Evaluating the Environmental Impacts of Pavement

Maintenance Strategies Based on Life Cycle Assessment

P Wu

1

, S M Paik

1

, Q Li

2

and X Wang

1

1

Corresponding Author, The Australasian Joint Research Centre for Building

Information Modelling, Curtin University, Kent Street, Bentley, WA6102, Australia

2

Main Roads Western Australia, Don Aitken Centre, Waterloo Cres, East Perth, WA

6004, Australia

Corresponding author and e-mail: Peng.wu@curtin.edu.au

Abstract. The concept of sustainable development calls for a change of the way about how

projects should be appropriate managed. Generally speaking, maintenance management, as an

integral part of the whole life cycle asset management, are well developed based on cost

effectiveness and performance improvement. Due to the rising recognition of environ mental

and social concerns, there is a need to include sustainability into the maintenance

manage ment of road projects. This paper will innovatively evaluate the environmental impact

of road pavement maintenance strategies in Australia through life cycle assessment. Eight

pavement maintenance strategies, from asphalt replacement to slurry seal, are investigate d.

The results show that 2.15 to 9.92 kg CO

2

e/m

2

can be generated by maintenance strategies at

the project level. Maintenance stage has relatively low impact on carbon emissions when

compared to the construction stage. However, at the network level, the annual monetary value

of the carbon emissions from maintenance strategies is estimated to be A$3.27 million, which

is significant when compared to the maintenance budget. The results offer useful insights for

road authorities to report their performance on sustainability and make relevant maintenance

decisions.

1. Introduction

Global climate change has been recognized one of the biggest threats to human development. In

order to address the challenge, environmental consideration, especially greenhouse gas emissions,

should be integrated into the decision making process of business, individuals and policy makers [1].

Many major initiatives have been developed in the building industry to address the concerns of

global climate change, e.g. the green building initiatives [2] and the carbon labelling schemes for

construction materials [3].

Road maintenance is a very large sector in Australia. The maintenance expenditure on all roads in

Australia in 2013 was A$7.8 billion [4]. The expenditure on road maintenance is expected to increase

[4]. However, the expenditure is not adequate to meet the needs of road maintenance, because

maintenance and rehabilitation activities can be very resource-intensive [4]. It is forecasted that with

the annual reduction of 15% of maintenance funds, a shortfall of A$17 billion can be expected for

road maintenance in Australia between 2010 and 2014 [4]. As such, how to effectively conduct

38

Wu, P., Paik, S., Li, Q. and Wang, X.

Evaluating the Environmental Impacts of Pavement Maintenance Strategies Based on Life Cycle Assessment.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 38-45

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

maintenance, such as selecting maintenance strategies and allocating maintenance funds, is

imperative for Australian road authorities.

Road maintenance has been a well-studied research area, especially in using deterioration

modelling techniques to predict the pavement performance [5]. Traditional maintenance management

decisions are based on the deterioration models, as well as the life cycle cost of various maintenance

strategies. For example, four major maintenance strategies, including rehabilitation, overlay,

Microsurfacing and slurry seal are investigated in [5]. A network-level budget allocation program

was also developed to optimize two indicators, including pavement performance improvement and

budget utilization [6]. It should be noted that as sustainability becomes a rising concern, it is

important to understand other aspects of road maintenance, such as the environmental impact of road

maintenance activities and effectively integrate these aspects into the maintenance management

framework.

It is widely acknowledged that maintenance activities should be conducted before road assets

deteriorate to achieve long-term performance. Many studies have therefore been conducted on

evaluating the deterioration of road pavement. Generally, the deterioration models have been well

developed. For example, Markov model has been widely used for deterioration forecasting and

performance under the curve can be used as an indicator of the improvement potential of pavement

strategies [7].

Over the past few years, a few other important indicators to evaluate the effectiveness of

maintenance strategies have also been developed. The environmental impacts of various maintenance

activities can be quite different because the inputs of these activities, such as resources and the use of

equipment, vary significantly. Life cycle assessment, which is a method to evaluate the

environmental outputs of products or processes based on the inputs, can be adopted [8]. A few

commonly adopted system boundaries, i.e. the life cycle stages that are included in the assessment,

are cradle-to-grave, cradle-to-gate and gate-to-gate. Cradle-to-grave refers to the full life cycle stages,

starting from raw materials extraction to final disposal. Cradle-to-gate refers to the life cycle stages,

starting from raw materials extraction to the point when the product leaves the production factory. In

addition, gate-to-gate refers to the life cycle stages within an organization, such as manufacturing

company or supplier. The assessment procedure has four stages, including scope definition, life cycle

inventory analysis to list all inputs (i.e. resources) and outputs (i.e. environmental impacts), impact

assessment to convert inputs to outputs, and interpretation [9].

Eight pavement maintenance strategies are investigated in this paper, including:

ASDG - Dense graded asphalt overlay/replacement. This strategy is related to the use of

asphalt replacement. The activities include asphalt mixing, paving and compacting. The

equipment used in this strategy include asphalt mixing plant, asphalt paver and asphalt

compactor. The depth of the asphalt replacement in this strategy is 30mm.

ASIM – Intersection mix asphalt overlay/replacement. Similar with ASDG, this strategy

is related to the use of asphalt replacement and the depth of the replacement is 40mm.

ASOG – Open graded asphalt replacement. Similar with ASDG, this strategy is related to

the use of asphalt replacement and the depth of the replacement is 30mm.

ASRS – Structural asphalt work. A full depth asphalt (150mm) will be replaced every 50

years and 5% of road placed will need patching and repair every 50 years.

GrOL – Granular overlay. This strategy refers to granular overlay with spray and seal.

RipSeal – RipSeal includes a 150mm cement stabilization, 50mm gravel placement and a

seal of 10mm.

Slurry – Slurry/micro surfacing. This strategy is cold mix surface treatment, including a

3-20mm layer of in-situ mixture of aggregate, bitumen, adhesion agents, water and

cement.

Evaluating the Environmental Impacts of Pavement Maintenance Strategies Based on Life Cycle Assessment

39

CS – Surface dressing. This strategy refers to simple repair or patching by spraying

bitumen on a road surface followed by the spreading of a layer or layers of aggregates.

This paper therefore aims to: 1) investigate the environmental impact, in terms of carbon

emissions value, of maintenance activities adopted in Australia; and 2) integrate the environmental

impact of maintenance activities into the decision making process, such as selecting opt imal

maintenance activities.

2. Research method

The life cycle assessment approach is adopted to evaluate the environmental impacts of the eight

maintenance strategies. The system boundary of the assessment is shown in Figure 1.

Figure 1. The system boundary of the life cycle assessment study.

As can be seen from Figure 1, this study includes the extraction of raw materials and on-site

maintenance activities, but excludes the transportation of raw materials from manufacturing plants to

sites, as well as end-of-life treatments. The analysis of the transportation stage requires an estimation

of the average transportation distance, on which future studies can help improve the estimation

accuracy. The end-of-life treatments involve many uncertainties related to the treatment strategies.

These two stages are therefore excluded from this study.

In addition, the functional unit of this study is one square meter of pavement. The Greenhouse

Gas Assessment Workbook for Road Projects [10] and the World Bank’s study on greenhouse gas

emissions mitigation [11] are referred to as the main sources for emission factors. The general

equation to estimate the carbon emissions is:

C = EF x Q

Where: C refers to the amount of carbon emissions; EF refers to the emission factors of various

sources, such as material usage and equipment usage; and Q refers to the quantity of the usage.

2.1. Emission factors

Four commonly adopted construction materials in these maintenance treatment strategies are asphalt,

crushed aggregate, gravel and cement. The emission factors of the four types of materials are based

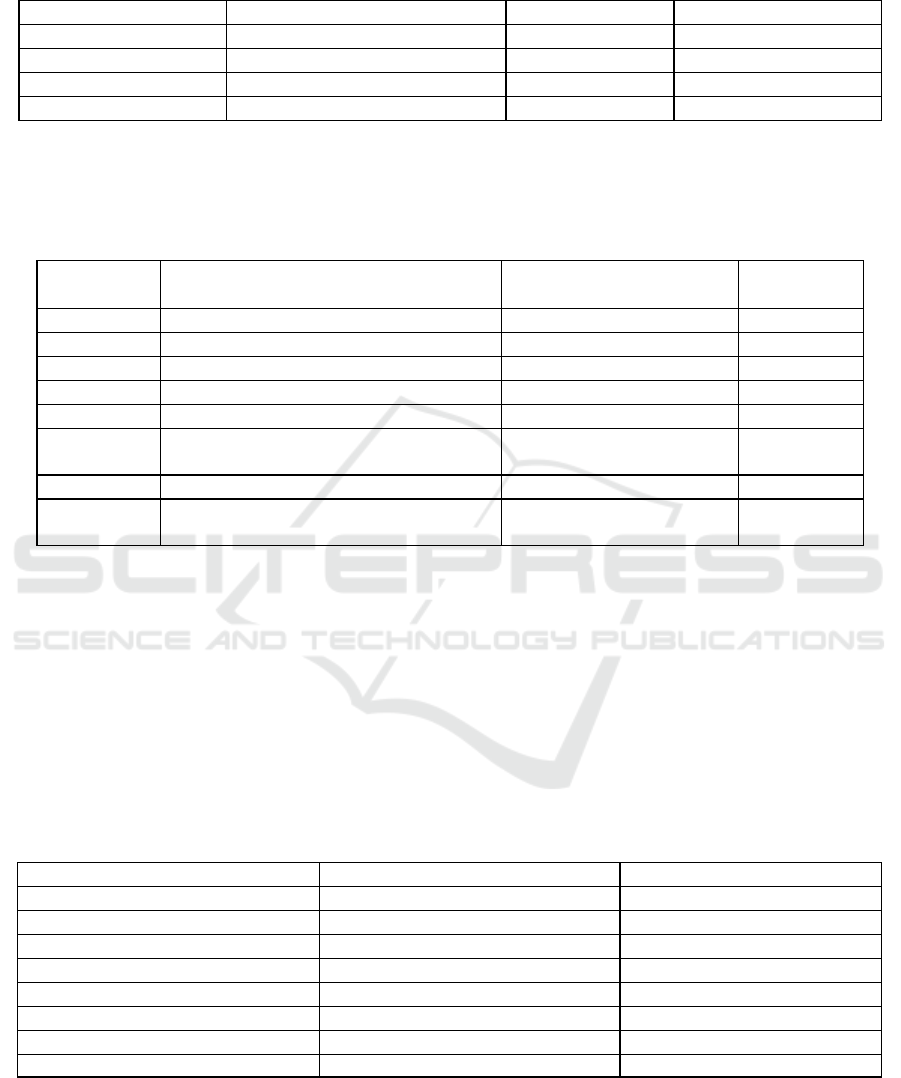

on [10] and listed in Table 1.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

40

Table 1. The emission factors of construction materials required in road maintenance.

Materials

Boundary

Unit

Emission factors

Bitumen

Mine to end-of-production

t CO

2

-e/t

0.630

Crushed aggregate

Mine to end-of-production

t CO

2

-e/t

0.005

Gravel (sand)

Mine to end-of-production

t CO

2

-e/t

0.003

Cement

Mine to end-of-production

t CO

2

-e/t

0.820

In addition, the emission factors of equipment usage in maintenance activities are calculated,

following the recommended factors in [10], [11] and [12]. The emission factors are listed in Table 2.

Table 2. The emission factors of equipment usage in road maintenance.

Materials

Technical specifications

Emission factors or fuel

consumption

References

ASDG

Asphalt replacement (30mm)

6.313 L/ m

3

[11]

ASIM

Asphalt replacement (40mm)

6.313 L/ m

3

[11]

ASOG

Asphalt replacement (30mm)

6.313 L/ m

3

[11]

ASRS

Full depth asphalt replacement

4.3 x 10-4 KL/ m

2

(Diesel)

[10]

GrOL

Granular + spray and seal

0.19 L/ m

3

[11]

RipSeal

150mm cement stabilization, 50mm

gravel + 10mm seal

0.31 L/ m

3

[11]

Slurry

30mm layer of in-site mixture

2.87kg CO

2

-e/ m

2

[12]

CS

Spraying bitumen followed by a layer

of aggregates

1.00kg CO

2

-e/ m

2

[12]

3. Results

Based on the information provided Main Roads Western Australia, there are 5,007 road sections

which have gone through maintenance in 2016. Table 3 presents the treatment areas and number of

road sections under each treatment strategy. As can be seen from Table 3, the most commonly

adopted treatment strategy is surface dressing with 2,980 road sections. Other commonly used

strategies include dense graded asphalt overlay/replacement (ASDG) with 1,077 road sections,

ripseal with 261 road sections and intersection mix asphalt overlay/replacement (ASIM) with 254

road sections. Table 4 shows the material consumption rate and cost of the eight maintenance

strategies.

Table 3. Background information of the 5,007 road sections under maintenance.

Treatment types

Treatment areas (m

2

)

No. of road sections

ASDG

120-107,008

1077

ASIM

78-38,717

254

ASOG

198-98,719

136

ASRS

82-14,672

42

GrOL

84-88,386

169

RipSeal

108-160,066

261

Slurry

270-160,621

88

CS

22-284,520

2980

Evaluating the Environmental Impacts of Pavement Maintenance Strategies Based on Life Cycle Assessment

41

Table 4. The unit cost and material consumption of maintenance strategies.

Treatment

types

Bitumen

(L)

Crushed

aggregate (m

3

)

Gravel

(m

3

)

Cement

(kg)

Unit cost

(A$/m

2

)

ASDG

3.6

0.03

0

0

52.07

ASIM

4.8

0.04

0

0

60.00

ASOG

3.6

0.03

0

0

48.00

ASRS

12

0.1

0

0

138.00

GrOL

1.8

0.0014

0

0

70.00

RipSeal

1.92

0.02

0

0.064

47.00

Slurry

1.8

0.0014

0.05

4.95

12.00

CS

1.8

0.0014

0.15

4.95

5.99

Based on the emission factors presented in Table 1 and Table 2, the carbon emission values of one

functional unit (i.e. one square meter of pavement treatment) under the eight treatment strategies are

presented in Table 5. As can be seen from Table 5, the carbon emissions value of different treatment

strategies vary significantly. Full asphalt replacement (ASRS) has the highest value of carbon

emissions (9.92 kg CO

2

e/ m

2

) due to its high amount of material usage, contributing to 87.5% of the

overall carbon emissions generated. On the other hand, other pavement maintenance strategies, such

as surface dressing and ASDG, have relatively low carbon emissions value, due to the low amount of

material usage. The contribution of material usage to the overall carbon emission values varies from

34.2% (for slurry seal) to 99.3% (GrOL).

Table 5. Emissions of different pavement treatment strategies.

Treatment

types

Emissions

from

extraction

(kg

CO

2

e/m

2

)

Equipment

usage

(l/m3)

Emissions

from

equipment

(kg

CO

2

e/m

2

))

Total

emissions

(kg

CO

2

e/m

2

)

Environmental

cost (A$/m

2

)

Percentage

(%)

ASDG

2.60

6.313

0.55

3.15

0.08

0.16

ASIM

3.47

6.313

0.73

4.20

0.11

0.18

ASOG

2.60

6.313

0.55

3.15

0.08

0.17

ASRS

8.68

Not needed

1.24

9.92

0.26

0.19

GrOL

6.22

0.190

0.08

6.30

0.16

0.23

RipSeal

5.55

0.310

0.04

5.59

0.14

0.31

Slurry

1.49

Not needed

2.87

4.36

0.11

0.94

CS

1.15

Not needed

1.00

2.15

0.06

0.93

4. Discussions

Global climate change has been recognized as an emerging issue that should be integrated in decision

making [13]. The issue has already re-shaped the decision making process of many areas. For

example, sustainability has been integrated into the decision making system of selecting structural

materials [14], including concrete [15] and precast components [16]. As road agencies are now under

increasing pressure to report their performance against environmental sustainability criteria, it is

important that the environmental emissions of road maintenance activities are accurately and

transparently reported [17].

The results of the study indicate that different maintenance strategies have different carbon

emission values when being implemented. The results are useful when making relevant maintenance

management decisions, especially when considering the impact of potential carbon tax [3]. In 2011,

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

42

the Australian government introduced the carbon tax as an effective measure to achieve the emission

reduction target. Although the carbon tax was abolished in 2014, it provides a useful indicator of the

monetary value of carbon emissions in Australia. A carbon tax of A$23 per tonne of carbon dioxide

was charged by the Australian Government. An inflation of 2% is assumed to calculate the carbon

tax at the time of this study. Based on the carbon tax of A$23 and an inflation of 2%, the carbon tax

of Australia in 2017 is calculated to be A$25.90.

The monetary values of emissions from maintenance strategies are shown in Table 5. As can be

seen in Table 5, the monetary value of carbon emissions of maintenance strategies are relatively low

when compared with the unit cost of the maintenance treatment. The average percentage values vary

from 0.16% to 1%. It appears that the environmental cost of the maintenance stage is relatively low

when compared to the construction stage. A hybrid input-output analysis was conducted to

investigate the energy consumption of road construction [18]. The results show that the embodied

energy of concrete road construction is 27.2GJ/m. Based on the emission factors provided by IPCC

[19], the estimated carbon emissions from the construction stage of road projects is 251.9 kg CO

2

/m

2

(assuming that the average treatment width is 8m, based on the 5,007 road sections in this study).

5. Conclusions

This study uses the process life cycle approach to investigate the carbon emissions of eight

maintenance strategies in Australia. The results indicate that the carbon emission values from

maintenance are relatively low when compared to the construction stage. Road maintenance can lead

to emissions from 2.15 to 9.92 kg CO

2

e/m

2

, which is around 1% of the emissions from construction.

As such, it can be usefully concluded that for a single and non-repeating road maintenance project,

maintenance strategies have relatively low impact on the carbon emission values of the project at a

specific time. However, it should be noted that the life cycle performance of maintenance strategies

should be investigated as the strategy can happen multiple times in the road project’s life cycle. In

addition, the carbon emission values at the network level is not an insignificant number to be

overlooked. For the 5,002 road sections, the annual emission value is 126,295 tonne CO

2

e, which is

equivalent to A$3.27 million. As sustainability has been an emerging issue for all industries,

including the building industry [19, 20, 21] and the infrastructure and urban planning [22, 23], it is

extremely important that the environmental impact is included in the decision making process.

It should, however, be noted that the emission values calculated in this study are based on a single

and non-repeating cycle. In real life cases, a life cycle consideration of maintenance strategies should

be conducted. In addition, this study does not evaluate the strategies that can be used to mitigate

carbon emissions. Useful methods, such as the lean philosophy [24] and carbon labelled materials [17,

25] can be tested and evaluated.

Acknowledgement

This research was funded by the Australian Research Council Discovery Early Career Researcher

Award (Project No. DE170101502) by the Australian Government.

References

[1] Zhong Y and Wu P 2015 Economic sustainability, environmental sustainability and

constructability indicators related to concrete-and steel-projects Journal of Cleaner

Production 108 748-756

[2] Wu P, Song Y, Shou W, Chi H, Chong H Y and Sutrisna M 2017 A comprehensive analysis of

the credits obtained by LEED 2009 certified green buildings Renewable and Sustainable

Energy Reviews 68 370-379

[3] Wu P, Xia B, Pienaar J and Zhao X 2014 The past, present and future of carbon labelling for

construction materials–a review Building and Environment 77 160-168

Evaluating the Environmental Impacts of Pavement Maintenance Strategies Based on Life Cycle Assessment

43

[4] Infrastructure Australia 2015 Infrastructure maintenance a report for infrastructure Australia

Available from: http://infrastructureaustralia.gov.au/policy-

publications/publications/files/GHD-Infrastructure-Maintenance.pdf (cited 25 Aug 2017)

[5] Giustozzi F, Crispino M and Flintsch G 2012 Multi-attribute life cycle assessment of

preventive maintenance treatments on road pavements for achieving environmental

sustainability The International Journal of Life Cycle Assessment 17 409-419

[6] Gao L, Xie C, Zhang Z and Waller S T 2012 Network‐Level Road Pavement Maintenance

and Rehabilitation Scheduling for Optimal Performance Improvement and Budget

Utilization Computer

‐

Aided Civil and Infrastructure Engineering 27 278-287

[7] Kobayashi K, Kaito K and Lethanh N 2012 A statistical deterioration forecasting method using

hidden Markov model for infrastructure management Transportation Research Part B:

Methodological 46 544-561

[8] Wu P, Xia B and Wang X 2015 The contribution of ISO 14067 to the evolution of global

greenhouse gas standards—A review Renewable and Sustainable Energy Reviews 47 142-

150

[9] Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, Rydberg T, Schmidt W P, Suh S,

Weidema B P and Pennington D W 2004 Life cycle assessment: Part 1: Framework, goal

and scope definition, inventory analysis, and applications Environment international 30

701-720

[10] Transport Authorities Greenhouse Group 2013 Greenhouse Gas Assessment Workbook for

Road Projects (Sydney:GHD)

[11] World Bank 2011 Greenhouse gas emissions mitigation in road construction and

rehabilitation: a toolkit for developing countries (Washinton: The International Bank for

Reconstruction and Development)

[12] Spray A, Parry T and Huang Y 2014 Measuring the carbon footprint of road surface treatments

A report published by the Pavement Research Centre at the University of California, Davis.

[13] Villoria S P, Tam W Y V, Merino, Del R M, Arrebola, C V and Wang X 2016 Effectiveness of

greenhouse-gas emission trading schemes implementation: a review on legislations,

Journal of Cleaner Production 127 49-58

[14] Zhong Y, Ling F Y Y and Wu P 2016 Using Multiple Attribute Value Technique for the

Selection of Structural Frame Material to Achieve Sustainability and Constructability

Journal of Construction Engineering and Management 143(2) 04016098

[15] Wu P, Xia B and Zhao X 2014 The importance of use and end-of-life phases to the life cycle

greenhouse gas (GHG) emissions of concrete–a review Renewable and Sustainable Energy

Reviews 37 360-369

[16] Wu P and Low SP 2011 Managing the embodied carbon of precast concrete columns Journal

of Materials in Civil Engineering 23(8) 1192-1199

[17] Wu P, Low S P, Xia B and Zuo J 2014 Achieving transparency in carbon labelling for

construction materials–Lessons from current assessment standards and carbon labels

Environmental Science & Policy 44 11-25

[18] IPCC 2006 IPCC guidelines for national greenhouse gas inventories: volume 2: energy

Available from: http://www.ipcc-

nggip.iges.or.jp/public/2006gl/pdf/2_Volume2/V2_2_Ch2_Stationary_Combustion.pdf

(cited 04 Sep 2017)

[19] Wu P, Song Y, Wang J, Wang X, Zhao X and He Q 2017 Regional Variations of Credits

Obtained by LEED 2009 Certified Green Buildings A Country Level Analysis

Sustainability 10(1) 20

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

44

[20] Li X, Wu P, Shen G Q, Wang X and Teng Y 2017 Mapping the knowledge domains of

Building Information Modeling (BIM) A bibliometric approach Automation in

Construction 84 195-206

[21] Li X, Shen G Q, Wu P, Fan H, Wu H and Teng Y 2017 RBL-PHP Simulation of lean

construction and information technologies for prefabrication housing production Journal of

Management in Engineering 34(2) 04017053

[22] Song Y, Wang X, Tan Y, Wu P, Sutrisna M, Cheng J C and Hampson K 2017 Trends and

opportunities of BIM-GIS integration in the architecture, engineering and construction

industry A Review from a Spatio-Temporal Statistical Perspective ISPRS International

Journal of Geo-Information 6(12) 397

[23] Wang T, Wang J, Wu P, Wang J, He Q and Wang X 2018 Estimating the environmental costs

and benefits of demolition waste using life cycle assessment and willingness-to-pay A case

study in Shenzhen Journal of Cleaner Production 172 14-26

[24] Wu P, and Feng Y 2012. Using lean practices to improve current carbon labelling schemes for

construction materials—a general framework Journal of Green Building 7 173-191

[25] Wu P, Feng Y, Pienaar J, Xia B 2015 A review of benchmarking in carbon labelling schemes

for building materials Journal of Cleaner Production 109 108-17

Evaluating the Environmental Impacts of Pavement Maintenance Strategies Based on Life Cycle Assessment

45