed knife is

installed on the frame, again on the pineapple stem

and leaf is crushed, Pineapple leaves and stems

along the baffle is spread evenly on the surface,

complete the grinding operation of pineapple stem

and leaf of the final.

3 DOUBLE ROLL STRUCTURE

TEST

Roll in installation tool, by the environmental impact

crushing object and surface uneven will jump a wide

range, in addition to the design of double roller to

test the instability caused by the operation object,

also need to take into account the dynamic balance

roll itself, otherwise it will directly affect the normal

use of the equipment or service life.

3.1 Processing and assembling of

double knives

Double roll pineapple stem leaf shattering and

returning machine has before and after the

installation of knife knife knife knife stick

installation, processing and assembly process to

consider the radial and axial double precision, and

ensure that the static and dynamic balance of the

single roll.

Roll design before considering the cutters and

stick the assembly simulation test calibration, modal

analysis shows that the knife roller of the first 5

natural frequencies in the range of 0.0018 ~

0.0163Hz can effectively avoid the inherent

frequency of the knife roller, so far, to ensure that

the high-speed operation of the knife roller is

reliable, then processing and installation. Simulation

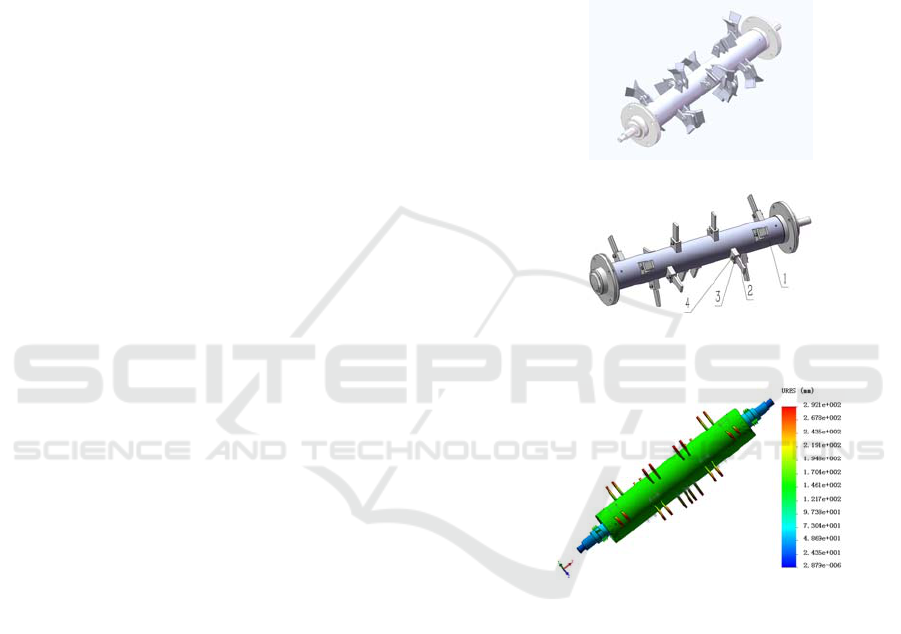

results are shown in Figure 4 (a, b, c).

4a Model diagram of front roller

1.After roller 2.Straight Knife 3.Straight Knife base

4.Bolt group

4b Model diagram of after roller

4c Analysis chart of modal at roller

Figure 4: Model and modal analysis diagram of knife

stick.

At the same time, the installation of the stick is

balanced by the balance of the shaft, and the

processing and installation are shown in Figure 5 (a,

b, c) (Zhang Yuan, 2017; Ou Zhongqing, 2017; Li

Ling, 2014).

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

618

5a Machining chart of knife stick + cutter seat

5b Tool bar + knife seat + blade machining map

5c Installation diagram

Figure 5: Tool roll processing and installation drawing.

3.2 Dynamic balance test of double

knives

Double roll pineapple stem leaf shattering and

returning machine balancing using HSC type China

Guangdong Foshan Shunde electric machinery

industry limited company to test the dynamic

balancing machine, the 75g standard balance

principle, the detection process marked with

standard magnet after welding of metal materials by

way of balance. The detection process is shown in

Figure 6 (a, b).

6a Machine effect

6b Detection page

Figure 6: Tool roll test process diagram.

3.3 Test result of whole machine index

The whole machine test of two roller pineapple stem

and leaf crushing and returning machine is carried

out in Xuwen County, Zhanjiang City, Guangdong

province (Tang Ningning, 2017; You Jiahan, 2017).

The demonstration base of the 100 mu

demonstration area of continuous pineapple

mechanization and crushing is returned, and the

relevant test results are shown in Table 1.

Table 1: Detection index and results.

index result

Productivit

y

(

h

m

2

/h

)

0.25

Fuel consumption

(

k

g

/h

m

2

)

16.12

S

p

rinkle evenness

(

%

)

0.59

stabilit

y

(

%

)

89.4

Pineapple Leak out of the ground

p

ass rate

(

%

)

92.4

Pinea

pp

le leaf smash

p

ass rate

(

%

)

98.9

Broken broken rate

(

%

)

0

Mean time to failure( h) 3.4

Visual vibration situation normal

Crushing Machine and Double Roll Balancing Test in Pineapple Stems and Leaves

619

From table 1 shows: pineapple leaf crushing pass

rate stable at 98.9%, pineapple head leakage height

pass rate stable at 92.4%, stability is 89.4%;

throwing non-uniformity and the average time was

0.59 and 3.4h, high working reliability of the whole

machine, meet the actual operation requirements and

design requirements.

4 CONCLUSIONS

A. double roller type structure of pineapple leaf

shattering and returning machine, using Daogun

double L thickening and flail Daogun after opening

with the knife edged, together with fixed cutters in

full consideration and dynamic balance of radial and

axial positioning, can effectively increase the

pineapple leaves into the crushing cavity after being

hit, cutting and two times the number of pieces,

achieved a crushing to the agronomic requirements,

effectively solved by repeated operation of soil

compaction and low production efficiency and

energy consumption of higher multiple tasks (Wang

Ruili, 2017).

B. test showed that after crushing and returning

machine dynamic balance detection after calibration,

pineapple leaf crushing pass rate stable at 98.9%,

pineapple head leakage height pass rate stable at

92.4%, stability is 89.4%; throwing non-uniformity

and the average time was 0.59 and 3.4h, the work

showed high reliability, meet the actual operation

needs.

ACKNOWLEDGEMENTS

This work was financially supported by the Central

Public-interest Scientific Institution Basal Research

Fund for Public Welfare Research and Capacity

Building of Guangdong Province

(2017A02028011);Science and Technology Program

special of Zhanjiang City(2015A03020);Chinese

Academy of Tropical Agricultural

Sciences(1630132017003);Collaborative innovation

and platform environment construction special of

Guangdong Province (2017A040406003).

I would like to thank the members of the

research group for their selfless help, especially the

communication author Zhang Yuan,and the friendly

farms in Guangdong Province for the project test of

strong support.

REFERENCES

Zhang Guo,Dai Fei,Zhao Hong.etc.Residue usage and

farmers' recognition and attitude toward residue

retention in China's croplands[J].Journal of Agro-

Environment Science.2017(5):981-988.

Ou Zhongqing,Zhang Jin,Li Ling.etc.Development Status

and Analysis of Pineapple Stem and Leaf Crushing

Backyard in Our Country[J].Agricultural

knowledge.2017(6):6-8.

Zhang Yurong.Mechanized straw crushing and returning

of crop stalks[J].Modern Agricultural

Equipments.2017(3):43-47.

Xie Yanmin.Application Analysis of Mechanized Straw

Crushing to Soil

Technology[J].JIANGXINONGYE.2017(12):42.

Cui Zhende,Zhang Jin,Ou Zhongqing.etc.Virtual design

and simulation of field pineapple stem-leaf chopper

based on SolidWorks[J].Guangdong Agricultural

Sciences.2013(19):193-196.

Zhang Yuan,Ou Zhongqing,Cui Zhende.etc.Design and

experiments of Pineapple leaf shattering and returning

machine[J].Journal of Agricultural Science and

Technology.2017,19(7):78-86.

Ou Zhongqing,Zhang Yuan,Cui Zhende.etc.The Pineapple

Leaves Crushed into the Field of Technology and the

Effect of Comparative Analysis[J].Modern

Agricultural Equipments.2017(3):43-47.

Li Ling,Zhang Jin,Ou Zhongqing.etc.Technology and

Birotor Equipment Design of Returning Pineapple

Leaves[J].Hubei Agricultural Sciences.2014(19):4075-

4047,4011.

Tang Ningning,Li Yue,Liang Dong.etc.The Design and

Optimizing on Flail Knife of Horizontal Banana Straw

Crushing-returning Machine[J].Journal of agricultural

mechanization research.2017(4):107-111,116.

You Jiahan,Chen Xuegeng,Zhang Benhua.etc.Design and

experiment of 4JSM-2000 type combined operation

machine for cotton stalk chopping and residual plastic

film collecting[J].Transactions of the Chinese Society

of Agricultural Engineering.2017(10):10-16.

Wang Ruili,Yang Peng,Rabiu.etc.Design and experiment

of combine machine for deep furrowing, stubble

chopping, returning and burying of chopped

straw[J].Transactions of the Chinese Society of

Agricultural Engineering.2017(5):40-47.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

620