Mechanical Structure Design and Dynamic Simulation of Rail Car

Guiliang Xie

1

, Yanmei Luo

2

and Guoyan Yu

2

1.EngineeringCollege, Guangdong Ocean University, Zhanjiang 524088, China

2.Marine equipment manufacturing and engineering technology research center of Guangdong province

,

Zhanjiang

524088, China

Keywords: Rail car, mechanical structure, Adams, virtual simulation prototype, self-adaptive

Abstract: Based on the analysis of the mechanical structure of the traditional rail car, a new type of rail car is

proposed with the actual operation requirements. The mechanical structure design with the front wheel

guiding mechanism ,body steering bearing mechanism and a new self-adaptive mechanism respectively,

which could enable the car to run normally in the deformed rail and optimize turning performance of the car

.The parameters of the self-adaptive mechanism and the required torque are analyzed from the kinetic view,

and an accurate and reliable virtual prototype model was established through combining the virtual

prototype technology with Pro/E and Adams modeling simulation. The simulation results show that the

design of the virtual prototype model is consistent with the mathematical model along with the friction is

reducing significantly when turning the car and the function that self-adaptive deformed rail is realized. This

verifies the rationality and practical feasibility of the mechanical structure for this rail car which also

provides a useful reference for the further development of the rail car prototype.

1 BACKGROUND

With the rapid expansion of the industrial scale of

factory aquaculture, high precision, convenient and

economical rail-type automatic feeding system has

rapidly become a research hot spot. Now like Arvo-

Tec 、 Strovik 、 TransFeed 、 Crystalvision etc.

international companies had developed the rail car of

the rail-type feeding machine with high precision,

low noise, long service life and other characteristics.

In contrast, China hasn't begun to do research on

rail-type feeding machine until recent years. Due to

the long distance of the guide rails, there are some

problems with the car such as wheel suspended and

wheel-slip as a result of manufacturing and

installation errors, and the wheel on the rail bend

would get stuck easily; In a way ,the car can’t run on

a rail with flexible deformation, which affects

automatic feeding robot accurate positioning and

bait throwing. The innovative structures of the self-

adaptive rail car, which is a kind of automatic

breeding equipment, not only solve the running

problem of factory aquaculture rail car but also

improve the automation level of factory aquaculture

by mechanical design and virtual prototype

platform[1-6]. Different from the traditional factory

aquaculture rail car, the rail car proposed in this

paper has the following two characteristics :①a

new self-adaptive mechanism is used to enable rail

car to run normally in the deformed rail. ②The

turning angle of body steering bearing mechanism

can be adjusted according to the turning radius of

rail and optimizing its turning performance. In order

to verify the rationality and practical feasibility of

the design, the virtual simulation platform has been

done by using virtual prototype technology, the

parameters of each mechanism and the operation of

each mechanism has been analyzed and determined.

Then making a judgment and giving suggestions for

optimization on rationality of mechanical structure

design of rail car.[7-10]

2 STRUCTURAL DESIGN OF

RAIL CAR

2.1 The Front Wheel Guiding

Mechanism

The guiding wheel of the guiding mechanism

contacts with the side surface of the rail when the

car turns. The guide shaft, the guide plate and the

connecting rod provide the force to make two front

wheels turn synchronously. Compared with the

conventional flange structure, this structure reduces

the friction force when the car turning and increases

the torque that the front wheels need in

turning phase, which would be better for car turning.

In order to accommodate different radius of bend,

the variable angle between two guide plates could be

adjusted according to the bend radius.

2.2 Body Steering Bearing Mechanism

The functions of steering bearing mechanism are as

follows:When the car sensor detects the corner

limit switch, The electric control device makes the

electric push rod work to push the steering bearing

rotating for a certain angle in the opposite direction

of the rail bend, which could drive the rear wheels

assembly to rotate for a certain angle in the opposite

direction of the rail car;When the front wheels of

the car leave the rail bend,the car sensor detects

the limit switch of rail bend, the electric push rod

pushes the body steering bearing mechanism to

return to the original state. The body steering

bearing mechanism cooperates with the front wheel

guiding mechanism which could enable rail car

turning in a smaller radius along with reducing the

collision with friction between the flange of the rear

wheels and the rail, transient turning radius and

friction noise, so that the rail car could pass through

the railbend smoothly.

2.3 Self-adaptive Mechanism

The self-adaptive mechanism comprises the self-

adaptive wheel and the clamping mechanism,when

the rail car suffers from deformed rail or slipping,

the front wheel sensor will send signal to PLC

thought detecting the car is in a non-running state.

Then PLC controls the electromagnet of the

clamping mechanism to work, therefore, the slider is

embedded with the groove of the ratchet, and the

ratchet is screwed in so that the bevel supports

wedge extending outwardly until the wedge is in

good contact with the rail and the car resumes

walking. PLC controls the electromagnet of the

clamping mechanism pushes the slider to retract and

stops the self-adaptive mechanism when the car

sensor detects the car is in a running state. Finally,

the rear wheels return to normal running. Through

the cooperation of the PLC and the self-adaptive

mechanism, the rail car could work normally in the

deformed rail.

3KINEMATIC ANALYSIS

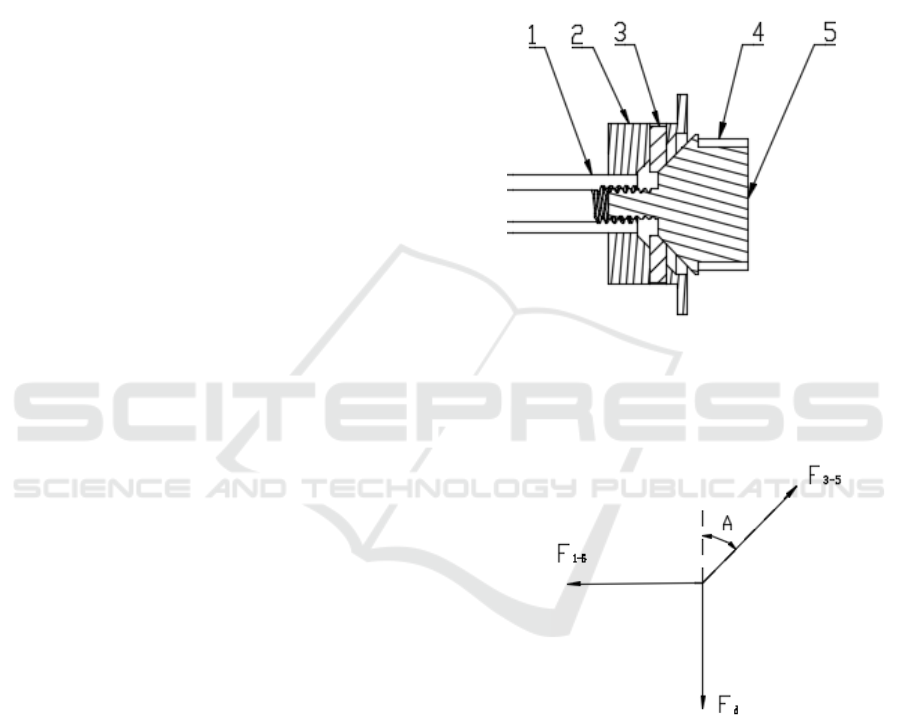

The rail car adopts the self-adaptive wheel as shown

in the figure, the self-adaptive mechanism is control

to be turned on and off by the cooperation of the

PLC and the clamping mechanism. The self-adaptive

wheel consists of a ratchet, a wheel hub and a wedge

.with the requirement of practical task ,the car loads

90 kg, running velocity is 18 m / min.

Figure 1:Partial structure of self-adaptive wheel 1.axle 2.

Wheel hub 3.wedge 4.groove 5. Ratchet.

Force analysis:

To ratchet

Figure 2: Force analysis of ratchet.

To wedge

= (1-1)

F

=F

(1-2)

F

=F

∗sinA (1-3)

F

=F

∗cosA (1-4)

Figure 3:Force analysis of wedge .

Solution of equation:

=

(1-5)

let

o

45=A

than

GF =

5-1

Assume the rear wheel loading 1000N, the screw

thread of the wheel axle adopts a left-handed

rectangular screw thread, friction coefficient of

thread friction joint[11] : u=0.1

5-1

F

is provided by the screwing force of the thread,

the working principle of the screw transmission joint

is as follows:

Figure 4:Principle of screw transmission joint.

Figure 5: Resistance.

According to mechanical principles[12]

F=G∗tan

A+B

=1000×tan20.7≈400N

(1-6)

M=F∗

=100×

=4000. (1-7)

Because

A

B

>

not self-locking, the ratchet will

return to the original position, when the clamping

mechanism is closed.

Because the adaptive wheel will generate a

torque resistance when it extends out of the wedge

=sin

360

12

2

×90×1000≈25000.

(1-8)

T=

+≈30000. (1-9)

4 RAIL CAR MODEL

Adams software has a strong dynamic simulation

function ,and Pro/E has powerful modeling

capabilities which can build a variety of complex

models, this paper combines the advantages of both,

Pro/E is used for modelling and the dynamic

simulation analysis is carried out in ADAMS.

Creating a model with Pro/E and Adams is a process

of continuous improvement, 3D solid modeling

includes two steps: part modeling and the car model

assembling, according to the structure characteristics

and functional requirements of the rail car to

complete the modeling and assembly along with

obtaining the 3D solid model. Rigid bodies and

constraints are defined by the interface program

Mechanism/Pro between Pro/E and ADAMS, then

the 3D solid assembly model established by Pro/E is

converted into ADAMS which could further perfect

ADAMS dynamic model. The specific modeling

steps are shown in figure 6.

Figure 6:Modeland simulation block flow sheet

4.1 Pro/E Model

The mechanical structure of the self-adaptive rail car

is modeled by Pro/E software . Figure 7 is a part

model of the rail car. Figure 8 is Pro/E model.

a. Rail car assembly

b. The Front wheel assembly

c. Body steering bearing mechanism

d.Self-adaptive mechanism

Figure 7: The mechanism of each part and the general

assembly model of the car

4.2 Adams Virtual Prototype Modeling

Simplifying the Pro/E model and importing it into

ADAMS. Generating the ADAMS model by the

interface software mechpro2005 between ADAMS

and Pro/E. Then combining the parts without

relative motion in ADAMS with Boolean sum,

defining material properties, constraints, forces,

contacts, and motions.

Figure 8:Adams model

5ADAMS DYNAMIC SIMULATION

AND ANALYSIS

5.1 Bend Running Simulation

The simulation conditions assume that the rail car

that loads 900N running on an annular rail which the

straight line is 1.5 m and the bend radius is 0.8m.

The car velocity curve and the car friction curve are

shown in Figure 9-12.

Figure 9: Relationship between car velocity and time

Figure 10: Friction of rear wheels in bend with body

steering bearing mechanism

Figure 11: Friction of rear wheels in bend without body

steering bearing mechanism

During the turning phase, the friction of the rear

wheels with body steering bearing mechanism is

about 35N, and the friction force of the rear wheels

without body steering bearing mechanism is about

65N.

Figure 12: Relationship between front wheels friction and

time

5.2 Self-adaptive Running Simulation

Figure 13: After the self-adaptive mechanism working,

the required torque of rear wheels

Figure 14: The displacement of CM of the rear wheels in

the vertical direction

Figure 15: The car velocity with the self-adaptive

mechanism working

Figure 16: The car accelerated velocity with the self-

adaptive mechanism working

6 RESULT

Figure 9 reflects the straight running and bend

running of rail car with the stable velocity, which

shows that the front wheel guiding mechanism and

the steering bearing mechanism meet the design

target. Figure 10-12 reflects that the friction is

relatively stable whether the rear wheels or the front

wheels, the friction of the rear wheels is obviously

reducing with the improvement of using steering

bearing mechanism. Figure 13 shows the driving

torque of the rear wheels is accelerating after the

self-adaptive mechanism working. According to the

analysis, it can be seen that,the problem is due to

the torque resistance that generated by the extension

of the wedges and the increase of the car

acceleration, the data curve shows that the

simulation results within a reasonable range are

consistent with the kinematic calculation results.

Figure 14 show the CM of the car, with 0.5mm

fluctuations, gradually rises after the self-adaptive

mechanism working. This phenomenon is due to the

discontinuity between wedge and wedge of the self-

adaptive mechanism.Because the sampled

fluctuation peaks are relatively small for the entire

system. Therefore, there is little effect to the system.

Through analysis, a spring pad can be added to the

end of the wedges that contact with the rail to reduce

the degree of fluctuation, So that the system is more

stable.

According to the dynamic simulation results in

ADAMS, it can be analyzed that the front wheel

guiding mechanism and body steering bearing

mechanism can make the car running smoothly all

the way,and obviously reduce the friction of the rear

wheels when the car runs in the bend. There is slight

fluctuation of the CM of the car after the self-

adaptive mechanism working , improving the

contact surface of the wedge with the rail and add a

spring pad can reduce the degree of fluctuation.

From the perspective of dynamic mathematical

model, Adams simulation results are consistent with

the dynamic mathematical model, when the input is

the same, the dynamic simulation results are

consistent with the mathematical model results,

which shows that the new structure can meet the

design and the actual operation requirements.

7 CONCLUSIONS

In this paper, a new type of self-adaptive rail car is

proposed, the front wheel guiding mechanism, body

steering bearing mechanism and self-adaptive

mechanism are simulated and analyzed by using

virtual prototype technology, the relevant simulation

results show that Adams simulation results are

consistent with the dynamic mathematical model,

when the input is the same, the dynamic simulation

results are consistent with the mathematical model

results, showing that the new structure meets the

design and the actual operation requirements, which

provides a theoretical basis for the next step of

physical manufacture.

REFERENCES

1. FengT, et al, 2015. Development and prospect of

development and application of aquaculture

equipment in China.Chinese Aquatic Product.(07),

p.91-93.

2. Cui L, et al, 2014. Design and experiment of

automatic feeding system based on PLC for industrial

aquaculturetrack.Guangdong AgriculturalScience,

41(22),p. 159-165.

3. Wu Q, et al, 2015.Present situation and development

trend of fish feeding machine. Jiangsu Agricultural

Science, 43(10), p.458-461.

4. Liu S, et al, 2017. Research progress of automatic

feeding system for industrial breeding. Fishery

Modernization, 44(2), p.1-5.

5. Atoum Y, et al, 2015. Automatic Feeding Control for

Dense Aquaculture Fish Tanks. IEEE Signal

Processing Letters, 22(8), p. 1089-1093.

6. YUKINORIM, et al, 2016. Demand feeding system

using an infrared light sensor for Brown-marbled

grouper juveniles, Epinephelus fuscoguttatus. Sains

Mlaysiana, 45(5), p.729-733.

7. LiZ, 2014. Introduction to ADAMS and examples.

Beijing: National Defend Industry Press.

8. Fan J, et al, 2006. Application and improvement of

virtual prototype software MSC.ADAMS. Beijing:

Machinery Industry Press.

9. Zheng k, et al, 2006. Advanced application example of

ADAMS 2005 mechanical design. Beijing: Machinery

Industry Press.

10. Yu X, et al, 2006.Research on dynamic simulation

parameter setting based on ADAMS. Computer

Simulation, 23(9), p.103-107.

11. Wu Z, 2012. Mechanical design course design manual.

Beijing: Higher Education Press.

12. Department of mechanical principles and mechanical

parts, northwest university of technology, 2013.

Mechanical principles, 8th. Beijing: Higher Education

Press.