Feasibility Study of Carbon Fiber Ceramic Matrix

Composites Used in Mechanical Seal Friction Pairs

J G Wang, Z P Guo

*

and A N Zhang

School of Mechanical Engineering, Xi’an Shiyou University, Xi’an,

Shaanxi(710065), China

Corresponding author and e-mail: Z P Guo, 310625000@qq.com

Abstract. The choice of mechanical seal friction material has great influence on the sealing

performance. As a new composite material, carbon fiber ceramic matrix composites have

excellent corrosion resistance, high mechanical strength, good heat resistance and heat

transfer performance, is the good choice of mechanical seal matching material. In the paper,

the temperature field and leakage value are simulated by computer when carbon fiber ceramic

matrix composites are applied to the friction pair. And the simulation results are verified by

experiments. Studies have shown that when carbon fiber ceramic matrix composites are used

in mechanical seal friction pairs, the sealing performance is significantly improved, including

reducing temperature rise, leakage and wear.

1. Introduction

The material of the mechanical seal friction pair has a great influence on the sealing effect [1].

Carbon fiber ceramic matrix composites is a new type of composite material. It has low density, good

thermal conductivity and corrosion resistance. The good thermal conductivity significantly reduces

the temperature rise of the sealed end face, prevents the thermal damage of the sealed end face, and is

advantageous to the stability of the liquid film between the friction pairs, thereby avoiding the sealing

failure. Smaller density increasess follow-up to moving parts, and good wear resistance can extend

the life of the seal ring. In summary, there are many benefits to using this material for sealing friction

pairs. In this paper, ANSYS software is used to study the temperature field between the static and

dynamic rings of the friction face. First, the temperature field under different materials is studied;

then, the speed and pressure of the friction pair are changed respectively to obtain the corresponding

temperature field; finally, the temperature of several points is measured by a mechanical seal test

bench to verify the accuracy of the numerical simulation.

2. CFD model

This article chooses SG04U type mechanical seal structure. Figure 1 shows the structure. And the

seal area ratio is 1.2952. The seal spring specific pressure is 0.15 MPa. The axial thickness of the

moving ring is 24mm. The axial thickness of the stationary ring is 30mm. The medium is 20#

mechanical oil. The thickness of the liquid film is 4μm. And the flow state is laminar [2-3].

638

Wang, J., Guo, Z. and Zhang, A.

Feasibility Study of Carbon Fiber Ceramic Matrix Composites Used in Mechanical Seal Friction Pairs.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 638-643

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1. SG04U type mechanical seal structure.

The following assumptions are made in the calculation:

1 The temperature field distribution is steady;

2 The temperature field is axisymmetric;

3 The heat flux density is evenly distributed on the sealing surface;

4 Consider only convection heat transfer and neglect heat radiation;

5 Fluid parameters do not change with temperature.

3. Result and discussion

3.1. Material

The following figure 2 and 3 are radial temperature distribution curves of the mechanical seal and

static ring end face obtained by using origin data processing software. There are four groups of

matching materials. The first group is carbon fiber ceramic matrix composites and graphite. The

second group is hard alloy and graphite. The third group is carbon fiber ceramic matrix composites

and hard alloy. The fourth group is SiC and hard alloy. The sealing shaft speed is 2000r/min. The

pressure in the sealing chamber is 0.4Mpa. The sealing medium is 20# mechanical oil. And the

sealing chamber temperature is 30°C. In the figure, the abscissa represents the temperature

measurement point number of the seal ring from the outer diameter to the inner diameter, and the

ordinate represents the magnitude of the temperature value.

Feasibility Study of Carbon Fiber Ceramic Matrix Composites Used in Mechanical Seal Friction Pairs

639

Figure 2.Temperature field paired with hard material.

Referring to Figure 2, when the moving ring is graphite, the stationary ring is respectively the

carbon fiber ceramic matrix composite and hard alloy. Also, the carbon fiber ceramic matrix

composite performs better as a static ring. At this circumstance, the temperature field between the

sealing faces is lower than the temperature field of the hard alloy.

Figure 3.Temperature field paired with soft material.

Referring to Figure 3, when the moving ring is a hard alloy, the stationary ring is a carbon fiber

ceramic matrix composite material and a silicon carbide alloy respectively. And carbon fiber ceramic

matrix composites perform better than silicon carbide.

In summary, it can be concluded that the carbon fiber ceramic matrix composite material performs

excellently under the condition of soft-to-hard material pairing in the absence of abrasive particles or

slurry in the sealing medium. This material makes the temperature drop very obvious and the radial

temperature change is small.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

640

3.2. Presure

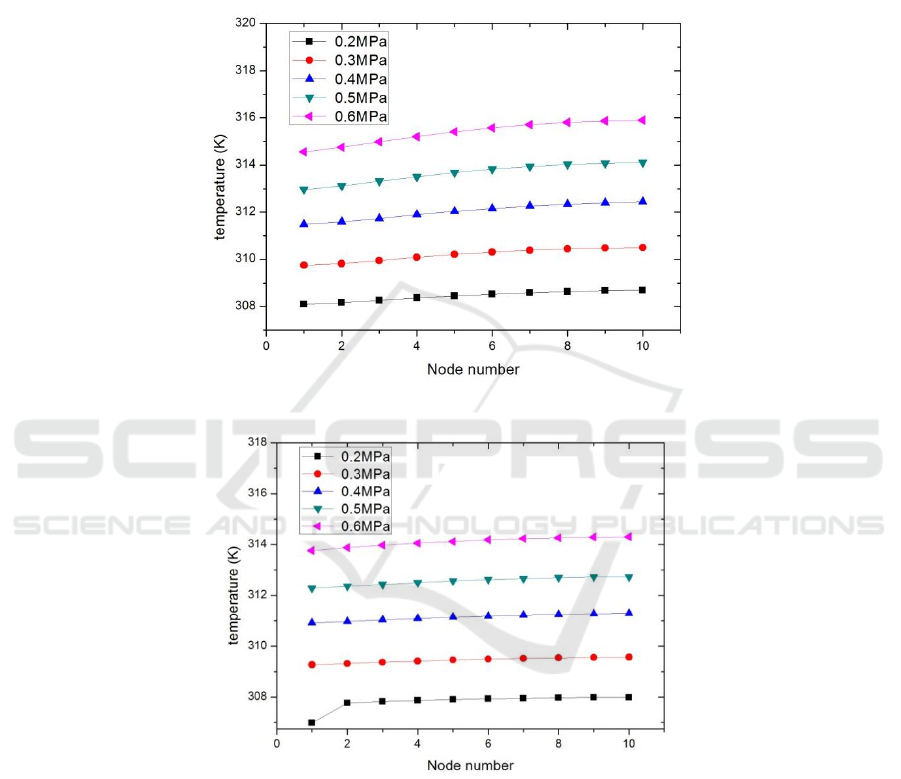

Figures 4 and 5 below show the sealed end surface temperature field when the seal chamber pressure

is changed using origin data processing software. The pressure in the sealing chamber was 0.2 MPa,

0.3 MPa, 0.4 MPa, 0.5 MPa, and 0.6 MPa, respectively. The sealing medium is 20# mechanical oil.

In the figure, the abscissa represents the temperature measurement point number of the seal ring from

the outer diameter to the inner diameter, and the ordinate represents the value of the temperature

value (unit: K).

Figure 4. Moving ring temperature under different pressures.

Figure 5. Stationary ring temperature under different pressures.

It can be concluded that carbon fiber ceramic matrix composites are used to material of the seal

friction pair. When the pressure in the seal chamber increases, the temperature of the contact surface

of the seal friction pair also increases. The reason is that the increase in pressure in the sealing

chamber leads to an increase in the heat flux of the sealing face. This leads to an increase in the heat

flux density of the ring annulus. Finally, the temperature of the end surface rises.

3.3. Rotating speed

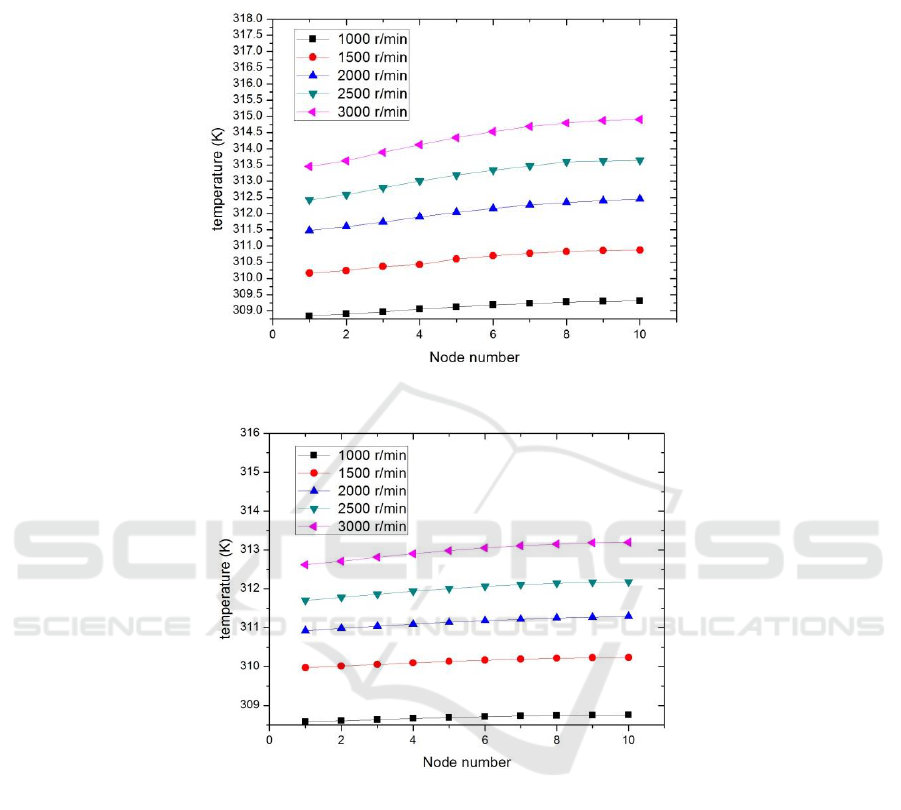

Figures 6 and 7 below show the seal face temperature field for changing the seal speed. The rotation

speeds were 1000 r/min, 1500 r/min, 2000 r/min, 2500 r/min, and 3000 r/min, respectively. The

sealing medium is 20# mechanical oil. In the figure, the abscissa indicates the temperature

Feasibility Study of Carbon Fiber Ceramic Matrix Composites Used in Mechanical Seal Friction Pairs

641

measurement points of the seal ring from the outer diameter to the inner diameter, and the ordinate

indicates the temperature value (unit: K).

Figure 6. Moving ring temperature at different rotation speeds.

Figure 7.Stationary ring temperature at different rotation speeds.

It can be found that changes in the rotational speed of the seal shaft directly affect the flow state

of the medium. The convective heat transfer coefficient of the friction ring changes. The higher the

speed, the more heat is generated. Therefore, the higher the seal shaft speed, the higher the seal ring

face temperature.

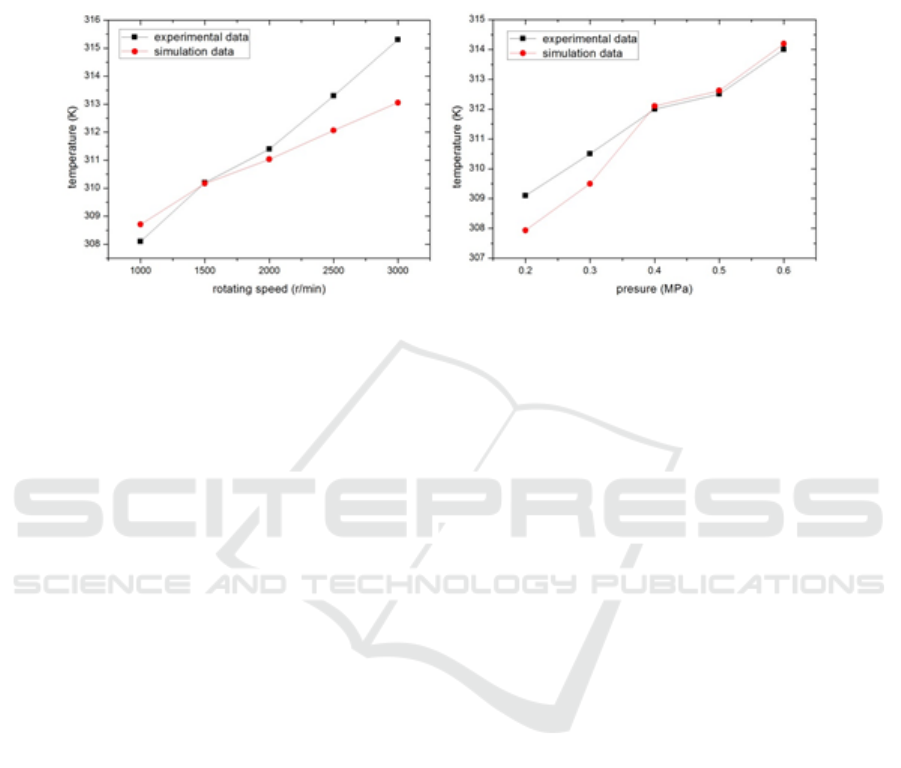

4. Experimental

The accuracy of the simulation results is verified experimentally. The static ring center temperature

of the mechanical seal of the carbon fiber ceramic matrix composite was tested under two conditions.

Experiment one: The sealing medium is 20# mechanical oil. The pressure in the sealing chamber

is 0.4 MPa. Sealing chamber temperature 30 °C. Carbon fiber ceramic matrix composites are moving

ring materials. Graphite is a stationary ring material. Change the seal shaft speed (1000r/min,

1500r/min, 2000r/min, 2500r/min, 3000r/min) to obtain the static ring center temperature.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

642

Experiment 2: The seal medium is 20# mechanical oil. Sealed shaft speed 2000r/min. Sealing

chamber temperature 30 °C. Carbon fiber ceramic matrix composites are moving ring materials.

Graphite is a stationary ring material. Change the pressure in the sealed chamber (0.2MPa, 0.3MPa,

0.4MPa, 0.5MPa, 0.6MPa) to obtain the center temperature of the stationary ring.

By comparing the curves in the figure 8, the numerical simulation data is accurate. First of all, the

trend of temperature change under pressure change and speed change is consistent. Second, there is a

small difference between the simulated and experimental values of the sample points. Therefore, the

simulation results have strong persuasive power.

5. Conclusions

As a mechanical seal friction pair material, carbon fiber ceramic matrix composites meet the basic

sealing requirements.

Whether it is with soft materials or hard materials, carbon fiber ceramic matrix composites

perform better. The temperature is lower, and the temperature field is more even and has a better

sealing effect.

Carbon fiber ceramic matrix composites are more suitable for hard to soft sealing conditions.

Under this condition, the temperature drop is even more pronounced.

The pressure in the seal chamber and the speed of the seal shaft have a great influence on the

temperature of the end face. The face temperature increases as the pressure in the seal chamber

increases. The face temperature increases as the rotational speed of the seal shaft increases.

References

[1] Zhao S and Wang X L. 2015 The effects of surface texture on the wear properties of

mechanical seals made of metal and polymers in Tribology, vol 06, 761-767. (in Chinese).

[2] Wang B and Hao M M. 2009 Numerical study on flow field of new-type hydrostatic-dynamic

hybrid lubrication seal in Lubrication Engineering, vol 07, 62-65+73. (in Chinese).

[3] Chen H L and Peng Z D. 2010 Study on temperature field of stern shaft mechanical seal based

on Ansys in Lubrication Engineering, vol 35. 73-76. (in Chinese).

Figure 8.Comparison of experimental and simulated data.

Feasibility Study of Carbon Fiber Ceramic Matrix Composites Used in Mechanical Seal Friction Pairs

643