Experimental Study on Mechanical Property and Fatigue

Failure of the Bamboo-based Composites

F P Yang

*

and X T Li

School of Naval Architecture, Ocean and Civil Engineering, Shanghai Jiao Tong

University, Shanghai 200240, PR China

Corresponding author and e-mail: F P Yang, yangfp@sjtu.edu.cn

Abstract. Bamboo is a kind of advanced bio-material and has good mechanical behaviour.

Bamboo-based composites have been rapidly developing for use in engineering, especially in

wind turbine structures. In the present study, a series of experiments were performed and the

results were presented concerning the monotonic tension and compression mechanics

properties and fatigue life of bamboo-based composites. The stress-life curve was shown and

the failure models of laminates were discussed. The results suggest that the bamboo-based

composites have different fracture models under tension, compression and reverse fatigue

loading. The composites can support load more abidingly under compression loading.

However, higher strength values can be obtained under tensile loading.

1. Introduction

Bamboo is a kind of bio-material and has good mechanical behaviour. As an economic and friendly

material, bamboo has got increasing use in a wide range of application in engineering [1]. The

properties of outside strip of bamboo are better than those of inside. Thus the grading process was

developed, which can make the laminated bamboo strip lumber of grading [2]. The advanced bio-

composite, compared with other materials, can replace GFRP and wood/epoxy, and be used in wind

turbine blades as a new generation of materials [3]. These materials have many advantages, such as

renewable, less dissipation of energy, low cost, no waste and the worn-out product s can be disposed

easily.

Synthetic fiber/resin composites have been concentrated on all the time, and most of the current

studies focused on their chemical and mechanical properties [4-5]. However, the research and discuss

on the natural fiber composites are relatively new. As more and more interest in and attention to

natural fiber composites, a study on the static and fatigue properties of theses composites is timely

and important. Since bamboo has often been used in engineering structures, some previous research

has been carried out on the basic mechanical and fracture properties of nature bamboo and bamboo

fiber reinforced composites [6-10]. However, bamboo culms or structures made of bamboo

sometimes bore the cyclic forces, such as wind loading. The fatigue damage and failure mode in

bamboo-based composites need to be given serious thought.

Some authors have been focusing on the fatigue properties of bamboo culms [11], structural

bamboo materials [12], textile or biodegradable composites [13-14]. The results show that such

composites did not suffer fatigue damage at stresses well below their static strength, normal and

276

Yang, F. and Li, X.

Experimental Study on Mechanical Property and Fatigue Failure of the Bamboo-Based Composites.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 276-283

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

shear strains at the fiber/resin interface could cause deterioration leading to fatigue failure [15]. Static

failure and fatigue damage in such composites take the form of fiber breakage, matrix cracking,

debonding, transverse ply cracking, and delaminating [16]. These processes sometimes occur

interactively or independently depending on the types and properties of the composites. Testing

conditions and material variables may sometimes influence the predominance of one mechanism over

another [17-18].

In order to understand the mechanical properties and fatigue behaviour of bamboo-based

composites, a series of experiments were performed concerning the monotonic tension and

compression mechanics properties and fatigue life of the laminated bamboo lumber used for wind

turbine structures. The stress-life curve was shown and the failure modes of the laminated bamboo

lumber were discussed.

2. Materials and experimental procedure

A novel type of laminated bamboo lumbers was chosen for the present study. The laminate was

comprised of moso bamboo curtain mats which were formed to panels using one-time vacuum

infusion processes. Rectangular slices selected from outside strip of bamboo were used to form the

bamboo curtain mats. Epoxy resin was used as the adhesive. The chemical components of outer

layers in the moso bamboo culm are listed in the Table 1. The processed bamboo laminate has the

physical properties with the bending modulus of elasticity (MOE) 28GPa/gm

3

, specific strength

140MPa/gm

3

, and density 1150kg/m

3

. The specimen was cut with precision machine tools. The

geometric configuration of the specimen employed is shown in Figure 1. according to ISO 527-4,

which is also a common standard used for wood-based products. The bamboo slices were aligned in

the axial direction.

All tests were carried out on an MTS Landmark servo-hydraulic machine as shown in Figure 2. at

room temperature. To obtain the monotonic strength of the laminated bamboo lumber, the specimens

were loaded to failure at a fixed displacement rate of 1mm/minute. The fatigue life tests were

performed utilizing the same specimen geometry used for monotonic tests. All the tests were under

load control at stress ratio R=-1 and the loading frequency f=5Hz.

Table 1. Chemical components of outer layers in the moso bamboo culm.

Components Moisture Ash

Hot Water

solubility

Alcohol-benzene

solubility

Lignin Pentosan Cellulose

(%) 13.7 1.22 8.31 7.15 24.77 31.54 42.59

Figure 1. Details of the specimen

geometry.

Figure 2. Specimen installed in

fatigue machine..

Experimental Study on Mechanical Property and Fatigue Failure of the Bamboo-Based Composites

277

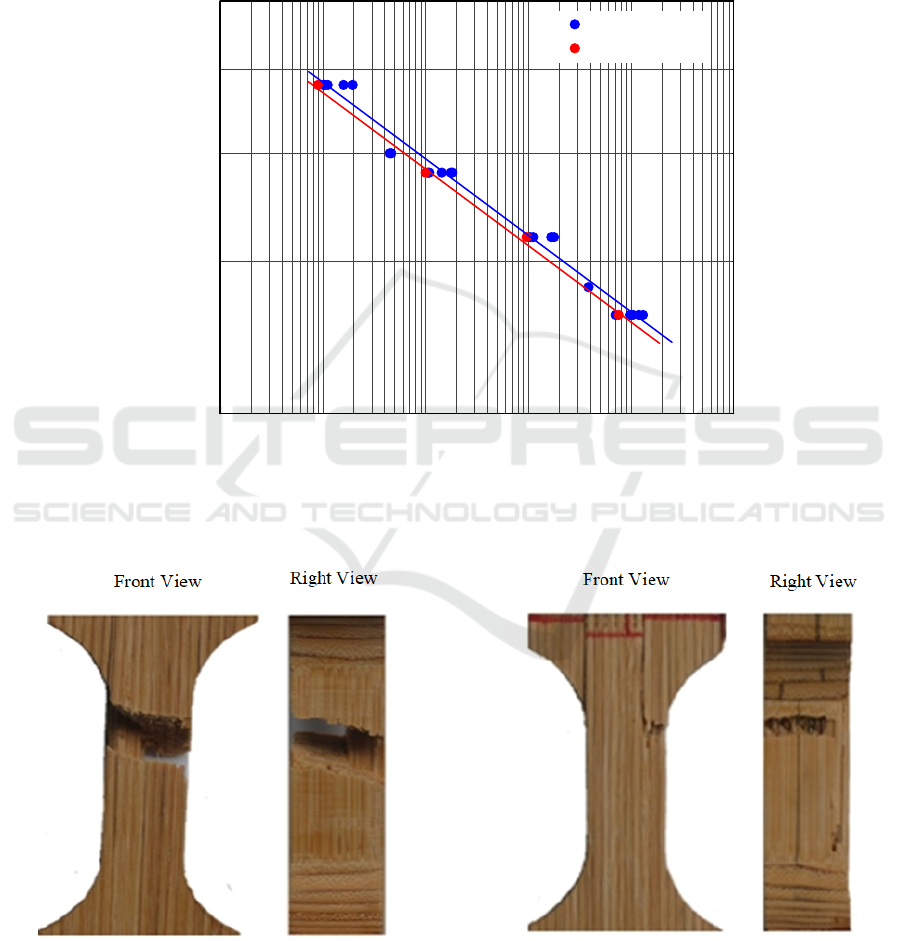

Figure 3. Stress-strain curves under tension and compression loading.

(a)

(b)

Figure 4. The failure mode and evolution for the laminated bamboo lumber: (a) under monotonic

tension loading; (b) under compression loading.

3. Results and discussion

3.1. Monotonic tension and compression tests

Tensile test: The standard tensile stress-strain behaviour is shown in Figure 3. In order to ensure the

accuracy of the results, two specimens were chosen to test. The average ultimate tensile strength is

about 190MPa. Under tensile loading, the laminated bamboo lumber failed in a progressive manner

instead of abrupt failure. As shown in Figure 4a, the failure process was involved with the rupture of

individual bamboo slices accompanied by progressive fracture of adjacent bamboo layers. The

fracture was straight and along the plane vertical to the axial direction.

0 3 6 9 12 15

0

50

100

150

200

250

Stress (MPa)

Strain (%)

Tension 1#

Tension 2#

Compression 1#

Compression 2#

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

278

Compression test: The compressive stress-strain behaviour is also shown in Figure 3. In the same

way, two specimens were tested and the average compression strength is 179MPa. Compared with

the tensile stress-strain curve, the composites can support load more abidingly under compression

loading. However, higher strength values can be obtained under tensile loading. The similar consults

have been obtained by John W H [3].

Under compressive loading, the laminated bamboo lumber failed in a debonding/buckling manner

as shown in Figure 4b. When the compressive load was up to some value, the composite buckled and

delaminating subsequently occurred.

3.2. Fatigue tests and failure modes

The stress ratio means the ratio of the minimum stress to the maximum stress for a fatigue cycle,

R=σ

min

/σ

max

. Because the laminated bamboo lumber has different failure mode and strength under

tensile loading and compression loading, the tension-compression cycle loading with the stress ratio

R=-1 were applied and analyzed. Six groups of stress levels from 65MPa to 120MPa and total 30

specimens were selected. For each stress level, five specimens were chosen to obtain the fatigue life.

The evaluation of the fatigue life for the composite is usually different with metallic materials. A

critical number of cycles of fatigue failure are defined according to the damage evolution during the

fatigue loading. Stiffness reduction is one of the methods more commonly used [19]. In this study,

the fatigue peak displacement d

max

was introduced as a damage parameter to describe the fatigue

damage. When the peak displacement including the tension and compression values increased up to

25%, the fatigue failure was considered to happen and the corresponding number of cycles is the

fatigue life.

The fatigue stress-life curve, namely S-N curve, is presented in Figure 5. The fitting formula of the

maximum stress S

max

vs. fatigue life N is as follows:

max

log 2.3452 0.08806logSN=−

(1)

In order to predict the fatigue life of the studied bamboo-based composites more efficiently and

accurately, it requires the P-S-N curve and suggests the fatigue life data follow the lognormal

distribution. The P–S–N curves can be established by connecting the Pth percentile points of the

distributions of fatigue life at different stress levels with each other. We can label N

i

as the fatigue

life of the nth specimen under the same stress level. The logarithmic life can be expressed as x

i

=logN

i

.

The mean fatigue life and standard deviation s can be written as the following equations

respectively.

∑

=

=

n

i

i

x

n

x

1

1

(2)

∑

−

−

=

n

i

xx

n

s

1

2

)(

1

1

(3)

For the fatigue life with the failure probability P, the logarithmic life can be expressed:

suxx

pp

+=

(4)

When the failure probability P=10%, u

p

=-1.282. So we can get the final fatigue life according to the

equation:

pp

xN

1

log

−

=

(5)

Experimental Study on Mechanical Property and Fatigue Failure of the Bamboo-Based Composites

279

For the S-N curve of the composite with the expression equation (1), the P-S-N curve with P=10%

can be calculated. The results were shown in Figure 5. and the following equation. From the picture,

we can see that the S-N curve and P-S-N curve are almost same, and the experimental data show

good consistency with each other.

p

NS log08933.034113.2log

max

−=

(6)

Figure 5. Stress-life curve for bamboo-

b

ased composites at R=-1.

(a)

(b)

Figure 6. The failure mode of the laminated bamboo lumber under cyclic tension-compression

loading (R=-1): (a) in low-cyclic fatigue (N

f

=1043); (b) in high-cyclic fatigue (N

f

=126020).

100 1000 10000 100000 1000000 1E7

50

75

100

125

150

σ

max

N

S-N curve

P-S-N curve

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

280

The fatigue failure of the laminated bamboo lumber under cyclic loading was shown in Figure 6.

When under low-cyclic fatigue loading, the fracture was propagated along a plane to some angle with

the axial direction (Figure 6a). In some local position, the delaminating happened. The failure

mechanism was similar with the “compressive mode”. Some reasons can be guessed that since

ultimate tensile strength of the laminated bamboo lumber was higher than compressive strength, at

the same stress value, the composite began to damage during supported the compression loading.

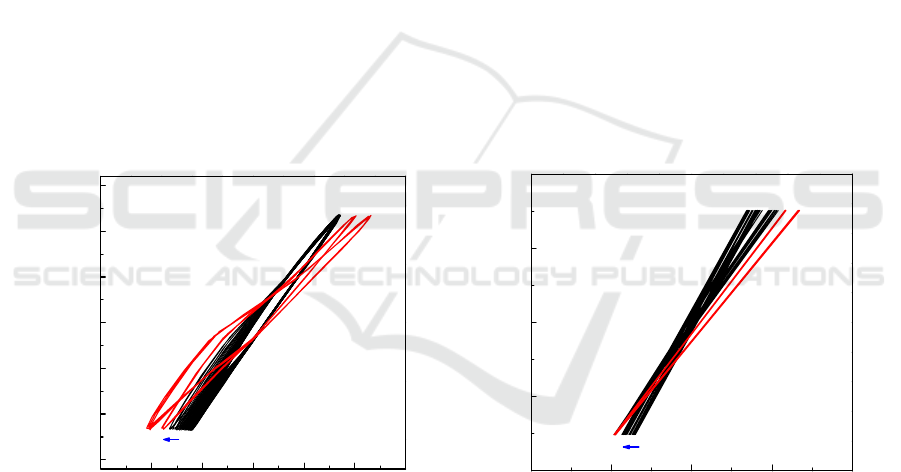

The stress-strain curves under low-cyclic fatigue loading are plotted in Figure 7a according to

every fixed cycle numbers. It can be shown that from the beginning of fatigue test, the maximum

strain was on the increase under compressive loading, but it kept unchanged in the tensile process

until the last dozens of cycles. The non-linear relationship between stress and strain at the stage of

compression was more obvious than tension loading. The conclusion can be suggested again that

under low-cyclic fatigue loading, the damage always began to occur during compressive loading.

When the damage accumulation was up to some extent, the composite was not able to bear more

loading and the failure happened.

Under high-cyclic fatigue loading, the failure happened with the progressive rupture of bamboo

slices, sometimes accompanied by debonding of bamboo layers. The fracture was propagated along a

plane vertical to the axial direction (Figure 6b). The failure mechanism was similar with the “tensile

mode”. The stress-strain curves for laminated bamboo under high-cyclic fatigue loading are plotted

in Figure 7b. Contrary to the behavior under low-cyclic fatigue loading, the maximum tension strain

increased more obviously than compression strain during the test. The damage introduced by tension

loading contributed more to the failure of the composite. It is suggested that at the low stress level,

the laminated bamboo lumber can support the cyclic compressive loading longer.

-3 -2 -1 0 1 2 3

-150

-100

-50

0

50

100

150

20

1020

1040

cycle numbers

N

f

=1043

1040

Stress (MPa)

Strain (%)

20

(a)

-2 -1 0 1 2

-100

-50

0

50

100

12.6k

20

20

12.5k

Stress (MPa)

Strain (%)

Cycle numbers

N

f

=126020

12.6k

(b)

Figure 7. Stress-strain curves of the laminated bamboo lumber for every fixed cycle numbers:

(a) under low-cyclic loading; (b) under high-cyclic loading.

4. Conclusions

In the present study, a series of experiments were performed and the results were presented

concerning the static and fatigue mechanics properties of bamboo-based composites. The stress-life

curve was obtained and the failure modes of the laminated bamboo lumber were discussed. Some

conclusions were obtained.

Experimental Study on Mechanical Property and Fatigue Failure of the Bamboo-Based Composites

281

The laminated bamboo lumber showed no exactly the same behavior under monotonic tensile and

compressive loading. The laminates can support the loading more abidingly under compression

condition. However, higher strength values can be obtained under tensile loading.

Under tensile loading, the laminated bamboo lumber failed in a progressive manner with a straight

fracture. The process was involved with the rupture of individual bamboo slices accompanied by

progressive fracture of adjacent bamboo layers. Under compressive loading, the failure was in a

debonding/buckling manner.

The failure mechanism of the laminated bamboo lumber was similar with the “compressive mode”

under low-cyclic fatigue loading. The fracture plane was at an angle to the axial direction. Under

high-cyclic fatigue loading, the failure happened with the progressive rupture of bamboo slices,

sometimes accompanied by debonding of bamboo layers.

Further investigation would be conducted on the microscopic damage mechanism and the

interface strength between the bamboo slices. An effective finite element analysis model is expected

to create and verify the experimental data.

Acknowledgements

This work is supported by Shanghai Natural Science Fund of China (Grant No. 16ZR1417700) and

the National Natural Science Foundation of China (Grants No. 11102107).

References

[1] Shigeyasu A and Sun U 2001 Fracture properties of bamboo Composites: Part B 32 451-59

[2] Jiang Z H, Sun Z J and Ren H Q 2006 Application of advanced bio-composites in wind blades

Acta Materiae Compositae Sinica 23 127-29

[3] John W H, Povl B, Bent F S, Jiang Z, Sun Z and Chen X 2009 Development of a bamboo-

based composite as a sustainable green material for wind turbine blades Wind Engng. 33

197-210

[4] Harris B 2003 Fatigue in composites: science and technology of the fatigue response of fibre-

reinforced plastics Cambridge: Woodhead Publishing

[5] Degrieck J and Paepegem W V 2001 Fatigue damage modeling of fibre-reinforced composite

materials review Appl Mech Rev. 54 279-300

[6] Li H, Zhang Q, Huang D and Deeks A J 2013 Compressive performance of laminated bamboo

Composites: Part B, 54 319–28

[7] Lee P, Odlin M and Yin H 2014 Development of a hollow cylinder test for the elastic modulus

distribution and the ultimate strength of bamboo. Construction and Building Materials 514

235–43

[8] Zou M, Wei C, Li J, Xu S and Zhang X 2015 The energy absorption of bamboo under dynamic

axial loading Thin-Walled Structures 95 255–261

[9] Hojo T, Xu Z, Yang Y and Hamada H 2014 Tensile Properties of Bamboo Jute and Kenaf

Mat-Reinforced Composite Energy Procedia, 56 72–9

[10] Wong K, Zahi S, Low K and Lim C 2010 Fracture characterisation of short bamboo fibre

reinforced polyester composites Maters. Design 31 4147–54

[11] Keogh L, O’Hanlon P, O’Reilly P and Taylor D 2015 Fatigue in bamboo International Journal

of Fatigue 75 51–56

[12] Song J, Surjadi J U, Hu D and Lu Y 2017 Fatigue characterization of structural bamboo

materials under flexural bending Inter. J. Fatigue

100 126–135

[13] Zangenberg J and Brondsted P 2015 Fatigue life in textile composites used for wind energy

engineering Fatigue of Textile Composites 403–40

[14] Saleh M A, Haron M H, Saleh A A and Farag M 2017 Fatigue behavior and life prediction of

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

282

biodegradable composites of starch reinforced with date palm fibers Inter. J. Fatigue 103

216–22

[15] Chung K F and Yu W K 2002 Mechanical properties of structural bamboo for bamboo

scaffoldings Engng. Struct. 24 429-42

[16] Kazuya O, Toru F and Yuzo Y 2004 Development of bamboo-based polymer composites and

their mechanical properties Composites: Part A. 35 377-83

[17] Arnold N T and Martin P A 2008 Fatigue evaluation and dynamic mechanical thermal analysis

of sisal fibre-thermosetting resin composites Comp. Science and Technology 68 925-32

[18] Amada S, Munekata T, Nagase Y, Ichikawa Y, Kirigai A and Yang Z 1997 The mechanical

structures of bamboos in viewpoint of functionally gradient and composite materials J. of

Composite Materials 30 800–19

[19] Yang F, Lin Q and Jiang J 2015 Experimental Study on Fatigue Failure and Damage of

sandwich structure with PMI Foam Core Fatigue Fract. Engng Mater. Struct 38 456–65

Experimental Study on Mechanical Property and Fatigue Failure of the Bamboo-Based Composites

283