Mechanical Optimization Design of Sugarcane Cane Species

Stripping Method

Zhong Hua Shen

1

, Yi Wei Liu

2

and Jing Bo Cong

3

1

School of mechanical and control engineering, Guilin University of Technology

2

School of mechanical and control engineering, Guilin University of Technology

3

School of mechanical and control engineering, Guilin University of Technology

Keywords: Sugarcane cleaner, mechanical optimization, Sensor, MATLAB.

Abstract: The traditional method of harvesting sugarcane has no advantage and is inefficient. Mechanization

harvesting is gradually gaining popularity, which leads to higher utilization rate of sugarcane harvester

machinery. Feedback information based on actual field operation. The need for sugarcane harvester is no

longer the basic requirement of breaking rate and low heterosis rate. It is to keep the sugarcane seedlings

under the premise of keeping the leaves clean, so that they can be planted again in the second year. In this

paper, a linear displacement sensor is added to automatically identify sugarcane sugarcane nodes and avoid

the damage of sugarcane seedlings. Therefore, the rationality of sugarcane peeling is improved, and the

benefit of mechanized harvesting of sugarcane is improved.

1 INTRODUCTION

Guangxi is the largest province of sugarcane

cultivation in China, and the largest sugarcane and

sugar production base in China. It's the most

important sugar area in the country.

Sugarcane is an important production of sucrose

raw material by using stem buds for asexual

reproduction. At present, in the process of sugarcane

stripping, the cane bud of sugarcane is destroyed,

and the planting of sugarcane will be affected, thus

affecting the development of the whole industry. It is

of great significance to study how to avoid the

cutting process of sugarcane peeling, and to realize

the effective planting of sugarcane in the second

year.

According to observation, sugar cane buds are

long in the next to next to sugarcane stem section

and, in the side of the sugar cane kind if use cameras

to collect images may be taken less than sugarcane

shoots and therefore cannot be directly by

identifying sugarcane sprout methods to achieve the

purpose of injury prevention buds. The stems of

sugarcane species have the characteristics of a week

around sugarcane, and can be accurately identified

from any Angle. Therefore, this paper USES the

identification of sugarcane planting stem to

indirectly obtain the position of sugarcane bud to

achieve the accurate identification of the sugarcane

bud, and provides the accurate signal for the study of

the control system.

This paper will use the MATLAB genetic

algorithm and direct search toolbox (GADS), genetic

algorithm and direct search toolbox extends the

ability to deal with optimization problems in

MATLAB, can be used to deal with traditional

optimization technology is difficult to solve the

problem, including those that are difficult to define

or not convenient for mathematical modeling

problem, can also be used to solve the problem of

objective function is relatively complex. In this

paper, MATLAB6.0 is used to solve the optimal

design of sugarcane stripping device.

2 THE RESEARCH STATUS

First, Moshashai of Iran used the method of gray

image threshold segmentation to make a preliminary

study on sugarcane stem node identification.

According to the characteristics of sugarcane

grayscale image, the accuracy rate of the stalk

festival was 88 percent. Lu is equal people introduce

technology of machine vision recognition sugarcane

stem section, the first by the support vector machine

SVM (support vector machine) method of internodes

and internode classification, to identify to identify

the clustering of the internodes class, obtain

internodes number and position of internodes;

Yellow is the person with Matlab as development

platform, this paper proposes a of sugarcane stem

section recognition method, through the gray

processing, Sobel edge detection, combined with the

mathematical morphology of expansion and

corrosion, obtain the edge of the cane internodes

straight line, identification of sugarcane stem section.

Huang Yi Qi, Wang Xiao Bo et al. designed a strain

- resistant strain - based sugarcane plant - resistant

bud system. These research directions have high

accuracy, but the feasibility is not high in actual

production.

Stripping is the key process in the harvesting

process of sugarcane. The quality of foliation

directly affects the harvest quality of sugarcane. At

present, the small leaf-stripping machine is divided

into two types: tail feeding and root feeding. The

stripping element in the rear feeding is mostly made

of nylon brush. As the name implies, sugarcane is

fed from the end of cane, and the cane is torn and

removed under the action of reverse comb of the leaf

brush. The root feeding machine mainly adopts

nylon strip brush or rubber finger stripping element,

and sugarcane is fed by sugarcane root to peel the

leaves. The stripping element of the nylon strip is

used to crack the sugarcane leaves and break the

cane leaves. The Angle of the rubber finger can be

wedged into the sheath, and the friction of the stem

will peel off the leaves. The principle of the whole -

pole cane harvester was basically the same as that of

the root feeding.

At present, most studies have been carried out

from heterogeneity, stem fracture rate, skin injury

rate and the life of the stripping element. In our

country, most of the sugarcane stripping device is

centrifugal impingement, and its mechanism mainly

consists of the input and output roller and the

stripping roller. Stripping leaves components

installed in a certain way on the strip leaf roller,

work, stripping leaves components with high speed

rotation roller impact on sugar cane, extrusion,

friction and tear effect, making the sugarcane leaf

peeling off.

3 DESIGN PRINCIPLE

To strip off leaf element structure size optimization

analysis, first of all to analyze strip leaf element in

the process of work stress: peel leaf element is at

work is to rely on high speed rotating shell leaf

element of sugarcane stalk push, friction, and makes

the sugarcane leaves from. The stripping mechanism

is mainly composed of input roller, output roller,

stripping roller and frame.

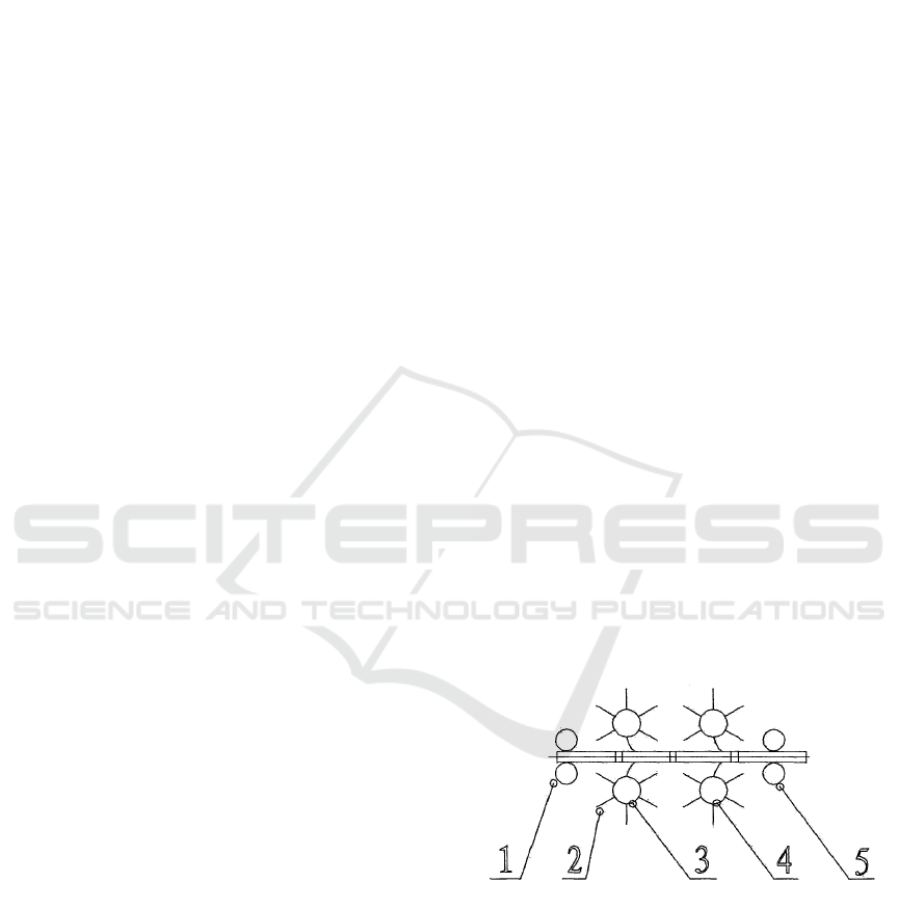

In this paper, design of stripping leaves device is

mainly composed of frame, type roller, 1 strip leaf

roll, 2 strip leaf roller and output roller chain drive

mechanism and motor etc plane diagram is shown in

figure 1. In each part, the upper and lower rollers are

included, and the rotation speed is the same with a

four gear group, and the reverse is reversed.

Generally speaking, it is not enough to have a set of

leaf-stripping roller. In particular, the sugarcane

leaves are more tightly packed. Therefore, we use

two sets of stripping roller, the first and the second

stage stripping roller. The speed is controlled by

three motors respectively. The distance between the

upper and lower input rollers is adjustable, and the

horizontal distance of the roller is adjustable. In

addition, the horizontal distance between the output

roller and the stripping roller can be adjusted.

Feeding roller, stripping roller (including the

first level stripping and second stripping roller) and

the output drum are driven by the driving motor and

driving chain and driving gear. The upper drum of

each drum group can be driven by the floating gear

connecting plate and the floating connecting plate,

and the driving shaft is floating in the circular arc

groove of the side plate. Under the force of rubber

strip, the root of sugarcane is entered into the leaf

roller. The elastic teeth of the stripping element are

in contact with the cane leaves. After stripping, the

sugarcane is output by the output roller.

Fig.1 Schematic diagram of leaf-stripping device.

1. Output roller 2. Stripping element 3. First stage

peeling roller 4. Second stage stripping roller 5. Input

roller.

The device enters the roller to choose rubber

material, and adopts the design method of hanging

rubber on the input roller. The outer cylinder of

rubber material can avoid the situation of damage to

sugar cane in the case of greater pressure and

friction. In order to increase the friction between

rubber drum and cane stem, it is necessary to use

groove design for rubber roller.

Fig.2 Structure of sugarcane leaf-stripping device.

1. Drive motor 2. Floating gear connecting plate 3.

Floating connection plate 4. Side board 5. Feeding roller

group 6. Drive shaft 7. Stripping roller 8. Output drum

group 9. Transmission chain 10. Transmission gear train.

In order to make sure that the sugarcane leaves

have low heterosis, at the same time it will not harm

sugarcane seedling, especially a sugarcane stalk

recognition device. The core component of this

device is a one-way displacement sensor. The

installation of the sensor shall be connected with a

fixed shaft section. The fixed shaft is fixed on the

base, side support plate and axial support plate. The

sugarcane seedling is usually long on the stem node,

and the one-way displacement sensor is selected

here. In addition, the data acquisition equipment to

be prepared is the data acquisition instrument and

DASP data signal processing software.

The main design principle is that when sugar

cane is introduced into the cane harvester through

the feeding device, if the stripping element is rolled,

it is the cane segment of the stem node, and the

stripping element is normally stripped; When the

sugarcane stalk is pushed through the roller, it is the

sudden increase or decrease of the diameter of the

sugarcane. In order to detect this floating change, a

detection platform can be connected to the stripping

element, which can reflect the compressed motion of

the stripping element to the detection platform. At

this point, the displacement value is measured by

one-way displacement sensor, and the sensor output

signal detects the position of the stem node.

The linear displacement sensor used in this

experiment, also known as linear sensor, is a linear

device belonging to metal induction. The function of

the sensor is to convert the measured physical

quantity into electricity. Generally speaking, it

consists of pull rod, aluminum tube, circuit board,

brush, brush holder, high frequency absorption

circuit, end cover and assembly parts. The working

principle is a sliding rheostat, which is used as a

voltage divider to display the actual position of the

measured position with relative voltage. The pull rod

is connected with the brush equal to the resistance

element for straight back and forth motion. When

the measurement changes, the linear transformation

is carried out between the resistance and the brush

contact. The function of linear displacement sensor

is to convert the mechanical linear displacement into

electrical signal, and the signal can be proportional

to the mechanical movement. The linear

displacement sensor used in this paper is ktr-50, the

power supply voltage is dc 24V, the output signal is

0-10v, the range is 50mm, and the maximum

working speed of the probe is 5m/s. The precision

can reach 0.05% of the range, i.e. 0.0025mm, which

can meet the detection. The data acquisition system

includes charge amplifier, data acquisition card,

processor and display equipment.

4 OPTIMUM DESIGN OF

SUGARCANE PEELING

LEAVES

The stripping element is mounted on the stripping

roller by means of the clamping device. When the

leaf roller is rotating, it is mainly used to peel the

leaves by the fingertip of the stripping element, and

the root is fixed on the leaf roller. In this way, one

end is fixed end, the other end is free, and the free

end is bent. The deformation degree of the stripping

element is large.

Fig.3 The Tester of Sugarcane Detaching machine.

5 MATLAB OPTIMIZATION

ALGORITHM GEOMETRIC

DESCRIPTION

MATLAB optimization technology mainly includes

the following two aspects:

5.1 Mathematical Modelling

Use mathematical methods to describe optimization

problems. Mathematical relations in the model

reflect the goals and constraints to be achieved in the

optimization problem. MATLAB commonly used

mathematical model is:

Error! Reference source not found.

Error! Reference source not found. (linear

equality constraints)

Error! Reference source not found.

(nonlinear inequality constrained)

Error! Reference source not found. (non-

linear equality constraints)

Error! Reference source not found. (The

lower bound and the upper bound of x)

In the formula, x, beq, lb and ub are vectors, A

and Aeq are matrices, c(x) and ceq(x) are functions.

Finally we measure the parameters of peeling

leaves quality for impurity rate (y), y = (remaining

amount of sugarcane leaf/sugarcane total quality

after peeling leaves) x 100%, here with rubber resin

as the shell element, through mathematical statistics

software SPSS regression analysis of data, can get

strip element mathematical model of the impurity

rate

:Error! Reference source not found.Error!

Reference source not found.

Equation above is the regression value of the

heterogeneity of rubber fat stripping element. Where

x1 represents the input roller speed; x2 is the

rotating speed of the stripping roller; The spacing of

the horizontal direction between the input roller and

the stripping roller; X4 is the output roller speed.

5.2 Mathematical Determination

After the mathematical model is built, a reasonable

optimization method is selected to solve the problem.

Due to mechanical optimization design is mostly

nonlinear constraint minimum optimization problem,

the commonly used method is by constructing

penalty function and so on will have a constrained

optimization problem into unconstrained

optimization problems to solve. Here we use the

sequential quadratic programming method (SQP

method) to analyze. The implementation of SQP

method in MATLAB is mainly divided into three

steps:

(1) Update of the Lagrange function Hessian

matrix;

(2) Quadratic programming problem solving;

(3) The calculation of one-dimensional search

and objective functions.

5.3 The Calculation of One-

Dimensional Search and Objective

Functions.

In this paper, using the SQP method to solving

nonlinear constrained optimization problems,

stripping leaves device in MATLAB algorithm, to

solve nonlinear optimization problems is mainly

composed of femion function to achieve, their calls

the format and syntax is as follows: x =

fmincon(fun.X0,A,b,Aeq,beq,lb,ub,nonlcon,options)

Results show that the optimal interval is: input roller

speed range is 150-250 r/min, stripping leaves roller

speed range is 600-900 r/min, stripping leaves roller

speed range is 600-900 r/min, the input is 200-300 -

mm, roller spacing interval output roller speed range

is 280-350 r/min. After the optimization interval was

determined, the regression equation was optimized

by MATLAB, and the optimal value of y3min=0.3%

was obtained. The optimization effect is the best.

REFERENCES

1. Lu Shang Ping, Wen You Xian, Ge Wei. Extraction

and identification of sugarcane stem nodes based on

machine vision [J].

2. Moshashai K, Almasi M, Minaei S, etal. Identification

of sugarcane nodes using image processing and

machine vision technology[J]. International journal of

Agricultural Research, 2008,3(5):357~364.

3. Kong Lin, Zhou De Jian, Chen Yan Hui. Design and

optimization of the stripping mechanism of the new

type of small sugarcane peeling machine [J]

4. Mou Xiang Wei. Study on the dynamic striking force

of elastic teeth on the stalks of sugarcane and the

mechanism of leaf sheath stripping [J].

5. Mou Xiang Wei, QU Ying Gang, Liu Qing Ting, Wu

Hao, Song Jian Ming. Flexible toothed roller cane

stripping device [J]

6. Huang Yi Qi, Qiao Xi, Tang Shu Xi, Luo Zhao Yu,

Zhang Pei Dong. Based on Matlab, the distribution of

sugarcane stem nodes is located in the experiment. [J]

7. Dong Zhen, Shen Dao Yan, Wei Jin, Meng Yan Mei,

Ye Chun Bo. Design and research of sugarcane

planting and sugarcane stalk detection device.

8. Xu Yang, Ye Feng, Peng Yan Kun, Tang Xiu Ying,

Shi Huan Ru, Chen Te Qing. Optimization design of

the strip element of sugarcane combined harvester

based on ANSYS [J]