Study on the Mechanism and Technical Index of

R

ubber Powder

/SBS Double Composite Modified Asphalt

Xiaojuan Li

1

, Yuan Li

2

and Xiaolong Wang

2

1.

Xi' an Highway Research Institute, Xi' an 710065, Shaanxi, China;

2.The Third Engineering Co.,ITD of CCCC.Second Highway Engineering Bureau,Xi’an 710064,ShanXi

Keywords: Composite modified; waste rubber powder; SBS; viscosity; road performance

Abstract: The composite modified technology will waste rubber and SBS modified, the analysis of the composite

modified asphalt under different rubber powder content and storage time of viscosity, penetration, softening

point and changes in the extension and the performance were compared. The results showed that 20%

crumb rubber content and composite modified asphalt has the best network structure, the performance best;

crumb rubber and SBS composite modified asphalt mixture performance and SBS modified asphalt mixture

performance difference and could meet the standard required value.

1 INTRODUCTION

The use of scrap rubber powder to modify the matrix

asphalt can improve the viscosity of asphalt,

improve the low temperature performance of

asphalt, improve anti-aging, anti-fatigue

performance, and ride comfort, safety, reduce the

noise of driving, and is conducive to the recycling of

used products [1-5]. At the same time, modified

asphalts such as SBS and SBR have also improved

the road performance of asphalt and asphalt

mixtures, and the technology is mature. However,

based on the complex traffic load and environmental

conditions as well as the expensive material costs,

the promotion and application of polymer modified

asphalt is severely limited. With the development of

rubber powder production technology, China's

normal-temperature crude rubber powder and fine

rubber powder have been industrialized and put into

production, and their prices are far lower than SBS,

PE, SBR and other modifiers, which has a good cost

advantage [6-10] .

Based on this, the composite modified

technology of waste rubber and SBS was modified

by the author, using the composite modified

technology of waste rubber and SBS was modified,

and the analysis of the composite modified asphalt

viscosity in different rubber powder content and

storage time under the penetration, softening point

and ductility changes, the road performance

verification, to not only reduce the engineering cost

of the modified asphalt, and improves the

performance of the road.

2 RAW MATERIAL DETECTION

AND PREPARATION METHOD

We strongly encourage authors to use this document

for the preparation of the camera-ready. Please

follow the instructions closely in order to make the

volume look as uniform as possible (Moore and

Lopes, 1999).

Please remember that all the papers must be in

English and without orthographic errors.

Do not add any text to the headers (do not set

running heads) and footers, not even page numbers,

because text will be added electronically.

For a best viewing experience the used font must

be Times New Roman, on a Macintosh use the font

named times, except on special occasions, such as

program code (Section 2.3.7).

2.1 Raw Materials

Using 30 mesh rubber powder and SK90# matrix

asphalt, the amount of rubber powder was 20%, and

the amount of SBS modifier was 1.5%, and waste

rubber powder/SBS double composite modified

asphalt samples were prepared. The technical

performance index of the matrix asphalt meets the

“Technical Specifications for Highway Asphalt

Pavement Construction” JTG_F40-2004, and the

performance indicators are shown in Table 1, 30

mesh with rubber powder gradation is shown in

Table 2.

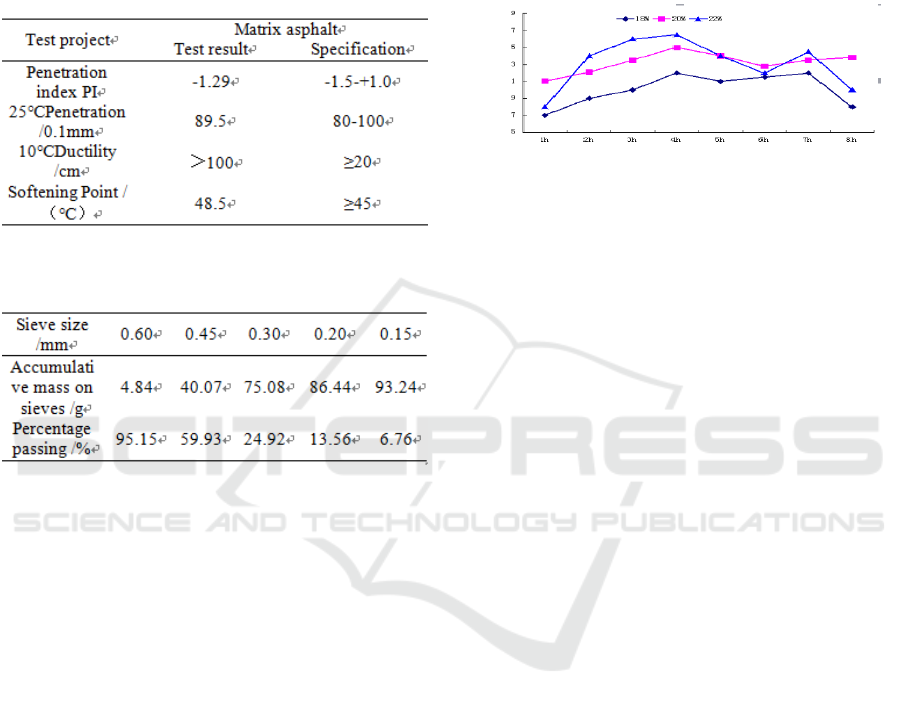

Table 1 Technical performance index of matrix asphalt.

Table 2 30 mesh rubber powder gradation.

2.2 Preparation Method of Waste

Rubber Powder and SBS

Composite Modified Asphalt

The method for preparing the waste rubber powder

and the SBS composite modified asphalt is as

follows: the modified asphalt is prepared by a

FLUKO AF25 high-speed shear dispersing

emulsifier, the stirring temperature is 150° C., the

stirring time is 30 min, the shearing temperature is

180° C., the shearing time is 45 min, and the rotating

speed. 7000r/min, oven placed 15h, oven

temperature 140 °C.

2.3 Performance Analysis of Composite

Modified Asphalt

SBS adopts 1.5% content to study the change of

performance index of composite modified asphalt

under different amount of rubber powder (18%,

20%, 22%) and different heat storage time (1, 2, 3,

4, 5, 6, 7, 8h).

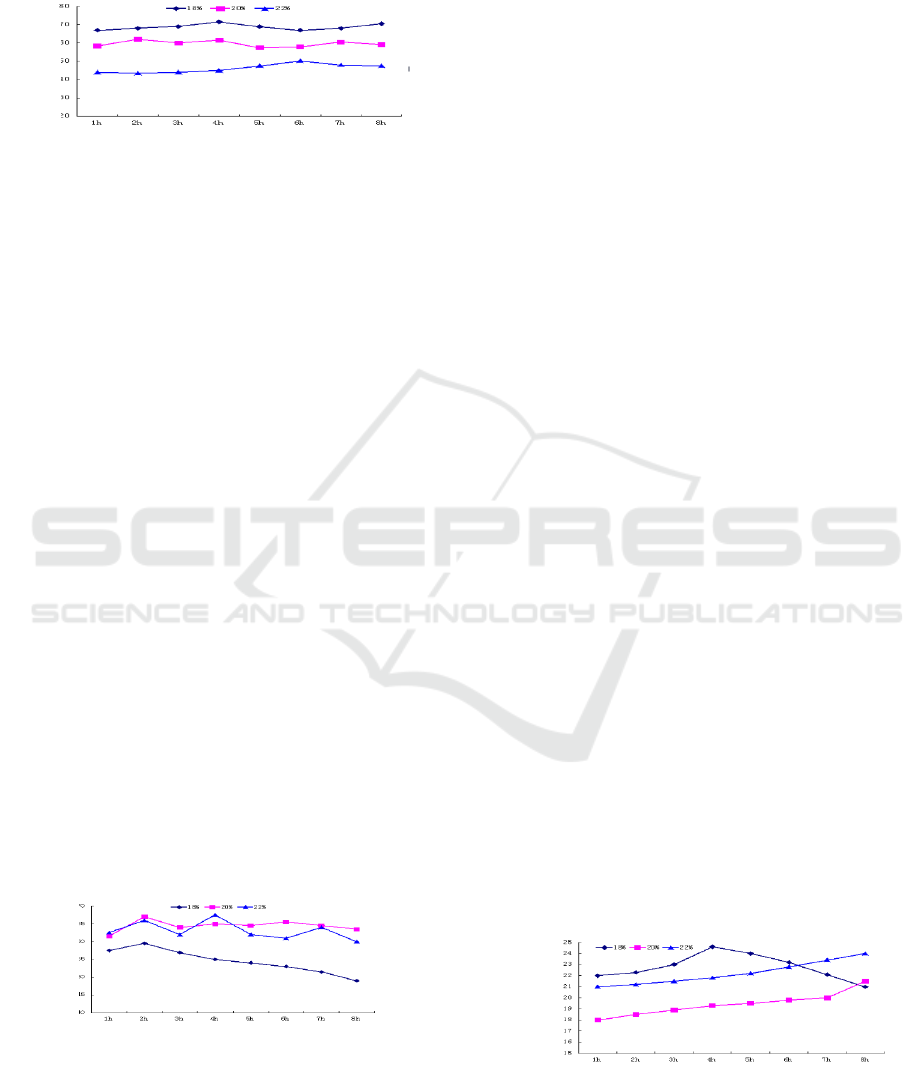

2.3.1 Viscosity

The change curve of viscosity with storage time is

shown in Figure 1.

Heat storage time(h)

Figure 1 The change curve of viscosity with storage time.

The Brucella viscosity of composite modified

bitumen increased with the increase of growth time,

and showed a trend of increase from 1 to 4h. The

variation was regular, and the dispersion between 6

and 8h was larger.

The reasons for the increase of viscosity of

compound modified asphalt include: first, the

swelling reaction of rubber powder in asphalt and

then the volume increase, so that the interaction

between rubber particles is strengthened. Secondly,

the falling rubber powder is dissolved in asphalt,

resulting in the increase of viscosity.

When the rubber powder content is 18%, the

swelling reaction of a single rubber powder is

relatively large, the rubber powder and the asphalt

are homogeneously mixed, but the overall reaction

swell is limited, and the interaction between the

rubber particles is relatively weak, the adhesive

powder has a tendency of free distribution in the

matrix bitumen, so the viscosity of the modified

asphalt is small.

When the amount of rubber powder increases,

the rubber powder swells continuously in the matrix

asphalt, and the effect of the unit volume of rubber

powder particles in the matrix asphalt is

continuously strengthened, and the network structure

in the modified asphalt is more stable, so the

viscosity increases; In addition, the swelling of the

rubber powder increases the absorption of light

components will increase, the asphalt becomes hard,

the viscosity of the composite modified asphalt

increases. When the content of rubber powder is

20%, the viscosity value of the composite modified

asphalt is relatively large, but when the content of

the rubber powder increases to 22%, the dispersion

of the viscosity test results becomes large.

viscosity

2.3.2 Penetration

The variation of penetration with storage time is

shown in Figure 2:

Heat storage time(h)

Figure 2 The change curve of the penetration with the

storage time.

As can be seen from Figure 2, with the increase

of the amount of rubber powder, the penetration rate

of modified asphalt shows a decreasing trend. When

the amount of rubber powder is 18%, the swelling

rate of the rubber powder is relatively fast and the

degree of swelling is relatively large, but the

network structure is not formed, so the penetration is

large. With the increase of the amount of rubber

powder, the number of particles in the asphalt

increased, and the rubber powder gradually changed

from the original favorable dispersion state to two

phase continuous system, and the asphalt became

hard, resulting in the decrease of penetration.

When the dosage of the rubber powder increased

from 20% to 22%, the penetration of the composite

modified asphalt continued to decrease, but the

amplitude was not significant. The main reason is

that when the amount of rubber powder increases to

a certain value, the network structure of the two

kinds of bitumen has been formed, so the effect of

excess rubber powder on penetration is no longer

obvious.

2.3.3 Softening Point

The variation of softening point with storage time is

shown in Figure 3:

Heat storage time(h)

Figure 3 The change curve of the softening point with the

storage time.

As can be seen from Figure 3, the softening point

of the composite modified asphalt increases with the

increase of the amount of rubber powder. When the

composite modified asphalt is just prepared, the

softening point first increases and then decreases

with the increase of the amount of the rubber powder

under the condition of ensuring a certain processing

temperature. In addition, the time required to reach

the peak value of the softening point of the

composite modified asphalt with different rubber

powder content is different, and the softening point

increases with the increase of the amount of rubber

powder.

The main reason for the above phenomena is that

when the rubber powder content increases from 18%

to 20%, the rubber powder in matrix asphalt changes

from free state to two phase continuous state, and

the bonding effect between gel particles is obviously

enhanced, and the skeleton structure is developed

and the softening point increases. However, the

addition of rubber powder continued to increase

from 20% to 22%, and colloidal particles reached

saturation state in asphalt, and its connection

function would weaken. Moreover, the bonding

effect between rubber particles was weakened due to

the serious agglomeration of rubber powder, so the

softening point of composite modified asphalt

decreased. In the process of thermal storage, the

peak softening point of composite modified asphalt

increases with the increase of the amount of rubber

powder. The main reason is that the network

structure of the composite modified asphalt is more

perfect as the reaction continues, and the filling

effect of the rubber powder will be better. Therefore,

the softening point increases.

In summary, when the amount of 20% rubber

powder is added, the composite modified asphalt has

good high temperature performance and relatively

stable properties.

2.3.4 Ductility

The variation of ductility with storage time is shown

in Figure 4:

Heat storage time(h)

Figure 4 The change curve of the ductility with the

storage time.

Penetratio

softening

i

ductilit

y

As can be seen from Figure 4, with the increase

of the amount of rubber powder, the dispersion of

the ductility is larger. With the storage process

carried out at a certain temperature, the addition of

rubber powder increased from 18% to 22%, and the

ductility of composite modified asphalt increased

with time. When the dosage of rubber powder was

20%, the ductility increased first and then increased

with time.

The variation of bitumen ductility is not obvious

when the dosage of rubber powder is 18% to 20%.

The main reason is that rubber particles still play a

major role in swelling when the amount of rubber

powder is 20%, and the cracking and desulfurization

of rubber powder reduce the number of molecular

chain segments in asphalt, so the change in ductility

is not significant. When the rubber powder content

increases from 20% to 22%, the concentration of

rubber particles in the asphalt increases, so that the

stress dissipation point increases and the asphalt

ductility increases.

In the heat storage process, when the content of

the rubber powder is 18%, the dispersity in the

asphalt is large, and the interaction between the

colloidal particles is weak. In the long-term heat

storage process, the deculturation and cracking of

the colloidal powder is the main factor, and the

ductility of modified asphalt increases with time.

When the content of rubber powder increased to

20%, the concentration of rubber powder in asphalt

increased, and the rubber powder was swelling and

the asphalt became hard. After 4h, the

desulfurization and cracking reaction of rubber

powder was significant, and the ductility of

composite modified asphalt increased first and then

increased with time. When the rubber powder

content further increased to 22%, the rubber powder

and the asphalt reached a saturated state, and the

swelling of the rubber powder was reduced. The

ductility of the composite modified asphalt was

mainly affected by the cracking and desulfurization

of the rubber powder, and therefore, it was gradually

increased with time.

3 STUDY ON ROAD

PERFORMANCE OF

COMPOSITE MODIFIED

ASPHALT

Using the median gradation range specified by the

SMA-13 specification, the road performance of

rubber powder and SBS composite modified asphalt

was verified at the optimum ratio of oil and stone.

The test results are shown in Table 3:

Table 3 Performance test results of waste rubber powder

and SBS composite modified asphalt mixture .

Table 3 shows that: SBS modified asphalt

mixture has the best comprehensive performance,

followed by composite modified asphalt mixture, the

worst performance is rubber asphalt mixture, and the

powder and SBS composite modified asphalt

mixture and SBS modified asphalt mixture

performance difference, and both meet the index

requirements in the "Technical Specifications for

Highway Asphalt Pavement Construction"

JTG_F40-2004.

4 CONCLUSIONS

(1)The Brookfield viscosity of the composite

modified asphalt increases with the development

time, and it basically increases between 1 and 4 h.

The change is more regular, and the dispersion

between 6 and 8 h is larger. When the amount of

20% rubber powder is added, the viscosity value of

the asphalt is large. When the amount of rubber

powder was increased to 22%, the viscosity test

results were not stable.

(2)With the increase of the amount of rubber

powder, the penetration degree of composite

modified asphalt gradually decreases, the dispersion

of ductility is large, and the addition of rubber

powder can not improve the low-temperature

properties of composite modified asphalt. The

softening point index of the composite modified

asphalt increases with the increase of the amount of

rubber powder, and the maximum of the softening

point increases with the increase of the amount of

rubber powder.

(3)When the amount of rubber powder is 20%,

there is the best network structure of composite

modified asphalt, and the rubber powder can play

the best filling effect in asphalt. The performance of

composite modified asphalt is the best, and the

amount of rubber powder is the best amount at this

time.

( 4) The performance of rubber powder and

SBS composite modified asphalt mixture has little

difference with that of SBS modified asphalt mixture,

which all meet the requirements of the standard.

REFERENCES

1. Wang Tingguo. Research on modified asphalt and

asphalt mixture with waste rubber powder [D]. Jilin:

Jilin University, 2004

2. Shi Hongbo,Zou Mingxu,Liao Kejian et al. Research

progress of waste rubber modified road asphalt[J].

Chemical Engineering and Industry Technology. 2005,

26(2): 27-30

3. Cao Guichang. Study on performance of modified

asphalt modified asphalt and its influencing factors

[D]. Beijing: Beijing University of Chemical

Technology, 2008