Simulation of Compression Properties of Pyramidal

Sandwich Panels of TC4 Titanium Alloy

H Wang

1

, K X Zhao

1

, B Zhao

2

, X R Chu

1

and J Gao

1, *

1

School of Mechanical, Electrical&Information Engineering, Shandong University,

Weihai, Weihai 264209, Shandong, China;

2

Beijing Aeronautical Manufacturing Technology Research Institute, Beijing 100024,

China

Corresponding author and e-mail: J Gao, shdgj@sdu.edu.cn

Abstract. As a functional structural material, the mechanical properties determine the

application of three-dimensional lattice structure. The panel thickness, core plate thickness,

ribs width, and unit size affect the mechanical properties of the pyramid lattice structure. In

this work, to give guidance for the design of pyramid lattice structure, the influences of the

above factors were studied through numerical simulation.

1. Introduction

As a new type of sandwich material, the key consideration of three-dimensional lattice structure in its

application is the mechanical properties. The static characteristics of three-dimensional lattice

structures mainly include flat compression, shear and bending. According to the experimental results,

the failure mechanism mainly includes panel wrinkling, core buckling and joint shedding and so on.

The mechanical properties of 6061 aluminum alloy tetrahedron lattice structure are tested by

Kooistra [1]. It is proved that the lattice structure of aluminum alloy tetrahedron is superior to that of

aluminum foam. In order to improve the stability of nodes, Queheillalt [2] proposed a pyramid

structure with node plane. Xue [3] and Yungwirth [4] have studied the ability of impact resistance of

three-dimensional lattice structure. It is pointed out that the energy absorption characteristics of

lattice structures are better than that of honeycomb structures when the impact energy is high. Bele [5]

and Bouwhuis [6]

used finite element simulation to optimize the molding process for aluminium

alloy pyramid core, and optimized the forming process. Numerical simulation is carried out to study

the free vibration problems of AISI 304 stainless steel sandwich beams with pyramidal truss core by

Lou [7] and the results are compared with theoretical solutions, it is found that theoretical solutions

agree well with numerical results. The vibration characteristics of the composite pyramidal truss core

sandwich plate with multiple piezoelectric actuator/sensor pairs were examined in the study by Li et

al.[8] Founded that the vibration level of the composite pyramidal truss core sandwich panel can be

effectively suppressed through the proposed piezoelectric actuator/sensor pairs using the velocity

feedback control and LQR control methods.

Wang, H., Zhao, K., Zhao, B., Chu, X. and Gao, J.

Simulation of Compression Properties of Pyramidal Sandwich Panels of TC4 Titanium Alloy.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 107-114

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

107

In this work, in order to give guidance for the design of the pyramid lattice structure, the

influences of panel thickness, core plate thickness, ribs width, and unit size on the compression

properties were studied numerical simulation.

2. Numerical simulation of compression properties

Pyramid lattice is a periodically distributed truss structure. The single-core modelling is used for

numerical simulation because the force condition of each core unit is the same when a uniform

pressure load is applied.

2.1. Introduction of numerical model

Figure 1. Pyramid pressure model assembly drawing.

The numerical model of the pyramidal structure for flat press is shown in Figure 1. The core height

(including upper and lower panels) is set to 15mm. The tie constraint is used between the core and

the upper and lower panels. The lower panel is subjected to a complete fixed constraint. The upper

panel is controlled by displacement, other degrees of freedom are restricted and the down press

forming process is completed through the displacement of Z direction. The tangential friction

coefficient was set to 0.36. The density of TC4 sheet is 4.4g/cm

3

, the Poisson's ratio is 0.34, the

elastic modulus and plastic data are obtained by tensile test at room temperature. The elastic modulus

of the material is 109715 MPa.

2.2. Pyramid structure relative density calculation

The

relative density of the lattice structure refers to the ratio of the volume of the core material to the

volume of space it occupies. For the nodal depressing process, the formed core does not have a

regular geometry due to the non-uniformity of the material flow. Therefore, the calculation of relative

density will be based on the geometric parameters of pre-formed panels before forming, as shown in

Figure 2.

Figure 2. Pre-formed panels geometry figure.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

108

The area in the black wireframe shown in Figure 2 is unique to a pyramidal unit, and the nodes in

the red wireframe are shared by four units. So the volume of core material is:

=

2

2

4

D2

(1)

Where, w is rids width and R is the radius of the circular corner, D is the unit size and t

2

is the

thickness of the sheet metal.

Simplified the formula, it can be obtained:

=

82

2

4

(2)

The volume of the formed core is:

=4D

(3)

Where, D is the unit size and h is the core height.

Therefore, the formula of relative density of pyramid structure is as follows:

̅ =

(4)

2.3. Influence of structural parameters

2.3.1. Influence of Panel thickness. To study the panel thickness t

1

influence, core plate thickness t

2

,

the ribs width w and the unit size D are set to 2mm, 4mm and 20mm, respectively. The simulation

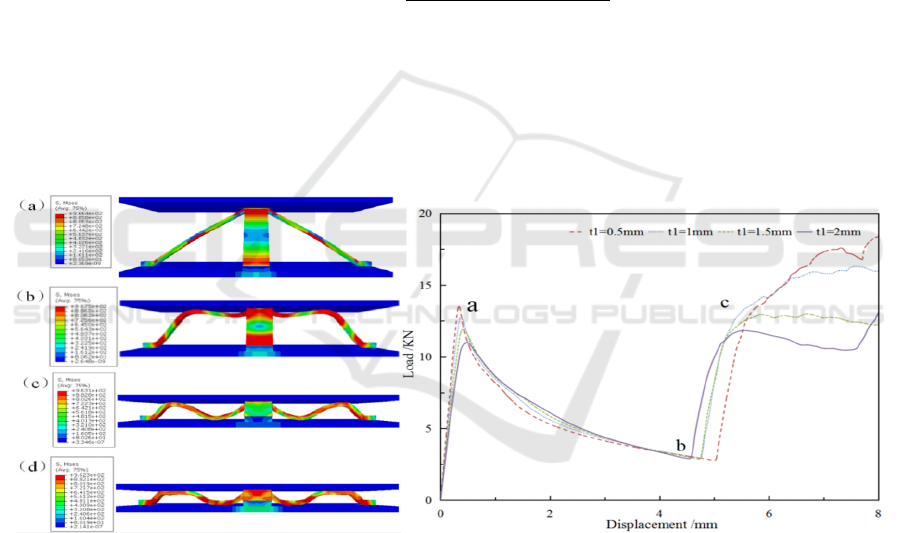

results with different panel thickness of 0.5 mm, 1 mm, 1.5 mm and 2 mm are shown in Figure 3.

Figure 3. Failure process of flat pressure and its load-displacement curve.

As shown in Figure 3, the compression process of the pyramid lattice structure can be divided into

four stages: (a) resistance to deformation, (b) buckling instability, (c) contact strengthening and (d)

densification. Corresponding to this, the flat pressure load also presents the four obvious stage

characteristics: firstly, before point a, the truss is stable and the load increases linearly (stage 0 to a);

secondly, the first plastic hinge appears at point a, truss rod buckling instability appears and the load

begins to decrease (stage a to b); thirdly, when the panel presses down to point b, the plastic hinges

contacts with the upper panel, the flat pressure load rises again, with the press continues, the plastic

hinges contacts with the lower panel, and the press load continues arising (stage b to c); finally, after

point c, the truss is completely destroyed, a large number of trusses contact with the panel occurs

which leads to the densification stage and the flat compression load increases further.

Simulation of Compression Properties of Pyramidal Sandwich Panels of TC4 Titanium Alloy

109

Usually the lattice structural failure occurs when the truss undergoes plastic yield instability and

the corresponding strength is compressive strength. The equivalent flat compressive strength formula

can be defined as:

σ=

(5)

Where, F is the peak load of plastic yield instability, D is the unit size.

The formula for calculating the equivalent modulus of flat compression is as follows:

=

⁄

(6)

Where, δ is the pressing height of linear stage and h is the original lattice height. According to

numerical simulation results and the formulas (5) and (6).

The equivalent flat compressive strength and modulus under different panel thickness are obtained

as shown in Table 1. As the thickness of the panel increases, the equivalent flat compressive strength

and modulus of the pyramidal element decrease. This is because under the condition of constant

height, the panel thickness increases and the truss rid tilt angle decreases, resulting in a reduction in

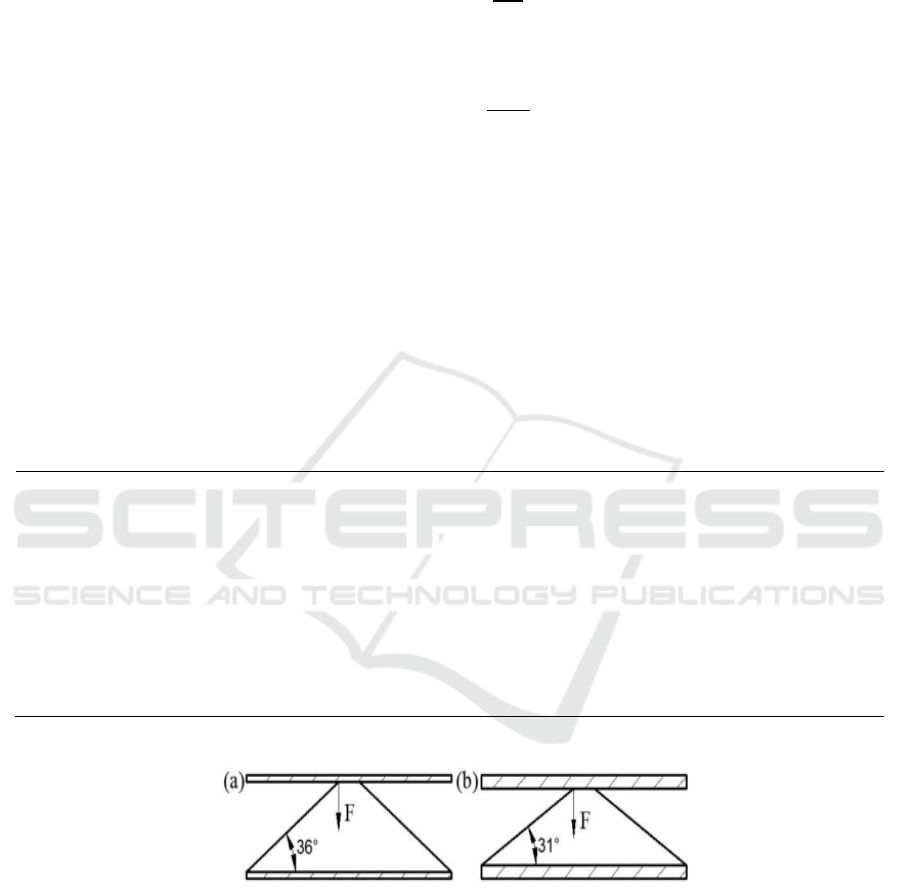

the ability of the truss rid to resist vertical downward loading. Figure 4 is the comparison of tilt

angles of truss rods for panel thicknesses of 1mm and 2mm. The larger tilt angle makes the core unit

with a panel thickness of 1 mm more efficient, resulting in a greater equivalent compressive modulus

with a lower relative density, indicating that by increasing the tilt angle, the compression

performance of the pyramid lattice can be improved.

Table 1. Equivalent flat compressive strength and modulus under different panel thickness.

Panel thickness(mm) 0.5 1 1.5 3

Relative density (%) 2.60 2.80 3.03 3.31

Equivalent flat compressive strength (MPa) 8.44 7.93 7.45 6.86

Equivalent flat compressive modulus (MPa) 379 339.9 268 209.86

Strength-to-density ratio(MPa) 3.25 2.83 2.46 2.07

Modulus-to-density ratio(MPa) 145.77 121.39 88.45 63.40

Figure 4. Effect of panel thickness on tilting angle of truss rid (a) t

1

=1mm, (b) t

1

=2mm.

2.3.2. Influence of Core plate thickness. The thickness of the panel t

1

, the width of the ribs w, and the

unit size D are set to 1mm, 4mm, 20mm, respectively and the thickness of the core plate is taken as

0.6mm, 1mm. 1.5mm, 2mm to study the influence of the core plate thickness.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

110

Figure 5. The influence of core plate thickness on the process of flat compression (a) t2=2mm, (b)

t2=0.6mm.

Figure 6. Simulation of load-displacement curve under different core plate thickness.

Figure 5 shows the comparison of stresses states during the pressing process when the core plate

thickness is 2mm and 0.6mm. It can be seen that changing the core plate thickness will affect the

failure process of the pyramidal core. When the core plate thickness is 2mm, only one plastic hinge

appears in the compression process, and the core has strong compressive resistance. When the core

plate thickness is 1mm, the core starts to have two plastic hinges. As shown in Figure 5 (b), when the

press displacement is 0.2mm, the truss quickly loses stability, two plastic hinges appear at the same

time and the ability of pressure resistance continues to decrease. In addition, double plastic hinge also

delayed the contact between the panel and the core. The load-displacement curve of different core

plate thickness is shown in Figure 6. As can be seen from Figure 6, the core plate thickness has a

significant effect on the ability of pressure resistance. By increasing the core plate thickness the

deformation resistance performance of the pyramid increases and the modulus of the flat

compression increases significantly. According to the formulas (5) and (6), the equivalent flat

compressive strength and modulus with different core plate thickness are shown in Table 2. With the

increase of core plate thickness, the equivalent flat compressive strength and the equivalent flat

Simulation of Compression Properties of Pyramidal Sandwich Panels of TC4 Titanium Alloy

111

compressive modulus increase accordingly. In addition when the core plate thickness increases, the

relative density increases correspondingly.

Table 2. Equivalent flat compressive strength and modulus under different core plate

thickness.

Core plate thickness (mm) 0.6 1 1.5 2

Relative densit

y

(%) 0.84 1.40 2.10 2.80

Equivalent flat compressive strength (MPa) 1.13 2.71 5.97 7.93

Equivalent flat compressive modulus (MPa) 138.32 185.69 299.58 339.90

Strength-to-density ratio(MPa) 1.35 1.94 2.84 2.83

Modulus-to-density ratio(MPa) 164.67 132.64 142.66 121.39

2.3.3. Influence of the rid width. The panel thickness, core plate thickness and the unit size were set

to 1mm, 2mm, and 20mm. The width of ribs was set to 2 mm, 4 mm, 6mm, and 8mm respectively.

The simulation results show that the failure process is still a classic four-stage form similar to Figure

3: linear strengthening, buckling instability, contact strengthening and densification. It is worth

noting that the compression process with different ribs widths all has only one plastic hinge, this

means that the ribs width is not a key factor affecting the number of plastic hinges. The load-

displacement curve is shown in Figure 7. The equivalent flat compressive strength and modulus are

shown in Table 3. It can be seen that increasing the ribs width can significantly improve the pressure

resistance performance of the pyramid structure, and the relative density is also increasing to some

extent.

Table 3. Comparison of equivalent flat compressive strength and modulus under different

ribs width.

Ribs width (mm) 2 4 6 8

Relative density (%) 1.49 2.80 3.96 4.96

Equivalent flat compressive strength (MPa) 2.51 7.93 13.5 18.91

Equivalent flat compressive modulus (MPa) 107.48 339.9 643.18 1044.4

Strength-to-density ratio(MPa) 1.68 2.83 3.41 3.81

Modulus-to-density ratio(MPa) 72.13 121.39 162.42 210.56

Figure 7. Simulation of load-displacement curves with different ribs width.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

112

2.3.4. Influence of unit size. The thickness of panel, the core plate thickness and the ribs width were

set to 1 mm, 2 mm and 4 mm respectively to study the effect of unit size. The unit sizes were set as

15mm, 20mm, 25mm, and 30mm, respectively. The failure process went through linear strengthening,

buckling instability, secondary strengthening, and densification.

Table 4. Comparison of equivalent flat compressive strength and modulus under different unit

sizes.

Unit size(mm) 15 20 25 30

Relative densit

y

(%) 3.61 2.80 2.29 1.93

Equivalent flat compressive strength (MPa) 16.51 7.93 4.07 2.24

Equivalent flat compressive modulus (MPa) 1042.95 339.9 207.34 51.01

Strength-to-density ratio(MPa) 4.57 2.83 1.78 1.16

Modulus-to-density ratio(MPa) 288.91 121.39 90.54 26.43

Figure 8. Simulation of load-displacement curve under different unit sizes.

The load-displacement curves are compared as shown in Figure 8 and the equivalent flat

compressive strength and modulus are shown in Table 4. It can be seen that the smaller the unit is,

the greater the relative density is and the better the compressive performance is. It can be seen that

with the decrease of unit size, the compressive strength and the equivalent flat compressive modulus

increases, meanwhile, the relative density also increases, in addition, the equivalent flat compressive

modulus increase faster than the strength, which means that the unit size have much more influence

on the modulus

3. Conclusions

In this paper, finite element simulations of compression Properties of Pyramidal Sandwich Panels of

TC4 Titanium Alloy were carried out. The influences of panel thickness, core plate thickness, ribs

width, and unit size on the pyramidal sandwich compression properties were obtained. The

conclusions are as follows:

The panel is a major part of the weight of the structure but it has little influence on the pressure

resistance. The core is the main supporting part of the structure, increasing core plate thickness or

ribs width can increase the structure ability of pressure resistance. The smaller the unit is, the greater

the relative density and the higher stability of the structure are.

Simulation of Compression Properties of Pyramidal Sandwich Panels of TC4 Titanium Alloy

113

References

[1] Kooistra G W, Deshpande V S and Wadley H N G 2004 Compressive behavior of age

hardenable tetrahedral lattice truss structures made from aluminium J. Acta Materialia

52(14) 4229-4237

[2] Queheillalt D T and Wadley H N G 2009 Titanium alloy lattice truss structures J. Materials &

Design 30(6) 1966-1975

[3] Xue Z Y and Hutchinson J W 2004 A comparative study of impulse-resistant metal sandwich

plates J. International Journal of Impact Engineering 30(10) 1283-1305

[4] Yungwirth C J, Radford D D, Aronson M and et al 2008 Experiment assessment of the

ballistic response of composite pyramidal lattice truss structures J. Composites Part B

Engineering 39(3) 556-569

[5] Bele E, Bouwhuis B A and Hibbard G D 2012 Finite Element Analyses of Failure Mechanisms

and Structure-Property Relationships in Microtruss Materials J.

[6] Bouwhuis B A 2010 Microstructural strengthening mechanisms in micro-truss periodic

cellular metals J. Doctoral

[7] Lou J, Ma L and Wu L Z 2012 Free vibration analysis of simply supported sandwich beams

with lattice truss core Materials Science and Engineering: B. Nov20 177(19) 1712-6

[8] Li M, Li F M and Jing X J 2017 Active vibration control of composite pyramidal lattice truss

core sandwich plates Journal of Aerospace Engineering Dec 9 31(2) 04017097

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

114