Characterization of a Single Layer of Si

0.73

Ge

0.27

and a

Quantum-well Structure of Si

0.4

Ge

0.6

/Ge by Quantitative

SIMS Depth Profiling Using the Analytical Depth Resolution

Function of the MRI Model

Q R Deng, H L Kang, Y S Han, X H Zhang, X W Mai, Q Q Huang and J Y

Wang

*

Department of Physics, Shantou University, 243 Daxue Road, Shantou, 515063

Guangdong, China

Corresponding author and e-mail: J Y Wang, wangjy@stu.edu.cn

Abstract. The analytical depth resolution function of the Mixing-Roughness-Information

(MRI) model is used to fit the measured SIMS depth profiling data of a single layer of

Si

0.73

Ge

0.27

and a Si

0.4

Ge

0.6

/Ge quantum-well structure on Si substrate. The interface

roughness and the individual layer thickness and the depth resolution values are determined

accordingly. The obtained layer thickness values in Si

0.4

Ge

0.6

/Ge quantum-well structure are

consistent with the ones measured by HR-TEM with a maximum relative error less than

1.2%.

1. Introduction

Quantum-well structures with layer thickness in the range of a few nm or tens of nm have been

widely used for micro-electronic devices [1]. The performance of device depends strongly on the

quality of the quantum-well structure. In particular, the variations of layer thickness and interface

roughness may have a significant influence on the function of device [2]. The layer thickness in a few

nm range is conventionally measured by HR-TEM, which involves the complex procedures of

sample preparation and measurement. On the other hand, quantitative SIMS depth profiling may

provide an alternative way to determine the layered structure with one nm resolution. Recently, with

the development of the advanced SIMS instrument, the artifacts that present often in any depth

profiling, such as sputtering induced roughness, crater effect and matrix effect, have been

significantly minimized and the HR-SIMS depth profile could be simply obtained. In this paper, it

will be demonstrated that not only could the quantum-well structure and the depth resolution but also

the interface roughness be well determined by fitting the measured SIMS depth profiling data using

the analytical depth resolution function of the MRI model.

2. Analytical depth resolution function of the MRI model

The measured depth profiles differ from the true concentration-depth profiles as a result of various

interactions of the ion beam bombardment with the measured sample, e.g. ion implantation, cascade

mixing, etc. A so-called depth resolution function (DRF) is often used to describe the distortion of

486

Deng, Q., Kang, H., Han, Y., Zhang, X., Mai, X., Huang, Q. and Wang, J.

Characterization of a Single Layer of Si0.73Ge0.27 and a Quantum-Well Structure of Si0.4Ge0.6/Ge by Quantitative SIMS Depth Profiling Using the Analytical Depth Resolution Function of

the MRI Model.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 486-492

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the measured depth profiles as compared to the true ones, which causes the depth profiles

degradation in the physical mechanism. Generally speaking, in sputter depth profiling, the measured

and normalized intensity I(z)/Io can be described as the convolution of the true concentration X(z') at

the original depth z' in the sample with a DRF g(z-z') as [3]:

0

0

()

(')( ') '

Iz

X

zgz zdz

I

∞

=−

∫

(1)

Where z' is the running depth parameter for which the composition is defined and z is the

sputtered depth. With the measured and normalized intensity I(z)/Io and a known DRF g(z-z'), the

true in-depth distribution of composition can be calculated by Eq. (1). Therefore, the exact

knowledge of the DRF is the key to accurate reconstruction of the original depth distribution of the

composition from the measured depth profile [4]. In the MRI model, the DRF g(z-z') takes into

account the three physically meaningful effects in any sputtering depth profiling: atomic mixing,

surface/interface roughness, Information depth, which are described, respectively , by [5]:

Mixing length (w):

()

'

1

(')exp

w

zz w

gzz

ww

−−+

⎡

⎤

−=

⎢

⎥

⎣

⎦

(2)

Roughness (σ):

2

2

1(')

(') exp

2

2

zz

gzz

σ

σ

πσ

⎡

⎤

−−

−=

⎢

⎥

⎣

⎦

(3)

I

nformation depth (λ):

()

'

1

(')exp

zz

gzz

λ

λλ

−−

⎡

⎤

−=

⎢

⎥

⎣

⎦

(4)

Where w is the atomic mixing length, σ is the surface/interface roughness and λ is the information

depth parameter. With the above three partial resolution functions, the DRF g(z-z') can be written as:

(') (') (') (')

w

gz z g z z g z z g z z

σλ

−= −⊗ −⊗ −

(5)

In general, the quantitative results of the MRI model are obtained by the numerical solution of the

convolution integral with combining Eq. (1) and Eq. (5).

With respect to the above-discussed refinements of the DRF in terms of symmetric (Gaussian

functions) and asymmetric (non-Gaussian functions) functions, it is necessary to clarify the

contribution to the depth resolution △z (16-84%). According to the MRI model, three physically

meaningful effects contribute to the depth resolution function. A symmetric contribution to the depth

resolution function originates from the intrinsic roughness and the surface roughening by ion

sputtering, which both are described by a Gaussian smearing function (see Eq. (3)), characterized by

its standard deviation of the surface roughness parameter σ. For the asymmetric broadening

functions, the atomic mixing is described by an exponential function (see Eq. (2)), characterized by

the atomic mixing length w; the information depth of the Auger electrons (for AES) is also described

by an exponential function (see Eq. (4)), characterized by the information depth λ. Hence, on the

basis of the three MRI parameters, the total depth resolution can approximately be rewritten as [6]

()( )

1/2

22

2

2 1.668 (1.668 )zw

σλ

⎡⎤

Δ= + +

⎣⎦

(6)

Characterization of a Single Layer of Si0.73Ge0.27 and a Quantum-Well Structure of Si0.4Ge0.6/Ge by Quantitative SIMS Depth Profiling

Using the Analytical Depth Resolution Function of the MRI Model

487

Fitting the experimental depth profile by the MRI model leads to obtain the values of σ, w and λ.

Then, the depth resolution △z can be calculated with Eq. (6).

2.1. Analytical solution for delta layer

For the special case of being an ideal delta function with vanishing thickness, an analytical

resolution function can be derived with the result I(z)/I

0

=g

△MRI

by Eq. (1) given by [7]

()

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

−−

+×

⎪

⎭

⎪

⎬

⎫

⎪

⎩

⎪

⎨

⎧

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

++

⎪

⎭

⎪

⎬

⎫

⎪

⎩

⎪

⎨

⎧

⎥

⎦

⎤

⎢

⎣

⎡

+

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−−

−×

⎪

⎭

⎪

⎬

⎫

⎪

⎩

⎪

⎨

⎧

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−−

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−−=

Δ

λ

σ

σλ

σ

λλ

σ

σ

σ

λ

wz

erf

z

w

wz

erf

ww

wzw

w

zg

MRI

2

1

1

2

1

exp

2

1

2

1

1

2

1

expexp1

2

1

2

2

(7)

For SIMS, assuming that practically all of the detected ions stem from the first atomic layer, the

information depth parameter in the MRI model for SIMS can be set to zero. The DRF for MRI-SIMS

is given by

()

()

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

+

−−

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

+

−=

−Δ

w

wz

erf

ww

wz

w

zg

SIMSMRI

22

1

2

1

exp

2

1

2

σ

σ

σ

(8)

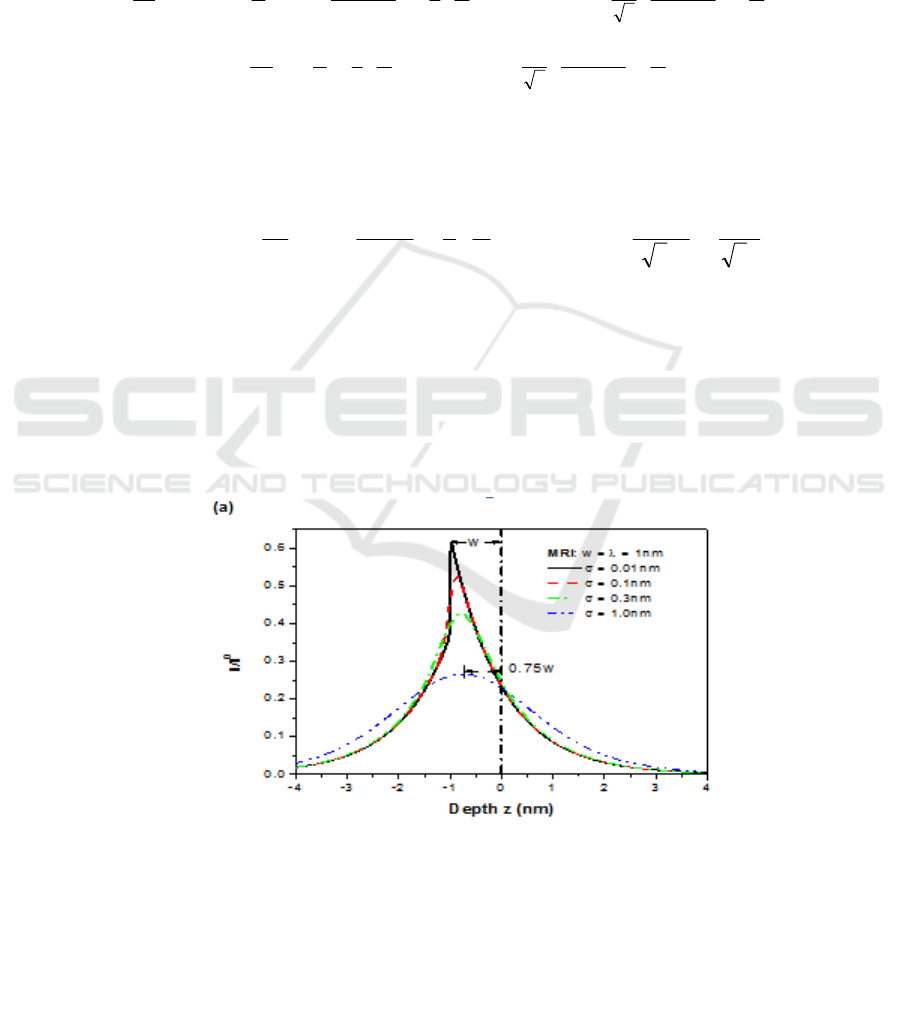

To demonstrate the behavior of the analytical resolution function of the MRI model for different

roughness, Figure 1. a shows a plot of Eq. (7) for w = λ = 1nm and σ = 0.01, 0.1, 0.3 and 1.0 nm. The

steep rise at z = z(0) -w is caused by the actual onset of complete mixing of the delta layer, with the

mixing zone length w governing the decay of the signal for z > z(0) -w. When the roughness

increases, this behavior is smoothed out because of the microscopically different spatial onsets of

mixing. [9] For increasing roughness, the maximum of the total DRF shifts from z = z(0) -w in the

direction of z = z(0), until it coincides with its centroid given by a combination of both exponential

functions for w and λ. [8]

Figure 1. Analytical depth resolution function of the MRI model (Eq. (7)) for w =λ = 1nm and

different roughness parameter values, σ = 0.01, 0.1, 0.3 and 1nm. Replotted from Ref [9].

2.2. Analytical solution for thick layer

As already proposed by Zalm [9] and later by Gautier et al.[10], including a term for layer thickness

appears to be possible in the analytical DRF. In the MRI model we can introduce a layer thickness d

= z

2

– z

1

, where z

1

denotes the beginning and z

2

the end of the layer. For SIMS (λÆ0), the DRF for a

layer with thickness of z

2

– z

1

is given by [8]

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

488

12

0

2

2211

1

(()/ )

2

22

11

exp

22

exp 1 exp 1

22 22

dMRISIMS

zwz zwz

Iz I erf erf

zw

ww

z zwz z zwz

erf erf

ww

ww

σσ

σ

σσ

σσ

−−

⎡⎤

+− +−

⎛⎞⎛⎞

=−

⎢⎥

⎜⎟⎜⎟

⎝⎠⎝⎠

⎣⎦

⎡⎤

+

⎛⎞

+−+

⎢⎥

⎜⎟

⎝⎠

⎢⎥

⎣⎦

⎧ ⎫

⎡⎤⎡⎤

+− +−

⎛⎞ ⎛⎞

⎪ ⎪

⎛⎞ ⎛⎞

×+ −−+ −

⎨ ⎬

⎜⎟ ⎜⎟

⎢⎥⎢⎥

⎜⎟ ⎜⎟

⎝⎠ ⎝⎠

⎝⎠ ⎝⎠

⎪ ⎪

⎣⎦⎣⎦

⎩ ⎭

(9)

In SIMS, the simple analytical solution of the ideal delta layer is usually applied for monolayers.

In reality, however, the thinnest layer is an atomic monolayer, with a thickness of 0.25 ± 0.05 nm in

most semiconductors and metals. If we assume a DRF of lower limit, for example for the case of

SIMS (Eq. (9)) with σ = w = 1 ML, the resulting FWHM (full width at half maximum) of the profile

for z

2

- z

1

= 0 is about 2.9 monolayers or ca.0.8 nm for a delta layer [8]. It shows that the FWHM of

the measured profile after Eq. (9) increases slightly with increasing layer thickness until it becomes

identical to the latter for a thickness above 8 monolayers [8]. For higher values of the DRF

parameters the deviation between an ideal delta layer and a monolayer is reduced.

In summary, analytical DRFs can be applied to the convolution integral of (1) Delta layers, (2)

Layers with any finite thickness and constant analyte concentration, (3) Multilayers of type 2). [8]

The main advantage of the analytical solution of the DRF is that the application of it is simple and

user friendly because no computer programming is necessary for graphical representation. It is

particularly useful for quantifying measured delta layer depth profiles in AES and SIMS [11]. This

paper will demonstrate that the layer thickness and the depth resolution values could be obtained by

fitting the measured SIMS depth profiles of a multilayer (a quantum-well structure) and a thick layer

respectively by applying the analytical solution of the convolution integral. It is customary to assume

X(z) and to calculate the intensity I(z)/I

0

in a “forward” manner with a known depth resolution

function g(z), and compare it with the measured I/I

0

(z). This procedure is performed repeatedly by

trial and error until an optimum fit of both is obtained. This is done by a computational program that

varies the X(z) distribution until the minimal value of the average deviation of the calculated from

the measured profiles is achieved. The final input X(z) is the reconstructed, original in-depth

distribution of composition.

3. Results and discussion

To demonstrate the application of the analytical MRI model, the measured SIMS depth profiles of

Si

0.73

Ge

0.27

superficial layer and Si

0.4

Ge

0.6

/Ge 10-period quantum well (QW) on Si substrate [2, 12]

will be quantified. Both layer structures were deposited on Si substrate by chemical vapor deposition

(CVD). The Si

1−x

Ge

x

superficial layer thickness is determined as 26.6 ± 0.5nm [2]. The Si

0.4

Ge

0.6

/Ge

10-period QW thickness values determined from HR-XTEM picture are listed in Table 1 [12]. The

SIMS profiling was performed with an Atomika 4500 instrument using primary ions of O

2

+

with a

range of energies (0.25–1keV) at near normal incidence. An area of 220x220 mm was scanned, and

the 30Si

+

and 70Ge

+

secondary ions were recorded.

Table 1. Si

0.4

Ge

0.6

/Ge QW thickness values determined by XTEM [12].

Figure 2 shows the measured and normalized Ge SIMS depth profiles as open circles for

Si

0.73

Ge

0.27

superficial layer on Si substrate using different O

2

+

beam energies from 0.4-2.0 keV. The

best fits for each measured depth profile using Eq. (9) are shown as solid lines in Figure 2. The

Period number 1 2 3 4 5 6 7 8 9 10

Si0.4Ge0.6 layer (nm) 8.6 8.6 8.6 8.5 8.5 8.5 8.4 8.5 8.4 8.6

Ge layer (nm) 12.6 12.7 12.6 12.6 12.7 12.7 12.7 12.7 13.0 12.8

Characterization of a Single Layer of Si0.73Ge0.27 and a Quantum-Well Structure of Si0.4Ge0.6/Ge by Quantitative SIMS Depth Profiling

Using the Analytical Depth Resolution Function of the MRI Model

489

corresponding MRI parameters are listed in Table 1 together with the depth resolution values

calculated from Eq. 6. It shows clearly that upon increasing the O

2

+

beam energy, the atomic mixing

length increases from 1.1nm to 3.0nm and the roughness parameter increases from 0.4 nm to 1.0 nm,

yielded the increasing of depth resolution, i.e. the degradation of measured depth profile.

Table 2. The best fits of the MRI parameter and the corresponding depth resolution values.

400 eV 500 eV 1keV 1.5 keV 2 keV

w (nm) 1.1 1.3 2.0 2.6 3.0

σ (nm) 0.4 0.4 0.7 0.8 1.0

Depth resolution (nm) 2.0 2.3 3.6 4.7 5.4

16 18 20 22 24 26 28 30

0.0

0.2

0.4

0.6

0.8

1.0

1.2

400eV

500eV

1keV

1.5keV

2keV

400eV

500eV

1keV

1.5keV

2keV

Exp.data

MRI fitting

Normalized intensity

Depth (nm)

Figure 2. The measured SIMS profiles (open circles) [2] and the fitted profiles (solid lines) using the

MRI analytical depth resolution function.

Table 3. The best fits of the MRI parameter and sputtering rate values.

250 eV 500 eV

w (nm) 0.9 0.1

σ (nm) 1.2 1.2

Sputtering rate (nm/s)

0.01 0.03

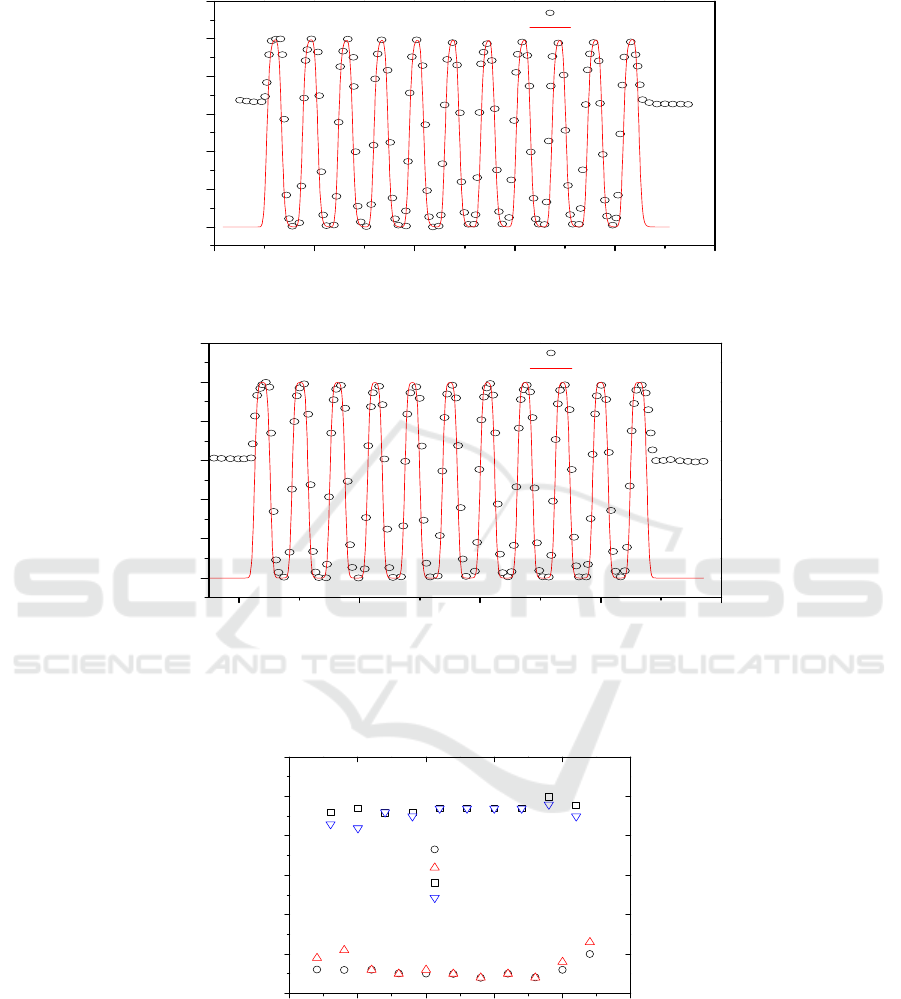

Figure 3 shows the measured and normalized Si SIMS depth profiles as open circles for

Si

0.4

Ge

0.6

/Ge 10-period QW structure on Si substrate using (a) 250 eV and (b) 500eV O

2

+

beam

energy sputtering. The best fits for the measured depth profiles using Eq. (9) are shown as solid lines

in the respective figure. The corresponding MRI parameters are listed in Table 2 together with the

average sputtering rate of Si

0.4

Ge

0.6

layer. Both the MRI fits are based on the same QW layered

structure that is taken as one of fitting parameters. The fitted individual layer thickness of each period

is shown by different symbols in Figure 4 and is compared with the value listed in Table 1. The

maximum relative error between the fitted thickness and the one obtained by XTEM is less than

1.2%. This implies that the quantitative SIMS depth profiling can provide an alternative way for

determination of nano-layered structure. Meanwhile, the fitted interface roughness of 1.2 nm in

Si

0.4

Ge

0.6

/Ge QW structure is slight higher than that of 0.4 nm in Si

0.73

Ge

0.27

superficial layer on Si

substrate. This implies that both samples prepared by CVD are very smooth.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

490

5000 10000 15000 20000 25000 30000

0.0

0.2

0.4

0.6

0.8

1.0

1.2

(a)

No r malized i ntensity

Sputting time(s)

Experiment Data

MRI fitting

2000 4000 6000 8000 10000

0.0

0.2

0.4

0.6

0.8

1.0

1.2

(b)

Experiment Data

MRI fitting

No r mali ze intensity

Sputting time(s)

Figure 3. SIMS depth profiles [12] of Si (open circles) (a) 250 eV and (b) 500eV O

2

+

and MRI fitted

profiles (solid lines) for Si

0.4

Ge

0.6

/Ge QW structure.

0 5 10 15 20 25

8

9

10

11

12

13

14

layer numbers in Si

1-x

Ge

x

/Ge QW

XTEM Si

1-x

Ge

x

layer thickness

MRI fitting

XTEM Ge layer thicknes

MRI fitting

relative error

:

1.2%

layer thickness (nm)

Figure 4. Comparison of the fitted and the measured (listed in Table 1) layer thickness values of

Si

0.4

Ge

0.6

and Ge sublayers in Si

0.4

Ge

0.6

/Ge QW structure.

4. Conclusions

The analytical DRF of the MRI model that is simple and user friendly has successfully been used to

quantify the measured SIMS depth profiling data of nano-layered structures. The individual layer

Characterization of a Single Layer of Si0.73Ge0.27 and a Quantum-Well Structure of Si0.4Ge0.6/Ge by Quantitative SIMS Depth Profiling

Using the Analytical Depth Resolution Function of the MRI Model

491

thickness, the interface roughness and the depth resolution values are determined accordingly. The

extracted layer thickness values for Si

0.4

Ge

0.6

/Ge quantum-well structure are consistent with the ones

determined by XTEM.

References

[1] Kang Y, Han-Din L, Morse M, Paniccia M J, Zadak M, Litski S, Sarid G, Pauchard A, Y H

Kuo, H W Chen, Zaoui W S, Bowers J E, Beling A, McIntosh D C, X Zheng and

Campbell J C 2009 Nature Photonics 3 59–63

[2] Dowsett M G, Morris R J H, Hand M and et al 2011 The influence of beam energy on apparent

layer thickness ultralow energy O2+ SIMS on surface Sil-xGex J. Surf. Interface Anal

43(1-2) 211-213

[3] Ho P S and Lewis H E 1976 Deconvolution method for composition profiling by Auger

sputtering technique Surf. Sci. 55 335–348

[4] Hofmann S 1998 Sputter depth profile analysis of interfaces Rep. Prog. Phys. 61 827–888

[5] Hofmann S 1994 Atomic mixing, surface roughness and information depth in high-resolution

AES depth profiling of a GaAs/AlAs superlattice structure J. Surf. Interface Anal. 21(9)

673-678

[6] Wang J Y, Starke U and Mittemeijer E J 2009 Evaluation of the depth resolutions of Auger

electron spectroscopic, X-ray photoelectron spectroscopic and time-of-flight secondary-ion

mass spectrometric sputter depth profiling techniques Thin Solid Films.517 3402–3407

[7] Liu Y, Hofmann S and Wang J Y 2013 An analytical depth resolution function for the MRI

model, Surf. Interface Anal. 45 1659-1660

[8] Hofmann S, Liu Y, Wang J Y and et al. 2014 Analytical and numerical depth resolution

functions in sputter profiling J. Appl. Surf. Sci. 314 942-955

[9] Zalm P C 1995 Ultra shallow doping profiling with SIMS Rep. Prog. Phys. 58 1321-1373

[10] Gautier B, Prost R, Prudon G and Dupuy J C 1996 Deconvolution of SIMS depth profiles of

Boron in Silicon Surf. Interface Anal. 24 733-745

[11] Kang H L, Lao J B, Li Z P and et al 2016 Reconstruction of GaAs/AlAs superlattice multilayer

structure by quantification of AES and SIMS sputter depth profile Applied Surface Science

38 584-588

[12] Morris R J H, Dowsett M G, Beanland R and et al 2013 O2+ probe-sample conditions for

ultralow energy SIMS depth profiling of nanometre scale Si

0.4

Ge

0.6

/Ge quantum wells J.

Surf. Interface Anal. 45(1) 348-351

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

492