CdSe@TiO

2

Hollow Spheres Photoanode for Quantum Dots

Sensitized Solar Cells

L B Yu

1

, Z Li

1,2,*

, L Feng

1,2

and H Song

1,2

1

College of Chemistry and Chemical Engineering, Hexi University, Zhangye City

734000, Gansu Province, People’s Republic of China

2

Key Laboratory of Hexi Corridor Resources Utilization of Gansu, Hexi University,

Zhangye City 734000, Gansu Province, People’s Republic of China

Corresponding author and e-mail: Z Li, lizhen_665@163.com

Abstract. TiO

2

hollow spheres (HS) with size around 200-300 n m were synthesized using

carbonaceous sphere as sacrificial template. CdSe quantum dots were deposited on to TiO

2

HS by hydrothermal process employing th ioglycollic acid (TGA) as linker molecu lar to fo rm

CdSe@TiO

2

HS photoanode for solar cell applicat ion. Based on CdSe@TiO

2

HS photoanode,

the photovoltaic performances of solar cells were tested and showed that a 24 h hydrothermal

process make CdSe@TiO

2

HS solar cells exh ibit a power conversion efficiency of 1.49%,

which is the best among the sample solar cells. Possible reason for the working princip le of

CdSe@TiO

2

HS solar cell was proposed according to experimental facts. Th is wo rk provides

a novel insight to design structure of photoanode for quantum dots sensitized solar cells.

1. Introduction

Quantum dots sensitized solar cells (QDSSCs) have become a focus of investigation due to several

advantages such as low fabrication cost, high theoretical power conversion efficiency, and multiple

excitons phenomenon [1, 2]. A typical QDSSCs consisted of a photoanode, polysulfide electrolyte

solution, and a counter electrode [3, 4]. The photoanode constructed based on QDs sensitized TiO

2

is

the most important component of QDSSCs, playing a key role for the light harvesting, charge

generation, and charge transport [5]. The TiO

2

nanoparticles with sized around 25 nm are most

commonly used in QDSSCs due to a high specific surface area for QDs loading. However, weak light

scattering ability make TiO

2

nanoparticles not a suitable candidate to enhance light harvesting

efficiency in visible light region. Because resonant scattering of light is predicted to happen when

particle size is comparable to the wavelength of incident light according to Mie theory [6]. In view of

these issues, fabrication of TiO

2

hollow spheres as photoanode materials are particular attractive for

QDSSCs due to its large interfacial surfaces and enhanced light harvesting efficiency caused by light

scattering and multiple times light reflection inside of hollow spheres [7, 8].

In this work, we explore the synthetic approach of TiO

2

hollow spheres (HS) using carbonaceous

spheres as template. Based on TiO

2

HS, CdSe quantum dots were sensitized onto TiO

2

to form

CdSe@TiO

2

HS photoanode for QDSSCs application. An acceptable power conversion efficiency of

1.49% for CdSe@TiO

2

HS solar cells proved that the TiO

2

hollow spheres have potential application

in design of QDSSCs.

Yu, L., Li, Z., Feng, L. and Song, H.

CdSe@TiO2 Hollow Spheres Photoanode for Quantum Dots Sensitized Solar Cells.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 513-518

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

513

2. Experimental

All reagents were purchased from Aladdin and were analytical reagent (AR) grade, which were used

directly without any further purification.

2.1. Fabrication of TiO

2

hollow sphere (HS) photoanode

The TiO

2

HS were synthesized using carbonaceous microspheres as template [9-11]. In a typical

synthesis route, the carbonaceous microspheres, which were obtained by hydrothermal process of

sucrose aqueous solution in Teflon-stainless autoclave at 180 °C for 8 h, were dispersed in the 1 M of

TiCl

4

aqueous solution under ultrasonic for 20 min. Then the suspension was aged for 6 h. After

aging, the suspension was filtered, washed and dried to get black powders. Subsequently, the black

powders were heated to 500 °C in a muffle furnace at the rate of 1 °C min

-1

, with holding of the

temperature at 500 °C for 3h. Finally, the resultant TiO

2

HS powders in white were acquired.

The TiO

2

HS powders, ethylcellulose, terpinol, and ethanol were mixed to form a viscous paste.

Then the paste was doctor-bladed onto the FTO glass (2.0×1.5 cm), and the active area was

controlled to be 0.25 cm

-2

. After drying in ambient, the products were annealed in muffle furnace at

500 °C for 1 h to eliminate the organic residuals.

2.2. Synthesis of CdSe@TiO HS photoanode

The decoration of CdSe quantum dots (QDs) onto TiO

2

HS was achieved by hydrothermal process

using TGA as linker molecular. Cd precursor solution was prepared by mixing 1.2 mmol of

Cd(NO

3

)

2

and 1.2 mmol of TGA in 25 mL deionized wate, and was tuned to transparent by addition

of NaOH solution (5 M) into the Cd-TGA solution. The 0.1 M of Na

2

SeSO

3

solution prepared by

refluxing Se powder and Na

2

SO

3

at 96 °C was used as Se precursors. 4.0 mL Se source was added to

the Cd-TGA reaction medium. Then the resultant solution was transferred to Teflon-lined stainless

autoclave in which the TiO

2

HS photoanode was previously placed. The sealed autoclave was placed

in an electric oven and maintained at 150 °C to form CdSe@TiO

2

HS photoanode. The products

obtained by hydrothermal time of 12 h, 24h, and 36 h were used to investigate the influence of

hydrothermal time on photovoltaic performance.

2.3. Solar cell assembly

Cu

2

S prepared by immersing in polysulfide solution containing 1 M sodium sulfide and 1M sulfur in

deionized water was employed as counter electrode for CdSe@TiO

2

HS solar cells.

For the photovoltaic applications, the prepared CdSe@TiO

2

HS photoanode and Cu

2

S counter

electrode were assembled in a fashion similar to sandwich. The space between the two electrodes was

filled with polysulfide consisted of 1M sodium sulfide and 1M sulfur aqueous solution.

2.4. Characterizations

We employed Quanta 450 FEG scanning electron microscopy (SEM) and Tecnai G2 F20

transmission electron microscope (TEM) to record morphology of the prepared products. For crystal

phase characterization, we used D/MAX-2400 X-ray diffractometer to analyse the crystalline nature

and structure of the samples.

With the assistant of Oriel I-V test station, we investigated the I-V performance of the solar cells.

A solar simulator was used to simulate sunlight illumination with intensity of 100 mW cm

-2

.

3. Results and discussion

The key to synthesize TiO

2

hollow spheres (HS) is how to get homogeneous size of carbonaceous

spheres. Figure 1 (a) shows the SEM image of carbonaceous spheres obtained by the hydrothermal

process of sucrose aqueous solution at 180 °C for 8 h. Apparently, the carbonaceous spheres with

size around of 500 nm can be successfully acquired after hydrothermal reaction, and the size

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

514

distribution is uniform, providing potential application as templates for fabrication of hollow spheres

structure.

Based on these carbonaceous spheres, the TiO

2

hollow spheres (HS) are prepared. Figure 1 (b)

gives the SEM image of TiO

2

HS. The spherical structure could be identified, and the inset image

shows the broken hollow spheres which shell and empty inside can be observe.

The TEM of TiO

2

HS in Figure 1 (c) further give the fine structure of HS, the shell and empty

inside of the HS can be easily discerned in the TEM image, indicating the carbonaceous spheres

template method is an effective approach to obtain TiO

2

HS. As shown in Figure 1 (b) and (c), the

size distribution of TiO

2

HS is between 200 nm - 300 nm, which is smaller than that of original

carbonaceous spheres, indicating a shrinkage phenomenon occurred during annealing process in

muffle furnace. The surface area measurements show the BET of TiO

2

HS is around 21.6 m

2

g

-1

.

Figure 1 (d) displays TEM image of the CdSe@TiO

2

HS prepared by hydrothermal process with

TGA as linker molecular. Although the hollow sphere structure is still remaining, many small

particles have covered on the surface of TiO

2

HS, indicating the formation of CdSe@TiO

2

HS and

providing its potential application as photoanode in QDSSCs.

Figure 1. (a) the SEM of carbonaceous spheres; (b) the SEM of TiO

2

hollow spheres (HS), the inset

is SEM of broken TiO

2

HS; (c) TEM of TiO

2

HS; (d) TEM of CdSe@TiO

2

HS.

The formation mechanism of CdSe@TiO

2

HS is illustrated in Figure 2 according to SEM and

TEM analysis results. As templates, carbonaceous spheres obtain by hydrothermal reaction of

sucrose play an important role in adsorption of Ti

4+

due to rich carboxyl and hydroxyl function group

on surface of carbonaceous spheres which are affinity to Ti

4+

. After adsorption of Ti

4+

, Ti

4+

@carbon

spheres are annealed in muffle furnace. The carbonaceous spheres are turned in CO

2

, leading to the

formation of TiO

2

HS. The disappearing of carbonaceous spheres is a gradually process due to the

slow temperature increase rate. Hence, the final products of TiO

2

HS show a shrinkage in comparison

with original carbonaceous spheres.

CdSe@TiO2 Hollow Spheres Photoanode for Quantum Dots Sensitized Solar Cells

515

CdSe QDs can be anchored onto TiO

2

HS by hydrothermal process using TGA as linker

molecular. The carboxylate group of TGA has a strong affinity to the TiO

2

, while the thiol group of

TGA can bind strongly to the CdSe QDs through the surface of Cd

2+

. By dipping TiO

2

HS

photoanode in precursor solution, the Cd

2+

and Se

2-

precursors can diffuse into the inside of the TiO

2

HS and bind chemically to the surface of hollow spheres, finally leading to the formation of

CdSe@TiO

2

HS. The CdSe QDs can be decorated on the outer and inner surface of the TiO

2

HS shell

because of the CdSe precursor solution is in ion scale which is beneficial to penetrate into hollow

sphere from all directions.

Figure 2. The illustration of carbonaceous spheres template method to construction of TiO

2

HS and

hydrothermal process to preparation of CdSe@TiO

2

HS.

Figure 3. The XRD pattern of TiO

2

HS and CdSe@TiO

2

HS.

Figure 3 displays the XRD pattern of the TiO

2

HS and CdSe@TiO

2

HS. For the XRD patter of TiO

2

HS, several diffraction peaks can be discerned by careful comparison with standard diffraction

pattern file of anatase TiO

2

(JCPDS # 21-1272), which can be respectively ascribed to the

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

516

corresponding planes of (101), (004), (200), (105), (211), (204), (220), indicating the crystal structure

of TiO

2

HS belongs to anatase TiO

2

. After the decoration of CdSe QDs on TiO

2

HS by hydrothermal

process, two other diffraction peaks can be observed around 44.2° and 52.4° for XRD pattern

CdSe@TiO

2

HS. These two diffraction peaks can be ascribed to the (220) and (311) planes of cubic

CdSe (JCPDS #19-0191), demonstrating the successful decoration of CdSe QDs on TiO

2

hollow

spheres.

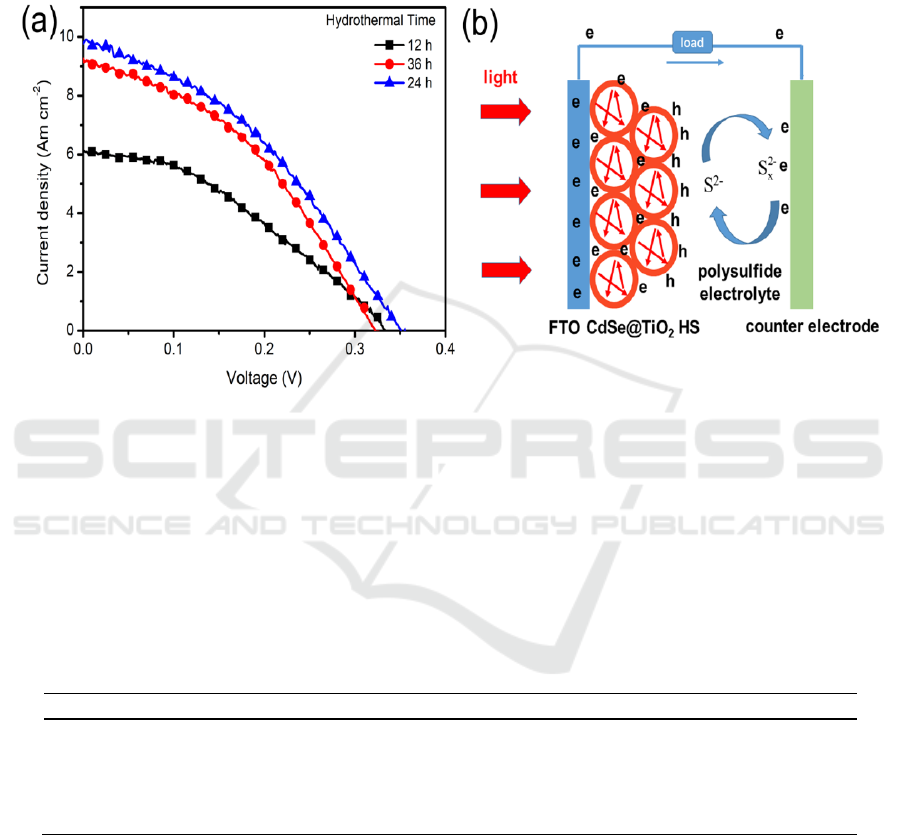

Figure 4. (a) I-V behaviours of CdSe@TiO

2

HS solar cells prepared by different hydrothermal

reaction time; (b) working principle of the CdSe@TiO

2

HS solar cells.

Based on CdSe@TiO

2

HS photoanodes, solar cells are assembled, and the relationship between

photovoltaic performance and hydrothermal reaction time of preparation CdSe@TiO

2

HS were

investigated. Figure 4 (a) shows the I-V curves of solar cells assembled with CdSe@TiO

2

HS

photoanode prepared by 12 h, 24 h, and 36 h of hydrothermal reaction time. Their photovoltaic

parameters including open voltage (V

oc

), short-circuit current density (Am cm

-2

), fill factor (FF), and

power conversion efficiency (PCE) are summarized in table 1.

Table 1. Parameters of CdSe@TiO

2

HS solar cells by different hydrothermal time

time

V

oc

(V)

J

sc

(Am cm

-2

)

FF

PCE (%)

12

0.33

6.11

0.36

0.74

24

0.35

9.78

0.43

1.49

36

0.32

9.26

0.45

1.36

As shown in Figure 4 (a), the best photovoltaic performance of CdSe@TiO

2

HS solar cells is

achieved by 24 h of hydrothermal reaction, which shows a V

oc

of 0.35 V, J

sc

of 9.78 Am cm

-2

, and FF

of 0.43, yielding a PCE of 1.49%. Less or more hydrothermal reaction time (12 h or 36 h) for

CdSe@TiO

2

HS photoanode produced a lower PCE than 24 h. Appropriate increase of hydrothermal

reaction time for CdSe@TiO

2

HS may lead to more CdSe QDs deposition on TiO

2

hollow spheres,

which can absorb more photons to generate excited electrons, resulting in the enhancement of PCE.

However, overdose of CdSe QDs on TiO

2

HS may provide more recombination sites hindering the

CdSe@TiO2 Hollow Spheres Photoanode for Quantum Dots Sensitized Solar Cells

517

efficient electrons transport, and leading to a decrease of PCE as indicated by CdSe@TiO

2

HS solar

cells prepared by 36 h of hydrothermal process.

Figure 4(b) illustrated the working principle of CdSe@TiO

2

HS solar cells. The great potential to

use TiO

2

HS as supporting architecture in QDSSCs is that the hollow sphere structure not only

provides enough space for adsorption of QDs, but also generates an effect of full utilization of light

caused by multiple times reflection of light inside of hollow spheres as shown Figure 4 (b), leading to

the enhancement of light harvesting efficiency. When light is fully utilized to excite QDs generate

more electrons, the photovoltaic performance of QDSSCs can be improved. Therefore, our

CdSe@TiO

2

HS solar cell produced an acceptable PCE of 1.49%, showing great potential application

of TiO

2

hollow spheres in design of QDSSCs.

4. Conclusions

The TiO

2

hollow spheres were synthesized using carbonaceous spheres template method.

Furthermore, CdSe@TiO

2

hollow spheres photoanode were constructed by a simple hydrothermal

process using TGA as linker molecular. The TEM, SEM, and XRD analysis results proved our

strategy is feasible to obtain CdSe@TiO

2

hollow spheres photoanode for QDSSCs. The photovoltaic

performance analysis results showed that the hydrothermal reaction time can influence the I-V

behaviours of CdSe@TiO

2

hollow spheres solar cells. The QDSSCs with a better PCE of 1.49% can

be obtained by 24 h of hydrothermal reaction time. The proposed working principle of the solar cell

implies a potential application of TiO

2

hollow spheres for design of high power conversion efficiency

QDSSCs.

Acknowledgments

This work has been financially supported by the University Research Project of Gansu Province

[grant number 2017A-089], the Surface Project of Key Laboratory of Hexi Corridor Resources

Utilization of Gansu Province [grant number XZ1604], and the Hexi University Principle Fund of

Scientific Innovation and Application [grant number XZ2017010].

References

[1] Ren X, Yu L, Li Z, Song H and Wang Q 2018 Superlattices Microstruct. 113 696-705

[2] Lu Y B, Li L, Su S C, Chen Y J, Song Y L and Jiao S J 2017 RSC Adv. 7 9795-9802

[3] Li Z, Yu L, Liu Y and Sun S 2014 Electrochim. Acta 129 379-388

[4] Choi Y, Seol M, Kim W and Yong K 2014 J Phys. Chem. C. 118 5664-5670

[5] Cai Y, Wang H E, Zhao X, Huang F, Wang C, Deng Z, Li Y, Cao G and Su B L 2017 ACS

Appl Mater Interfaces 9 10652-10663

[6] Zhang Q, Chou T P, Russo B, Jenekhe S A and Cao G 2008 Angew Chem. Int. Ed. Engl. 47

2402-2406

[7] Lai X, Li J, Korgel B A, Dong Z, Li Z, Su F, Du J and Wang D 2011 Angew. Chem. Int. Ed.

Engl. 50 2738-2741

[8] Du J, Qi J, Wang D and Tang Z 2012 Energy & Environmental Science 5 6914

[9] Ren H, Yu R, Wang J, Jin Q, Yang M, Mao D, Kisailus D, Zhao H and Wang D 2014 Nano

Lett 14 6679-6684

[10] Wang Y, Shu Y, Xu J and Pang H 2017 Cryst Eng Comm 19 684-689

[11] Wang Y, Liu T, Huang Q, Wu C, Shan D and Mater J 2016 Res. 31 2317-2328

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

518