High-temperature Creep Behavior of Al

x

CrMnFeCoNi High-

entropy Alloys

C M Cao, J Xu, Y X Hao, W Tong and L M Peng

*

CAS Key Laboratory of Mechanical Behavior and Design of Materials, Department

of Modern Mechanics, School of Engineering Science, University of Science and

Technology of China, Hefei, Anhui 230027, PR China

Corresponding author and email: L M Peng, penglm@ustc.edu.cn

Abstract. The creep deformation behavior of thermomechanically-treated Al

x

CrMnFeCoNi

(x=0.4 and 0.6) high-entropy alloys was investigated under constant tensile loadings at 600-

700 °C. It was found that the two alloys exhibited a mixed structure of fcc+bcc solid solutions

with equiaxed grains and higher Al content produced a larger volume fraction of bcc phase.

The double logarithmic plot of creep rate versus applied stress in Al

0.4

CrMnFeCoNi alloy was

divided into two distinct regions with different stress exponents and activation energies

depending on testing temperature and applied stress. In contrast, the Al

0.6

CrMnFeCoNi alloy

exhibited a single value of stress exponent without transitional features. The

Al

0.6

CrMnFeCoNi alloy showed lower creep resistance at a given stress and testing

temperature compared to Al

0.4

CrMnFeCoNi alloy, which was ascribed to the higher stacking

fault energy in the former alloy.

1. Introduction

Unlike traditional alloys that have one or two major metal elements, multi-component alloys or high

entropy alloys (HEAs) contain at least five major elements with concentration range of 5-35 at% and

have been an attractive subject as promising solid solution materials [1]. HEAs exhibit excellent

mechanical properties such as excellent wear resistance, good corrosion resistance and high-

temperature softening resistance [2-6]. The intrinsic mechanisms such as sluggish diffusion and

lattice distortion for HEAs suggest an effective heat-resistance during plastic deformation process,

especially under high-temperature performance. The single-fcc structured CoCrFeMnNi alloy has

been widely investigated due to its excellent thermodynamic stability and high toughness especially

in extreme low temperature [7]. Nevertheless, its strength and creep resistance needs to be further

improved. One of the effective approaches is to introduce a certain amount of bcc solid solution into

this alloy via adding other metal elements to obtain dual-phased microstructures. With this concept in

mind, (FeCoNiCrMn)

100-x

Al

x

alloys were recently developed and their tensile properties in cast state

were investigated at room temperature to examine the influence of microstructures [8].

Unfortunately, quite few reports have been available up to date on the high temperature creep

deformation of these alloys.

Accordingly, the aim of present study is to investigate the tensile creep behavior of

Al

x

CrMnFeCoNi high-entropy alloys. The stress exponent and activation energy for creep were

Cao, C., Xu, J., Hao, Y., Tong, W. and Peng, L.

High-Temperature Creep Behavior of AlxCrMnFeCoNi High-Entropy Alloys.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 71-76

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

71

estimated based on the power-law creep equation to examine the corresponding mechanisms

responsible for the creep deformation. The activation volume was determined to evaluate the effect

of Al on the creep resistance and the creep fracture models were discussed based on SEM

observations.

2. Experimental

The cast ingots with the nominal compositions of Al

x

CrMnFeCoNi (x=0.4 and 0.6 in molar ratio)

were fabricated by vacuum-induction melting a mixture of six pure metals (all in high purity of 99.9

wt%) in a water-cooled copper crucible. All ingots were melted at least five times to ensure chemical

homogeneity, and were drop-casted into a steel mold. The cast alloys were homogenized at 1150 °C

for 12 h in argon gas, and then rolled at 950 °C to obtain a thickness reduction of 40%. The rolled

plates were finally recrystallized at 1100 °C for 2 h. Dog-bone shaped specimens with a gauge length

of 25 mm were cut by electrical discharge machining. The tensile samples were tested on the CSS-

3905 multi-functional machine under different loadings.

The crystalline structures of the samples were identified by X-ray diffraction (XRD) (PANalytical

X’Pert Pro) with Cu-K

α

radiation at 40 kV. The microstructures were observed using an optical

microscope (OM) (AxioImager.Alm) and phase-compositional analysis were conducted using an

energy dispersive spectroscope (EDS). For microstructural observation, samples were initially

polished to 2500-grit SiC paper and, subsequently, etched with a solution composed of hydrogen

peroxide and hydrochloric acid.

3. Results and discussions

3.1. Microstructures and XRD diffraction analysis

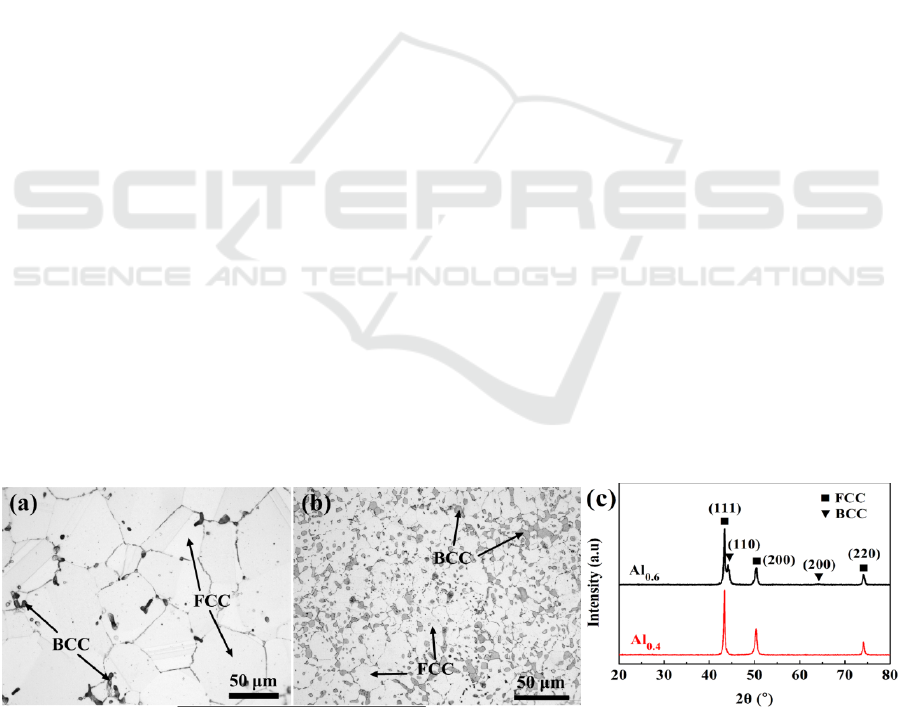

Figure 1 shows the microstructures and XRD patterns of Al

x

CrMnFeCoNi alloys (subsequently

denoted as Al

x

where x=0.4 or 0.6). Typical equiaxed grains and annealing twins are observed in the

morphologies of these alloys. The bright and dark regions located at grain boundaries are identified

as fcc and bcc phases, respectively. The volume fraction of bcc phase and the corresponding (110)

bcc

peak increase with the increase of Al concentration. The chemical compositions of phases measured

by EDS are summarized in the Table 1. It is worth noting that Mn is homogeneously distributed in

both fcc and bcc phases and bcc phase is enriched in Al and Ni, which is attributed to the mixing

effect of enthalpies. The enthalpies of Cr-, Mn-, Fe-, Co- and Ni-Al are -10, -19, -11, -19 and -22

kJ/mol [9], respectively. Accordingly, Ni, not Cr and Fe tend to diffuse to bond with Al, leading to

the formation of Ni-Al-rich bcc phase. In addition, the grain size of fcc phase for Al

0.6

is smaller

compared to that of Al

0.4

as the grain-boundary bcc phases can hinder the growth of fcc phase.

Figure 1. Microstructures of (a) Al

0.4

CrMnFeCoNi alloy and (b) Al

0.6

CrMnFeCoNi alloy, and (c)

XRD patterns.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

72

Table 1. Chemical compositions of Al

x

HEAs obtained by EDS.

Alloys Crystal Chemical compositions/at. %

Al C

r

Mn Fe Co Ni

Al

0.4

Overall 6.42 19.50 18.72 18.81 17.58 18.97

FCC 6.05 19.92 18.64 19.55 17.65 18.34

BCC 22.95 6.00 18.15 7.41 12.02 33.48

Al

0.6

Overall 9.71 18.70 17.86 17.97 17.82 17.93

FCC 6.89 20.81 18.06 20.00 18.66 15.59

BCC 24.12 7.09 16.62 8.15 14.71 29.33

3.2 Creep deformation

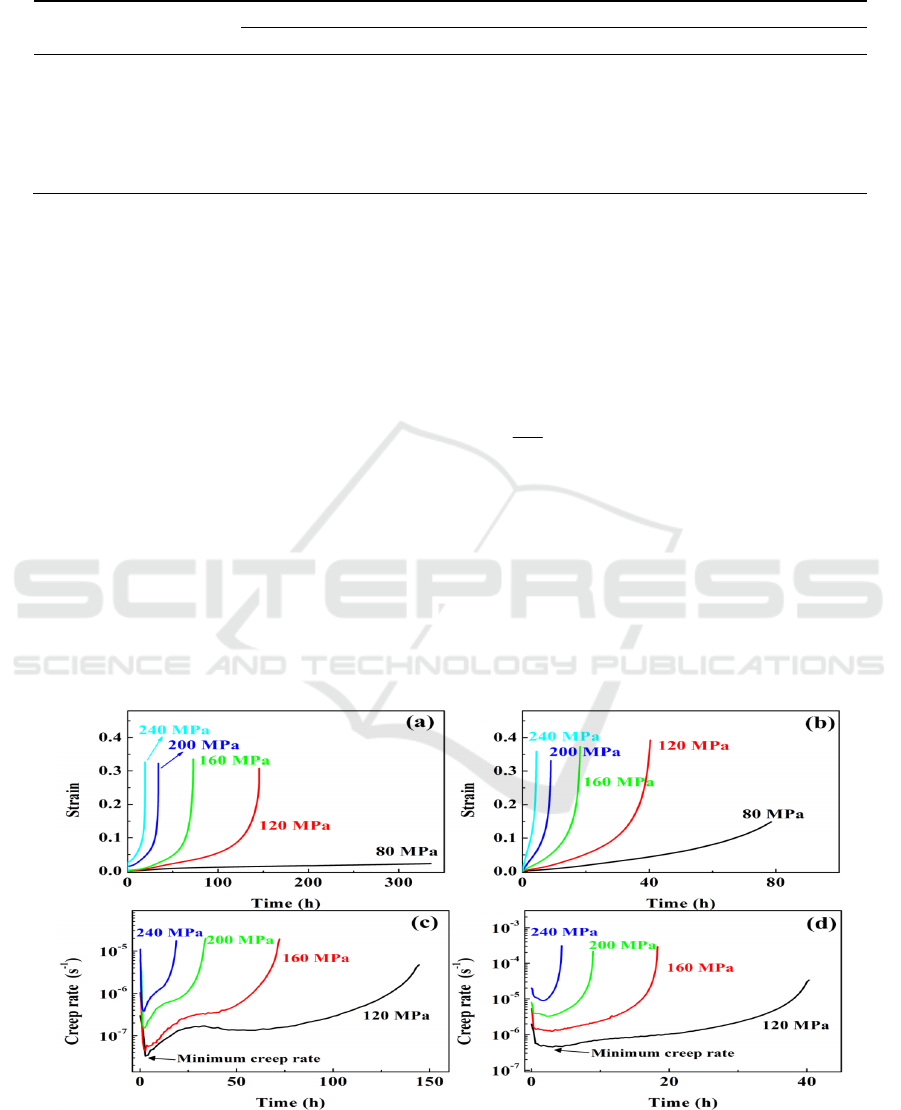

Figure 2 exhibits the variations of creep strain and creep rate with testing temperature of Al

0.4

and

Al

0.6

alloys at 650 ºC. It is found that Al

0.6

shows a higher creep rate than Al

0.4

at a given temperature

and stress. The creep deformation at the minimum creep rate held a short duration especially under

higher applied stresses. In this case, the minimum creep rate is taken as the steady-state creep rate

ε

&

,

and usually used to evaluate the creep behavior by correlating with the applied stress

σ

based on the

Arrhenius-type equation [10]:

)exp(

R

T

Q

A

n

−=

σε

&

(1)

Where

A

is a material-dependent constant,

σ

is the applied stress,

n

is the stress exponent, and

Q

is the

activation energy for creep deformation. As shown in Figure 3, the stress exponents were determined

by plotting the variation of the steady-state creep rate with the applied stress on double logarithmic

scales. It is found that the exponents of Al

0.4

at 650 ºC and 700 ºC exhibit a stress-dependent

transition with two distinct stress regions, i.e. low-stress region I with

n =1.6-2.2 and high-stress

region II with

n

=4.2-4.9, indicating a transition of rate-controlling mechanisms. In contrast, Al

0.6

shows no transition in the stress exponents, with a single value of 5.8 at 600 and 2.8-3.5 at 650-700

ºC.

Figure 2. Creep curves at 650 ºC for (a) Al

0.4

and (b) Al

0.6

alloys, and creep rate curves at 650 ºC for

(c) Al

0.4

and (d) Al

0.6

alloys at selected loadings.

High-Temperature Creep Behavior of AlxCrMnFeCoNi High-Entropy Alloys

73

Figure 3. Steady state creep rate as a function of the applied stress on a double logarithmic plot for

(a) Al

0.4

and (b) Al

0.6

alloys.

Based on equation (1), the activation energy was estimated by plotting the steady-state creep rate

against

1/T

at constant stresses on a semi-logarithmic scale as depicted in Figure 4. The average

values of activation energy for region I and II are calculated as 258 and 349 kJ mol

-1

, respectively,

which are close to that of steady-state flow of FeCoNiCrMn alloy (

284–333 kJmol

-1

) [10]. In

contrast, the average activation energy at 650-700 ºC is 188 kJ mol

-1

.

Figure 4. Arrhenius plot of steady-state creep rate versus temperature to determine the activation

energy of (a) Al

0.4

CrMnFeCoNi alloy and (b) Al

0.6

CrMnFeCoNi alloy.

In general, it is difficult to determine which element is the contributing solute atom in the HEAs

and the activation energies for lattice diffusion of constituent elements are not available. The

activation energy of Al element is 126 kJ mol

-1

, which is much lower than those for lattice diffusion

of other constituent elements in the CrMnFeCoNi alloy (288–317 kJ mol

-1

) [11,12]. Thus, it is

reasonable to deduce that the creep deformation in these alloys is controlled by the five major

elements with high activation energy. For Al

0.4

alloy, the creep mechanism of low-stress region is

ascribed to the viscous glide of dislocations, which coincides with the previous research on the

deformation mechanism with the stress exponent of 2 in FeCoNiCrMn alloy [10]. The activation

energy of 258 kJ mol

-1

is slightly lower than that of lattice diffusion of constituent elements in the

CrMnFeCoNi alloy, suggesting that the creep rate is controlled by the diffusion of constituent

elements as the solute atoms. In the region II, the stress exponent is close to 5, suggesting a

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

74

dislocation-climb mechanism. The larger activation energy of region II compared to that of region I

is attributed to more constituent elements involved in solute atmosphere with the increase of stresses.

The activation energy of 349 kJ mol

-1

for region II is close to that of lattice diffusion of Ni (317.5 kJ

mol

-1

), indicating that the creep rate is probably controlled by the sluggish diffusing species such as

Ni. However, for Al

0.6

tested under 650-700 ºC, the activation energy of 188 kJ mol

-1

is much lower

than that of major constituent elements. It is reported that the activation energy of pipe diffusion is a

value around 0.4-0.7 times of the activation energy of lattice diffusion [13]. Considering the stress

exponent of ~3, it can be inferred that the viscous glide of dislocations controlled by pipe diffusion is

responsible for the creep mechanism in this region.

It is well known that the activation volume

*

V

as a common parameter can be employed to

analyze the deformation mechanism. This parameter is defined as [14]

σ

ε

∂

∂

=

&

ln

*

RTV

(2)

where R represents the gas constant. The

*

V values for Al

0.4

are calculated as 1.40×10

-4

, 1.48×10

-4

and 2.03×10

-4

m

3

mol

-1

for 600 ºC, 650 ºC and 700 ºC, respectively. For Al

0.6

,

*

V takes corresponding

values of 1.80×10

-4

, 1.89×10

-4

and 2.41×10

-4

m

3

mol

-1

. As a result, higher activation volume in the

Al

0.6

alloy causes a higher creep rate compared to Al

0.4

under identical testing conditions. Similar

feature have been verified in the previous investigation of the stress relaxation test on Al

x

CoCrFeNi

alloys [14].

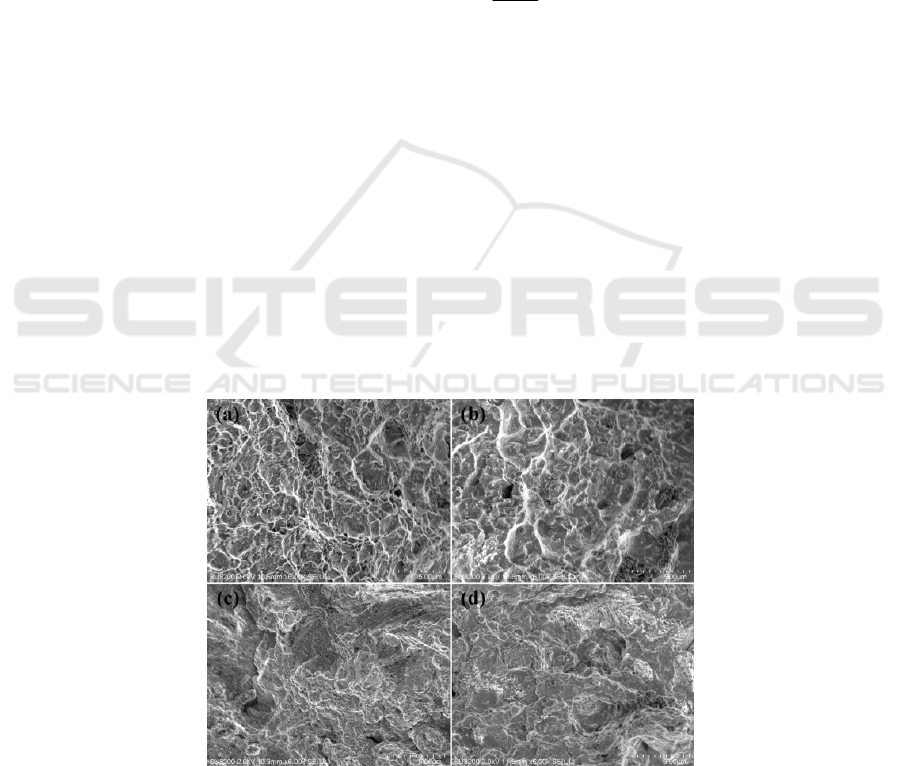

3.3. Fractographs

Fracture morphologies of the two HEAs after creep rupture were presented in Figure 5. It was

observed that the fractographs of Al

0.4

exhibited typically ductile fracture with obvious dimples,

whereas the fractographs of Al

0.6

revealed a quasi-cleavage fracture mode characterized by cleavage

surfaces and tearing ridges. It can be also noted that more oxides appear on the fracture surfaces

subjected to long-term exposure at 700 ºC.

Figure 5. Fractographs of Al

0.4

CrMnFeCoNi alloy crept at (a) 600 ºC and (b) 700 ºC, and

Al

0.6

CrMnFeCoNi alloy at (c) 600 ºC and (d) 700 ºC.

High-Temperature Creep Behavior of AlxCrMnFeCoNi High-Entropy Alloys

75

4. Conclusions

Two alloys showed equiaxed grains with fcc+bcc duplex structure, and higher Al content yields more

volume of bcc phase and finer microstructure. Two creep-deformation regions for Al

0.4

alloy are

observed. In the low-stress region, the stress exponent is about 2 and the activation energy is 258 kJ

mol

-1

. The lattice diffusion controlled dislocation-glide mechanism is operative for the creep

deformation. In contrast, the stress exponent of ~5 and the activation energy of 348 kJ mol

-1

indicate

that lattice diffusion of sluggish diffusing species controlled dislocation-climb is responsible for the

creep mechanism in the high-stress region. In the Al

0.6

alloy, stress exponents are 5.8 at 600 °C and

3.2 at 650-700 °C. The calculated activation energy of 188 kJ mol

-1

at 650-700 °C implies that the

creep deformation was dominated by dislocation glide controlled by pipe diffusion. In addition, the

Al

0.4

CrMnFeCoNi alloy with less stacking fault energy exhibits higher creep resistance compared to

Al

0.6

CrMnFeCoNi alloy. The investigated findings are important not only for understanding the

tensile creep behavior of Al

x

CrMnFeCoNi alloys, but also for future application of HEAs in high

temperature.

Acknowledgements

This work was supported by the Natural Science Foundation of China (No. 11572306) and the

Fundamental Research Funds for Central Universities (WK2090050040).

References

[1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H and Chang S Y 2004 Adv.

Eng. mater. 6 299

[2] Poletti M G, Fiore G, Gili F, Mangherini D and Battezzati L 2017 Mater. Des. 115 247

[3] Gwalani B, Ayyagari A V, Choudhuri D, Scharf T, Mukherjee S, Gibson M and Banerjee R

2018 Mater. Chem. Phys. 210 197

[4] Lin C M and Tsai H L 2011 Intermetall. 19 288

[5] Chokshi A H 2018 Mater. Chem. Phys. 210 152

[6] He J Y, Wang H, Wu Y, Liu X J, Nieh T G and Lu Z P 2017 Mater. Sci. Eng. A. 686 34

[7] Otto F, Dlouhý A, Somsen C, Bei H, Eggeler G and George E P 2013 Acta Mater. 61 5743

[8] He J Y, Liu W H, Wang H, Wu Y, Liu X J, Nieh T G and Lu Z P 2014 Acta Mater. 62 105

[9] Takeuchi A and Inoue A 2005 Mater. Trans. 46 2817

[10] He J Y, Zhu C, Zhou D Q, Liu W H, Nieh T G and Lu Z P 2014 Intermetall. 55 9

[11] Edalati K and Horita Z 2011 Scr. Mater. 64 161

[12] Tsai K Y, Tsai M H and Yeh J W 2013 Acta Mater. 61 4887

[13] Fu J X, Cao C M, Tong W, Hao Y X and Peng L M 2017 Mater. Sci. Eng. A. 690 418

[14] Cao T, Shang J, Zhao J, Cheng C, Wang R and Wang H 2016 Mater. Lett. 164 344

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

76