Chemical Flooding Process Integration of Low Viscosity Loss

Points Injection Technology Research and Application

S G Zhu

1

, F S Wang

1

, D K Xu

1

, C J Liu

1

, Q Z Li

1

,X L Song

1

, Q Ma

1

, H C Li

1,*

, L

J Wang

1

, P Li

2

, P F Tang

3

and G L Gao

1

1

Production and Engineering Research Institute Daqing oilfield Limited liability

company, Daqing

2

No.4 Oil Production Plant of Daqing Oilfield Co. Ltd, Daqing

3

No.6 Oil Production Plant of Daqing Oilfield Co. Ltd, Daqing

Corresponding author and e-mail: H C Li, lihaicheng@petrochina.com.cn

Abstract. Injection technology for water flooding points exist at the polymer solution flowing

through the injection allocation generated when mechanical degradation,big viscosity loss

need to inject (over 30%) and low permeable reservoirs with low relative molecular mass of

polymer solution, in order to make sure no problem such as block reservoir.Chemical

flooding process is studied in the integration of hierarchical points injection

technology,designed the low viscosity loss high throttling pressure regulator, wide adjusting

range low molecular weight and regulator of the choke points and the whole process of the

integration of eccentric injection allocation, layered injection and dual regulation of relative

molecular mass.Hydraulic characteristics, laboratory test results show that within the scope of

the flow rate of 70 m

3

/d, viscosity loss rate has dropped from 30% to 10%, and separate

injection technology compatible with water flooding, injection string meet blank water

flooding, separate chemical flooding and subsequent water flooding process need, reduce the

investment and production cost, is the application of more than 3000 Wells.Field test results

show that 2-3 interval cast get success rate of 95.6%, a 95% success rate increase.Statistics a

layered polymer injection blocks, separate injection Wells using layer is 9.8% higher than

general Wells, the thickness of use increased by 10.3%.

1. Introduction

Daqing oilfield is a heterogeneous multi-layer sandstone oilfield with largely different permeability,

tertiary oil recovery technology has become an important means for its stable production. Practice

showed[1,2] that chemical flooding could increase crude oil recovery ratio by more than 20

percentage points compared with water flooding. At present, the oil production of chemical flooding

wells is close to 1/3 of total output. With the development of chemical flooding, the class II and III

reservoirs with big difference in permeability and large interlayer contradictions have gradually

become the main development objects. However, in order to alleviate the contradiction between

layers, the separate injection technology needs to be improved in the process of chemical flooding

medium injection. Because of the mechanical degradation of polymer solution by shearing, the

conventional water flooding injection allocator has serious degradation of polymer and large

Zhu, S., Wang, F., Xu, D., Liu, C., Li, Q., Song, X., Ma, Q., Li, H., Wang, L., Li, P., Tang, P. and Gao, G.

Chemical Flooding Process Integration of Low Viscosity Loss Points Injection Technology Research and Application.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 167-173

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

167

viscosity loss. It can`t be directly applied to separate injection of chemical flooding wells. In addition,

the replacement of separate injection pipe string in the process of water flooding changing to

chemical drive and chemical drive changing to subsequent water drive will result in increase in

production cost.

In order to resolve these problems, this paper studies the integrated injection technology with

separate layer and separate mass in the whole process of chemical flooding. Low viscosity loss and

high throttle pressure regulators, wide molecular weight range and low throttle regulators of separate

mass, and whole process integrated eccentric injection devices are designed. Double adjustment of

layered injection volume and relative molecular mass has been achieved. The separate injection

technology is fully compatible with the water drive process. The pipe column can meet the needs of

separate injection in the whole process, including the blank water drive, chemical flooding and

subsequent water flooding. And it will reduce the cost of investment and production. The integrated

injection technology with separate layer and separate mass in the whole process of chemical flooding

can greatly improve the adaptability of the process, saves the cost of investment, and has the

conditions of scale application, and can play an important role in the oil production.

2. Study on low viscosity loss and high throttle pressure regulator

2.1. Choking element with streamlined annular depressurizing channel structure

The flow passage of the polymer solution is composed of multistep equidistant streamline units of

choking element outer surface and inner wall of deviation hole of eccentric injection device. When

the polymer solution flows through the throttling unit of flow passage, the flow velocity is changed

by the change of the flow area. As the shear degradation rate of polymer solution is related to the

flow stability [3,4], easy to change of the flow field of polymer solution and easy to deform of the

polymer molecular chain lead to the shear degradation rate of polymer solution becoming faster. In

order to reduce shear degradation rate of the polymers, we designed choking element with

streamlined annular pumpdown channel structure. We got its velocity vector diagram by fluid

numerical simulation software, and compared it with velocity vector diagram of old semicircle

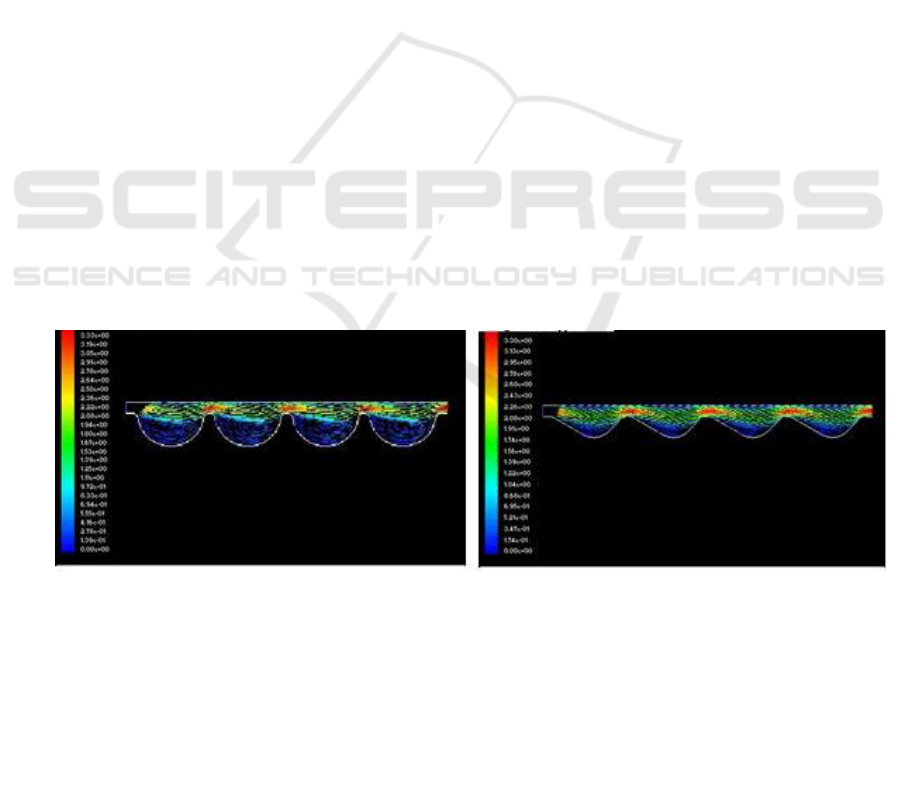

throttling device ,show in Figure 1, show in Figure 2.

Figure 1. Semicircle annular pumpdown unit. Figure 2. Streamlined annular pumpdown unit.

The results of analysis and calculation show that the pressure distribution of streamline

depressurization unit is more uniform than the semicircle depressurization unit, flow field trend is

stable, flow around is significantly lower than the latter, and turbulence is not prone; because of the

influence of flow around, backflow phenomenon of the semicircle depressurization unit is more

serious. Therefore, a streamline multistage pumpdown unit choking device is preferred. The device

of separable combination structure can be used in series for reducing the investment cost and

processing difficulty,show in Figure 3.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

168

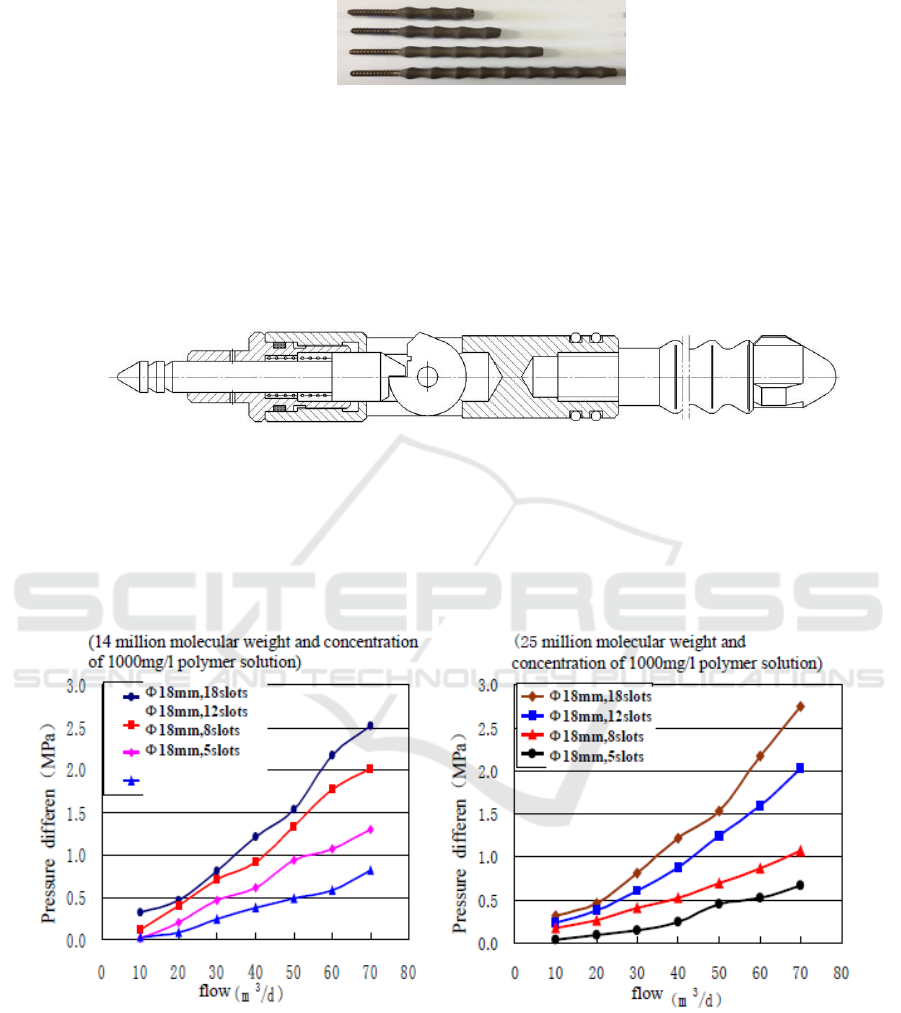

Figure 3. Physical map of separable combination pressure regulation device.

2.2. Pressure regulator of low viscosity loss and high throttle

A pressure regulator is composed of pressure regulating plugging device and whole process

integrated eccentric distributor,show in Figure 4. Injection pressure is controlled by throwing and

pulling the injection tools and changing number of slots of streamlined annular pumpdown unit, To

achieve the purpose of controlling injection volume of injection layer[5, 6].

Figure 4. Pressure regulating plug.

Performance indicators:

When the pressure regulator is in the range of 70m3/d flow, the maximum throttling pressure

difference is about 2.7MPa. The viscosity loss rate of polymer solution is less than 9.2%,show in

Figure,show in Figure 6

Figure 5. Contrast curve of pressure regulator

flow and throttle pressure difference.

Figure 6. Contrastcurve of pressure regulator

flow and throttle pressure difference.

3. Study on separate mass regulators with wide molecular weight range and low throttle

3.1. regulation mechanism of polymer molecular weight

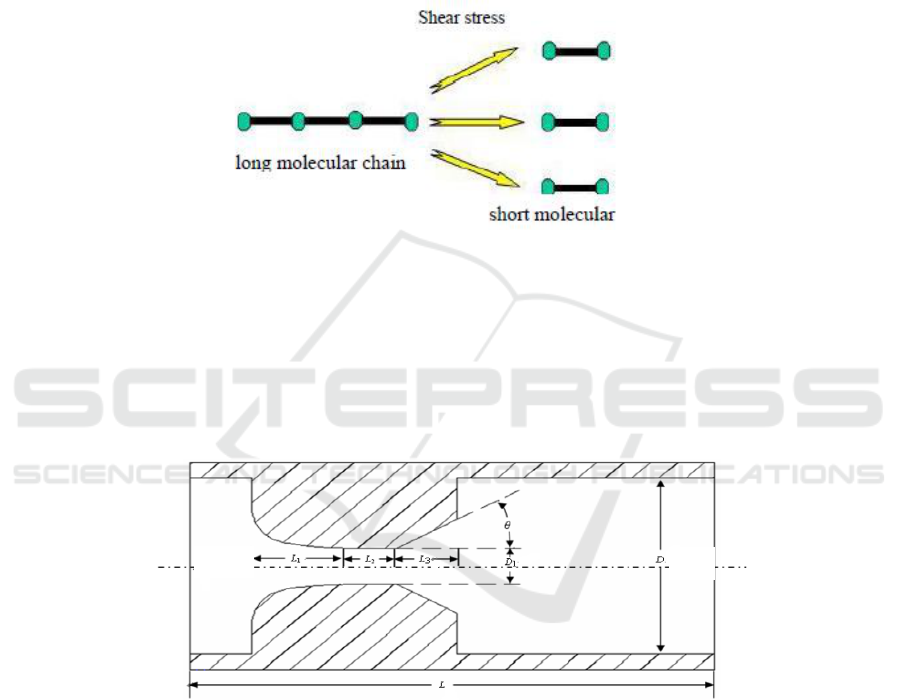

The rheological property of polymer aqueous solution belongs to non Newtonian fluid, and it has

both viscous and elastic properties. From the microscopic point of view, polymer molecules are

Chemical Flooding Process Integration of Low Viscosity Loss Points Injection Technology Research and Application

169

distributed in aqueous solutions with particles, branched and reticular structures, and the molecular

chains are flexible chain structure. The polymer molecules conformation will be changed by external

force. For example, when a coiled polymer chain is subjected to a certain stretching force, the

polymer chain will be stretched. When the external force is lost, it can recover the original state. But

when the force exceeds the critical value (such as the mutation of polymer solution rate), the polymer

chain will break, and this will result in the irreversibility of recovery. Mechanical degradation caused

molecular chains to decompose and break, changed the shape and size of polymer molecules, so

these resulted in the decrease of polymer molecular weight [7]. show in Figure 7

Figure 7. Diagram of shearing polymer Molecular weight.

3.2. regulating element of Molecular weight

According to the above principle of mechanical degradation, we designed a "hyperbolic + trapezoidal

mouth" type molecular weight regulating element,show in Figure 8. The degradation strength of

polymers can be controlled by changing the nozzle diameter, so as to achieve the purpose of

adjusting the molecular weight of polymer(The nozzle is made from ceramic material, Diameter 2.0-

6.0mm, Increasing at intervals of 0.2mm).

Figure 8. Structure schematic of "hyperbolic + trapezoidal mouth" type molecular weight regulating

element.

3.3. Molecular weight regulating plug

A molecular weight regulator is composed of pressure regulating plugging device and whole process

integrated eccentric distributor,show in Figure 9. Molecular weight degradation rate is controlled by

throwing and pulling and changing the nozzle diameter, so as to achieve the purpose of adjusting the

molecular weight of polymers.

exit

porch

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

170

Figure 9. Molecular weight regulating plug.

Performance indicators:

The range of molecular weight adjustment can reach 20-50% In the 50m3/d flow range,show in

Figure 10.

Figure 10. Curve of molecular weight regulator flow--molecular weight.

4. Design of a matching eccentric injection proration device

A medium oriented eccentric polymer injection device is designed innovatively,show in Figure 11

(patent number: ZL201020673891.4). On the basis of the structure of the conventional eccentric

water injection allocator, the guide body is moved up to the center of the eccentric cylinder, that is,

the lower part of the stabilizer. It not only keeps the advantages of high success rate of throwing and

pulling in underside guide structure, but also has the advantages of short throwing and pulling tools

in upside guide structure. The maximum outer diameter of the eccentric injection proration device

working cylinder is 114 mm, The length is 1640mm,The inner diameter is 46mm, The diameter of

eccentric hole is 20 mm, Entering from the bottom of eccentric hole can slow down the blockage of

polymer solution.

The injection proration device is fully compatible with the water injection process, layered water

injection can be realized by directly using water drive Water distribution plug and layered testing and

adjusting technology, and it is compatible with the development of testing and adjusting combination

process in recent years.

Figure 11. Structure schematic of eccentric water injection allocator.

5. Research on integrated separate injection technology with separate mass of the whole

process

Using packers to divide oil layers on different properties, and applying pressure regulators in high

permeable layers. The high molecular weight polymer from wellhead entered the high permeability

Chemical Flooding Process Integration of Low Viscosity Loss Points Injection Technology Research and Application

171

reservoir after reducing injection pressure through pressure regulator. For the low permeability

reservoir, the high molecular weight polymer from wellhead must be degraded by molecular weight

regulator, and the polymer of molecular weight reduction must meet the requirement of injection

scheme. The polymer solution is injected in a way of separate layer and separate mass through dual

control of molecular weight and pressure regulator.

The layer of separate injection is not restricted by grades, and throwing in and pulling and control

can be achieved on any layer. And multi-layer injection can be realized on the class II and class III

reservoirs. The separate injection pipe string is fully compatible with the water flooding injection

process, and it can meet the injection requirement of different displacement stages. There is no need

to replace the pipe string when injection way is changed, and the cost of operation is reduced.

6. Site application

The integrated separate injection technology with separate mass of the whole process for chemical

flooding has been applied for more than 3000 wells on site in Daqing Oilfield, and more than 50

wells in other oil fields by the end of 2017. The statistics indicated that the number of layers

developed in a chemical block was 9.8 percentage higher than that of general wells in Daqing oilfield.

The producing thickness was 10.3 percentage higher. The full well seal rate was 100%. The success

rate of one time throwing in and pulling was 95.6%. The effective flow allocation time of 2-3 layer

was about 1.5-2 days. After application of this technology, The liquid absorption thickness of

polymer injection wells had been obviously increased, and the utilization of poor reservoirs had been

obviously improved.

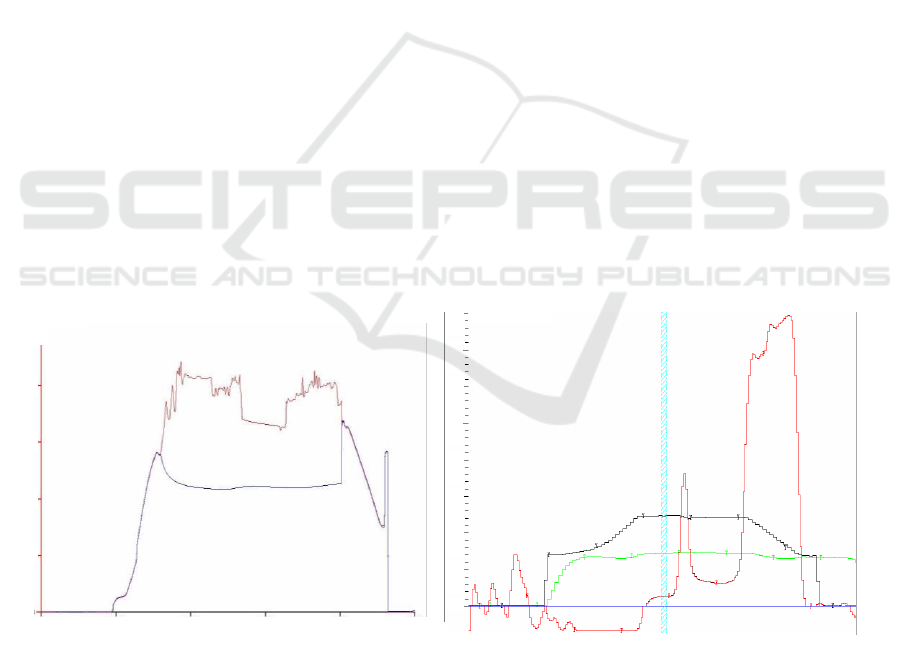

6.1. test effects

The 1# injection well in a block is divided into 2 reservoirs. There were 3 times to salvage the

plugging device and throw the pressure regulator. There was 1 times of up and down the instrument

for pipe sealing. It took only 0.5 days to complete all above test work. The success rate of throwing

in and pulling was 100%. pipe sealing was qualified,show in Figure 12. It took 1 day to complete

flow test allocation,show in Figure 13.

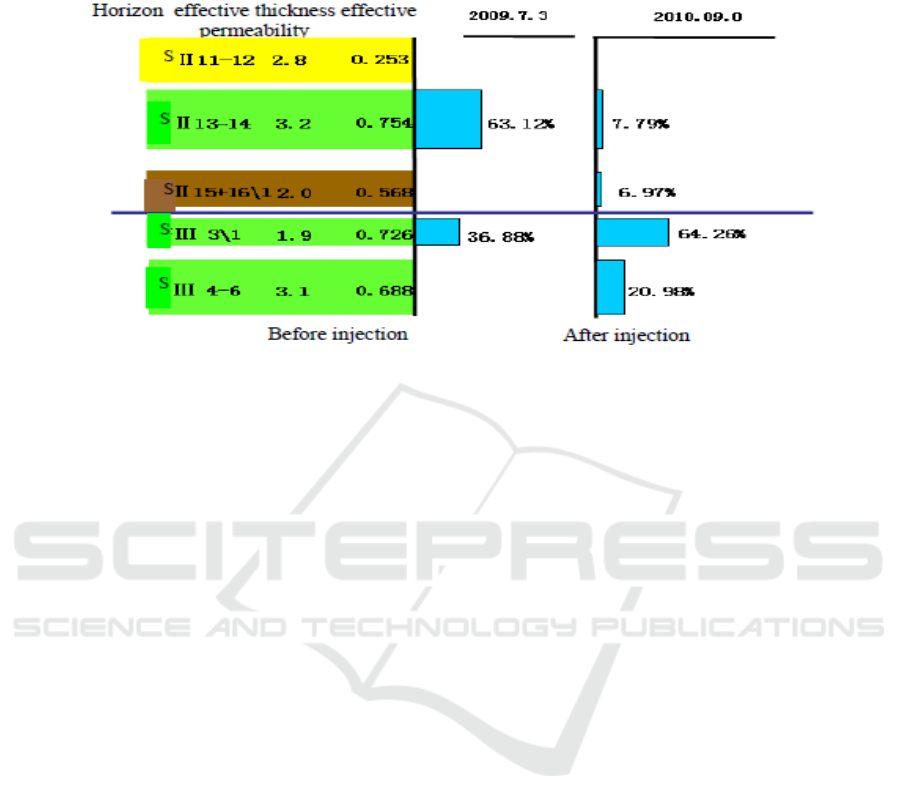

6.2. separate injection effects

The 2# injection well in a block was generally injected water during the blank water flooding phase.

Only 2 of the 5 layers absorbed water. The used proportion of effective thickness was only 39.2%.

After separate polymer injection, the number of water absorbing reservoirs increased from 2 to 4.

0 .209

0 .418

0 .628

0.146

min( h )

64

6 0 0

1 1 2

56

5 2 5

96

48

4 5 0

80

40

3 7 5

64

32

3 0 0

48

24

2 2 5

32

16

1 5 0

16

8

75

0

Figure 12. 1#well sealing result. Figure 13. 1#wellseparateflow test result.

0

0 .837

P (MPa)

40

20

15

10

5

0

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

172

The used proportion of effective thickness increased to 78.5%. The used proportion had Increased by

39.3 percentage,show in Figure 14.

Figure 14. 2#wellContrast diagram of injection profile.

7. Conclusions

A low viscosity loss and high throttle pressure regulating element has been optimized and designed.

The viscosity loss rate decreased from 30% of the water separate injection to less than 10% under the

same conditions.

A wide molecular weight regulating device has been developed. The adjustment range of

molecular weight reached 20-50%. The demand for different molecular weight of different layers in

the same well was satisfied.

Dual control of layered injection volume and layered molecular weight has been realized.

The separate injection pipe string was fully compatible with the water flooding injection process,

and it has met the needs of separate injection in the whole process, including the blank water drive,

chemical flooding and subsequent water flooding. And it will reduce the cost of investment and

production.

References

[1] Li H C H 2012 Present situation of Stratified injection technology in polymer flooding in

Daqing oilfield J. petroleum and natural gas geology 33 (2) 296-301

[2] Gao G L, Yang H, Li H C H and et al 2012 Present situation of Stratified injection technology

in polymer flooding process J. oil production engineering 1 (2) 1-4

[3] Pei X H, Duan H, Cui H Q and et al 2006 Eccentric fragmentation injection technology of

polymer flooding J. Daqing petroleum geology and development 25 (5) 68-69 73

[4] Li J Y 2010 Study and application of polymer flooding with multi layered sub pressure

injection technology J. Inner Mongolia petrochemical industry (1) 130-132

[5] Chen X D, Duan H and et al 2004 Principle and Application of Separate Zone Polymer

Flooding in Multi Zone Reservoirs J. Daqing petroleum geology and development 23 (4)

53-54

[6] Yang Z Q, Wang Y, Liang F M and et al 2001 2-3 ZONAL INJECTION TECHNIQUE OF

POLYMER FLOODING J. Daqing petroleum geology and development (3) 28-29

[7] Cheng J C H, Wang D M, Wu J Z H and et al 2000 Molecular weight optimization for Polymer

flooding J. Acta Petrolei Sinica 21(1) 102-106

Chemical Flooding Process Integration of Low Viscosity Loss Points Injection Technology Research and Application

173